Tea leaf residue modified oxidized cellulose composite film, and preparation method and application thereof

A technology of oxidizing cellulose and composite film, which is applied to the preservation of meat/fish with chemicals, etc., can solve the problems of high price of laccase, low extraction rate and purity of tea residue hemicellulose, large amount of plasticizer, etc. Wide range of sources, renewable price, easy recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

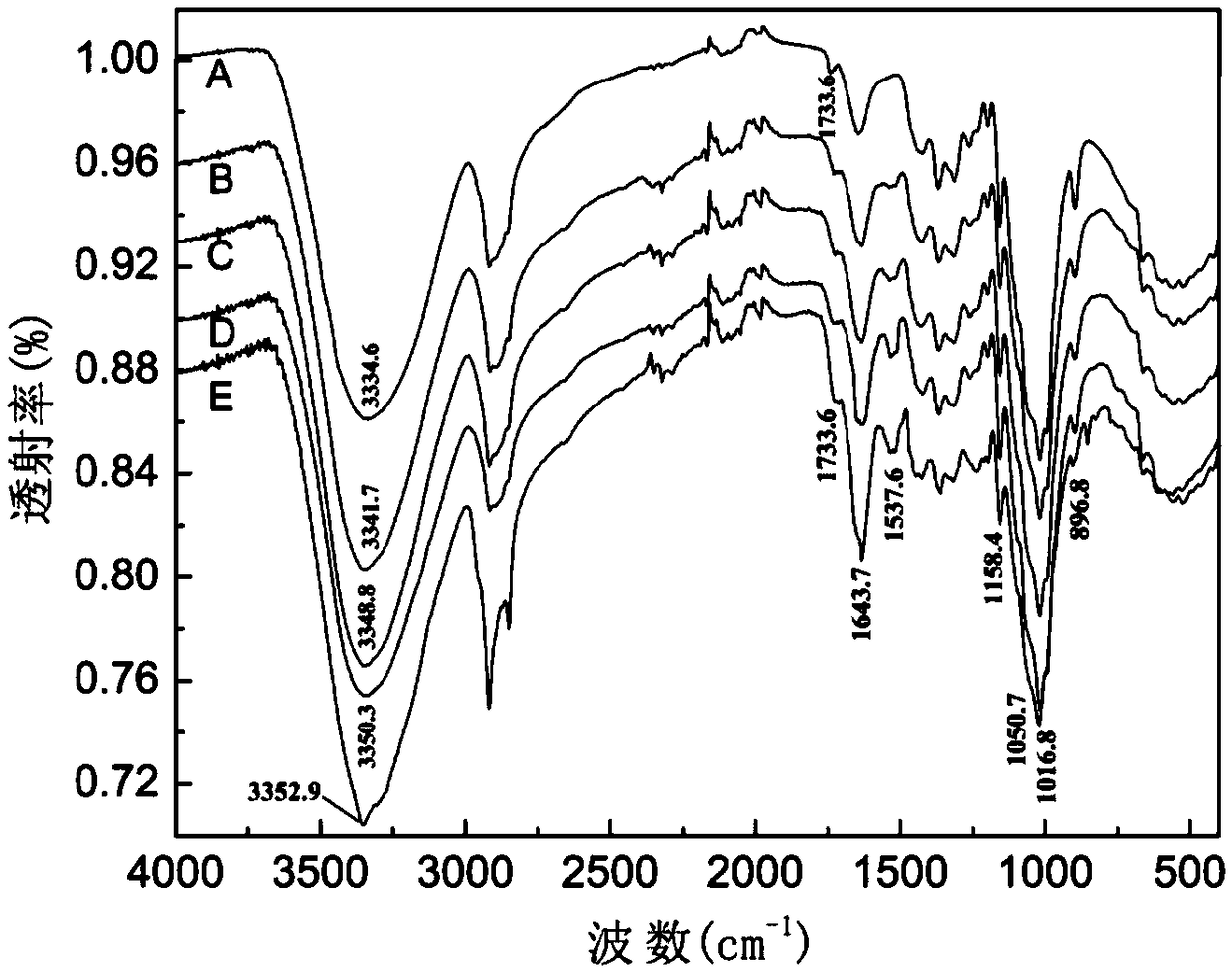

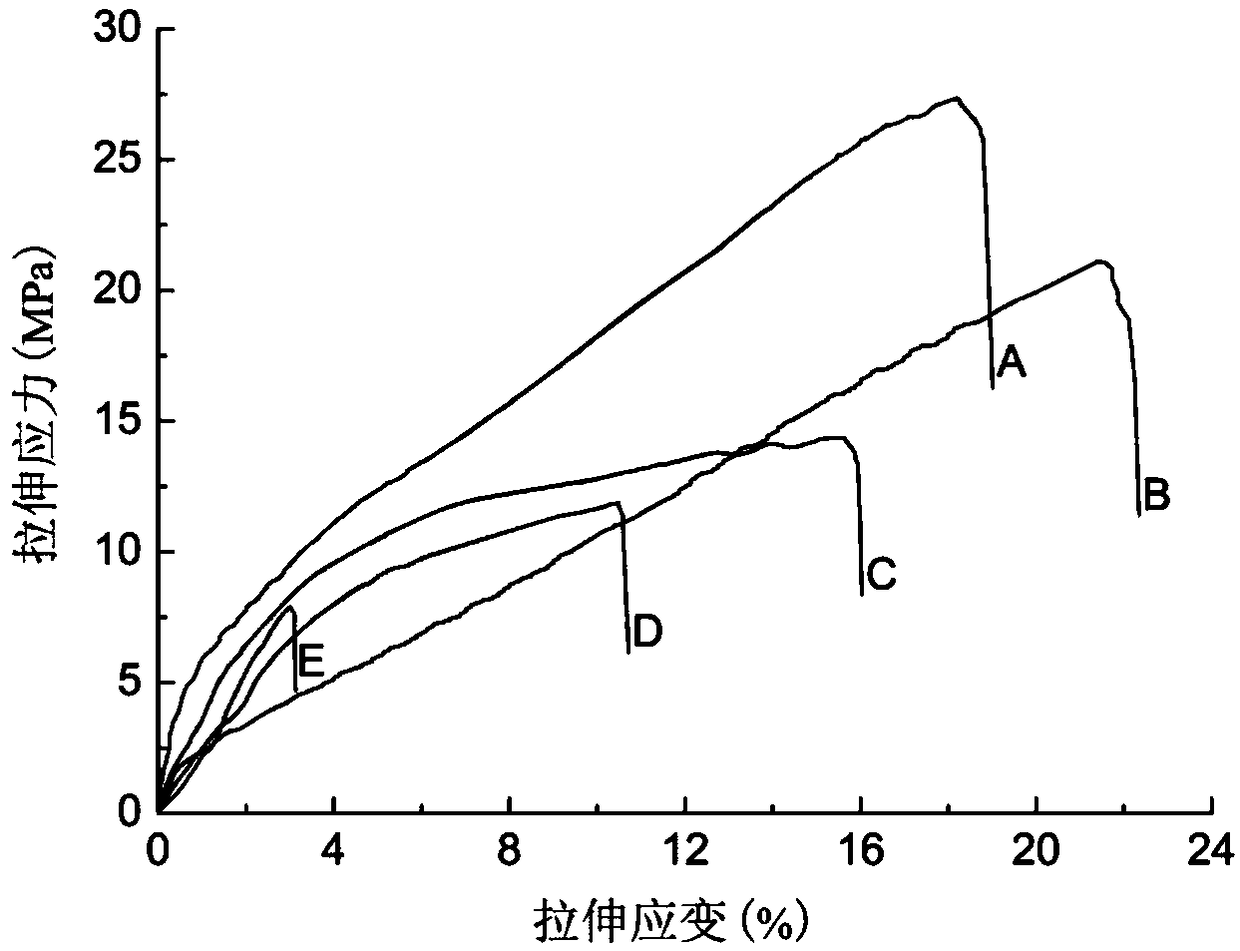

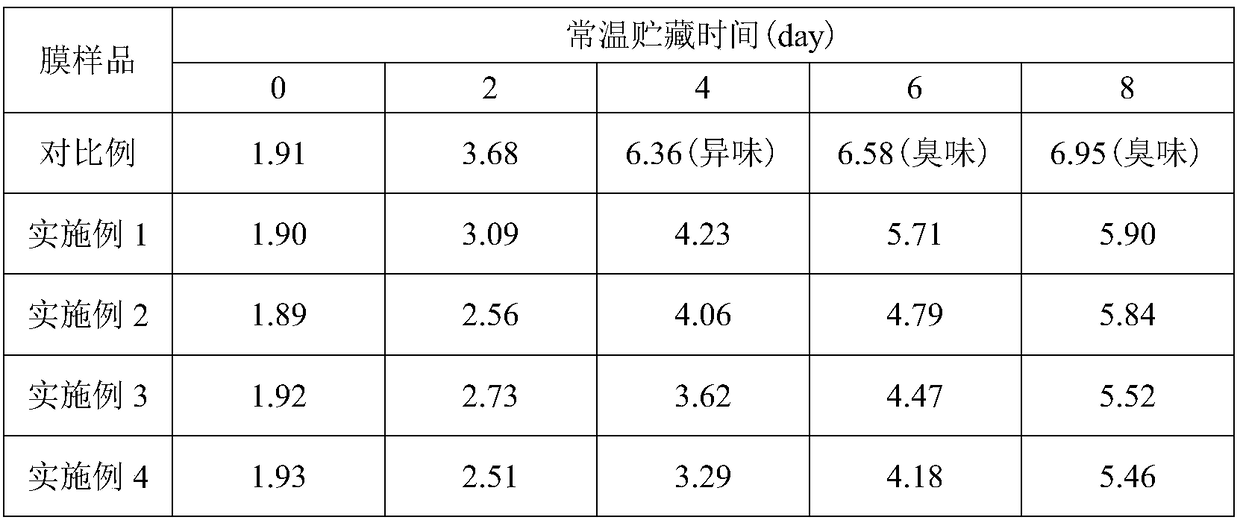

Method used

Image

Examples

Embodiment 1

[0032] (1) Soak tea residues in deionized water at 70°C for 4 hours to remove soluble pigments, wash and dry at 80°C for 4 hours, crush and pass through a 150-mesh sieve to obtain tea residue powder.

[0033] (2) Add selective oxidized cotton cellulose to 25 g of ionic liquid 1-butyl-3-methylimidazole acetate, heat the oil bath to 95 ° C and continue stirring for 45 minutes to dissolve the selectively oxidized cellulose and obtain the selected An ionic liquid solution of selectively oxidized cotton cellulose, wherein the mass concentration of selectively oxidized cotton cellulose is 1%.

