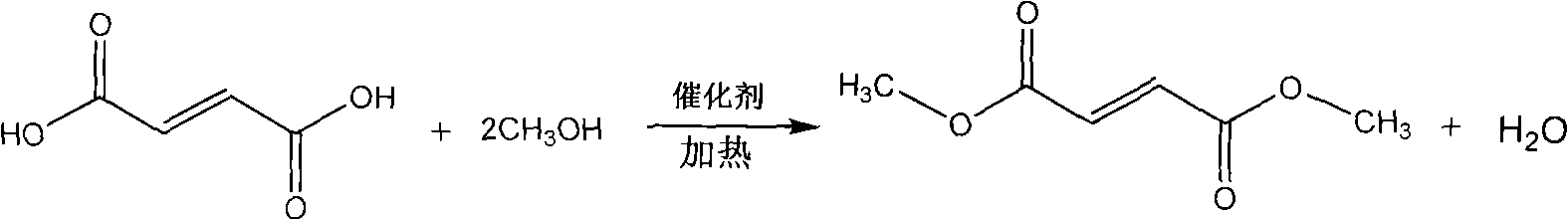

Preparation method of dimethyl fumarate

A technology of dimethyl fumarate and fumaric acid, which is applied in the field of preparing dimethyl fumarate, and can solve the problems that the synthetic reaction of dimethyl fumarate has not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: (compared with the concentrated sulfuric acid)

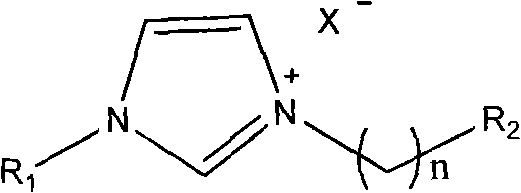

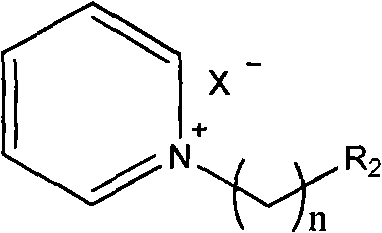

[0036] Add 0.12 g of ionic liquid catalyst 1, and when concentrated sulfuric acid is used as the catalyst, take 0.037 g, fumaric acid and methanol into the reactor in a molar ratio of 1:3, raise the temperature to 75° C. under stirring, and react for 3 hours. The reaction results are listed in Table 1.

[0037] Table 1. Ionic liquid catalyst 1 compared with concentrated sulfuric acid

[0038]

[0039]

[0040] a Isolated yield

Embodiment 2

[0041] Embodiment 2: (compared with the concentrated sulfuric acid)

[0042] Add 0.12 g of ionic liquid catalyst 2, and when concentrated sulfuric acid is used as the catalyst, take 0.037 g, fumaric acid and methanol in a molar ratio of 1:3 into the reactor, raise the temperature to 80° C. under stirring, and react for 4 hours. The reaction results are listed in Table 2.

[0043] Table 2. Ionic liquid catalyst 2 compared with concentrated sulfuric acid

[0044]

[0045] a Isolated yield

Embodiment 3

[0047] Add the ionic liquid catalyst, fumaric acid and methanol into the reactor, heat and stir, and carry out the esterification reaction. The specific results are listed in Table 3.

[0048] Table 3. Fumaric acid and methanol esterification experimental results

[0049]

[0050]

[0051] a Isolated yield

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com