Patents

Literature

30results about How to "Increase the rate of isomerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

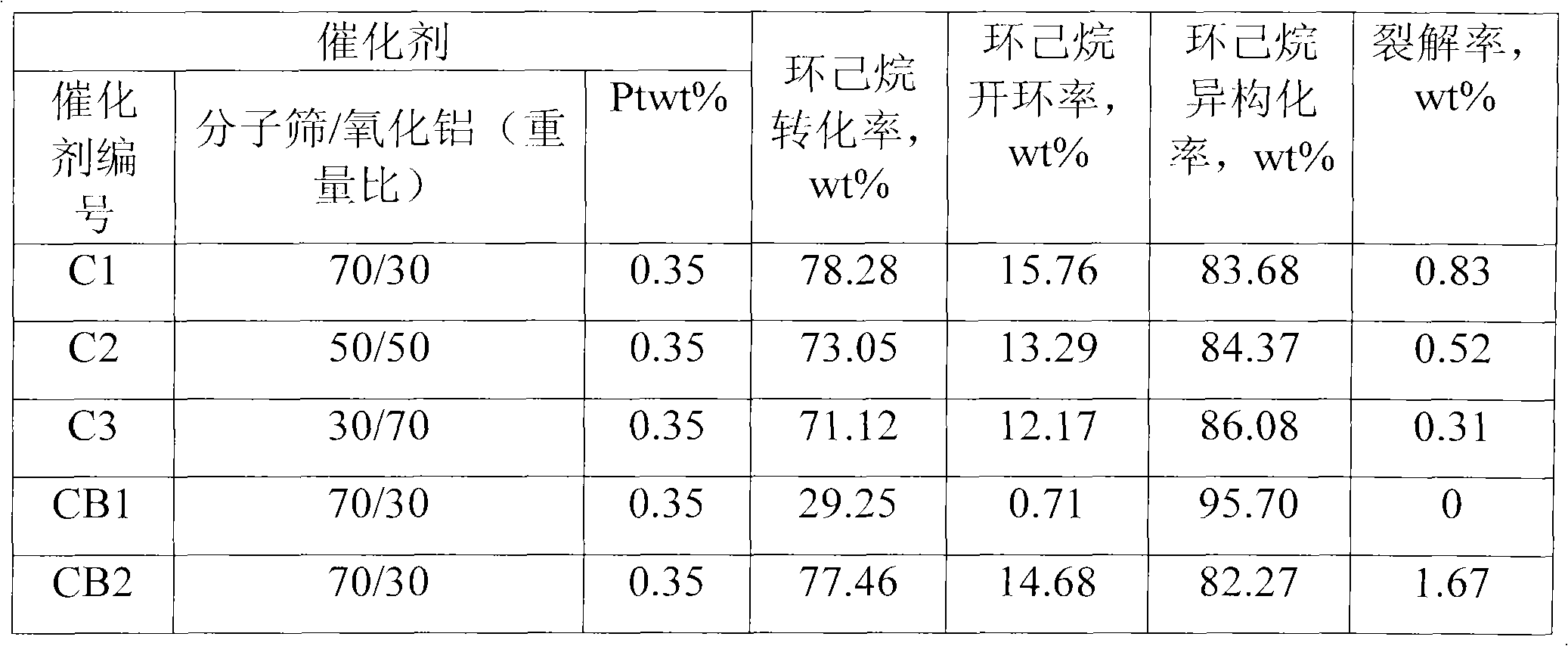

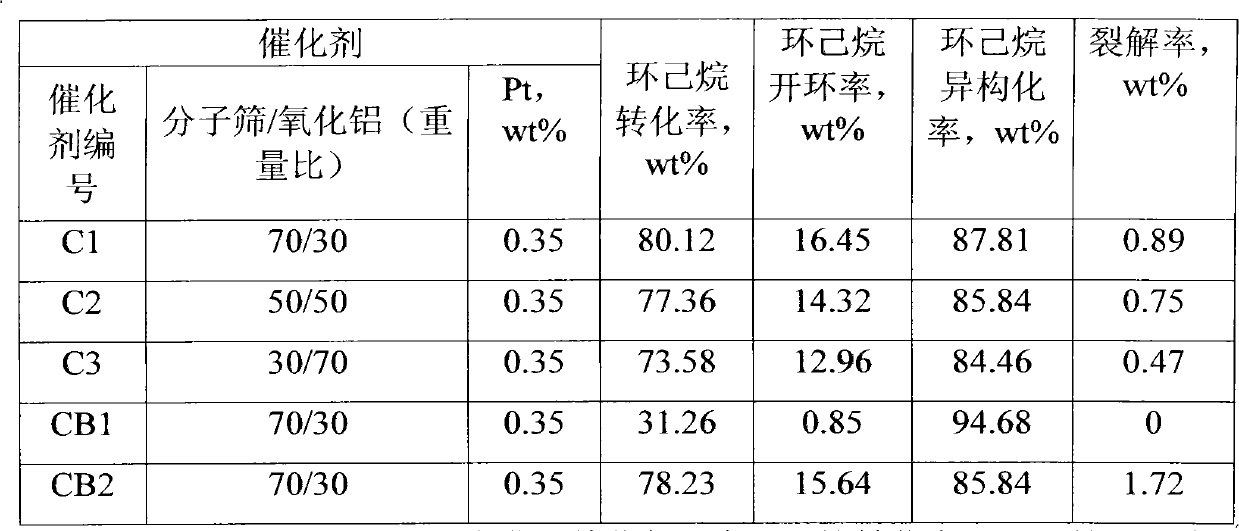

Naphthenic hydrocarbon hydro-conversion catalyst and preparation method and application thereof

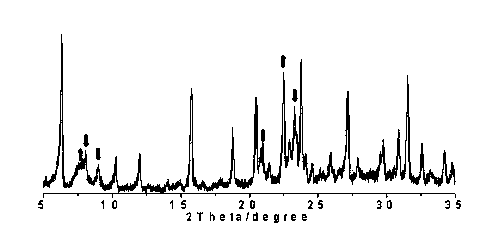

ActiveCN101992120ALow cracking rateShort synthesis timeMolecular sieve catalystsHydrocarbon by hydrogenationCyclic alkaneMolecular sieve

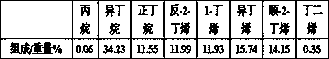

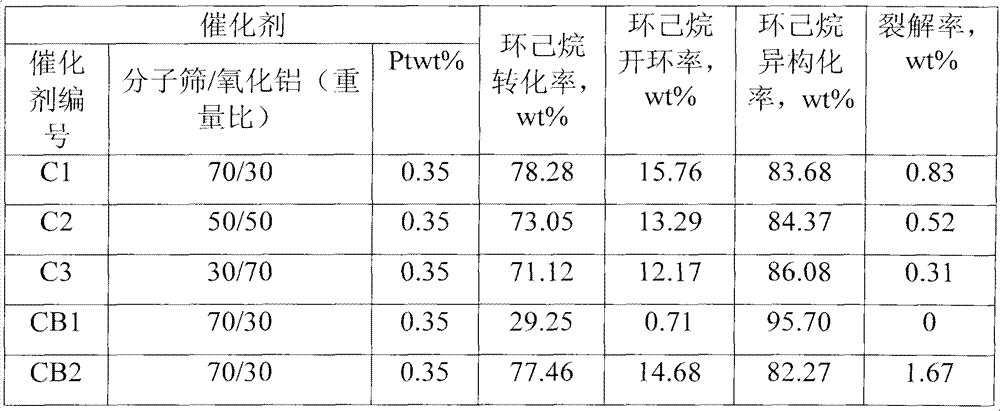

The invention discloses a naphthenic hydrocarbon hydro-conversion catalyst and a preparation method and application thereof. The naphthenic hydrocarbon hydro-conversion catalyst comprises a carrier active metal Pt, wherein a carrier consists of 10 to 90 weight percent of hydrogen-type Y-Beta composite molecular sieve, and an inorganic refractory oxide; and the active metal Pt content of the catalyst is 0.05 to 0.6 percent. The catalyst is prepared by an immersion method; and the obtained catalyst can be applied to hydro-conversion of various naphthenic hydrocarbon-containing raw materials andhas high conversion rate, high naphthenic hydrocarbon ring opening rate and low cracking rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

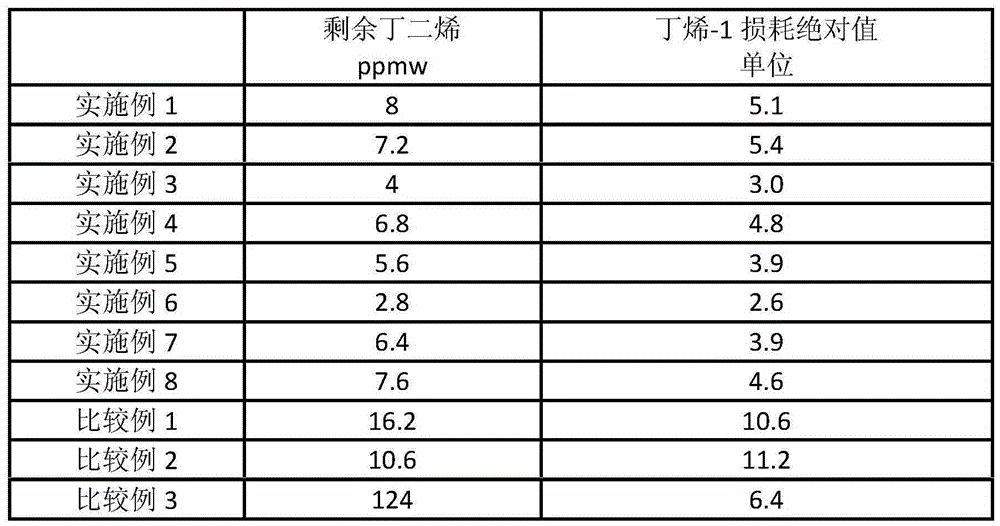

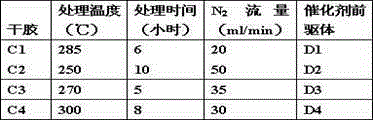

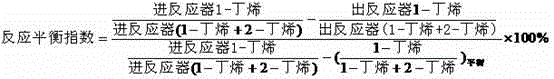

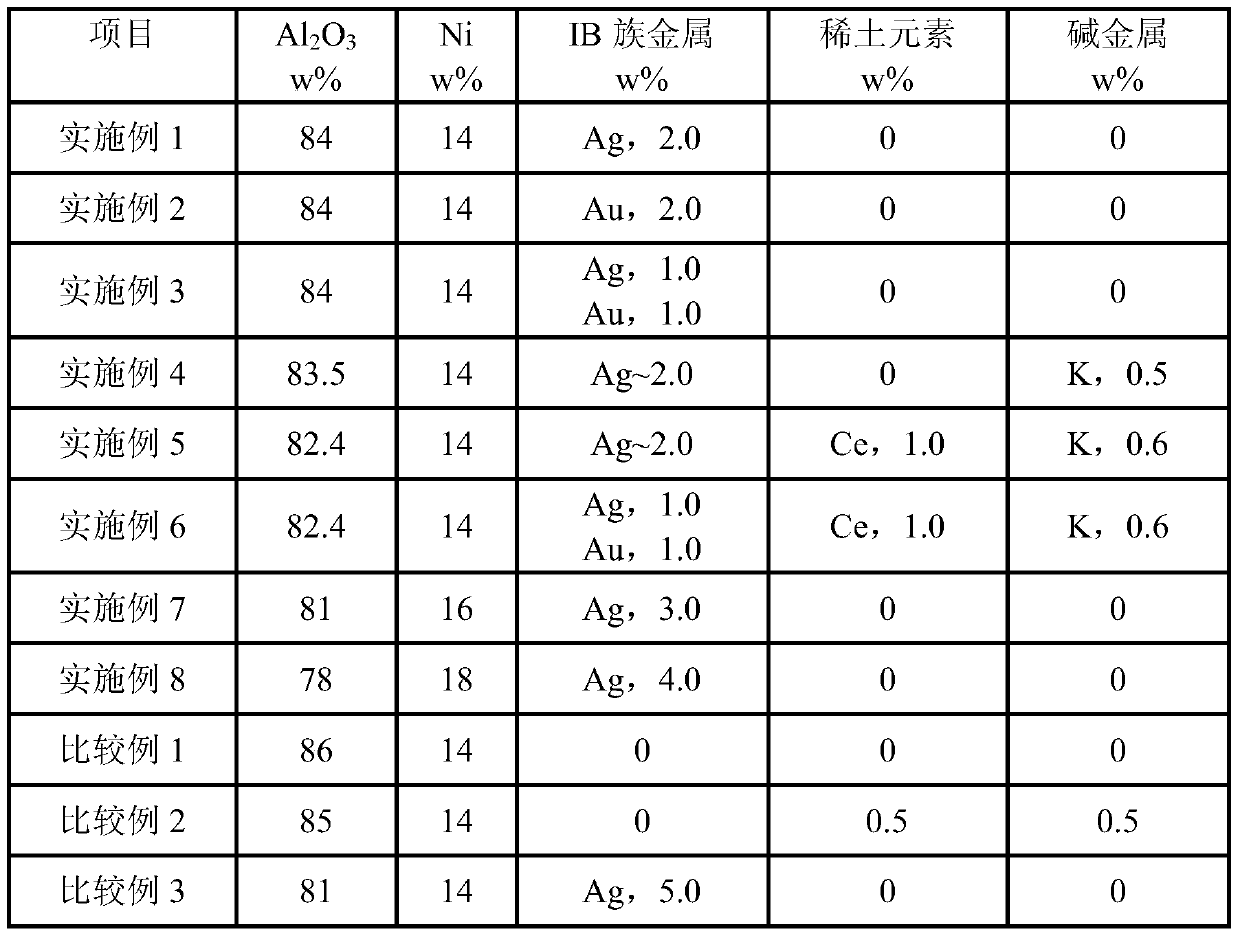

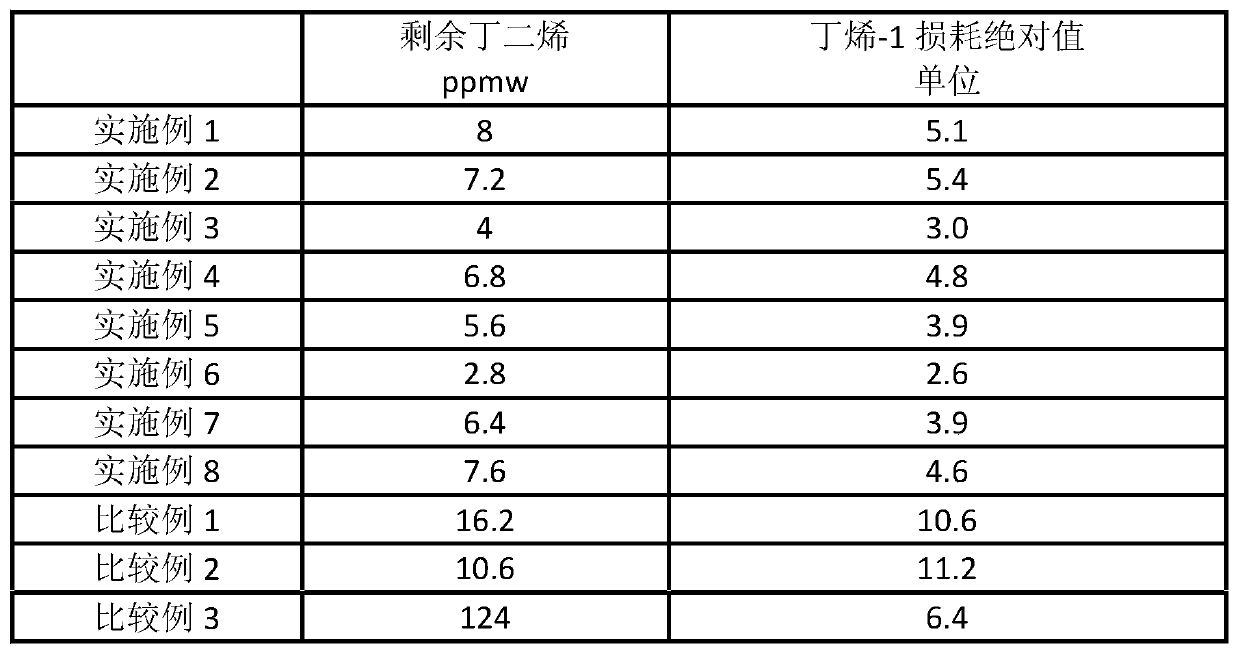

Catalyst for selective hydrogenation of butadiene

ActiveCN106582706AImprove technical effectLow costHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickelOxide

The invention relates to a catalyst for selective hydrogenation of butadiene, and mainly solves the technical problems of high catalyst cost and high n-butene loss in the prior art. The catalyst for selective hydrogenation of butadiene comprises the following components in parts by weight: (a) 5-20 parts of metal nickel or oxide thereof; (b) 0.5-4 parts of metals in IB group or oxides thereof; (c) 0-2 parts of alkali metals or oxides thereof; (d) 75-88 parts of a carrier aluminum oxide. The technical scheme better solves the technical problem, and can be applied to selective hydrogenation of materials containing butadiene.

