Molecular sieve-containing alumina pellet and preparation method thereof

A technology for sieving alumina and containing alumina, which is applied in the field of alumina pellets containing molecular sieve and its preparation, can solve the problems such as the inability to meet the requirements of moving bed reaction, and achieves easy large-scale industrial production, high molecular sieve content and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

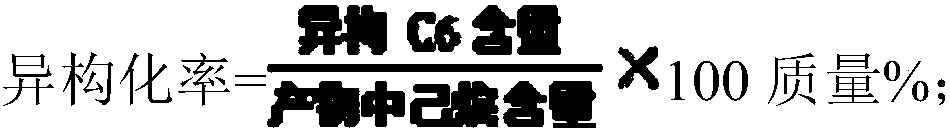

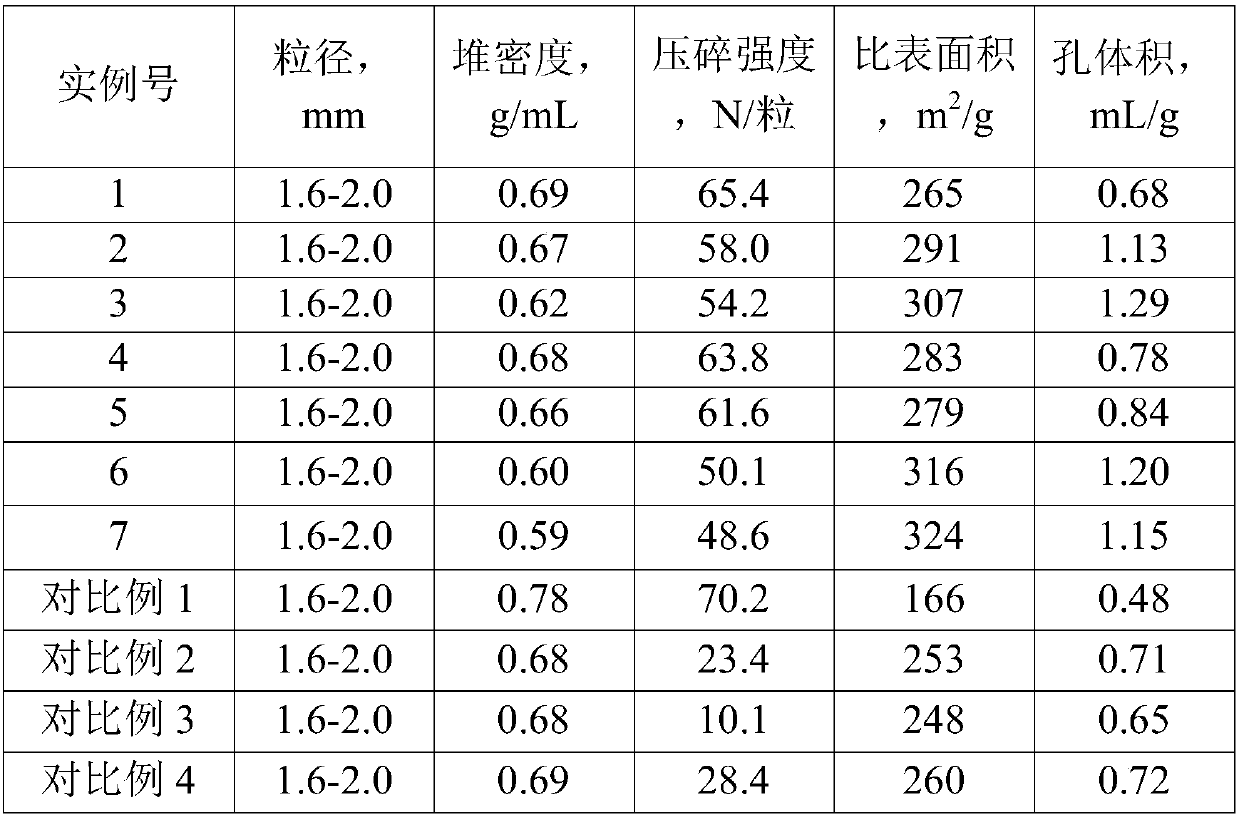

[0033]The present invention also provides a molecular sieve-containing alumina pellet prepared by the provided preparation method. The specific surface area of the alumina pellet containing molecular sieve can be 150-500m 2 / g, preferably 200-400m 2 / g, the pore volume can be 0.3-1.5mL / g, preferably 0.5-1.3mL / g.

[0034] After the molecular sieve-containing alumina pellets of the present invention are loaded with active components, a catalyst containing molecular sieves can be prepared.

[0035] One embodiment is to prepare a catalyst for aromatization of light hydrocarbons. The catalyst includes alumina pellets containing molecular sieves and zinc, based on the alumina pellets containing molecular sieves, the content of the zinc is 0.1-10% by mass, and the The molecular sieve in the alumina ball containing molecular sieve is ZSM-5 molecular sieve. The catalyst is suitable for C 4 -C 6 Monomer hydrocarbons (such as isobutane) or olefinic light hydrocarbons undergo aroma...

example 1

[0042] (1) Preparation of mixed sols.

[0043] Take 54.8g of high-purity pseudo-boehmite (produced by Condea, Germany, brand SB, containing 40g of alumina) prepared by hydrolysis of alkoxy aluminum, 30.0g of urea and 135g of deionized water and mix and stir for 0.5h to form alumina suspension solution; 2.0 g of nitric acid solution with a concentration of 24% by mass was added dropwise to the aluminum hydroxide suspension as the first acid solution for the first peptization, stirred for 0.5 h, and the pH value was controlled to 3.8 to obtain alumina sol.

[0044] Add 40g of HZSM-5 molecular sieve to the alumina sol, the molar ratio of silica to alumina is 50 (produced by Sinopec Catalyst Changling Branch), and 3.0g of nitric acid solution with a concentration of 24% by mass is added dropwise as the second acid The solution was subjected to the second peptization, the pH value was controlled at 2.5, and stirred at 20°C for 2 hours to obtain a mixed sol, the viscosity of the mix...

example 2

[0052] (1) Preparation of mixed sols.

[0053] Get 54.8g of high-purity pseudo-boehmite (produced by Condea, Germany, brand SB, containing 40g of alumina) prepared by hydrolysis of alkoxy aluminum, 35.0g of urea and 140g of deionized water and mix and stir for 0.5h to form aluminum hydroxide To the suspension, 2.0 g of nitric acid solution with a concentration of 24% by mass was added dropwise as the first acid solution for the first peptization, stirred for 0.5 h, and the pH value was controlled to be 3.8 to obtain alumina sol.

[0054] Add 60g of HZSM-5 molecular sieve to the alumina sol, the molar ratio of silicon oxide to aluminum oxide is 50 (produced by Sinopec Catalyst Changling Branch), and 3.2g of nitric acid solution with a concentration of 24% by mass is added dropwise as the second acid The solution was subjected to the second peptization, the pH value was controlled to 2.3, and stirred at 20°C for 2 hours to obtain a mixed sol, the viscosity of the mixed sol was 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com