Catalyst for alkane isomerization, and preparation method and application thereof

A catalyst and isomerization technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve poor selectivity and stability, complex operation, weak catalyst acidity and other problems, to achieve the effects of high activity and stability, safe preparation method, and improved liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Select 100g specific surface area as 135m 2 Dissolve 10g of phosphotungstic acid in water, then pour it into the silica pellets and soak for 2 hours, take it out and dry it naturally, and then bake it in a muffle furnace for 3 hours. The temperature is 400°C, take it out and cool down naturally.

[0026] Dissolve 0.6g of palladium chloride and 1g of gallium nitrate in dilute hydrochloric acid, adjust the pH value of the solution to 1, pour the carrier after natural cooling into the prepared above solution, soak for 2 hours, and put it into the muffle furnace Calcined for 5 hours at a temperature of 450° C. to prepare an alkane isomerization catalyst.

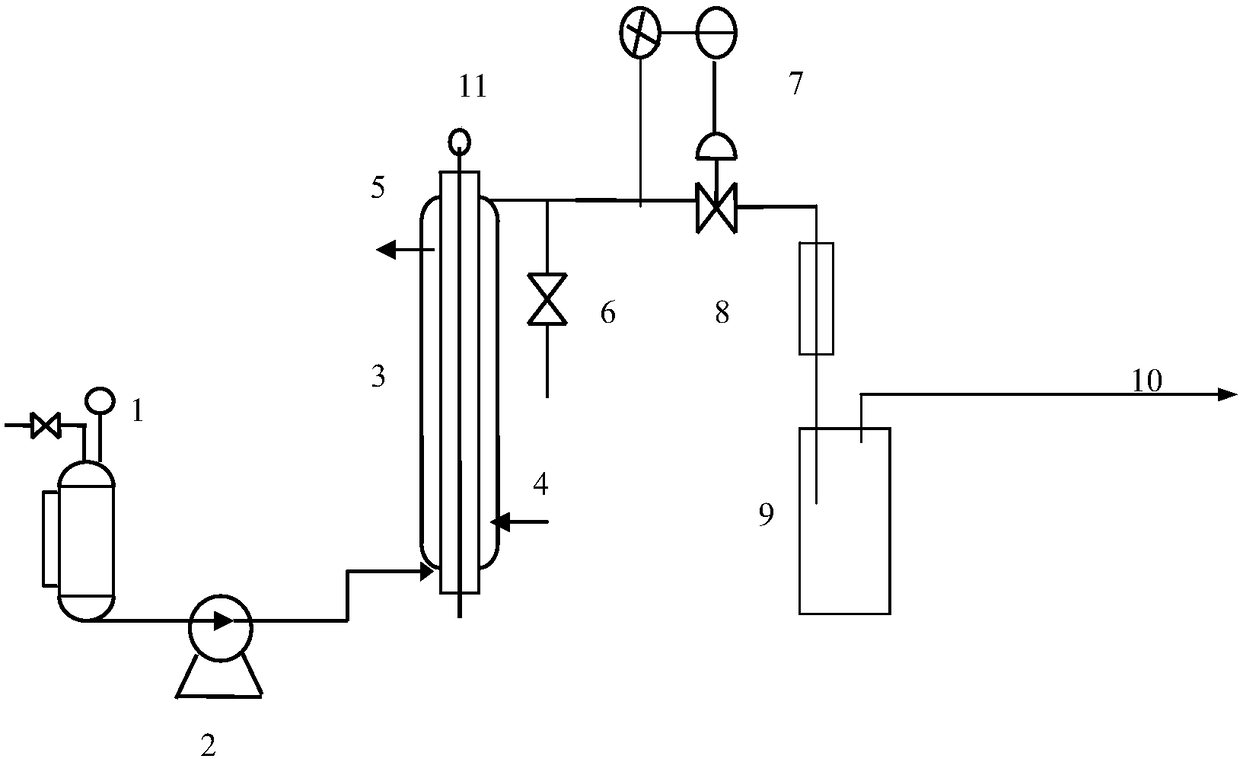

[0027] Using a structure such as figure 1 In the fixed-bed reactor shown, take 50ml of the obtained catalyst and place it in a Φ25×2.5mm fixed-bed reactor, use n-hexane as raw material at a reaction temperature of 230°C, a pressure of 1.2MPa, and a space velocity of 0.5h -1 The isomerization reaction was carried out un...

Embodiment 2

[0029] Select 100g specific surface area as 160m 2 / g of silica pellets as a carrier, 10g of phosphomolybdic acid was dissolved in water, then poured into the silica pellets and soaked for 2 hours, taken out and air-dried naturally, then roasted in a muffle furnace for 3 hours, and then roasted The temperature is 450°C, take it out and cool down naturally.

[0030] Dissolve 0.5g of palladium chloride and 0.8g of gallium nitrate in dilute hydrochloric acid, adjust the pH value of the solution to 2, pour the carrier after natural cooling into the prepared above solution, soak for 2 hours, and put it into the muffle furnace Medium calcination for 5 hours at a calcination temperature of 500°C to prepare an alkane isomerization catalyst.

[0031] Using a structure such as figure 1 In the fixed-bed reactor shown, take 50ml of the obtained catalyst and place it in a Φ25×2.5mm fixed-bed reactor, use n-heptane as raw material at a reaction temperature of 260°C, a pressure of 1.5MPa, ...

Embodiment 3

[0033] Select 100g specific surface area as 145m 2 / g of silica pellets as a carrier, 10g of phosphomolybdic acid was dissolved in water, then poured into the silica pellets and soaked for 2 hours, taken out and air-dried naturally, then roasted in a muffle furnace for 4 hours, and then The temperature is 500°C, take it out and cool down naturally.

[0034] Dissolve 0.6g of palladium chloride and 1.1g of gallium nitrate in dilute hydrochloric acid, adjust the pH value of the solution to 3, pour the carrier after natural cooling into the prepared above solution, soak for 2 hours, and put it into the muffle furnace Medium calcination for 4 hours at a calcination temperature of 500°C to prepare an alkane isomerization catalyst.

[0035] Using a structure such as figure 1 In the fixed-bed reactor shown, take 50ml of the obtained catalyst and place it in a Φ25×2.5mm fixed-bed reactor, use n-heptane as raw material at a reaction temperature of 260°C, a pressure of 1.5MPa, and a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com