Owner:CHINA PETROLEUM & CHEM CORP +1

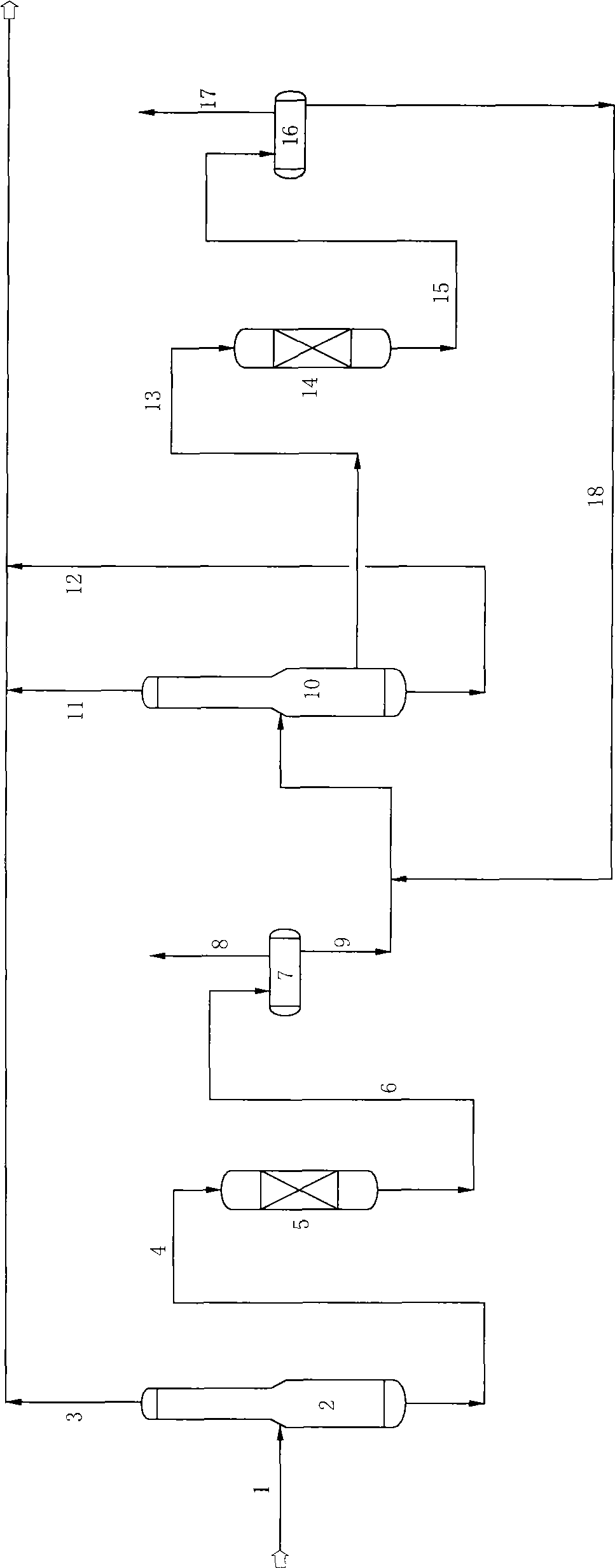

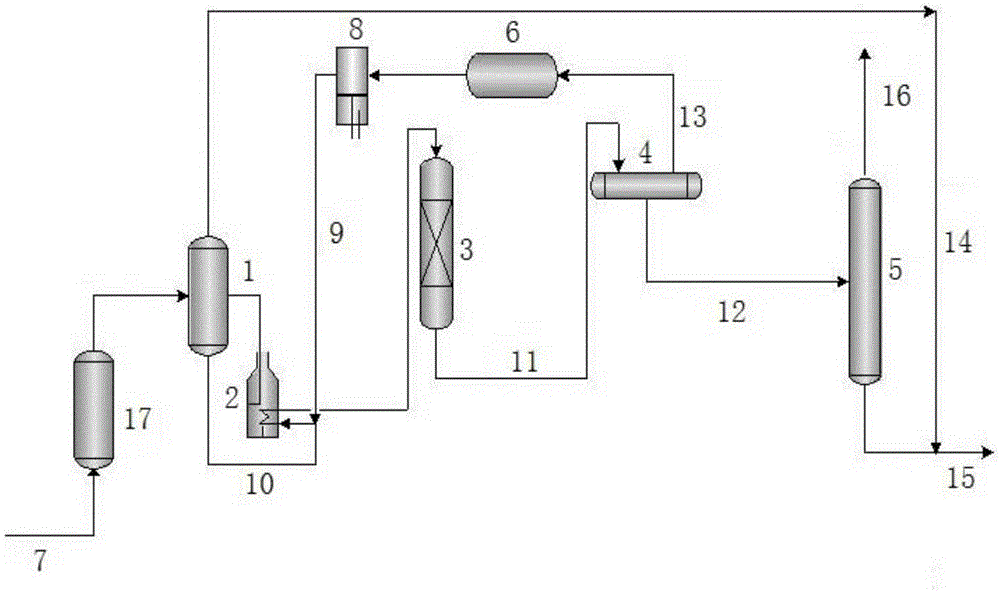

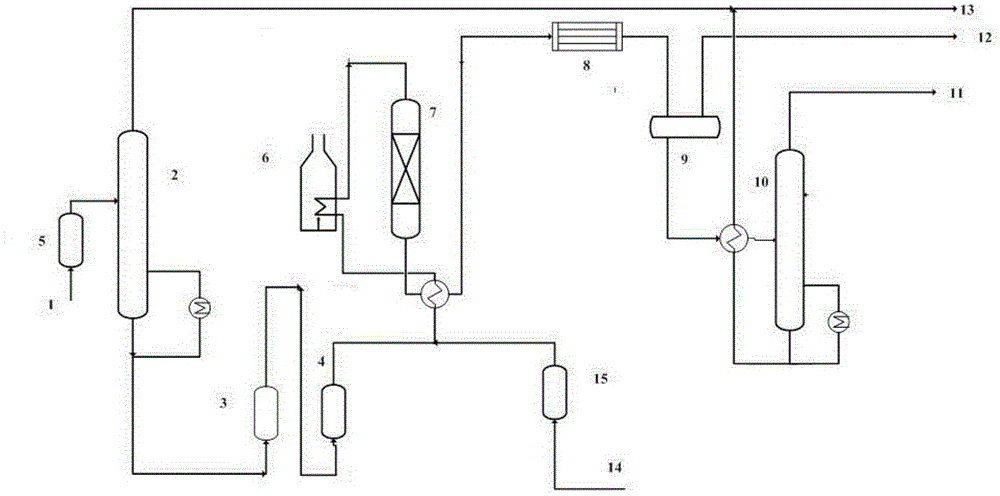

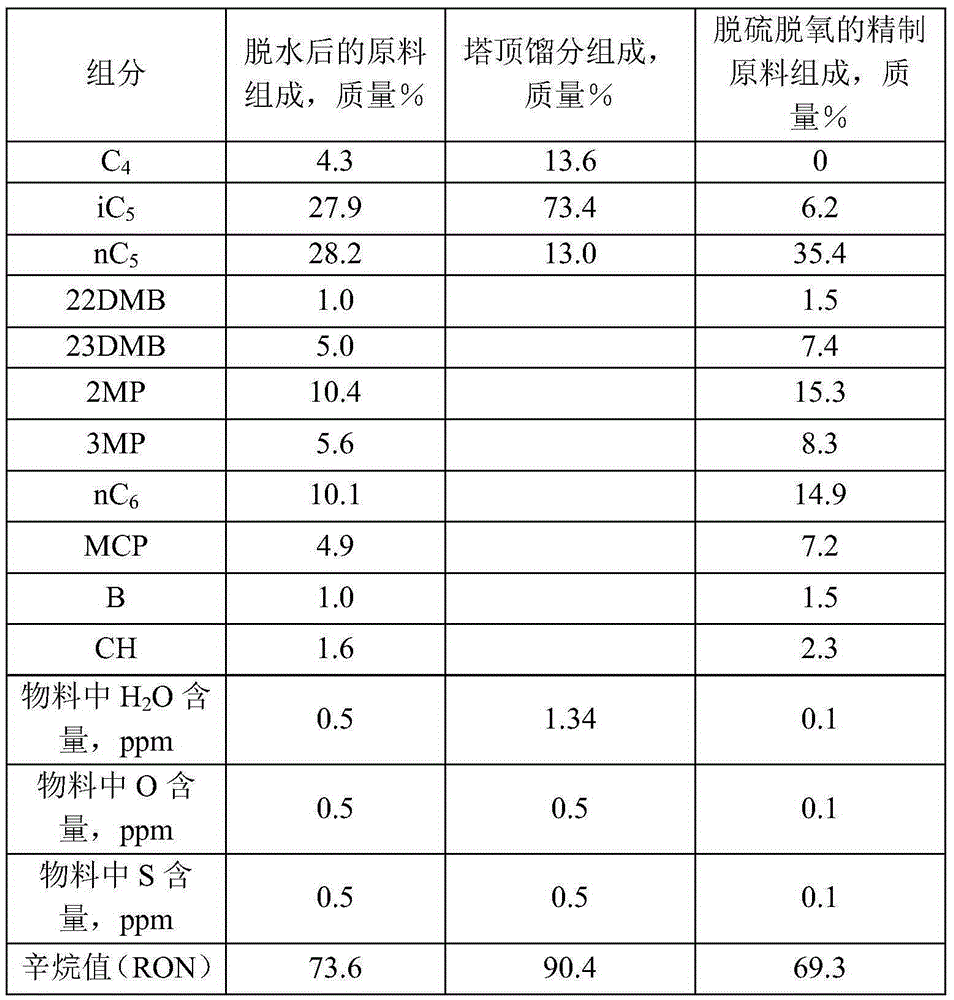

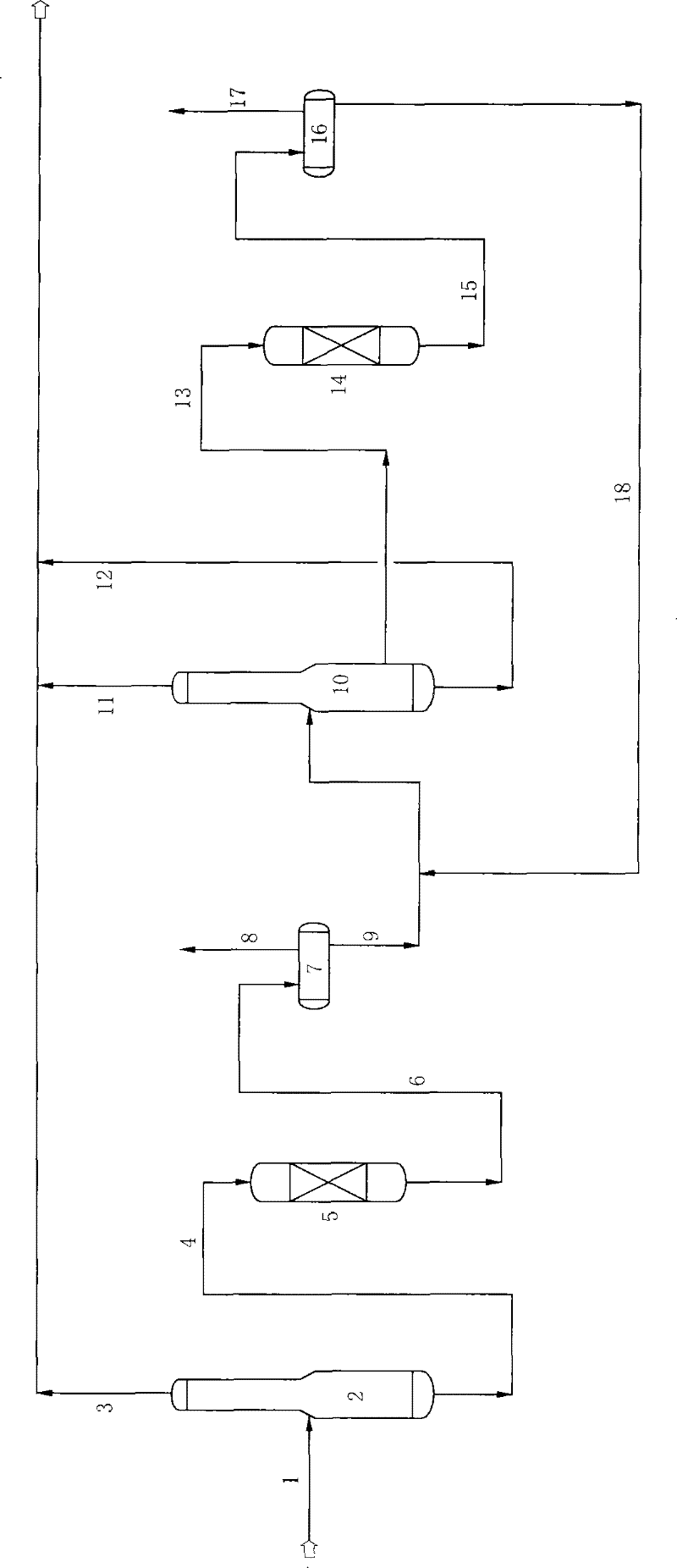

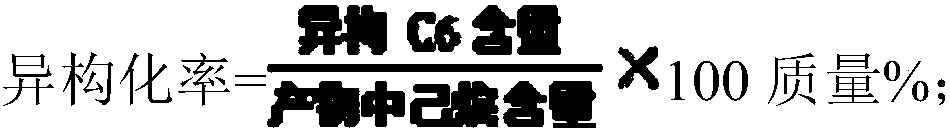

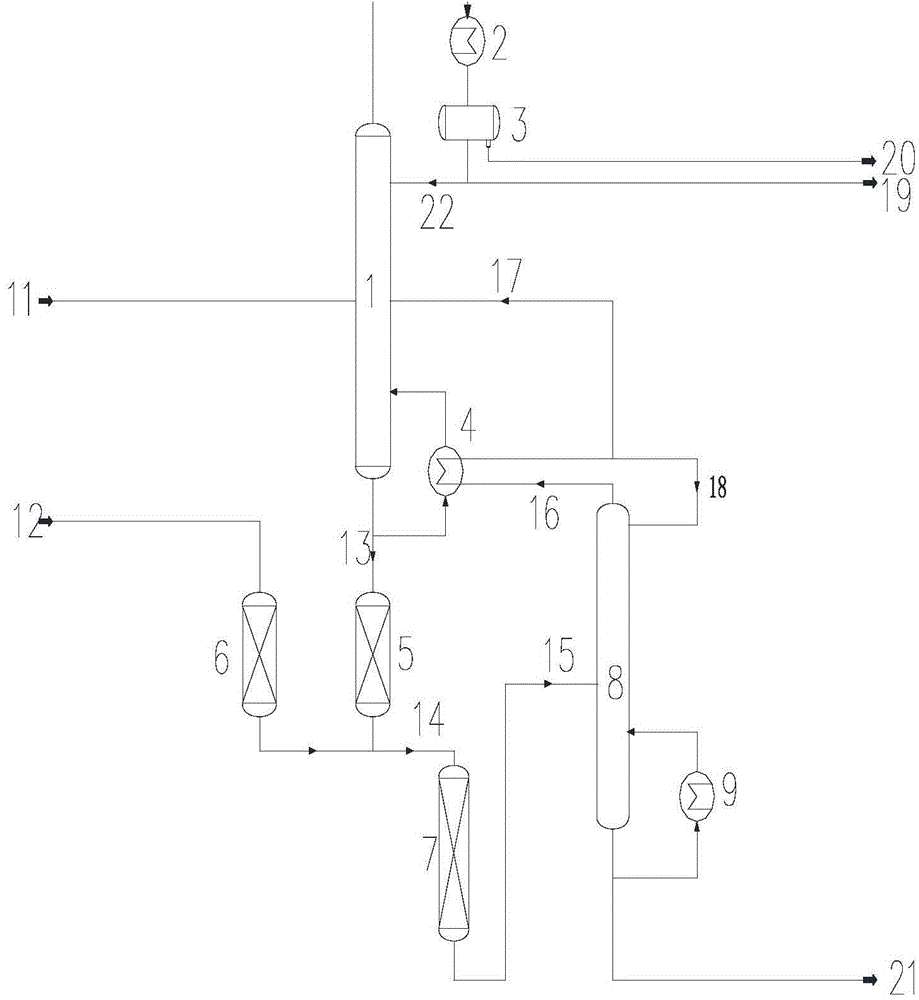

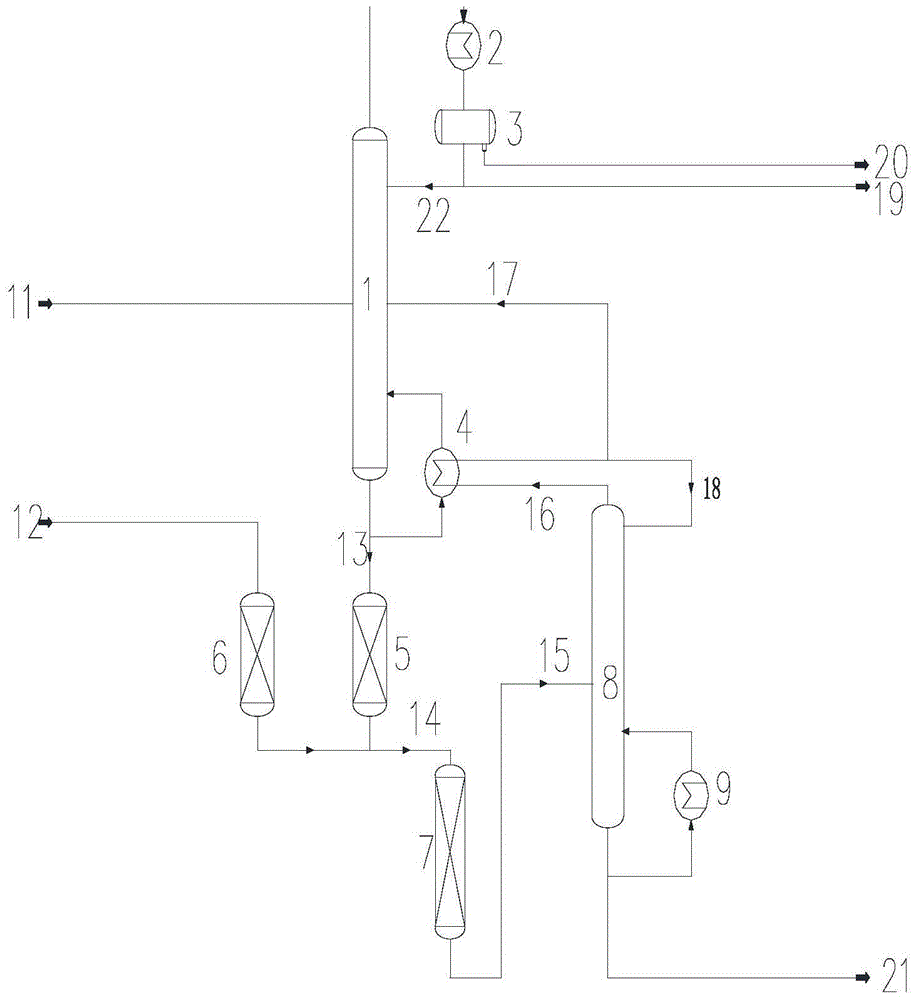

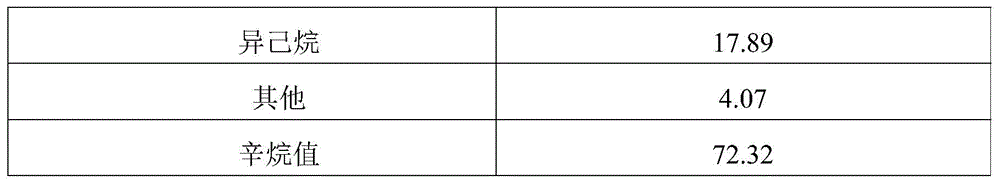

Light hydrocarbon isomerization method

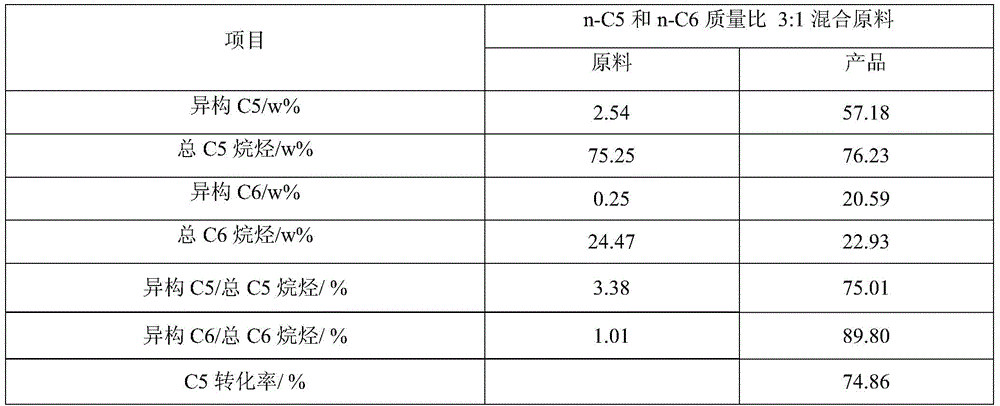

ActiveCN101544905AIncrease the rate of isomerizationGuaranteed isomerization rateHydrocarbon by isomerisationRefining to change hydrocarbon structural skeleton2-methylbutaneIsomerization

The invention relates to a light hydrocarbon isomerization method comprising the following steps: light hydrocarbon materials are firstly separated by a de-isopentane tower, tower top streams are extracted as isomerization products, and tower bottom streams enter a front isomerization reactor to generate isomerization reaction; liquid phase streams obtained by the gas-liquid separation of outlet streams of the front reactor are separated in a de-isohexane tower, and tower top streams and tower bottom streams of the de-isohexane tower are extracted and then mixed with the tower top streams of the de-isopentane tower and are together taken as a gasoline-stripping stabilization system of the isomerization products; siding streams of the de-isohexane tower are extracted into a rear isomerization reactor; and liquid phase streams obtained by the gas-liquid separation of reaction streams of the rear isomerization reactor completely return and are mixed with the liquid phase streams of a gas-liquid