Catalyst for selective hydrogenation of butadiene and isomerization of 1-butylene, and preparation method and application thereof

A catalyst, butadiene technology, applied in the direction of isomerization hydrocarbon production, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high catalyst cost and expensive precious metals, etc. The effect of low hydrogenation loss rate and high isomerization rate of 1-butene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

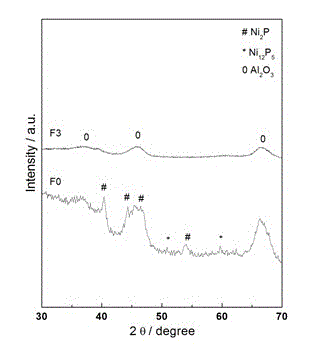

Image

Examples

Embodiment 1-4

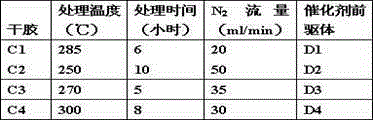

[0032] Catalyst preparation steps (1)

[0033] Weigh nickel nitrate according to the weight shown in Table 1 and add 500ml of deionized water, then add 0.05mol / L nitric acid to adjust the pH value to 2-3, then add diammonium hydrogen phosphate, cerium nitrate, and magnesium nitrate according to the weight shown in Table 1 , citric acid, and then stirred at room temperature for 1 hour to obtain solutions A1-A4, respectively.

[0034] Table 1 Catalyst preparation table

[0035]

[0036] 110g, 100g, 96g and 92g of aluminum hydroxide powder were added to the solutions A1-A4 to disperse them in the solution to obtain slurries B1-B4 respectively.

[0037] Catalyst Preparation Step (2)

[0038] The resulting slurries B1-B4 were transferred into a hydrothermal synthesis kettle, and subjected to hydrothermal treatment at 120° C. for 5 hours. After the hydrothermal treatment was completed, the obtained slurry was transferred into a rotary evaporator to evaporate the water to d...

Embodiment 5-10

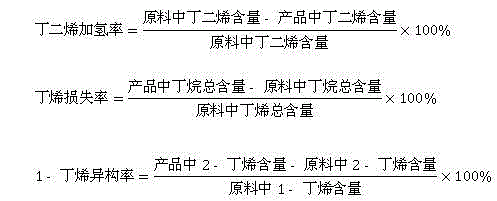

[0054] The reactivity of the catalyst was evaluated by selective hydrogenation of butadiene. Before each catalyst evaluation, the catalyst needs to be pretreated in a hydrogen atmosphere at 200°C for 2 hours, and then cooled to the reaction temperature. A mixed carbon four is used as a raw material, and the composition of the raw material is shown in Table 4. The reaction products were analyzed online by Agilent7890 gas chromatograph.

[0055] Table 4 raw material composition

[0056]

[0057] Using F1-F4 as the catalyst, F0 as the reference, and the above-mentioned mixed carbon four as the raw material, the reaction temperature is 80-120°C, the total pressure is 1.5-2.0MPa, and the space velocity is 5-10h -1 , Under the condition that the hydrogen / butadiene molar ratio is 1.0-2.0, the selective hydrogenation reaction is carried out, and the reaction results are listed in Table 5.

[0058] Table 5 process conditions and reaction results

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com