Coal gas purifying method

A gas and gas furnace technology, which is applied in the field of gas purification in chemical engineering, can solve the problems of high cost, large area occupied by process equipment, and various process control parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

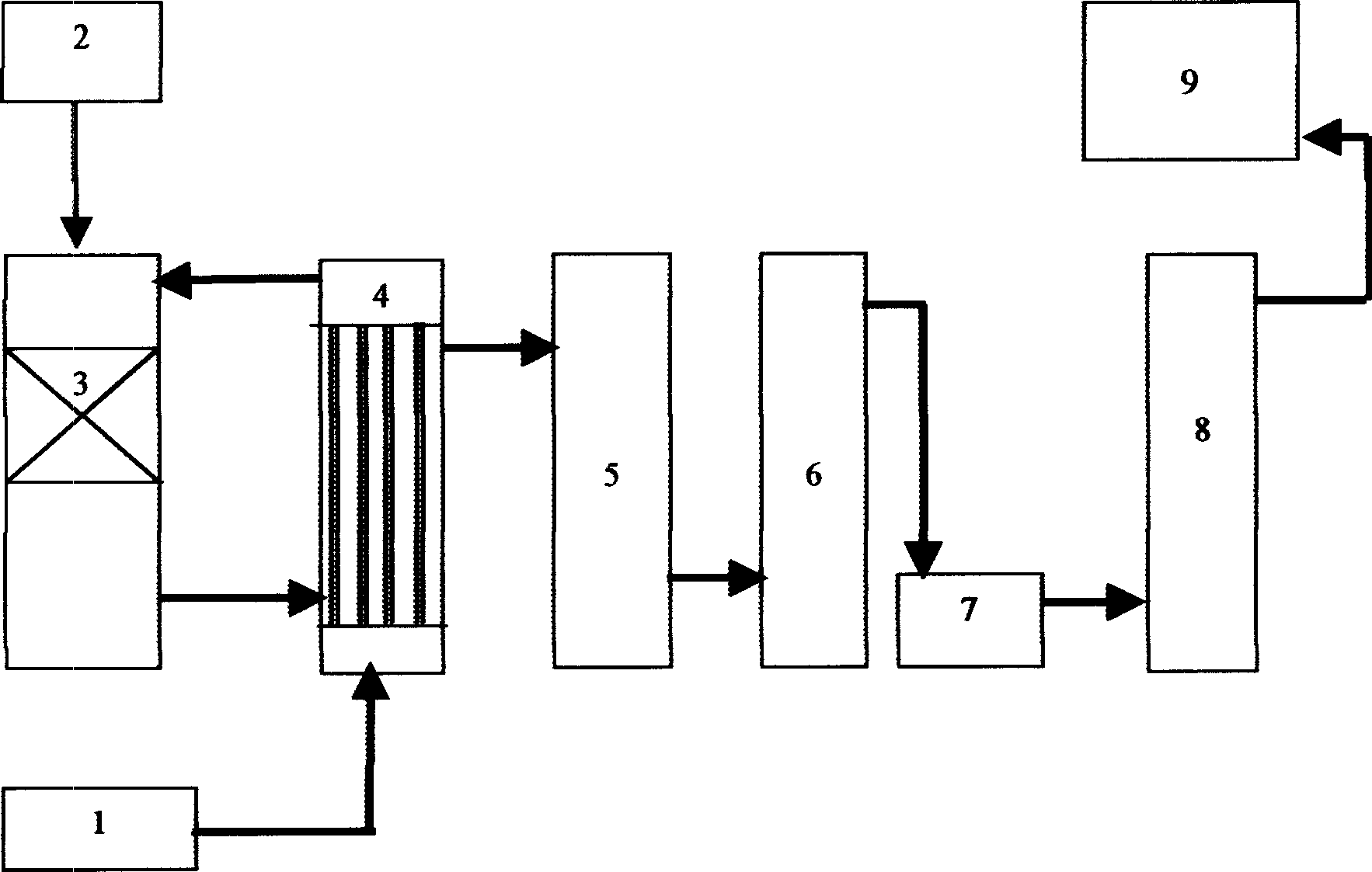

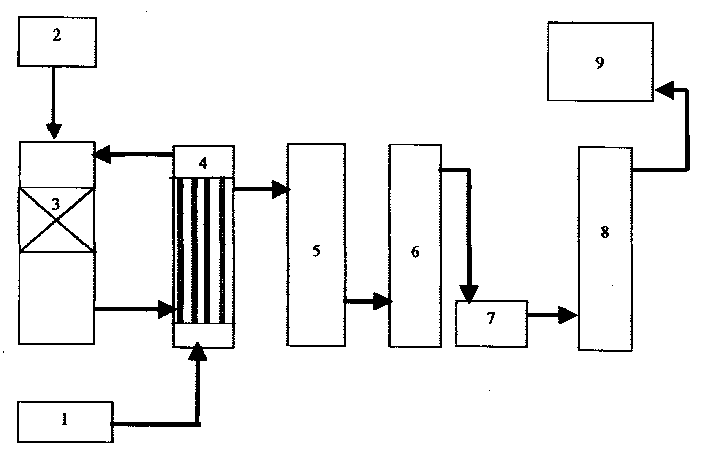

[0028] Specific embodiments of the present invention are as attached to the specification figure 1 As shown, the high-temperature hot coke oven gas 1 from the top of the coke oven at about 600°C to 800°C is sent to the gas heat exchanger 4 through the insulated pipeline, and the temperature rises to 900°C to 1000°C after heat exchange with the cracked gas. It is sent to the upper part of the cracking reformer 3, mixed with an appropriate amount of process oxygen sent from the oxygen generator 2, and burned. When the temperature rises to 1100℃~1300℃, most of the tar, benzene group, naphthalene group, organic sulfur, cyanide and ammonia in the coke oven gas are cracked into low molecular weight compounds or simple substances under the action of high temperature. While falling, H in the gas 2 O undergoes a conversion reaction to produce CO and H 2 After completing the cracking conversion reaction of the coal gas, the temperature drops to 1100°C-1200°C, and after most of the dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com