separator of the front isomerization reaction system and together taken as feeding materials of the de-isohexane tower. The method has higher normal paraffin isomerization ratio, wherein the C6 normal paraffin realizes the complete isomerization basically, thereby greatly improving the octane number of the light hydrocarbon materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

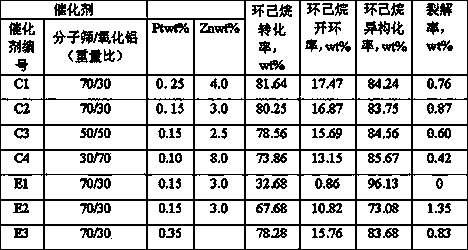

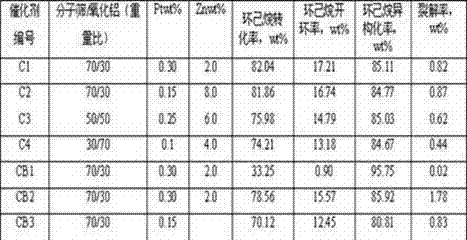

Cyclane hydro-conversion catalyst, preparation method and applications

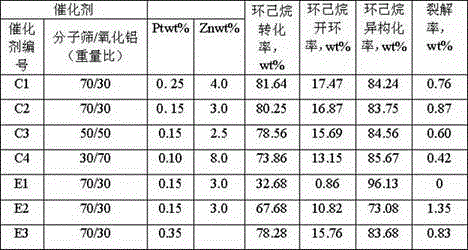

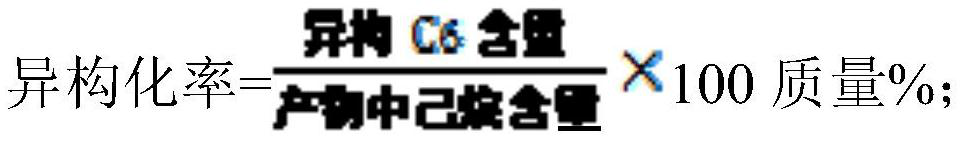

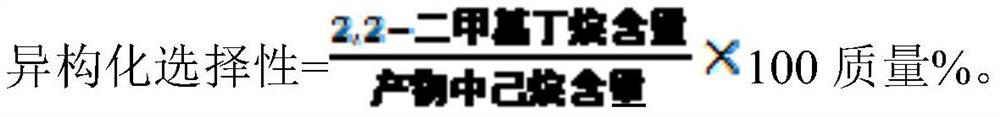

ActiveCN103372459AEasy to prepareLow costMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveIsomerization

The invention discloses a cyclane hydro-conversion catalyst. The catalyst comprises carriers and active metals Pt and Zn. The carriers are composed of hydrogen-type Y / Beta / ZSM-12 composite molecular sieves and inorganic refractory oxides. In the carriers of the catalyst, by weight, the content of the hydrogen-type Y / Beta / ZSM-12 composite molecular sieves is 10wt%-90wt%, the specific surface area of the hydrogen-type Y / Beta / ZSM-12 composite molecular sieves is 600 m<2> / g-800 m<2> / g, and the pore volume is 0.30 cm<3> / g-0.40 cm<3> / g. The content of the active metal Pt of the catalyst, by weight, is 0.02%-0.04%, and the content of Zn of the catalyst, by weight, is 0.5%-15%. When used for cyclane hydro-conversion, the catalyst is advantaged by high conversion rate, high cyclane ring opening rate, high isomerization rate and low cracking rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

