Coated acidifying agent for feed and preparation method thereof

The technology of acidifier and coating is applied in the field of preparation of acidifier for feed, which can solve the problems of loss of feed nutrients, and achieve the effects of improving adsorption, improving coating effect and saving cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

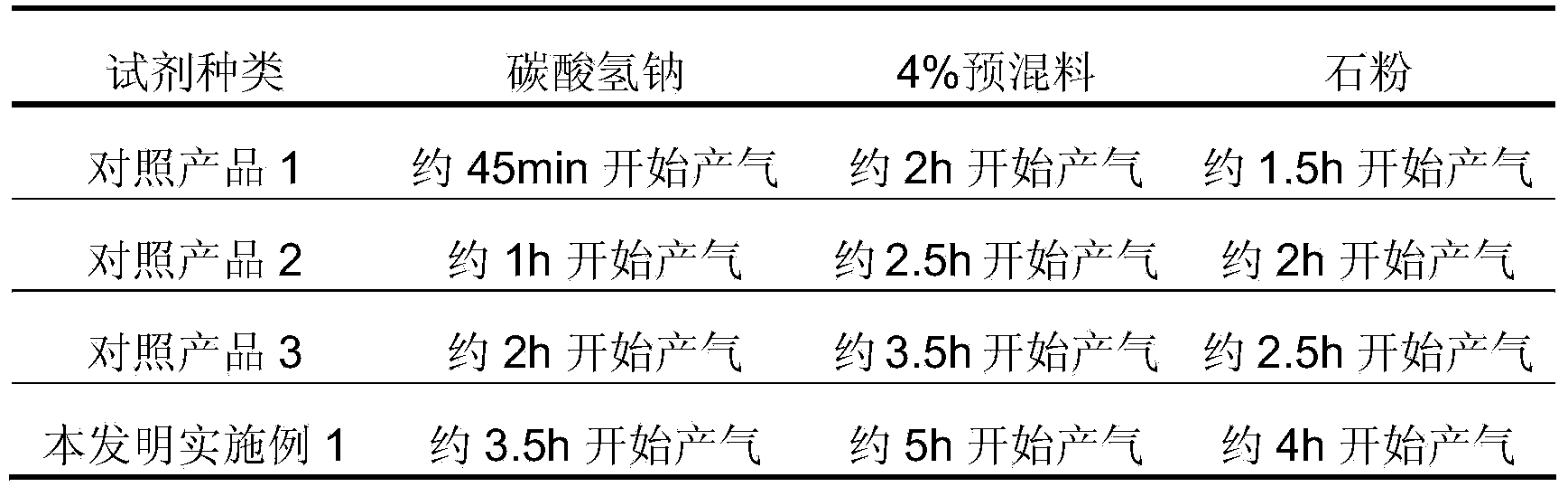

Examples

Embodiment 1

[0044] The process of preparing a kind of coating feed acidulant:

[0045] step 1:

[0046] Weigh 350g of silicon dioxide and 400g of phosphoric acid passed through a 60-mesh sieve into a sample bag, mix and shake until the phosphoric acid is completely absorbed; use a peristaltic pump to spray 100g of the coating solution into a fluidized bed coater for coating Granulation treatment;

[0047] Wherein, the coating solution includes polyacrylic acid resin emulsion and film coating premix with a mass ratio of 4:1, and the film coating premix specifically includes: polyethylene glycol (plasticizer), hard Magnesium fatty acid (anti-sticking agent), lecithin (surfactant), capsanthin (color).

[0048] Step 2:

[0049] Mix 150 g of citric acid and 8 g of fumaric acid with the coated product, and mix evenly to obtain the coated acidulant product. Coating process conditions: compressed air pressure 0.4Mpa, spray volume 0.36kg / min, spray temperature 32°C, air volume 2600m 3 / h.

Embodiment 2

[0051] The process of preparing a kind of coating feed acidulant:

[0052] step 1:

[0053] Weigh 400g of silicon dioxide and 500g of phosphoric acid passed through a 60-mesh sieve into a sample bag, mix and shake well until the phosphoric acid is completely absorbed; use a peristaltic pump to spray 120g of the coating solution into a fluidized bed coater for Coating and granulation treatment;

[0054] Wherein, the coating solution includes a polyacrylic acid resin latex solution and a film coating premix with a mass ratio of 6:1, and the film coating premix specifically includes: triethyl citrate (plasticizer), Micronized silica gel (anti-sticking agent), polysorbate-20 (surfactant), turmeric (color).

[0055] Step 2:

[0056] Mix 180 g of citric acid and 3 g of fumaric acid with the coated product, and mix evenly to obtain the coated acidulant product. Coating process conditions: compressed air pressure 0.5Mpa, spray volume 0.7kg / min, tablet bed temperature 40°C, air vol...

Embodiment 3

[0058] The process of preparing a kind of coating feed acidulant:

[0059] step 1:

[0060] Weigh 480g of silicon dioxide and 500g of phosphoric acid passed through a 60-mesh sieve into a sample bag, mix and shake well until the phosphoric acid is completely absorbed; use a peristaltic pump to spray 120g of the coating solution into a fluidized bed coater for Coating and granulation treatment;

[0061] Wherein, the coating solution includes polyacrylic acid resin emulsion and film coating premix with a mass ratio of 8:1, and the film coating premix specifically includes: glycerol triacetate (plasticizer), talcum powder (anti-sticking agent), polyoxyethylene fatty acid ester (surfactant), natural beta carotene (color).

[0062] Step 2:

[0063] Mix 180 g of citric acid and 3 g of fumaric acid with the coated product, and mix evenly to obtain the coated acidulant product. Coating process conditions: compressed air pressure 0.5Mpa, liquid spray volume 0.7kg / min, tablet bed te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com