[0034] Wherein, the selective oxidized cellulose is obtained as follows: cotton cellulose is pulverized, passed through an 80-mesh sieve, immersed in a sodium hydroxide solution with a mass concentration of 8%, and ultrasonically treated for 45min at 25°C (ultrasonic frequency: 20kHz, the ultrasonic intermittent time is 5s, the working time is 3s, and the ultrasonic power is 600W), then fully...

Embodiment 2

[0039] (1) Soak tea residues in deionized water at 75°C for 4 hours to remove soluble pigments, dry at 90°C for 5 hours after washing, and pass through a 150-mesh sieve after crushing to obtain tea residue powder;

[0040] (2) Add selective oxidized cotton cellulose to 25g of ionic liquid 1-allyl-3-methylimidazolium chloride salt, heat the oil bath to 90°C and continue stirring for 90min to dissolve the selectively oxidized cellulose and obtain the selected An ionic liquid solution of selectively oxidized cotton cellulose, wherein the mass concentration of selectively oxidized cotton cellulose is 1.2%.

[0041] Wherein, the selective oxidized cellulose is obtained as follows: cotton cellulose is pulverized, passed through an 80-mesh sieve, immersed in a sodium hydroxide solution with a mass concentration of 9%, and ultrasonically treated at 35°C for 30min (ultrasonic frequency: 20kHz, the ultrasonic intermittent time is 5s, the working time is 3s, and the ultrasonic power is 8...

Embodiment 3

[0047] (1) Soak tea residues in deionized water at 80°C for 3 hours to remove soluble pigments, wash and dry at 95°C for 4 hours, crush and pass through a 150-mesh sieve to obtain tea residue powder;

[0048] (2) Add selective oxidized cotton cellulose to 30 g of ionic liquid 1-allyl-3-methylimidazolium chloride salt, heat the oil bath to 95 ° C and continue stirring for 60 minutes to dissolve the selectively oxidized cellulose and obtain the selected An ionic liquid solution of selectively oxidized cotton cellulose, wherein the mass concentration of selectively oxidized cotton cellulose is 1.5%.

[0049] Wherein, the selective oxidized cellulose is obtained as follows: cotton cellulose is pulverized, passed through an 80-mesh sieve, immersed in a sodium hydroxide solution with a mass concentration of 9%, and ultrasonically treated at 30°C for 50min (ultrasonic frequency: 20kHz, the ultrasonic intermittent time is 5s, the working time is 3s, and the ultrasonic power is 800W), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com