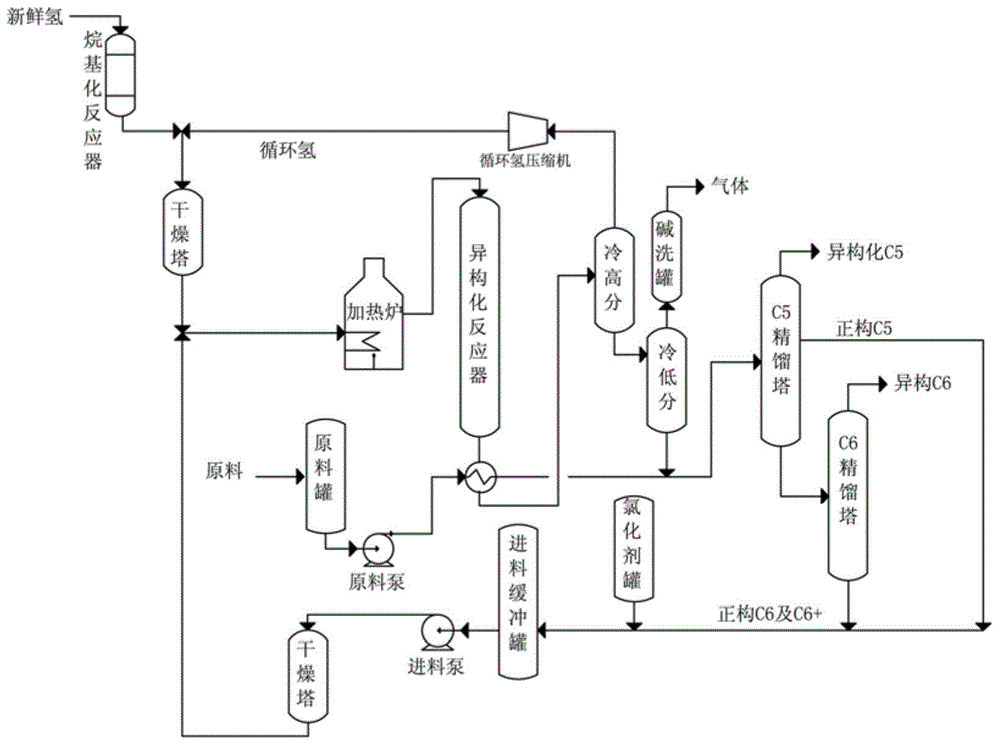

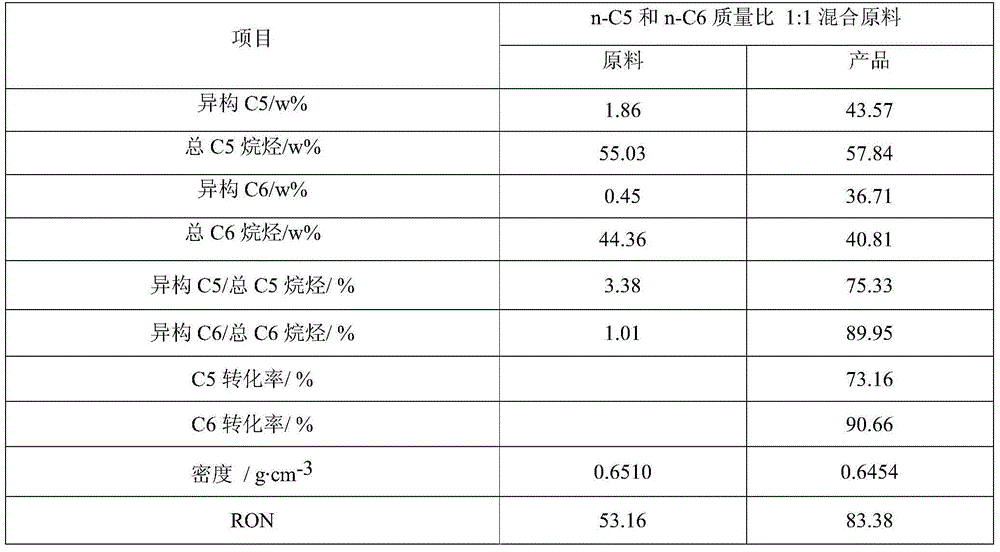

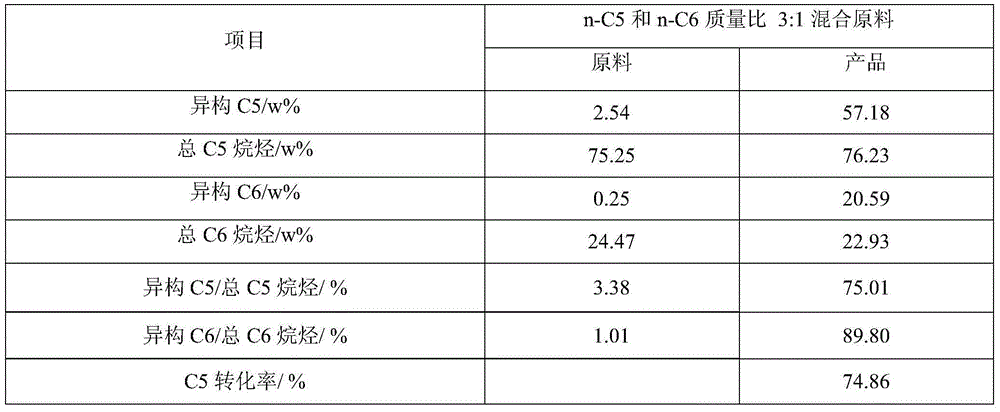

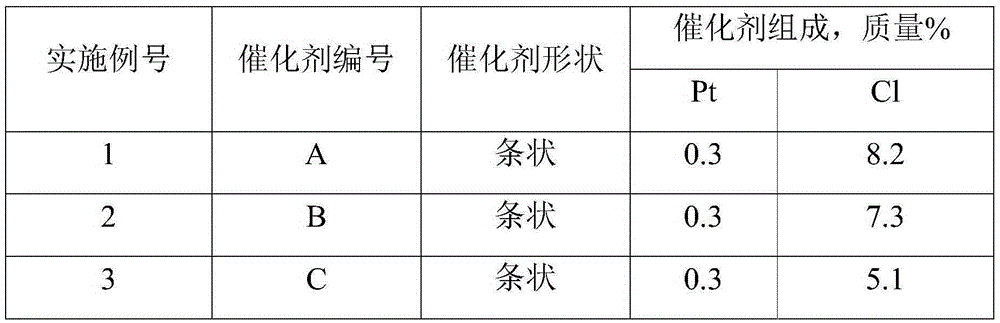

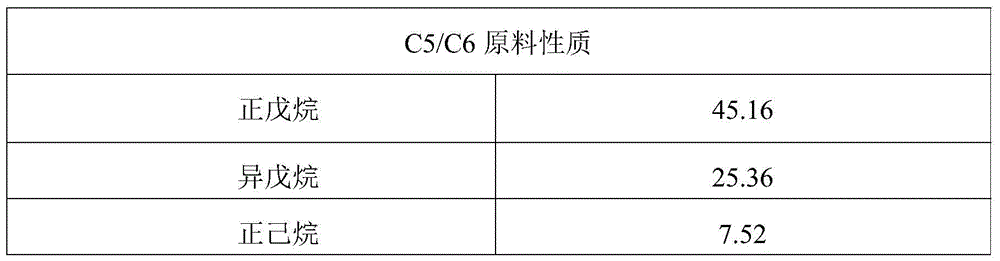

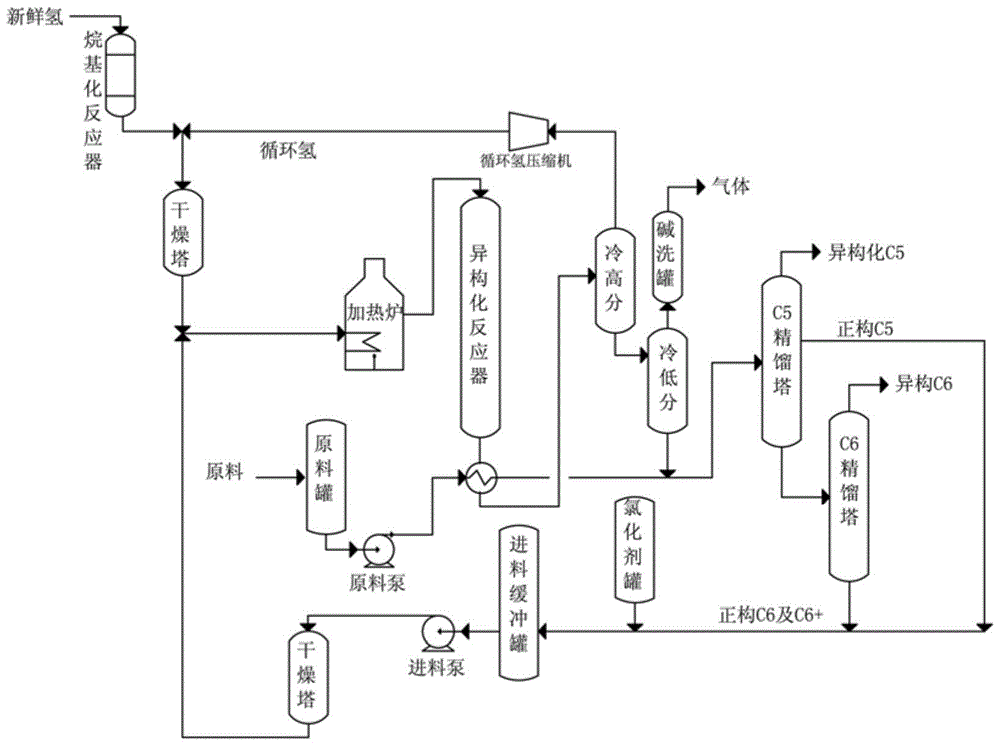

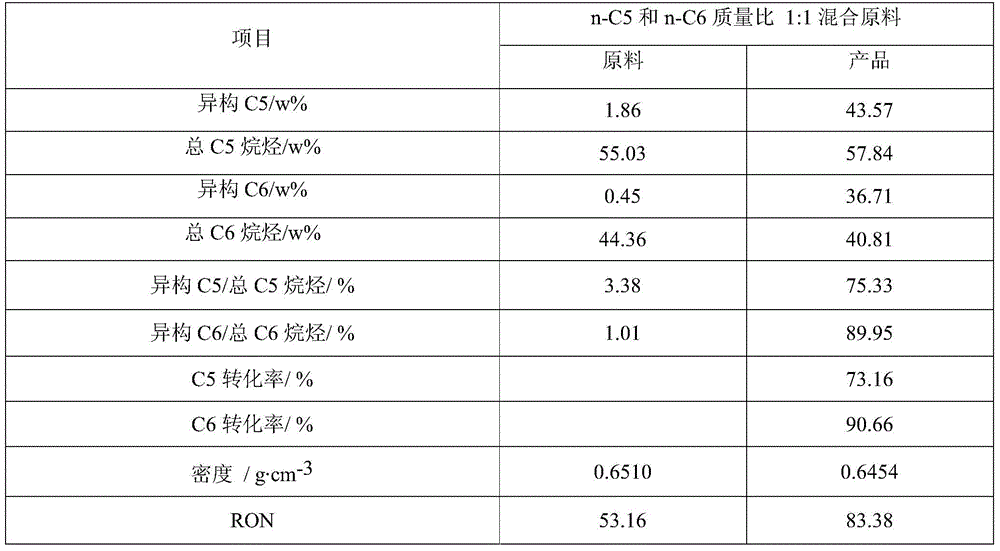

Low-temperature isomerization method for low-carbon normal alkanes

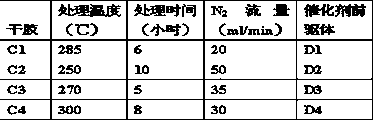

ActiveCN104892337AHigh isomerization activityImprove stabilityHydrocarbon by isomerisationMetal/metal-oxides/metal-hydroxide catalystsAlkaneLiquid product

The invention relates to a low-temperature isomerization method for low-carbon normal alkanes, wherein the low-temperature isomerization method includes the following steps: (1) carrying out heat exchange of a light hydrocarbon raw material containing normal C5 and normal C6 as principal components with an isomerization product, and after heat exchange, rectifying to obtain heterogeneous C5, normal C5 and a heavy hydrocarbon; (2) rectifying the heavy hydrocarbon again, to obtain heterogeneous C6 and a heavy hydrocarbon, mixing the normal C5 with the heavy hydrocarbon, and then supplementing chlorine; (3) carrying out drying dehydration on the material obtained after chlorine supplement, mixing with dried fresh hydrogen and circulating hydrogen, heating, and carrying out an isomerization reaction under the action of a catalyst after heating; and (4) after carrying out heat exchange of the isomerization product with a fresh raw material, carrying out first gas-liquid separation, wherein the obtained non-condensable gas is circulating hydrogen; and carrying out gas-liquid separation on the obtained liquid again, mixing the obtained liquid with a fresh raw material, and then rectifying. The yield of the liquid product obtained by the low-temperature isomerization method is more than 98%, the isomerization rate is 60%-90%, and the octane value can be increased by 10-30.

Owner:NINGBO ZHONGXUN ENVIRONMENTAL TECH CO LLC

Method for isomerization of light hydrocarbon

ActiveCN1840513AHigh activityIncrease the rate of isomerizationPhysical/chemical process catalystsHydrocarbon by hydrogenationAlkane2-methylbutane

The isomerization method for lighter hydrocarbons comprises: rectifying the material to remove water and isopentane; then, with carrring-SO42- ZrO2 as solid super acidic catalyst, taking hydroisomerization reaction. This invention can improve yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

