Method for isomerization of light hydrocarbon

A technology for isomerization and light hydrocarbons, applied in organic isomerization, chemical instruments and methods, hydrogenation hydrocarbon production, etc., can solve the problems of low octane number of isomerization products, high reaction temperature, low catalyst activity, etc. To achieve the effect of increasing the isomerization rate, increasing the octane number, and increasing the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

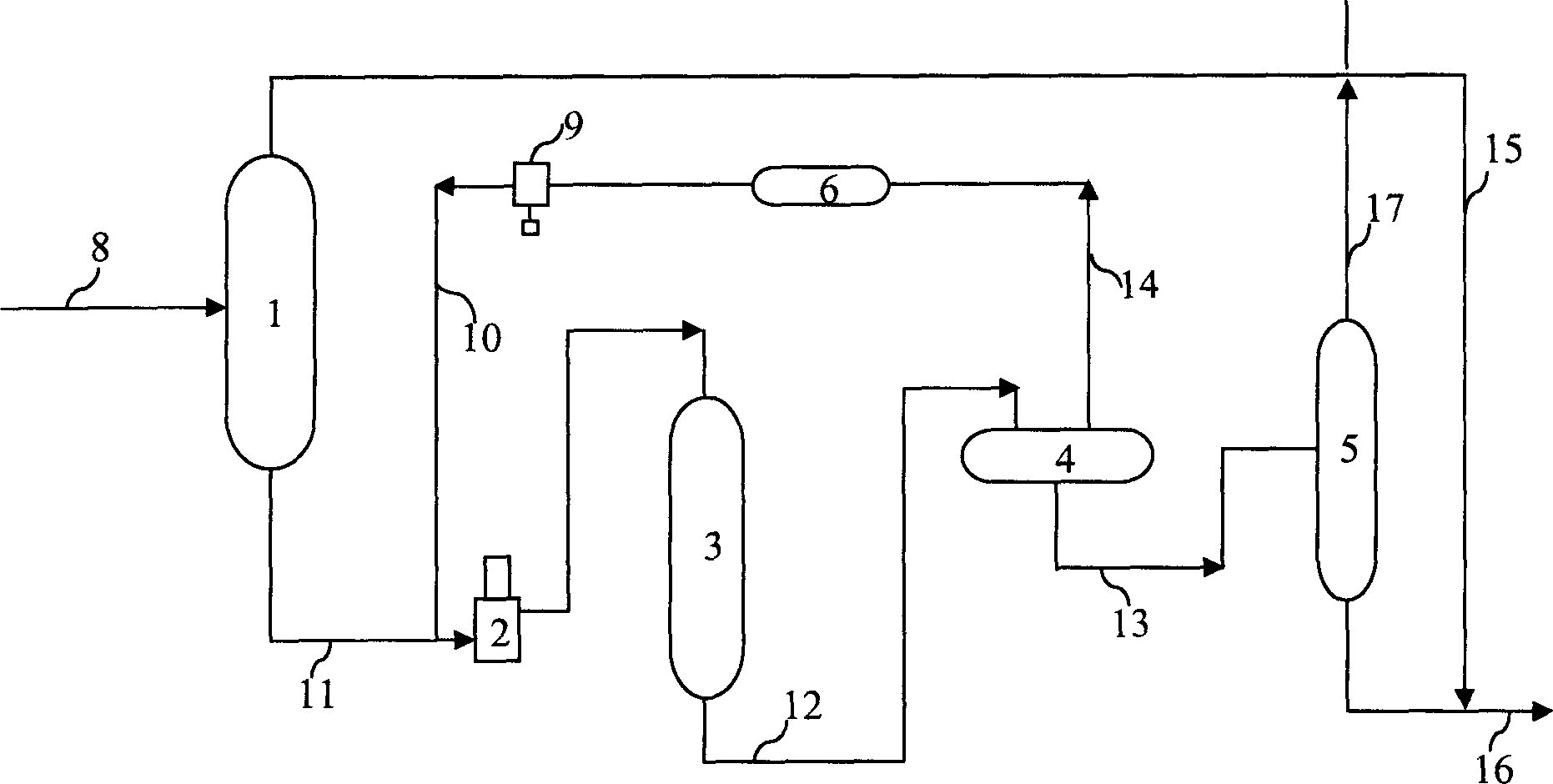

Image

Examples

preparation example Construction

[0016] The preparation method of the catalyst includes impregnating zirconium dioxide with sulfuric acid or ammonium sulfate aqueous solution with a concentration of 0.1-3.0 mol / L, then drying and roasting to obtain sulfate-supported zirconium dioxide, which is a solid superacid. In order to prevent the carbon deposition of the solid superacid in the isomerization reaction, the solid superacid is preferably impregnated with a VIII metal compound, and the liquid / solid ratio is 0.4 to 4.0:1, preferably 0.6 to 2.0: 1. After drying, bake at 500-700°C, preferably for 2-6 hours. The Group VIII metal compound used to prepare the immersion solution is preferably chloropalladium acid, chloroplatinic acid or ammonium chloroplatinate.

[0017] Described zirconium dioxide can adopt any known method to prepare, preferably adopt following method to prepare:

[0018] (1) Contact the soluble zirconium salt solution with the alkali solution to make the pH value 1.2 to 13.5 to generate zirconi...

example 2

[0030] Catalyst B was prepared according to the method of Example 1, except that the pH controlled during the preparation of the hydrogel of zirconium hydroxide was 8.5, and the hydrothermal treatment time was 6 hours. The zirconia in Catalyst B has both monoclinic and tetragonal phases, the content of active components and the ratio of monoclinic phase in zirconia are shown in Table 1.

example 3

[0032] Catalyst C was prepared according to the method of Example 1, except that concentrated ammonia water was added until the pH was 12, and then the resulting zirconium hydroxide hydrogel was hydrothermally treated at 150° C. for 20 hours. The zirconia in Catalyst C has both monoclinic and tetragonal phases, the content of active components and the ratio of monoclinic phase in zirconia are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com