A kind of environment-friendly process method of producing motor gasoline from naphtha

A process method, the technology of gasoline for vehicles, which is applied in the field of coal chemical industry, can solve the problems of complex process and high energy consumption, and achieve the effects of good thermal stability, high yield and low sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

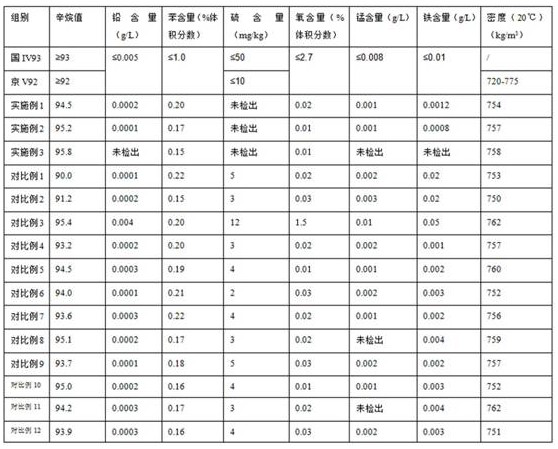

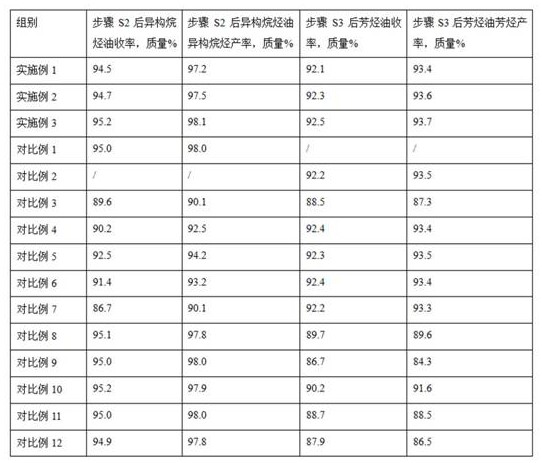

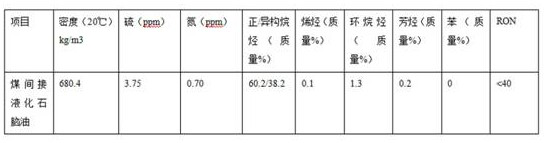

Examples

preparation example 1

[0035] Preparation Example 1 WO 3 / ZrO 2 / Al 2 o 3 Preparation of Mg-doped Pt / Ni Bimetallic Catalyst Supported by Solid Strong Acid

[0036] Add 10g of ammonium metatungstate solution dropwise to 100mL mixed solution of 4g zirconium oxychloride and 2g aluminum isopropoxide under stirring, adjust the pH value of the solution to 9, heat to 80°C for 0.5h, then centrifuge at 3000r / min 10min, the solid precipitate was washed with deionized water, filtered, dried at 80°C for 2h, and calcined at 300°C for 2h to obtain WO 3 / ZrO 2 / Al 2 o 3 Solid strong acid carrier; dissolved in 0.6gH 2 PtCl 6 and 0.4g NiCl 2 Add 0.02g MgCl to 20mL aqueous solution 2 , after mixing well, add 5g WO 3 / ZrO 2 / Al 2 o 3 Solid strong acid carrier, 1000W ultrasonic dispersion for 0.5h, heated to 80°C for 1h, concentrated under reduced pressure to half of the original volume, filtered, and dried at 80°C for 2h to obtain WO 3 / ZrO 2 / Al 2 o 3 Solid strong acid supported Mg-doped Pt / Ni bimet...

preparation example 2

[0037] Preparation Example 2 WO 3 / ZrO 2 / Al 2 o 3 Preparation of Mg-doped Pt / Ni Bimetallic Catalyst Supported by Solid Strong Acid

[0038] Add 10g of ammonium metatungstate solution dropwise to 100mL mixed solution of 7g of zirconium oxychloride and 3g of aluminum isopropoxide under stirring, adjust the pH value of the solution to 10, heat to 90°C for 1h, then centrifuge at 3000r / min for 10min , the solid precipitate was washed with deionized water, filtered, dried at 80°C for 2h, and calcined at 450°C for 2h to obtain WO 3 / ZrO 2 / Al 2 o 3 Solid strong acid carrier; dissolved in 1.4gH 2 PtCl 6 and 0.6g NiCl 2 Add 0.1g MgCl to 20mL aqueous solution 2 , after mixing well, add 5g WO 3 / ZrO 2 / Al 2 o 3 Solid strong acid carrier, 1000W ultrasonic dispersion for 1h, heated to 90°C for 2h, concentrated under reduced pressure to half of the original volume, filtered, and dried at 80°C for 2h to obtain WO 3 / ZrO 2 / Al 2 o 3 Solid strong acid supported Mg-doped Pt / N...

preparation example 3

[0039] Preparation Example 3 WO 3 / ZrO 2 / Al 2 o 3 Preparation of Mg-doped Pt / Ni Bimetallic Catalyst Supported by Solid Strong Acid

[0040] Add 10g ammonium metatungstate solution dropwise to 100mL mixed solution of 5g zirconium oxychloride and 2.5g aluminum isopropoxide under stirring, adjust the pH value of the solution to 9.5, heat to 85°C for 1 hour, centrifuge at 3000r / min 10min, the solid precipitate was washed with deionized water, filtered, dried at 80°C for 2h, and calcined at 400°C for 2h to obtain WO 3 / ZrO 2 / Al 2 o 3 Solid strong acid carrier; dissolved in 0.8gH 2 PtCl 6 and 0.5g NiCl 2 Add 0.06g MgCl to 20mL aqueous solution 2, after mixing well, add 5g WO 3 / ZrO 2 / Al 2 o 3 Solid strong acid carrier, 1000W ultrasonic dispersion for 1h, heated to 85°C for 1.5h, concentrated under reduced pressure to half of the original volume, filtered, and dried at 80°C for 2h to obtain WO 3 / ZrO 2 / Al 2 o 3 Solid strong acid supported Mg-doped Pt / Ni bimetall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com