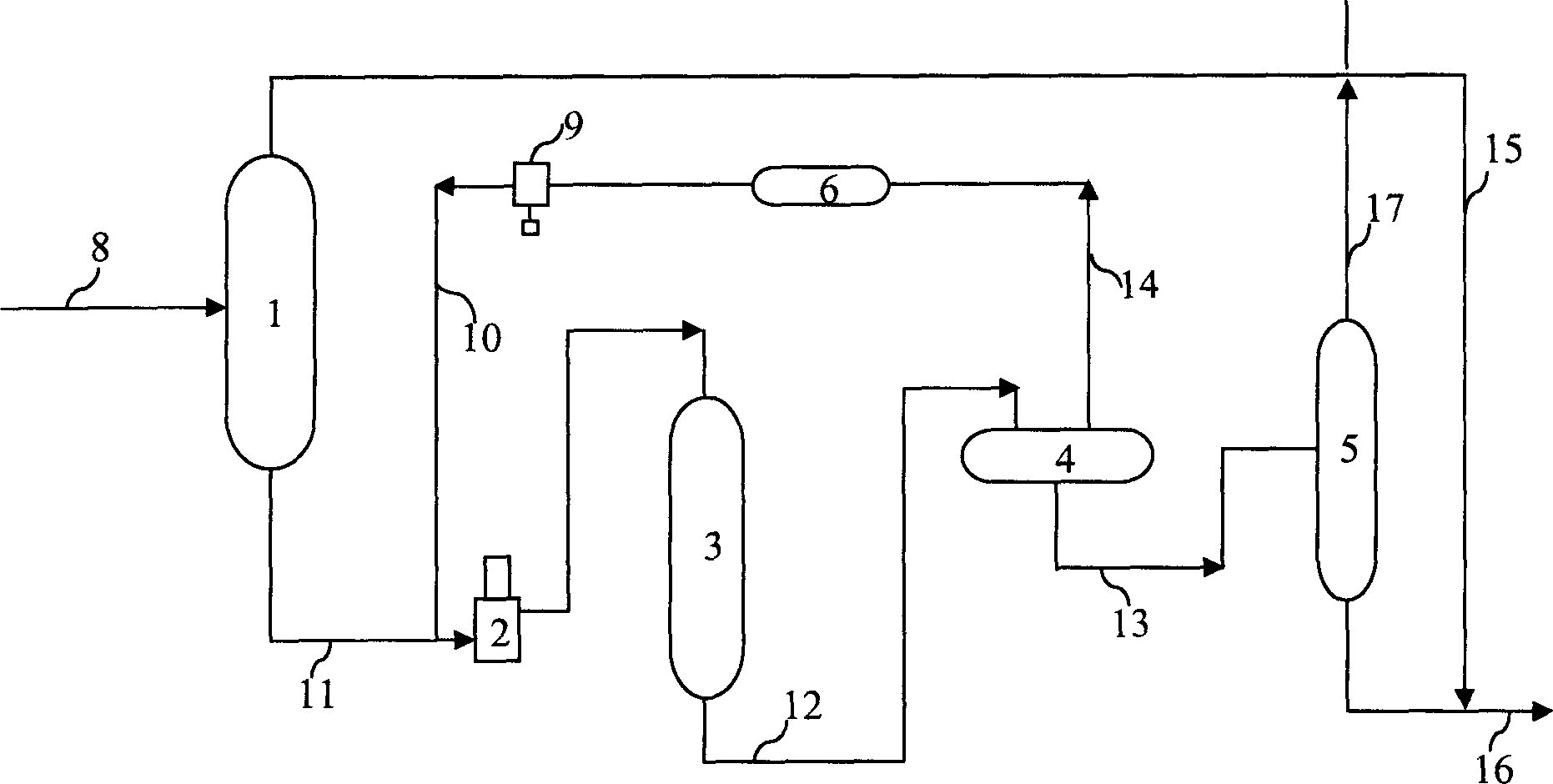

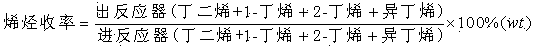

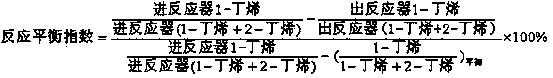

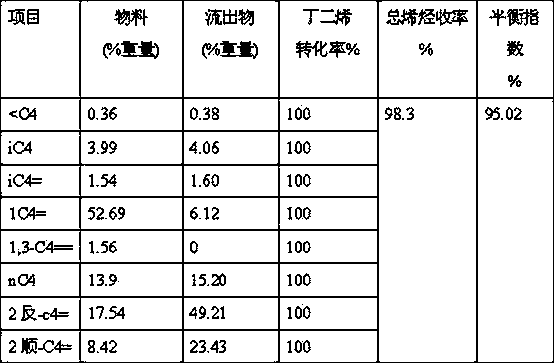

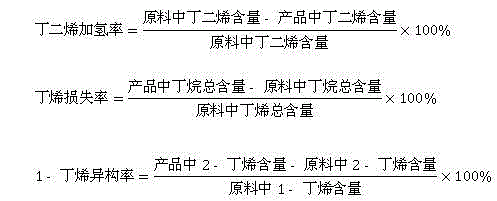

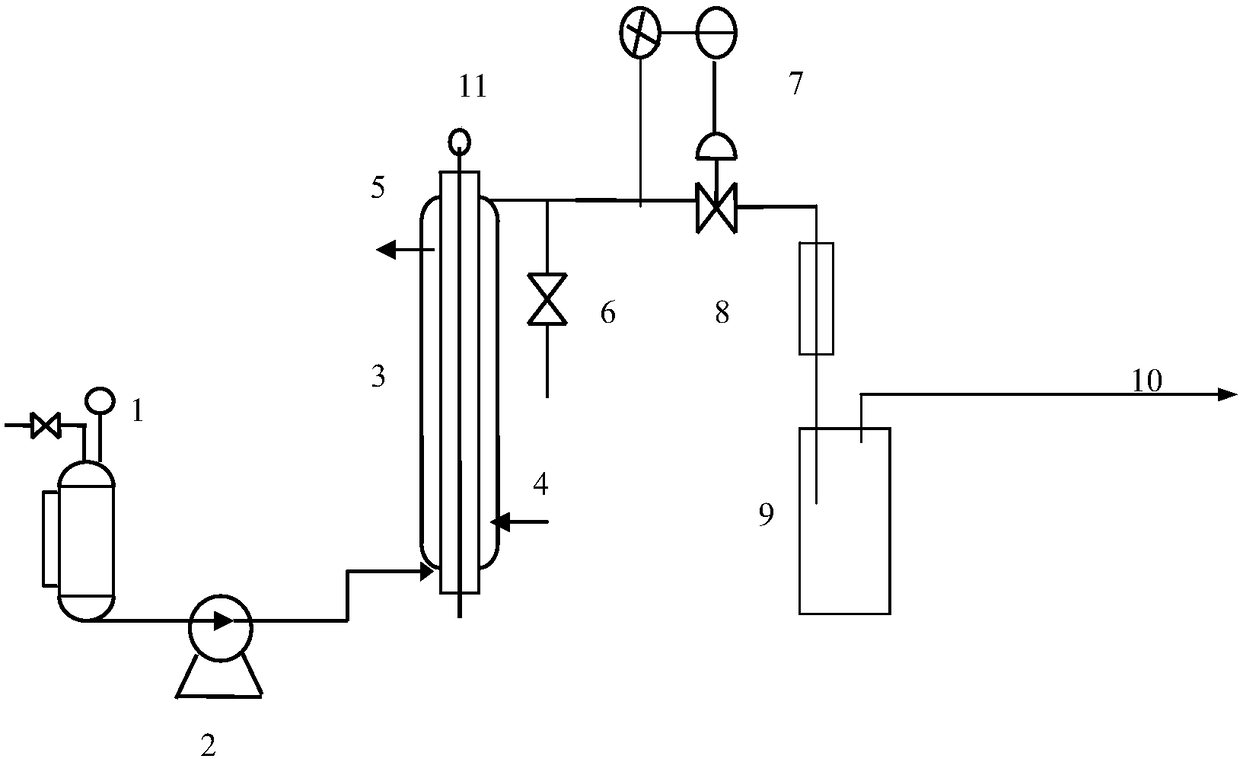

Method for increasing butene-2 yield through C4 fraction containing small amount of butadiene

InactiveCN103420765AIncrease the rate of isomerizationHigh yieldHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsButenePolymer science

The present invention relates to a method for increasing a butene-2 yield through a C4 fraction containing a small amount of butadiene, wherein the technical problem of low olefin yield in the prior art is mainly solved with the present invention. The technical scheme comprise that a C4 fraction containing a small amount of butadiene and hydrogen are adopted as raw materials, and the raw materials contact a catalyst at a reactor inlet temperature of 30-70 DEG C under a pressure of 1.2-2 MPa according to a hydrogen / butadiene ratio of 2.0-3.0, wherein the catalyst is a nickel base catalyst. With the technical scheme, the problem in the prior art is well solved, and the method can be widely used for olefin disproportionation, alkylation and other industrial productions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation catalyst for naphthenic hydrocarbon and preparation method and application thereof

ActiveCN103785462APromote activityImprove conversion rate and open loop rateMolecular sieve catalystsHydrocarbon by hydrogenationMolecular sieveOxide

The invention discloses a hydrogenation conversion catalyst for naphthenic hydrocarbon. The catalyst comprises a carrier and active metal Pt and Zn, wherein the carrier comprises hydrogen type Y-Beta composite molecular sieve and inorganic refractory oxide. The hydrogen type Y-Beta composite molecular sieve accounts for 10-90 wt% of the catalyst carrier (calculated by the weight of the catalyst carrier), and has specific surface area of 500-700 m<2> / g, and pore volume of 0.25-0.45 cm<3> / g. The active metal Pt accounts for 0.02-0.4 wt% of the catalyst (calculated by the weight of the catalyst); and the Zn accounts for 0.5-15% of the catalyst (calculated by the weight of the catalyst). The catalyst has low content of noble metal, and shows high conversion rate, high ring opening rate of naphthenic hydrocarbon, high isomerization rate and low cracking rate for hydrogenation conversion of naphthenic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

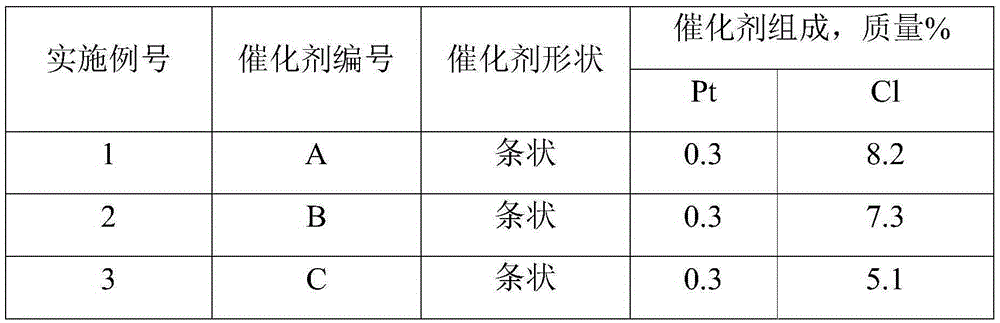

Light alkane isomerization method

InactiveCN106635137AHigh activityIncrease the rate of isomerizationHydrocarbon oils refiningHydrocarbon oils treatmentAlkaneIsomerization

The invention discloses a light alkane isomerization method. The method comprises the following steps: successively carrying out dehydration treatment and rectification treatment on a light alkane raw material, letting the treatment product contact with a chlorine-containing alumina catalyst, and carrying out hydroisomerization to obtain an isomerization product, wherein the chlorine-containing alumina catalyst is obtained after chlorine is introduced into an alkane solution containing alkyl aluminum chloride. isomerization activity of the chlorine-containing alumina catalyst can be effectively enhanced, yield of isoalkane is raised, and octane number of the isomerization product is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-carbon alkane isomerization method

InactiveCN106635162AHigh activityIncrease the rate of isomerizationTreatment with hydrotreatment processesHydrocarbon oils refiningDeoxidizationChemistry

The invention discloses a low-carbon alkane isomerization method. The method comprises the following steps: after carrying out dehydration treatment, rectification treatment, desulfurization treatment and deoxidization treatment on low-carbon alkane raw materials in sequence; enabling the low-carbon alkane raw materials to be in contact with a chlorine-containing aluminum oxide type catalyst; carrying out hydroisomerization reaction to obtain an isomerized product, wherein the chlorine-containing aluminum oxide type catalyst is used for introducing chlorine by adopting an alkane solution containing alkyl aluminum chloride. According to the method disclosed by the invention, the activity of the chlorine-containing aluminum oxide type isomerization catalyst can be effectively improved and the yield of isomerized alkane is properly improved; the octane value of the isomerized product is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

