Catalyst for selective hydrogenation of butadiene

A selective hydrogenation and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, hydrogenation to hydrocarbons, etc., can solve the problems of limited application and development, poor selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

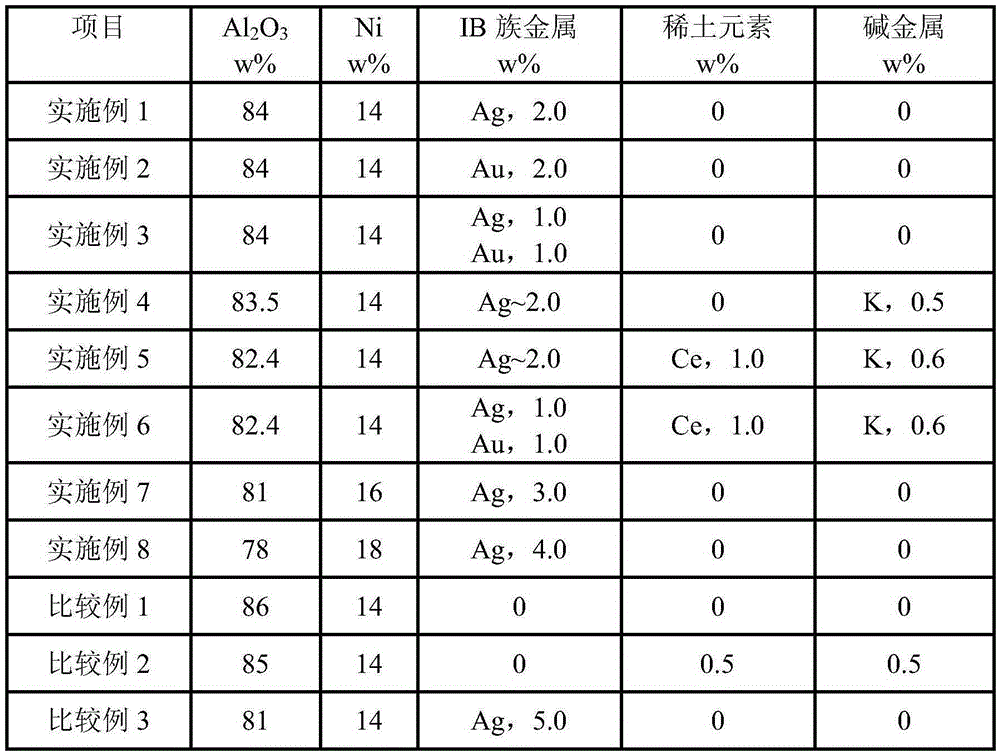

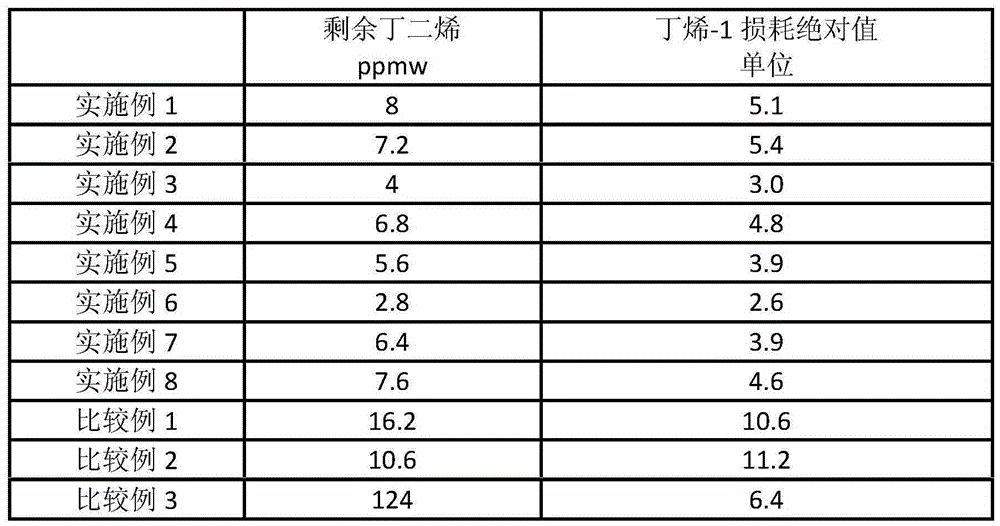

Examples

Embodiment 1

[0035] 1. Catalyst preparation

[0036] Take by weighing 14 grams of pseudo-boehmite equivalent to 10 grams of alumina, 130 grams of alumina, and 9 grams of asparagus powder, mix, then add 20 grams of polyvinyl alcohol-containing solution (mass concentration is 5%), and the mass concentration is 3.0 grams of 68% nitric acid, 200 milliliters of water, squeezed into mm clover-shaped carrier, the wet strip was dried at 110°C for 4 hours and then calcined at 750°C for 4 hours to obtain carrier Z1. Mix 20 grams of the above-mentioned carrier with nickel nitrate-silver nitrate mixed aqueous solution 26 containing 14 grams of nickel and 2.0 grams of silver, dry at 110° C. for 8 hours, and calcinate at 550° C. for 4 hours to obtain a Ni-based catalyst. Restore with hydrogen for 4 hours before use, the reduction temperature is 450°C, and the volumetric space velocity of hydrogen is 50 hours -1 , to obtain a low isomerism, selective hydrogenation catalyst, the specific composition is...

Embodiment 2

[0046] 1. Catalyst preparation

[0047] Take by weighing 14 grams of pseudo-boehmite equivalent to 10 grams of alumina, 130 grams of alumina, and 9 grams of asparagus powder, mix, then add 20 grams of polyvinyl alcohol-containing solution (mass concentration is 5%), and the mass concentration is 3.0 grams of 68% nitric acid, 200 milliliters of water, squeezed into mm clover-shaped carrier, the wet strip was dried at 110°C for 4 hours and then calcined at 750°C for 4 hours to obtain carrier Z1. Mix 20 grams of the above carrier with 26 grams of nickel nitrate-silver nitrate mixed aqueous solution containing 14 grams of nickel and 2.0 grams of silver, dry at 110°C for 8 hours, and calcined at 550°C for 4 hours to prepare a Ni-based catalyst. Restore with hydrogen for 4 hours before use, the reduction temperature is 450°C, and the volumetric space velocity of hydrogen is 50 hours -1 , to obtain a low isomerism, selective hydrogenation catalyst, the specific composition is show...

Embodiment 3

[0057] 1. Catalyst preparation

[0058] Take by weighing 14 grams of pseudo-boehmite equivalent to 10 grams of alumina, 130 grams of alumina, and 9 grams of asparagus powder, mix, then add 20 grams of polyvinyl alcohol-containing solution (mass concentration is 5%), and the mass concentration is 3.0 grams of 68% nitric acid, 200 milliliters of water, squeezed into mm clover-shaped carrier, the wet strip was dried at 110°C for 4 hours and then calcined at 750°C for 4 hours to obtain carrier Z1. Mix 20 grams of the above-mentioned carrier with 26 grams of nickel nitrate-silver nitrate-auric acid mixed aqueous solution containing 14 grams of nickel, 1.0 grams of silver and 1.0 grams of gold, dry at 110°C for 8 hours, and bake at 550°C for 4 hours to prepare Obtain Ni-based catalyst. Restore with hydrogen for 4 hours before use, the reduction temperature is 450°C, and the volumetric space velocity of hydrogen is 50 hours -1 , to obtain a low isomerism, selective hydrogenation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com