Method for separating and extracting fumaric acid

A technology of fumaric acid and reactor, which is applied in the field of bioengineering, can solve the problems that the adsorption capacity of resin has not been effectively utilized, it is difficult to realize industrial application, and the increase of energy consumption and material consumption has achieved wide industrial production prospects and operation. Good stability, low material consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

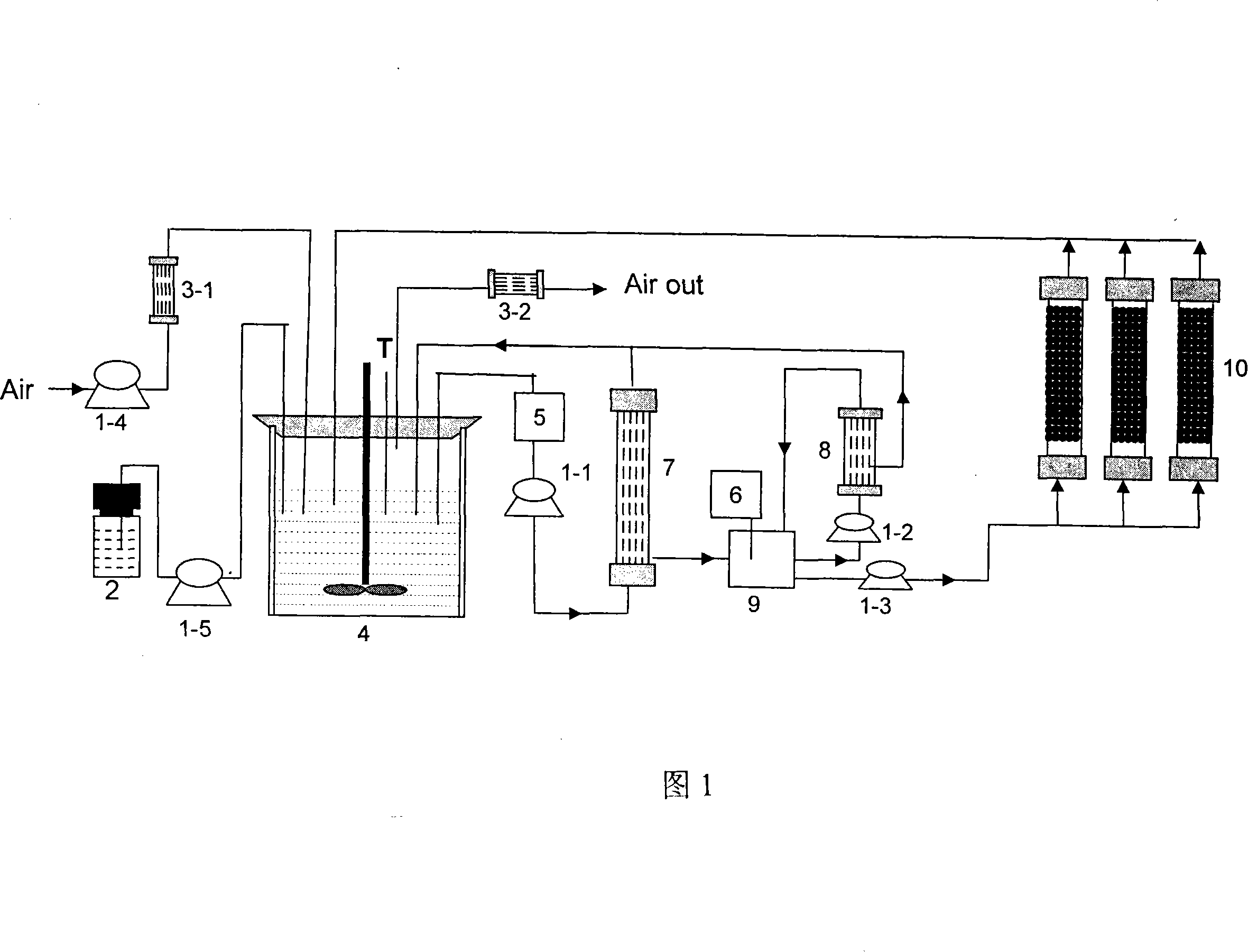

[0052] In conjunction with shown in Fig. 1, adopt the Rhizopus species Rhizopus Oryzae (Rhizopus Oryzae) ME-F11 (China Center for Type Culture Collection, preservation number is CCTCC NO: M 207066) The steps of in-situ separation and extraction of fumaric acid are as follows:

[0053] (1) Preparation of spore suspension: Inoculate Rhizopus Oryzae (Rhizopus Oryzae) ME-F11 on solid medium (yeast extract juice 5.0g / L, malt extract juice 5.0g / L, peptone 5.0g / L, glycerin 20g / L L, agar 20g / L) was cultured at 35°C for 6 days. After the spores matured, the spores were washed out with sterile water, placed in a sterilized Erlenmeyer flask filled with glass beads, fully shaken at 35°C and 120rpm for 50min, Evenly disperse the spores and filter them with sterilized absorbent cotton to obtain a spore suspension with a concentration of spores controlled at 10 6 pcs / ml spare;

[0054] (2) Seed culture: seed culture solution (glucose 40g / L, urea 3g / L, KH 2 PO 4 0.5g / L, MgSO 4 0.5g / L, F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com