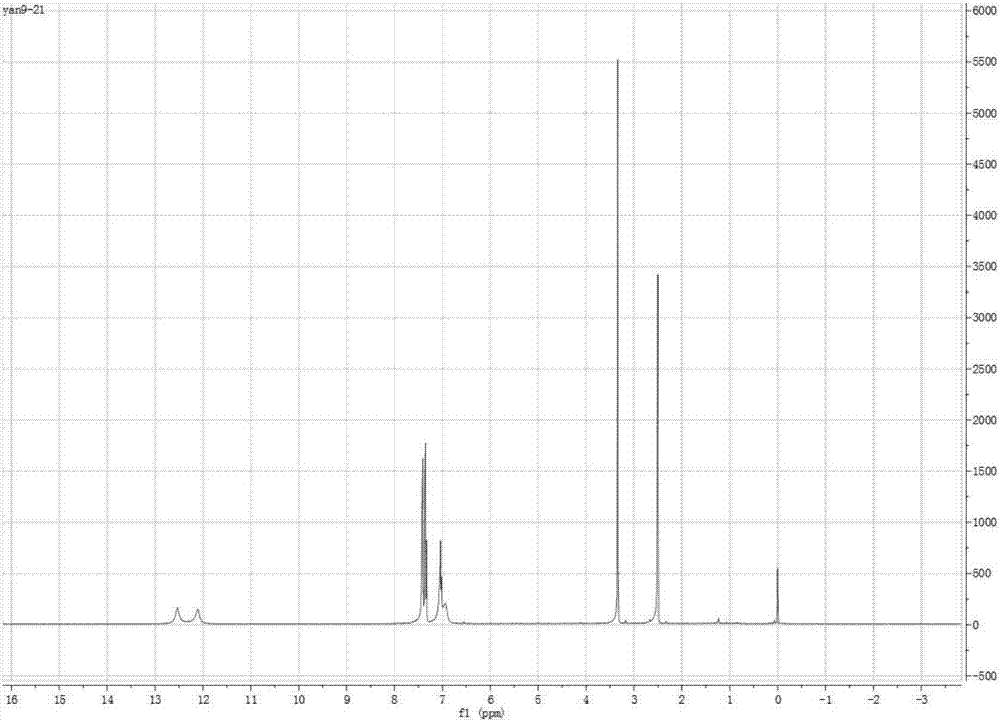

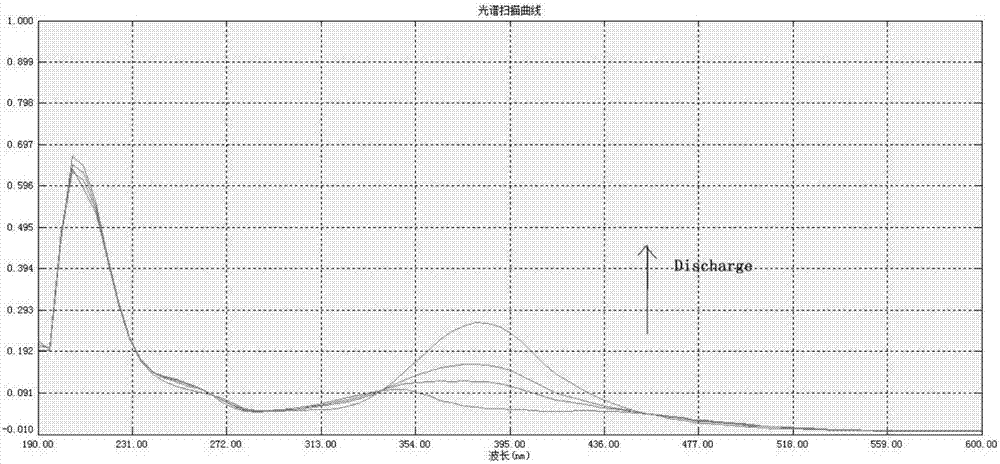

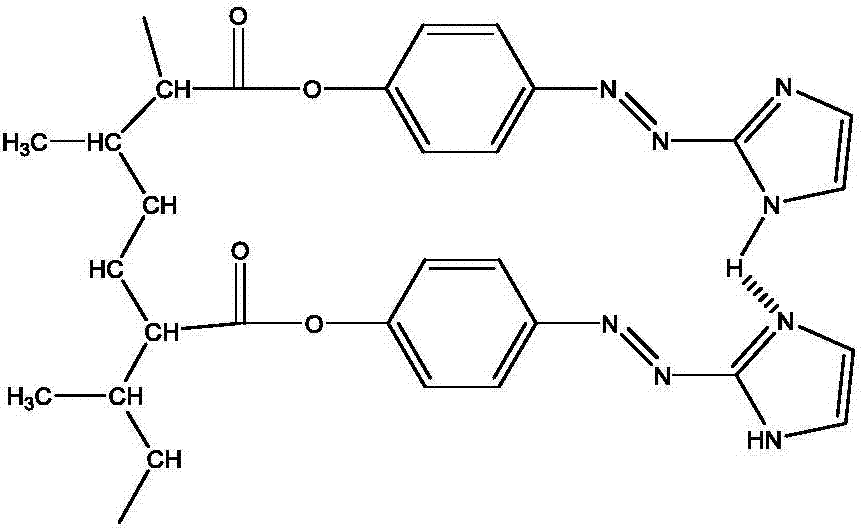

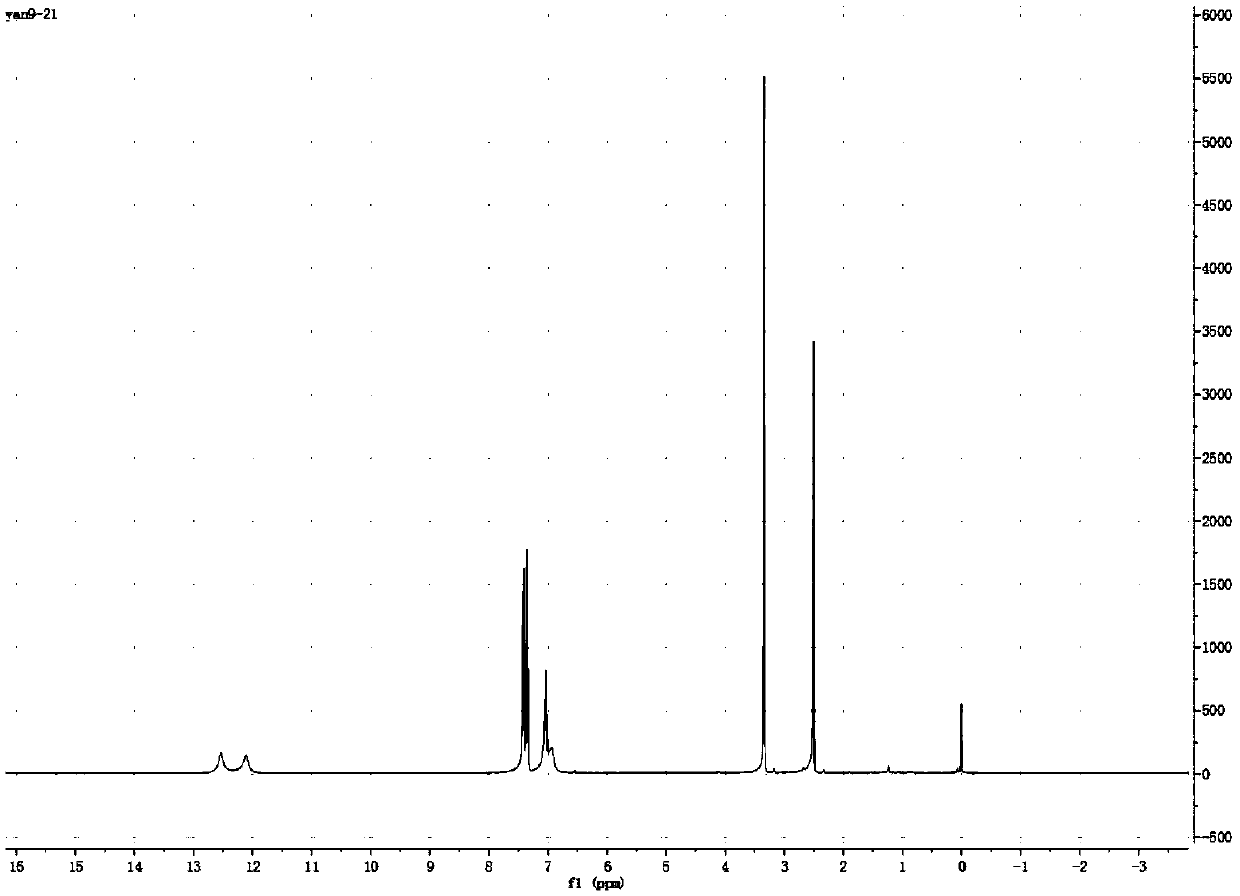

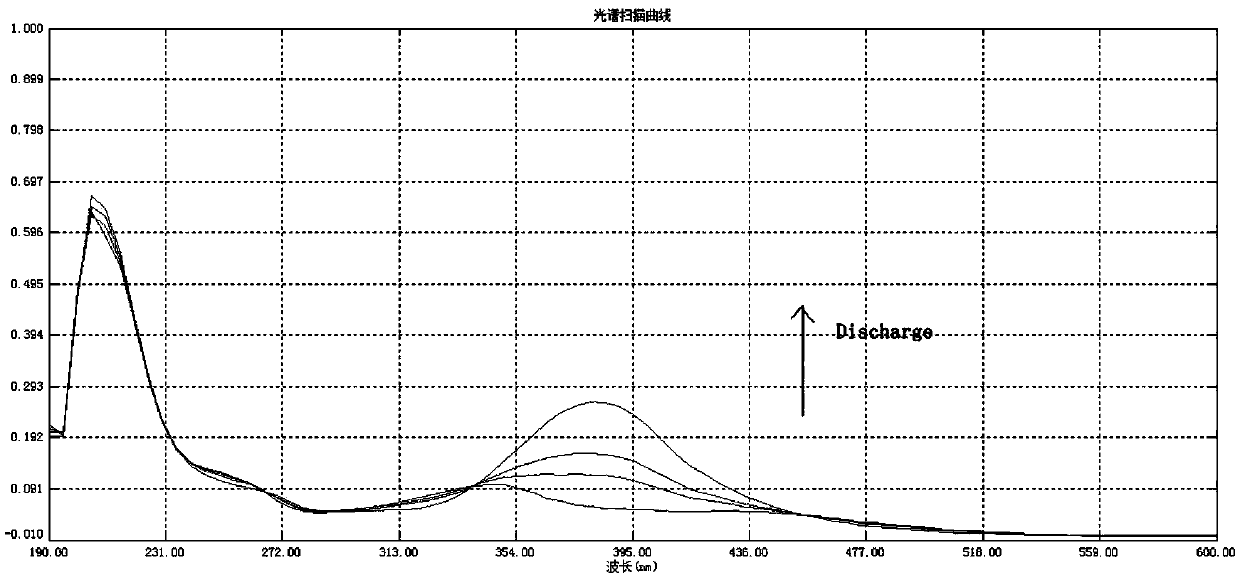

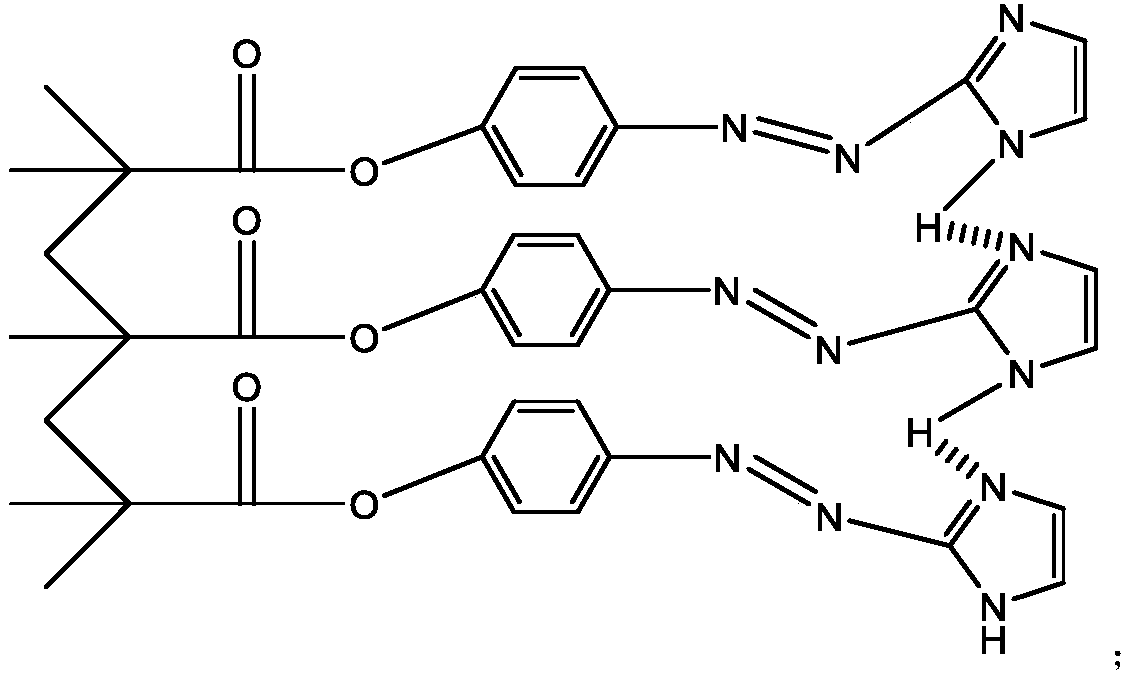

Heterocyclic azobenzene high-polymer energy storage material and preparation method thereof

ActiveCN107098995AIncrease the rate of isomerizationHigh heat storage densityHeat-exchange elementsIsomerizationSide chain

The invention relates to a heterocyclic azobenzene high-polymer energy storage material and a preparation method thereof. Heterocyclic azobenzene with a monomer molecular formula of C9N5H9 exists on a high-polymer side chain to achieve trans-cis heat storage and cis-trans heat release; and a high-polymer chain is polymethyl methacrylate (PMMA). The grafting density of a heterocyclic ring is that every 3-10 carbon atoms are grafted with one heterocyclic azobenzene. The maximum isomerization rate of the energy storage material provided by the invention reaches 90%, and is improved by 15% compared with monomer molecules; and the maximum heat storage density reaches 130Wh / kg and is improved by nearly 55% compared with the monomer molecules. The obtained azo heterocyclic molecule, compared with an azobenzene molecule, is greatly improved in the aspect of energy storage density in a half-life period, and has a great potentiality in the aspect of heat storage. The exothermic peak of a polymer material is scanned with DSC, then released energy is obtained by performing integration on the exothermic peak using software, and then the released energy is divided by quality to obtain an extremely good heat storage density which reaches 130Wh / kg.

Owner:TIANJIN UNIV

Light hydrocarbon isomerization method

ActiveCN101544905BIncrease the rate of isomerizationGuaranteed isomerization rateHydrocarbon by isomerisationRefining to change hydrocarbon structural skeleton2-methylbutaneIsomerization

Owner:CHINA PETROLEUM & CHEM CORP +1

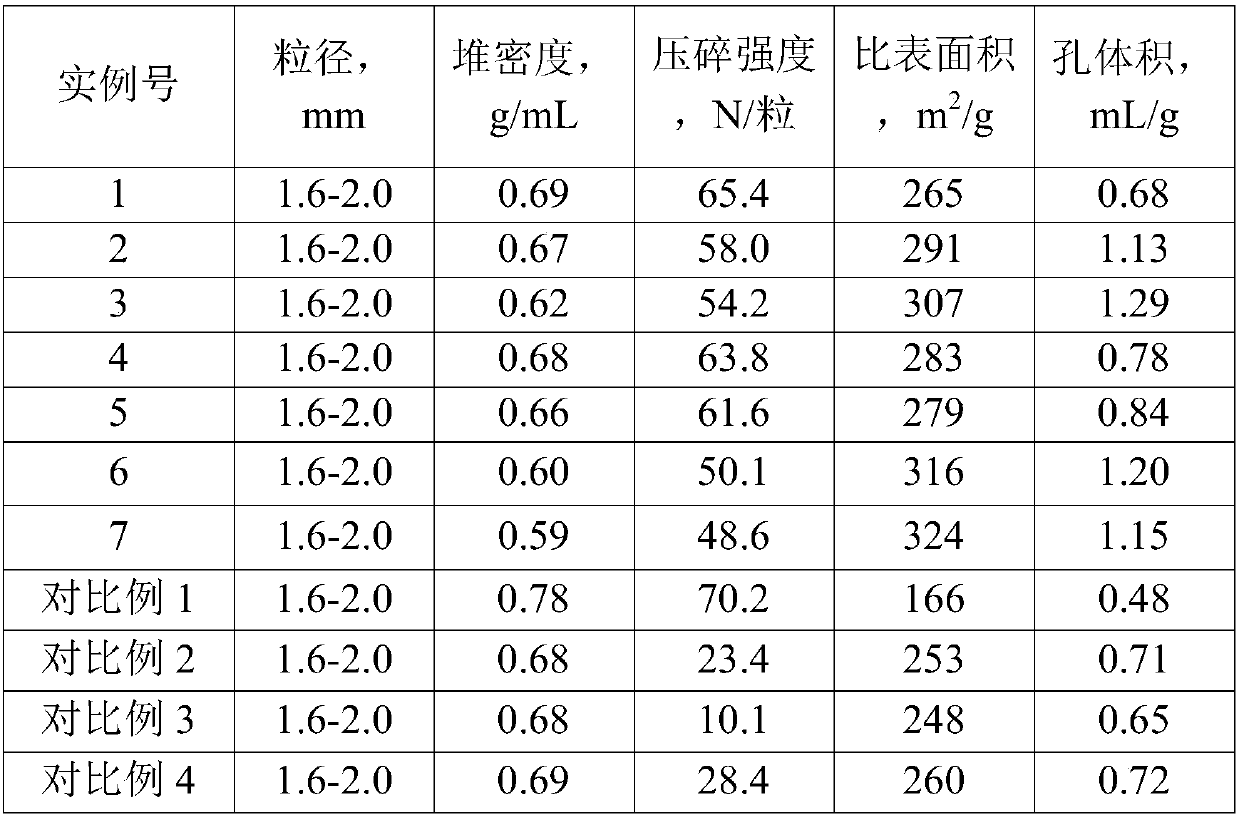

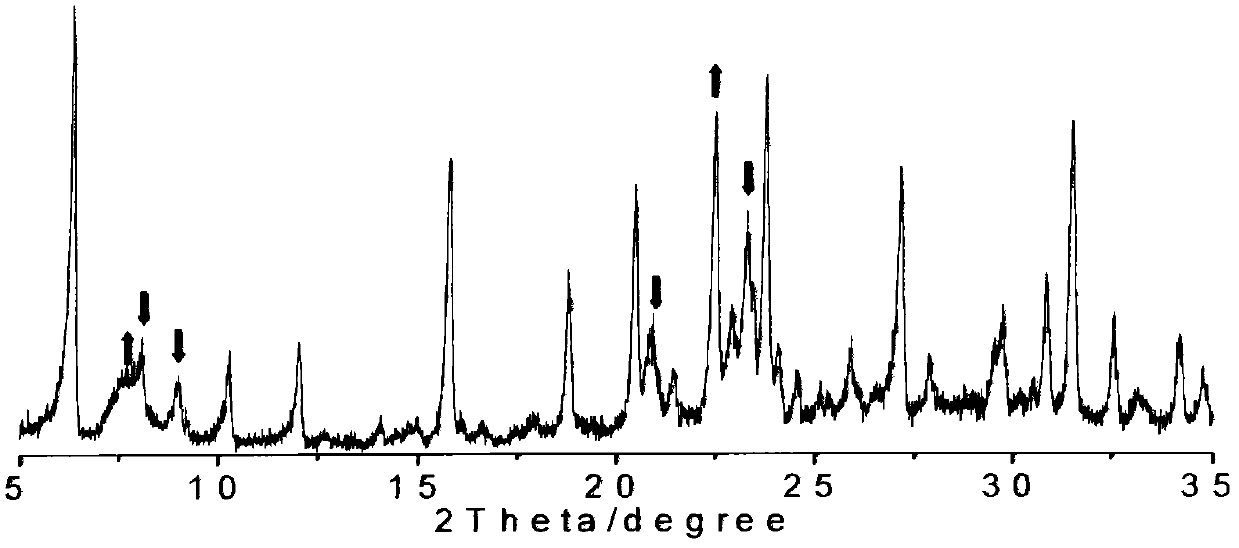

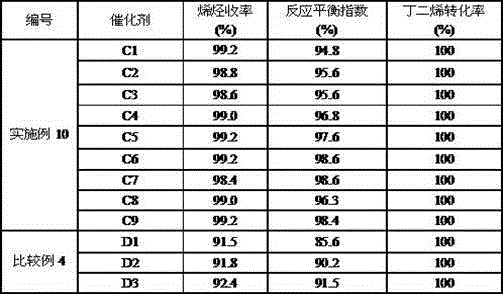

Molecular sieve-containing alumina pellet and preparation method thereof

ActiveCN109692703AEasy to operateEase of large-scale industrial productionHydrocarbon by isomerisationCatalyst carriersMolecular sieveAluminium hydroxide

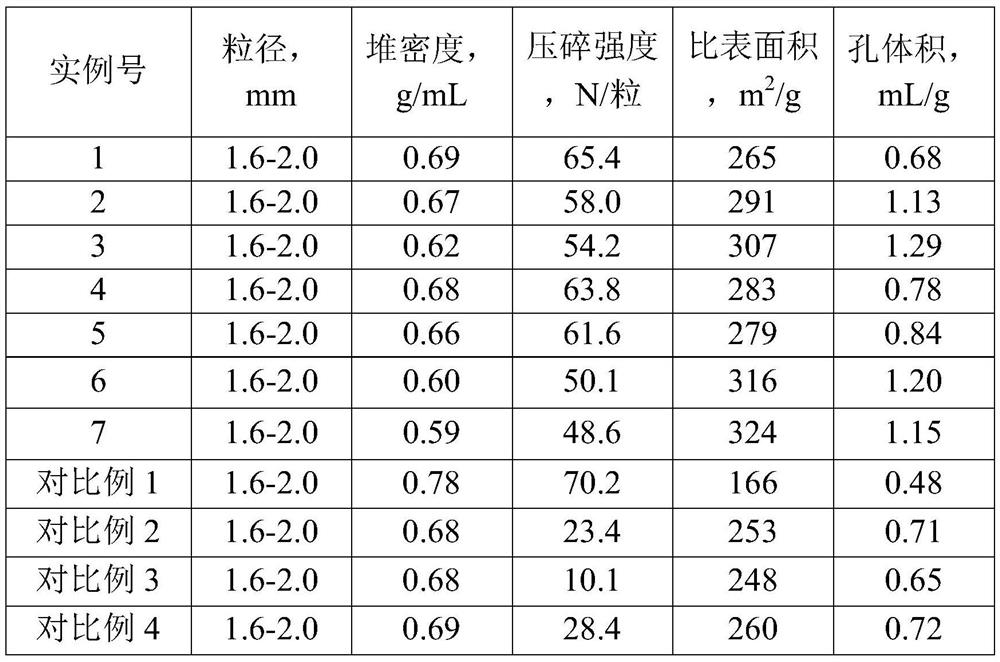

The invention relates to a molecular sieve-containing alumina pellet and a preparation method thereof. The preparation method comprises: (1) preparation of a mixed sol: mixing pseudo-boehmite, urea and deionized water to obtain an aluminum hydroxide suspension liquid, adding a first acid solution to the aluminum hydroxide suspension liquid, carrying out first peptization to obtain an alumina sol,mixing the alumina sol and a molecular sieve, adding a second acid solution, and carrying out second peptization to obtain a mixed sol; and (2) preparation of molecular sieve-containing alumina pelletby hot oil column molding: mixing the mixed sol obtained in the step (1) and hexamethylenetetramine, adding into a hot oil column in a dropwise manner, molding to obtain pellets, taking out the molded pellets, washing, drying, and roasting to obtain the molecular sieve-containing alumina pellet. According to the present invention, the obtained molecular sieve-containing alumina pellet has characteristics of high molecular sieve content and high crushing strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

