A kind of butadiene selective hydrogenation, 1-butene isomerization catalyst and its preparation method and application

A catalyst and butadiene technology, which is applied in the direction of isomerization hydrocarbon production, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of expensive precious metals and high catalyst costs, and achieve low catalyst costs and butene processing. Effect of low hydrogen loss rate and high isomerization rate of 1-butene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0032] Catalyst preparation steps (1)

[0033] Weigh nickel nitrate according to the weight shown in Table 1 and add 500 ml of deionized water, then add 0.05 mol / L nitric acid to adjust the pH value to 2-3, then add diammonium hydrogen phosphate, cerium nitrate, and nitric acid according to the weight shown in Table 1 Magnesium, citric acid, and then stirred at room temperature for 1 hour to obtain solutions A1-A4, respectively.

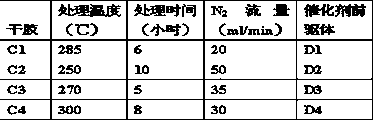

[0034] surface Catalyst Preparation Table

[0035]

[0036] 110g, 100g, 96g and 92g of aluminum hydroxide powder were added to the solutions A1-A4 to disperse them in the solution to obtain slurries B1-B4 respectively.

[0037] Catalyst Preparation Step (2)

[0038] The resulting slurries B1-B4 were transferred into a hydrothermal synthesis kettle, and subjected to hydrothermal treatment at 120° C. for 5 hours. After the hydrothermal treatment was completed, the obtained slurry was transferred into a rotary evaporator to evaporate the wate...

Embodiment 5-10

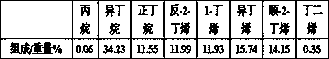

[0054] The reactivity of the catalyst was evaluated by selective hydrogenation of butadiene. Before each catalyst evaluation, the catalyst needs to be pretreated in a hydrogen atmosphere at 200°C for 2 hours, and then cooled to the reaction temperature. A mixed carbon four is used as a raw material, and the composition of the raw material is shown in Table 4. The reaction products were analyzed online by Agilent 7890 gas chromatograph.

[0055] Table 4 Raw material composition

[0056]

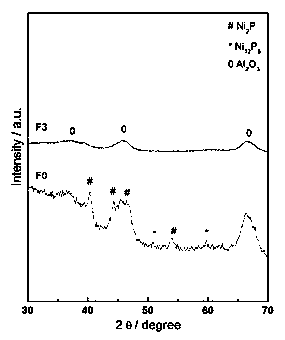

[0057] Using F1-F4 as the catalyst, F0 as the reference, and the above-mentioned mixed carbon four as the raw material, the reaction temperature is 80-120°C, the total pressure is 1.5-2.0 MPa, and the space velocity is 5-10 h -1 , Under the condition that the hydrogen / butadiene molar ratio is 1.0-2.0, the selective hydrogenation reaction is carried out, and the reaction results are listed in Table 5.

[0058] Table 5 Process conditions and reaction results

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com