Thin coal seam mined-out area paste body filling construction method

A technology of paste filling and construction method, which is applied in the fields of filling, mining equipment, earthwork drilling, etc., can solve the problems of pollution, increase in construction cost, increase in pumping equipment and operating cost, etc., to eliminate environmental pollution and reduce investment. and the effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0047] The construction method of paste filling in the goaf of the thin coal seam according to the present invention adopts the method of backfilling the underground seepage water in the goaf after filling it with a water bag, and uses the water-filled water bag to occupy part of the space in the goaf, correspondingly reducing the filling volume of the paste The gob filling is carried out in the same way, and the water-filled water bag is finally solidified in the filling body of the entire goaf, becoming a component of the whole filling body;

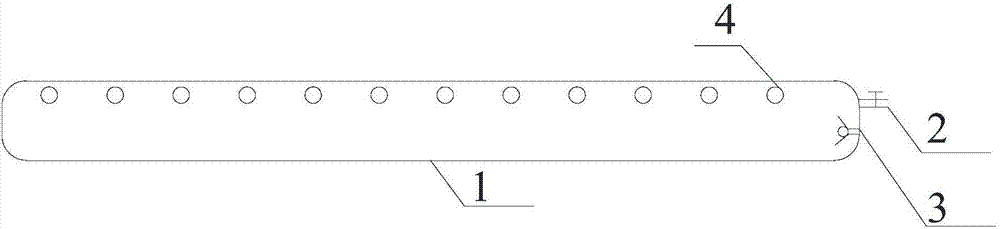

[0048] like figure 1 As shown, the above-mentioned water bag 1 is a rubber bag, which is in the shape of a flat strip; along the longitudinal direction of the water bag, a through hole 4 for the insertion of the filling tube is arranged at a certain distance inside the top edge of the water bag; when the water bag is filled w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com