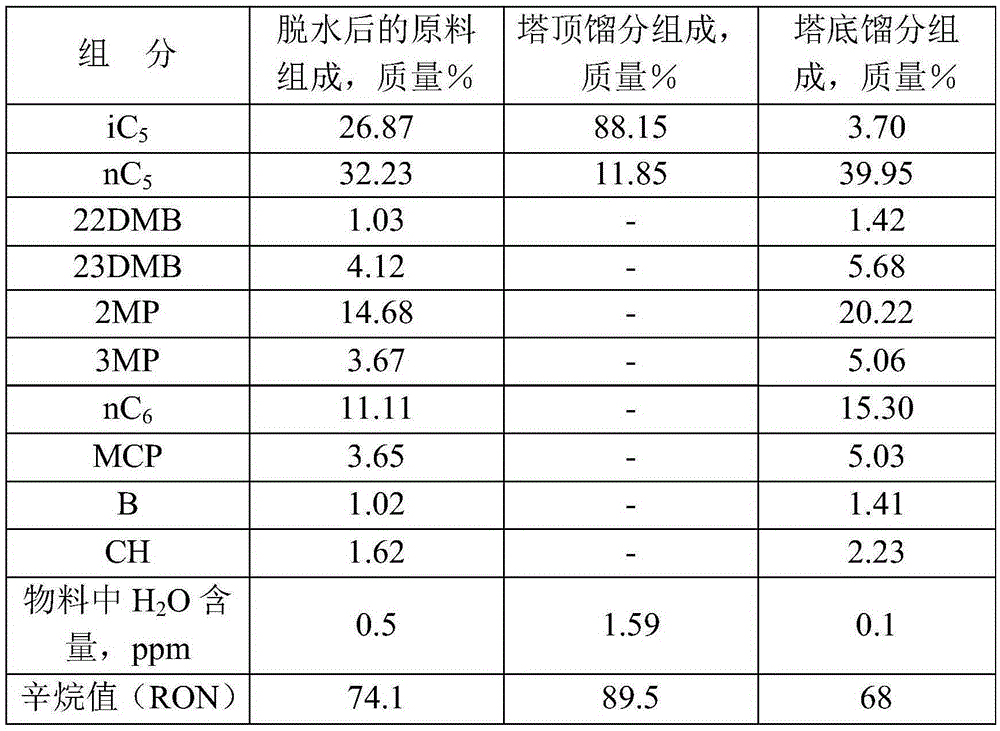

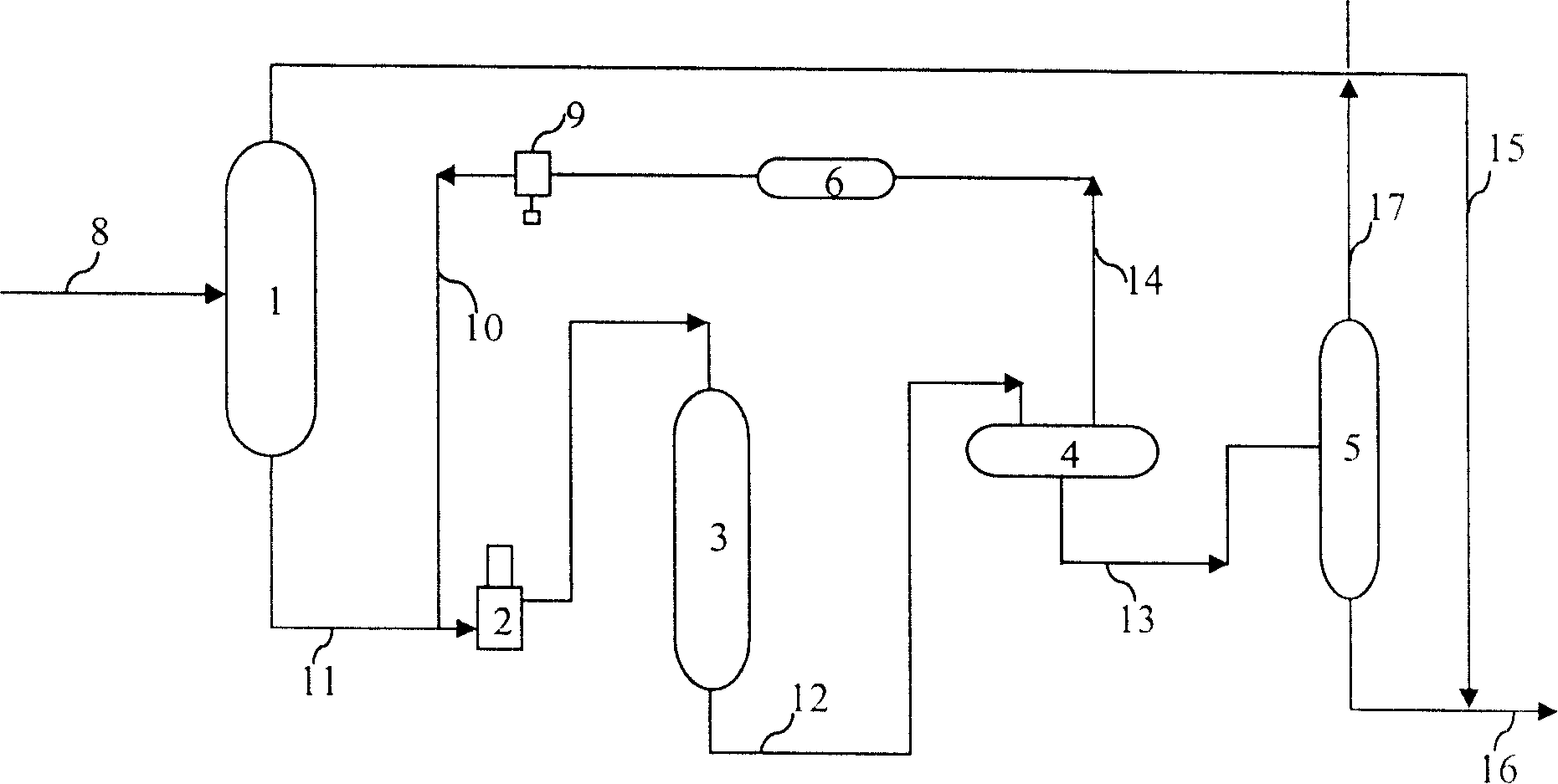

C5/C6 alkane low-temperature isomerization method

ActiveCN104945212AReduce heating effectReduce energy consumptionHydrocarbon by isomerisationDistillation purification/separation2-methylbutaneAlkane

The invention relates to a C5 / C6 alkane low-temperature isomerization method. According to the method, raw materials enter an isopentane-removing tower to remove moisture and separate into an isopentane fraction and an isopentane-removed fraction; the isopentane-removed fraction and hydrogen are dried and then enter an isomerization reactor to carry out an isomerization reaction under the condition of low temperature so as to generate an isomerization reaction product; the isomerization reaction product enters a depentanizer to produce a pentane fraction and an isohexane fraction; the isohexane fraction goes into a downstream process; after heat exchange with materials at the bottom of the isopentane-removing tower, the pentane fraction which is used as a reboiler heat source of the isopentane-removing tower is divided into two paths; after being used as a feedstock of the isopentane-removing tower to remove the isopentane fraction, one path enters the reaction feed process again; and the other path used as top reflux of the depentanizer returns back to the depentanizer again. The method provided by the invention has advantages of low plant investment, low energy consumption, high isomerization rate of products and octane number and the like.

Owner:SHANGHAI HOTO PETROCHEM ENG

Method for isomerization of light hydrocarbon

ActiveCN100395220CHigh activityIncrease the rate of isomerizationPhysical/chemical process catalystsHydrocarbon by hydrogenationAlkane2-methylbutane

The isomerization method for lighter hydrocarbons comprises: rectifying the material to remove water and isopentane; then, with carrring-SO42- ZrO2 as solid super acidic catalyst, taking hydroisomerization reaction. This invention can improve yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

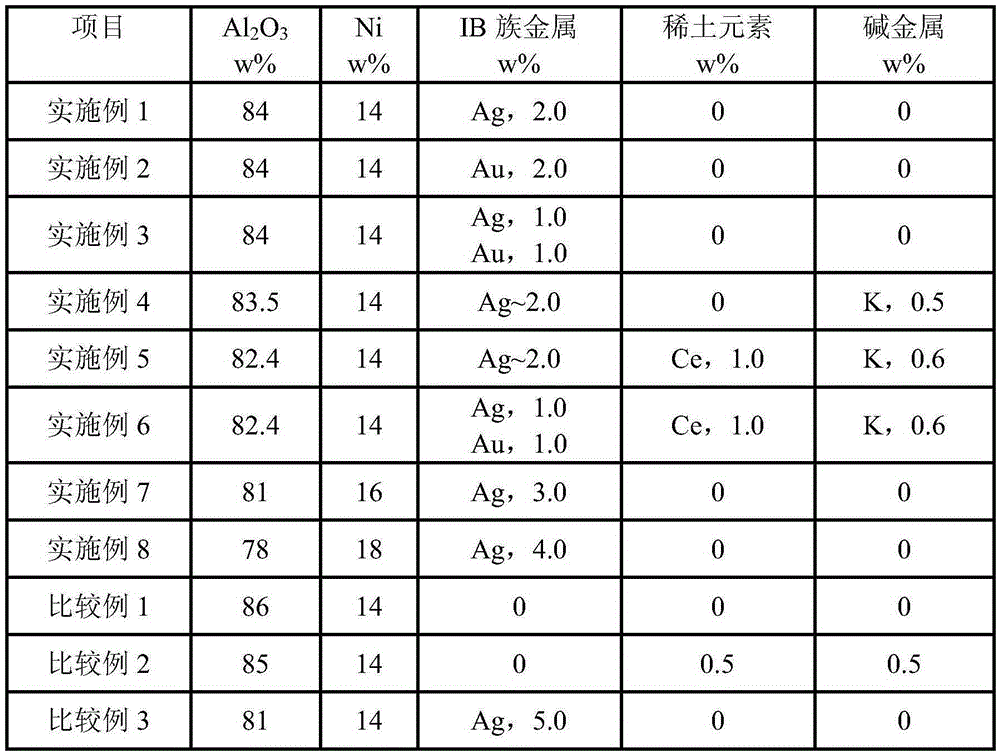

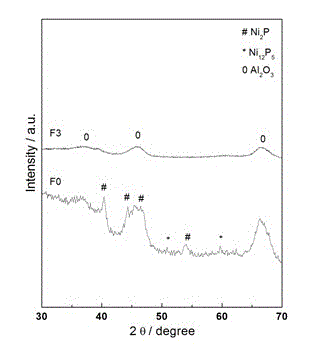

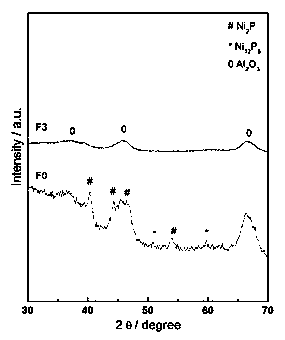

Catalyst for selective hydrogenation of butadiene and isomerization of 1-butylene, and preparation method and application thereof

ActiveCN105709786ALow costIncrease the rate of isomerizationHydrocarbon by isomerisationPhysical/chemical process catalystsRare-earth elementIsomerization

The invention discloses a catalyst for selective hydrogenation of butadiene and isomerization of 1-butylene. The catalyst is composed of an active component, i.e., amorphous nickel phosphide, an alumina carrier, an auxiliary agent X1 and an auxiliary agent X2. In a final catalyst, the weight of nickel in amorphous nickel phosphide, in terms of metallic nickel, accounts for 5 to 12% of the total weight of the catalyst, a mol ratio of phosphorus to nickel is 2.0-2.4: 1, a mol ratio of the auxiliary agent X1 to nickel is 0.01-0.05: 1 and a mol ratio of the auxiliary agent X2 to nickel is 0.5-1.5: 1, with the balance being the carrier; and the auxiliary agent X1 is at least one selected from rare earth elements, and the auxiliary agent X2 is at least one selected from alkali earth metals. The catalyst is a non-noble metal catalyst, has catalytic activity equivalent to the catalytic activity of a noble metal catalyst when applied to selective hydrogenation of a C4 raw material for removal of butadiene, can substantially reduce catalyst cost, and shows high 1-butylene isomerization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cycloalkane hydroconversion catalyst and preparation method and application thereof

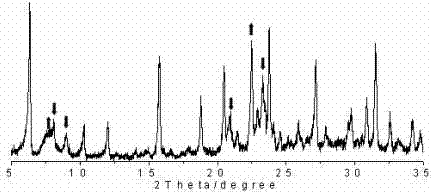

ActiveCN102441426BLow cracking rateShort synthesis timeMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveHydrogen

The invention discloses a cycloalkane hydroconversion catalyst and a preparation method and application thereof. The cycloalkane hydroconversion catalyst consists of a carrier and active metal Pt, the carrier consists of a hydrogen type Y / Beta / ZSM-12 composite molecular sieve and inorganic refractory oxide, the content of the hydrogen type Y / Beta / ZSM-12 composite molecular sieve in the carrier is10 to 90 percent by the weight of the catalyst carrier, and the content of the active metal Pt is 0.05 to 0.6 percent by the weight of the catalyst. The catalyst has a higher conversion rate, a higher cycloalkane ring-opening rate, a higher isomerization rate and a lower cracking rate when being used in the hydroconversion of cycloalkane-containing materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst and method for preparing butene-2 through butene-1 hydroisomerization

ActiveCN104437498AAdjust hole structureHelp long runHydrocarbon by isomerisationHydrocarbon by hydrogenationButeneAlkene

The invention relates to a catalyst and a method for preparing butene-2 through butene-1 hydroisomerization. The technical problems in the prior art the n-butene hydroisomerization is low in conversion rate, the total olefin yield is low and the butene-2 is low in selectivity are mainly solved. With the adoption of the technical scheme, a mixed-phase alumina carrier consisting of theta-phase alumina and delta-phase alumina is adopted, the theta-phase alumina accounts for 60-90wt%, and the delta-phase alumina accounts for 10-40wt%. The problems are well solved, and the catalyst and method can be used for industrial production of cracking C4 fractions and increasing the yield of butene-2.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cyclane hydro-conversion catalyst, preparation method and applications

ActiveCN103372459BEasy to prepareLow costMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveIsomerization

The invention discloses a cyclane hydro-conversion catalyst. The catalyst comprises carriers and active metals Pt and Zn. The carriers are composed of hydrogen-type Y / Beta / ZSM-12 composite molecular sieves and inorganic refractory oxides. In the carriers of the catalyst, by weight, the content of the hydrogen-type Y / Beta / ZSM-12 composite molecular sieves is 10wt%-90wt%, the specific surface area of the hydrogen-type Y / Beta / ZSM-12 composite molecular sieves is 600 m<2> / g-800 m<2> / g, and the pore volume is 0.30 cm<3> / g-0.40 cm<3> / g. The content of the active metal Pt of the catalyst, by weight, is 0.02%-0.04%, and the content of Zn of the catalyst, by weight, is 0.5%-15%. When used for cyclane hydro-conversion, the catalyst is advantaged by high conversion rate, high cyclane ring opening rate, high isomerization rate and low cracking rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of C5/C6 alkane low-temperature isomerization method

ActiveCN104945212BReduce heating effectReduce energy consumptionHydrocarbon by isomerisationDistillation purification/separationRefluxIsomerization

The invention relates to a C5 / C6 alkane low-temperature isomerization method. According to the method, raw materials enter an isopentane-removing tower to remove moisture and separate into an isopentane fraction and an isopentane-removed fraction; the isopentane-removed fraction and hydrogen are dried and then enter an isomerization reactor to carry out an isomerization reaction under the condition of low temperature so as to generate an isomerization reaction product; the isomerization reaction product enters a depentanizer to produce a pentane fraction and an isohexane fraction; the isohexane fraction goes into a downstream process; after heat exchange with materials at the bottom of the isopentane-removing tower, the pentane fraction which is used as a reboiler heat source of the isopentane-removing tower is divided into two paths; after being used as a feedstock of the isopentane-removing tower to remove the isopentane fraction, one path enters the reaction feed process again; and the other path used as top reflux of the depentanizer returns back to the depentanizer again. The method provided by the invention has advantages of low plant investment, low energy consumption, high isomerization rate of products and octane number and the like.

