Coal-based gas dreg light-weight micro-pore concrete composite sheet material and preparation method thereof

A composite board and concrete technology, applied in the field of building materials, can solve the problems of environmental damage, depletion of natural building materials, and high cost, and achieve the effects of good thermal insulation performance, elimination of environmental pollution, and non-flammable durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

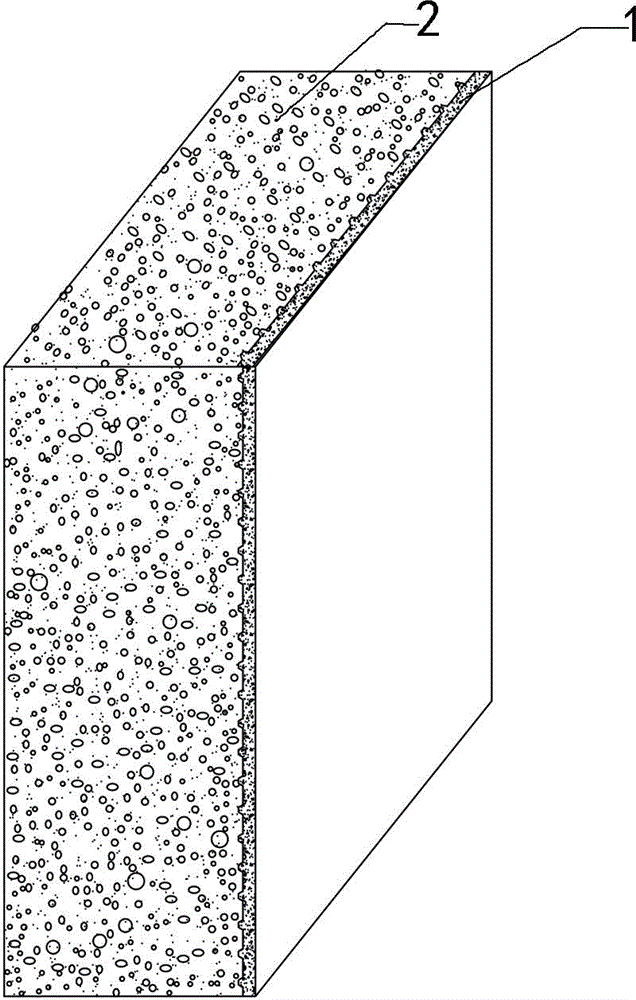

Image

Examples

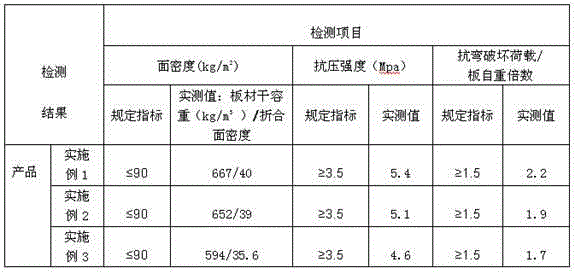

Embodiment 1

[0049] The raw material composition of the decorative mortar surface layer 1 is as follows according to the weight ratio per cubic meter of mortar:

[0050] River sand 1850 kg / m 3 ;

[0051] Cement 450 kg / m 3 ;

[0052] Admixture 50 kg / m 3 ;

[0053] Water reducer 3kg / m 3 ;

[0054] Tap water 105kg / m 3 ;

[0055] The raw material composition of lightweight microporous concrete insulation layer 2 is as follows according to the weight ratio per cubic meter of slurry:

[0056] Cement 330 kg / m 3 ;

[0057] Coal gas slag 380kg / m 3 ;

[0058] Admixture 40 kg / m 3 ;

[0059] Water reducer 4kg / m 3 ;

[0060] Tap water 90kg / m 3 ;

[0061] Foaming agent 0.5kg / m 3 .