Owner:SHANGHAI HOTO PETROCHEM ENG

Butadiene selective hydrogenation catalyst

ActiveCN106582706BLow costReduce lossHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsAlkali metalMetal

Owner:CHINA PETROLEUM & CHEM CORP +1

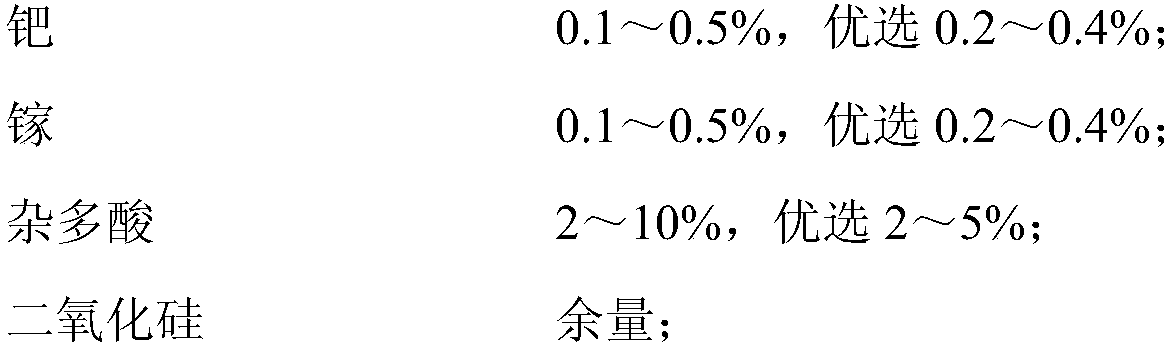

Catalyst for alkane isomerization, and preparation method and application thereof

InactiveCN108499605AHigh activityImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oils refiningPhosphomolybdic acidIsomerization

The invention specifically relates to a catalyst for alkane isomerization, and a preparation method and application thereof, belonging to the technical field of catalysts. The catalyst for alkane isomerization comprises the following chemical components by mass: 0.1 to 0.5% of palladium, 0.1 to 0.5% of gallium and 2 to 10% of heteropoly acid, with the balance being silica, wherein heteropoly acidis one or more selected from the group consisting of phosphotungstic acid and phosphomolybdic acid. The catalyst for alkane isomerization in the invention is prepared by loading heteropoly acid onto silica pellets and carrying out modification with the noble metals palladium and gallium, and has a proper specific surface area, specific pore volume, activity and high stability. When the catalyst isapplied to an isomerization reaction, the isomerization rate and liquid yield of the catalyst are greatly improved compared with conventional catalysts, wherein the isomerization rate is greater than59.3%, and the liquid yield is greater than 95.7%; so the catalyst is suitable for industrial promotion. The preparation method of the invention is safe, environmentally friendly and simple.

Owner:CHINA PETROLEUM & CHEM CORP

A method for isomerizing low-carbon normal paraffins at low temperature

ActiveCN104892337BHigh isomerization activityImprove stabilityHydrocarbon by isomerisationMetal/metal-oxides/metal-hydroxide catalystsLiquid productAlkane

The invention relates to a low-temperature isomerization method for low-carbon normal alkanes, wherein the low-temperature isomerization method includes the following steps: (1) carrying out heat exchange of a light hydrocarbon raw material containing normal C5 and normal C6 as principal components with an isomerization product, and after heat exchange, rectifying to obtain heterogeneous C5, normal C5 and a heavy hydrocarbon; (2) rectifying the heavy hydrocarbon again, to obtain heterogeneous C6 and a heavy hydrocarbon, mixing the normal C5 with the heavy hydrocarbon, and then supplementing chlorine; (3) carrying out drying dehydration on the material obtained after chlorine supplement, mixing with dried fresh hydrogen and circulating hydrogen, heating, and carrying out an isomerization reaction under the action of a catalyst after heating; and (4) after carrying out heat exchange of the isomerization product with a fresh raw material, carrying out first gas-liquid separation, wherein the obtained non-condensable gas is circulating hydrogen; and carrying out gas-liquid separation on the obtained liquid again, mixing the obtained liquid with a fresh raw material, and then rectifying. The yield of the liquid product obtained by the low-temperature isomerization method is more than 98%, the isomerization rate is 60%-90%, and the octane value can be increased by 10-30.

Owner:NINGBO ZHONGXUN ENVIRONMENTAL TECH CO LLC

A kind of cycloalkane hydrogenation catalyst and its preparation method and application

ActiveCN103785462BHigh activityReduce manufacturing costMolecular sieve catalystsHydrocarbon by hydrogenationMolecular sieveHydrogen

The invention discloses a hydrogenation conversion catalyst for naphthenic hydrocarbon. The catalyst comprises a carrier and active metal Pt and Zn, wherein the carrier comprises hydrogen type Y-Beta composite molecular sieve and inorganic refractory oxide. The hydrogen type Y-Beta composite molecular sieve accounts for 10-90 wt% of the catalyst carrier (calculated by the weight of the catalyst carrier), and has specific surface area of 500-700 m<2> / g, and pore volume of 0.25-0.45 cm<3> / g. The active metal Pt accounts for 0.02-0.4 wt% of the catalyst (calculated by the weight of the catalyst); and the Zn accounts for 0.5-15% of the catalyst (calculated by the weight of the catalyst). The catalyst has low content of noble metal, and shows high conversion rate, high ring opening rate of naphthenic hydrocarbon, high isomerization rate and low cracking rate for hydrogenation conversion of naphthenic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing industrial fructose from isomerized glucose by chemical catalysis

ActiveCN109369734BAvoid ineffective degradationHigh selectivitySugar derivativesFructose productionIsomerizationPtru catalyst

The invention discloses a method for preparing industrial fructose by chemically catalyzing isomerization of glucose. The steps are as follows: (1) prepare aqueous glucose solution, add borax and sodium hydroxide to the aqueous glucose solution in sequence, then add magnesium-based solid base, and react under an inert atmosphere ; (2) After the reaction, recover the solid alkali catalyst through solid-liquid separation, send the liquid into the electrodialysis system, separate the glucose and fructose complexes, and obtain the fructose borate complex solution; (3) complex the fructose borate The fructose solution flows through the boron special-effect resin to remove borax and sodium hydroxide to obtain pure fructose products. The invention adopts the combination of homogeneous base catalysis and heterogeneous solid base catalysis, which not only applies to higher substrate concentration, but also improves the isomerization rate and fructose selectivity. The simple and efficient separation of the latter provides the possibility for the development of large-scale industrial fructose-based fuels and chemicals, and has a good application prospect.

Owner:HUAIYIN TEACHERS COLLEGE

A kind of butadiene selective hydrogenation, 1-butene isomerization catalyst and its preparation method and application

ActiveCN105709786BLow costIncrease the rate of isomerizationHydrocarbon by isomerisationPhysical/chemical process catalystsRare-earth elementAlkaline earth metal

The invention discloses a butadiene hydrogenation and 1-butene isomerization catalyst. The catalyst is composed of an active component amorphous nickel phosphide, an alumina carrier, an auxiliary agent X1 and an auxiliary agent X2. In the final catalyst, The weight of nickel in the amorphous nickel phosphide is calculated as metallic nickel, accounting for 5-12% of the total catalyst weight, the molar ratio of phosphorus to nickel is 2.0-2.4:1, and the molar ratio of auxiliary agent X1 to nickel is 0.01-0.05: 1. The molar ratio of auxiliary agent X2 to nickel is 0.5-1.5:1, and the rest is a carrier. The auxiliary agent X1 is selected from at least one rare earth element, and the auxiliary agent X2 is selected from at least one alkaline earth metal element. The catalyst is a non-precious metal catalyst, which has catalytic activity comparable to that of a noble metal catalyst in the process of selective hydrogenation of C4 raw materials to remove butadiene, and can greatly reduce the cost of the catalyst. At the same time, the catalyst of the present invention also has extremely high 1‑butene isomerization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Naphthenic hydrocarbon hydro-conversion catalyst and preparation method and application thereof

ActiveCN101992120BLow cracking rateShort synthesis timeMolecular sieve catalystsHydrocarbon by hydrogenationCyclic alkaneMolecular sieve

The invention discloses a naphthenic hydrocarbon hydro-conversion catalyst and a preparation method and application thereof. The naphthenic hydrocarbon hydro-conversion catalyst comprises a carrier active metal Pt, wherein a carrier consists of 10 to 90 weight percent of hydrogen-type Y-Beta composite molecular sieve, and an inorganic refractory oxide; and the active metal Pt content of the catalyst is 0.05 to 0.6 percent. The catalyst is prepared by an immersion method; and the obtained catalyst can be applied to hydro-conversion of various naphthenic hydrocarbon-containing raw materials andhas high conversion rate, high naphthenic hydrocarbon ring opening rate and low cracking rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of alumina pellet containing molecular sieve and preparation method thereof

ActiveCN109692703BEasy to operateEase of large-scale industrial productionHydrocarbon by isomerisationCatalyst carriersPseudoboehmiteMolecular sieve

The invention relates to a molecular sieve-containing alumina pellet and a preparation method thereof. The preparation method comprises: (1) preparing a mixed sol: mixing pseudoboehmite, urea and deionized water to obtain an aluminum hydroxide suspension; Adding the first acid solution to the aluminum hydroxide suspension for the first peptization to obtain an alumina sol; mixing the alumina sol with molecular sieves and adding the second acid solution for the second peptization to obtain a mixed sol; (2) heating oil Column molding to produce alumina pellets containing molecular sieves: mix the mixed sol obtained in step (1) with hexamethylenetetramine and drop them into a hot oil column to form pellets, take out the pellets, wash, dry and roast , to obtain alumina pellets containing molecular sieves. The molecular sieve-containing alumina pellets provided by the invention have high molecular sieve content and high crushing strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

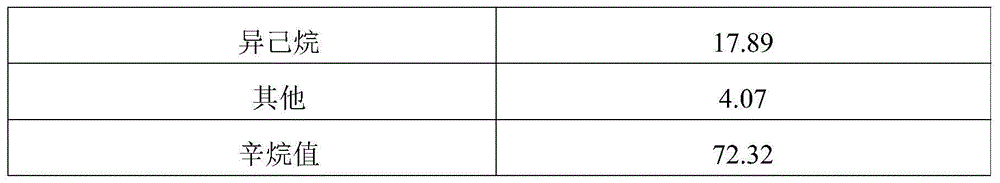

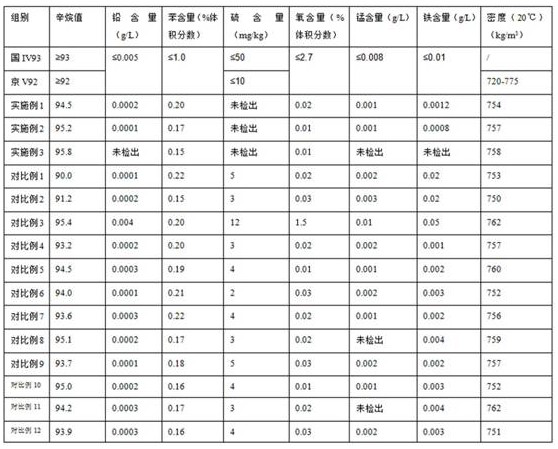

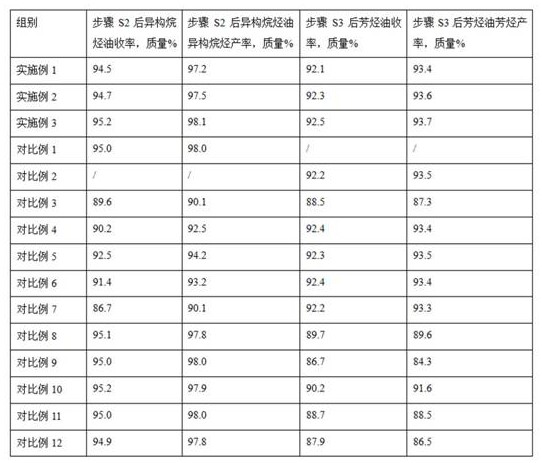

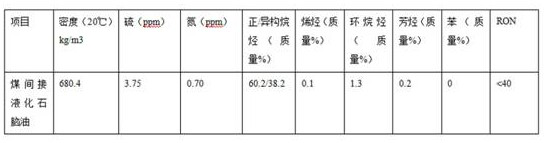

A kind of environment-friendly process method of producing motor gasoline from naphtha

ActiveCN113980702BImprove qualityAvoid poisoningCatalyst carriersHeterogenous catalyst chemical elementsAlkaneNaphtha

The invention provides an environment-friendly process for producing motor gasoline from naphtha, which belongs to the technical field of coal chemical industry. C 4‑ Component, C 5 / C 6 components and C 7+ component, where C 5 / C 6 Components undergo hydroisomerization reaction to obtain isoparaffin oil, C 7+ The components are reformed to obtain aromatic oil, and the C 4‑ After components, isoparaffin oil and aromatic oil are mixed evenly, motor gasoline is obtained. The present invention is an environmentally friendly process for producing ultra-low-sulfur, olefin-free, high-octane clean motor gasoline, which has the advantages of simple method, mild reaction conditions, low cost, and can significantly increase the octane value of motor gasoline, and has wide applications. prospect.

Owner:弘润石化(潍坊)有限责任公司

A kind of heterocyclic azobenzene polymer energy storage material and preparation method thereof

ActiveCN107098995BIncrease the rate of isomerizationHigh heat storage densityHeat-exchange elementsIsomerizationPolymer science

The invention relates to a heterocyclic azobenzene high-polymer energy storage material and a preparation method thereof. Heterocyclic azobenzene with a monomer molecular formula of C9N5H9 exists on a high-polymer side chain to achieve trans-cis heat storage and cis-trans heat release; and a high-polymer chain is polymethyl methacrylate (PMMA). The grafting density of a heterocyclic ring is that every 3-10 carbon atoms are grafted with one heterocyclic azobenzene. The maximum isomerization rate of the energy storage material provided by the invention reaches 90%, and is improved by 15% compared with monomer molecules; and the maximum heat storage density reaches 130Wh / kg and is improved by nearly 55% compared with the monomer molecules. The obtained azo heterocyclic molecule, compared with an azobenzene molecule, is greatly improved in the aspect of energy storage density in a half-life period, and has a great potentiality in the aspect of heat storage. The exothermic peak of a polymer material is scanned with DSC, then released energy is obtained by performing integration on the exothermic peak using software, and then the released energy is divided by quality to obtain an extremely good heat storage density which reaches 130Wh / kg.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com