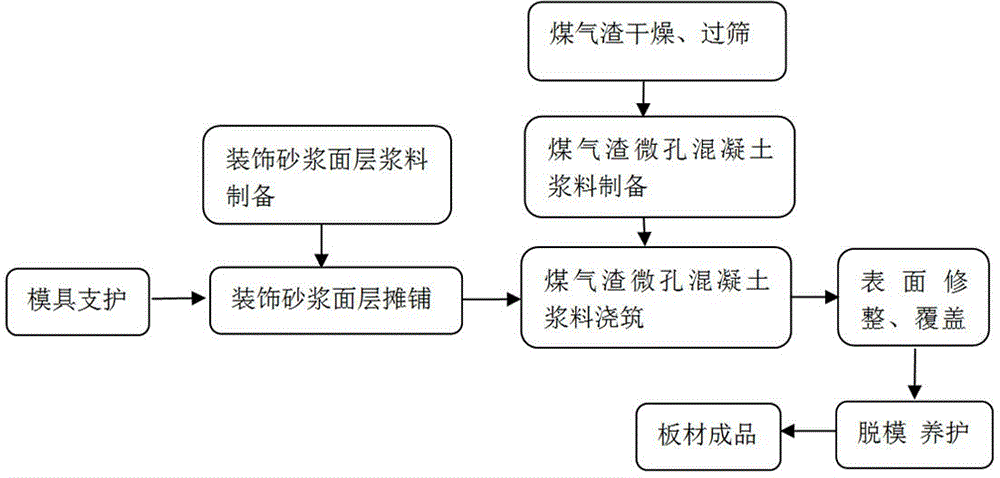

[0062] The preparation method of the sheet material of embodiment 1 is as follows, as figure 2 Shown:

[0063] Step 1. Naturally air-dry the undisturbed coal gas slag in the open air;

[0064] Step 2, sieve the slag that has been air-dried to a loose state with a sieve with an aperture of 5 mm, and reta...

Embodiment 2

[0075] The raw material composition of the decorative mortar surface layer 1 is as follows according to the weight ratio per cubic meter of mortar:

[0076] River sand 2000 kg / m 3 ;

[0077] Cement 400 kg / m 3 ;

[0078] Admixture 70 kg / m 3 ;

[0079] Water reducer 3.5kg;

[0080] Tap water 120kg / m 3 ;

[0081] Inorganic pigments 4 kg / m 3 ;

[0082] The raw material composition of lightweight microporous concrete insulation layer 2 is as follows according to the weight ratio per cubic meter of slurry:

[0083] Cement 295 kg / m 3 ;

[0084] Coal gas slag 460kg / m 3 ;

[0085] Admixture 55kg / m 3 ;

[0086] Water reducer 3.6kg / m 3 ;

[0087] Tap water 120kg / m 3 ;

[0088] Foaming agent 0.9kg / m 3 .

[0089] The preparation method of the sheet material of embodiment 2 is as follows:

[0090] Step 1. Naturally air-dry the undisturbed coal gas slag in the open air;

[0091] Step 2, sieve the slag that has been air-dried to a loose state with a sieve with an apertu...

Embodiment 3

[0102] The raw material composition of the decorative mortar surface layer 1 is as follows according to the weight ratio per cubic meter of mortar:

[0103] River sand 2200 kg / m 3 ;

[0104] Cement 490 kg / m 3 ;

[0105] Admixture 85 kg / m 3 ;

[0106] Water reducer 4.2kg / m 3 ;

[0107] Tap water 140kg / m 3 ;

[0108] Inorganic pigments 6.5 kg / m 3 ;

[0109] The raw material composition of lightweight microporous concrete insulation layer 2 is as follows according to the weight ratio per cubic meter of slurry:

[0110] Cement 260 kg / m 3 ;

[0111] Coal gas slag 310kg / m 3 ;

[0112] Admixture 70kg / m 3 ;

[0113] Water reducer 3.2kg / m 3 ;

[0114] Tap water 150kg / m 3 ;

[0115] Foaming agent 1.2kg / m 3 .

[0116] The preparation method of the plate of embodiment 3 is as follows:

[0117] Step 1. Naturally air-dry the undisturbed coal gas slag in the open air;

[0118] Step 2, sieve the slag that has been air-dried to a loose state with a sieve with an apertur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Dry unit weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com