Patents

Literature

32results about How to "High interest rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

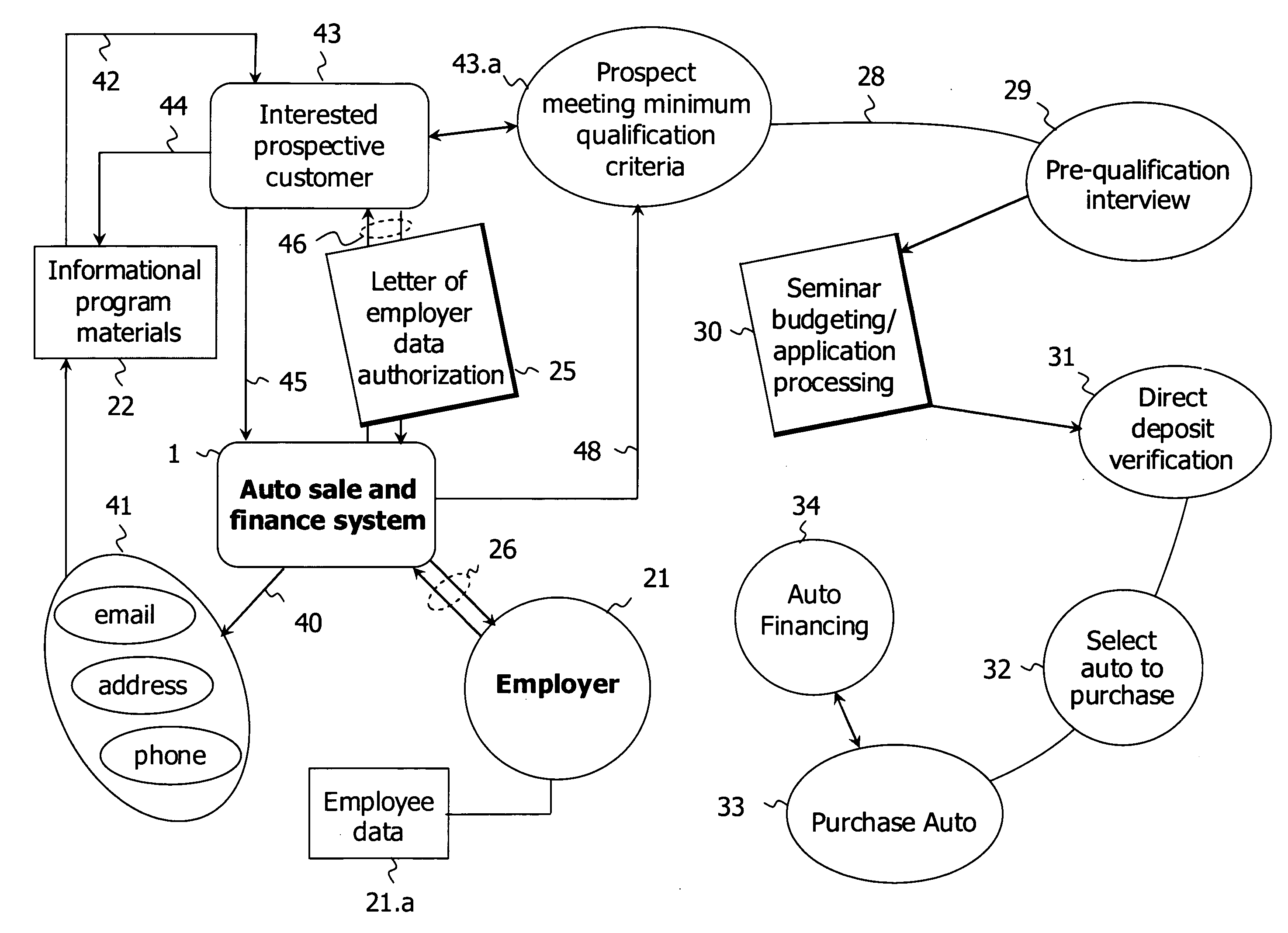

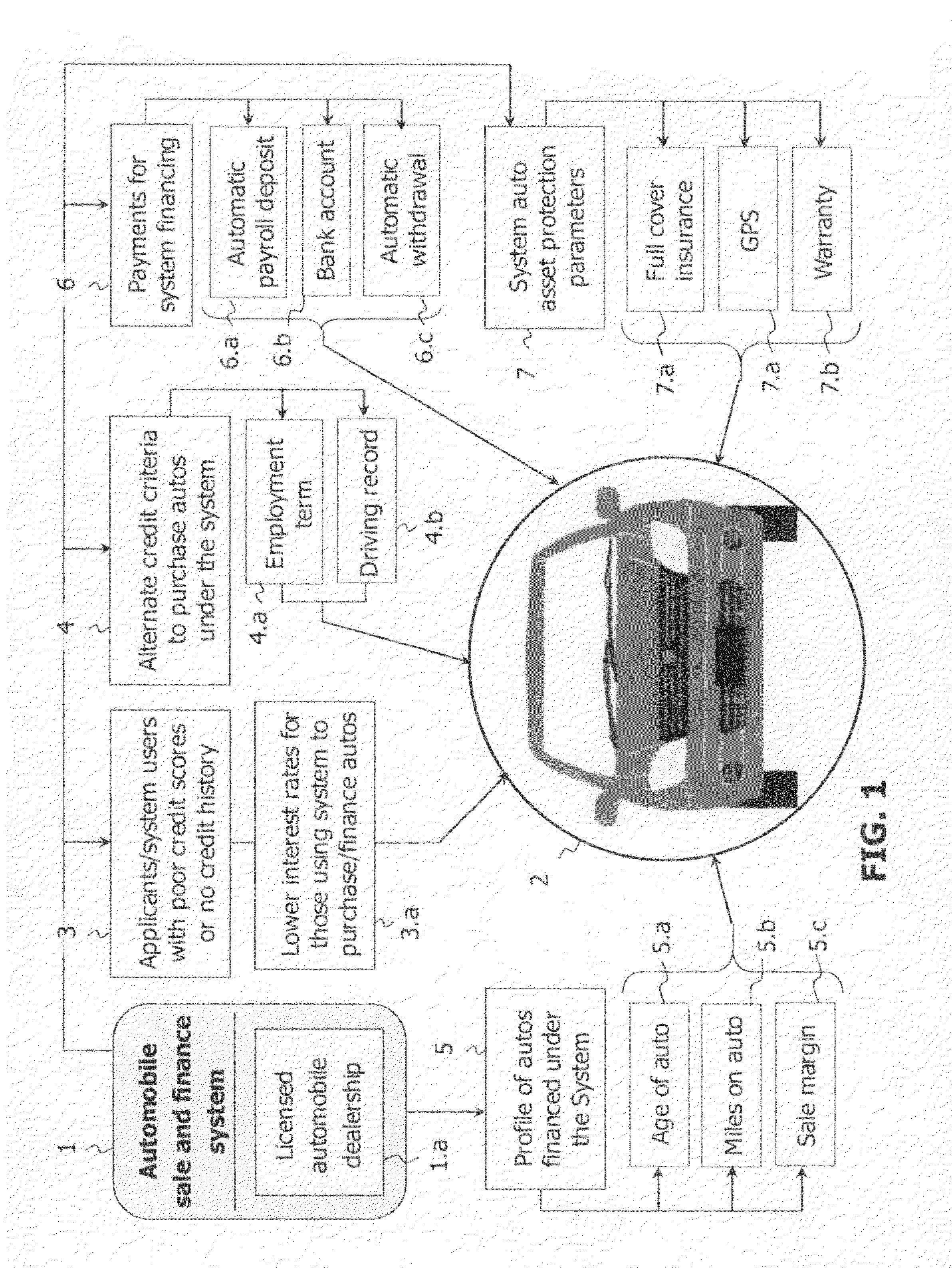

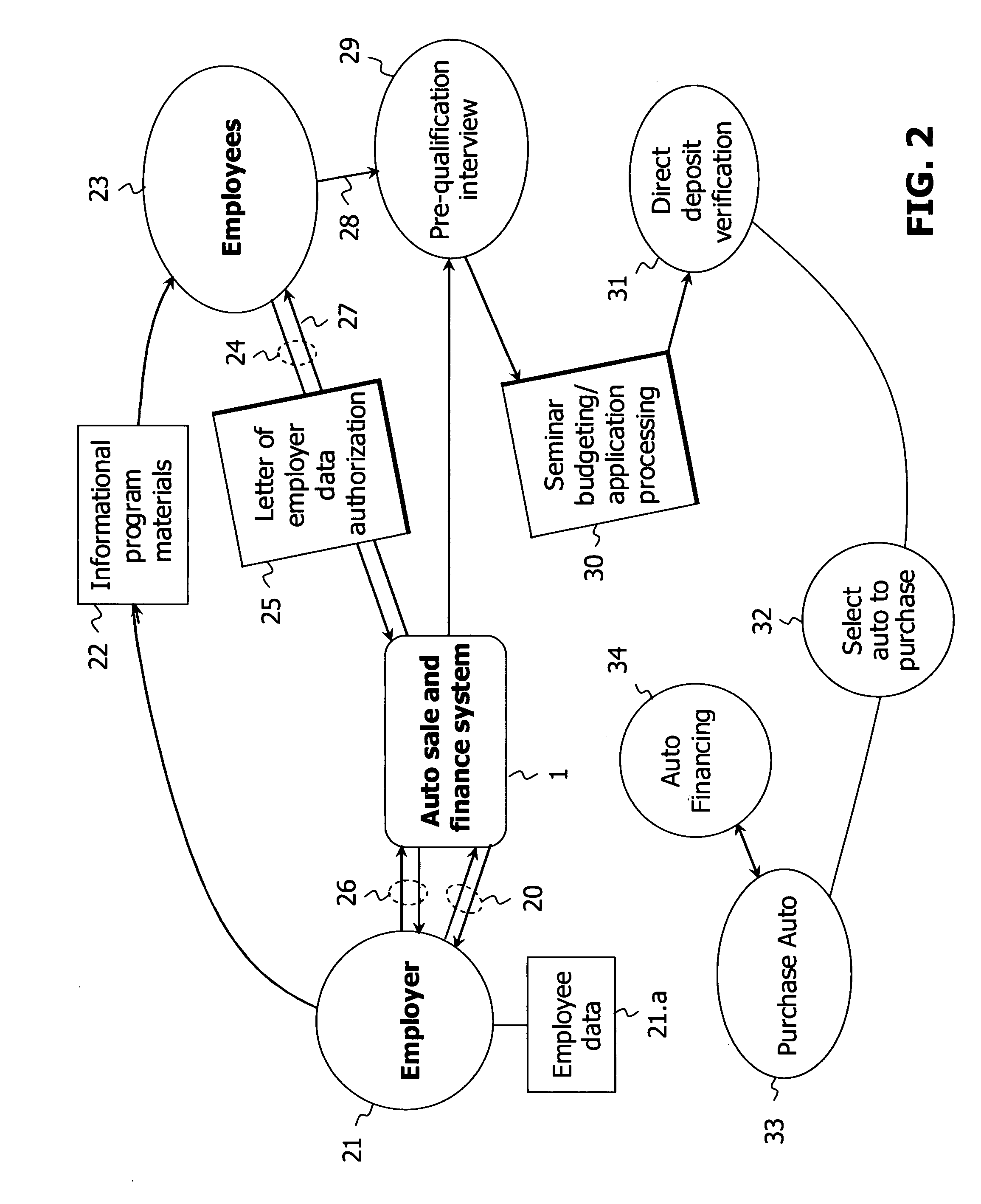

Sub-prime automobile sale and finance system

InactiveUS20070288271A1Raise interest ratesHigh riskFinancePosition fixationSystem structureProgram planning

A system to provide automobile financing to individuals with relatively lower credit scores or ratings, or no credit rating, due to lack of credit or lending purchases, that would otherwise only qualify for sub-prime, higher interest loans. Due to the overall system structure, lower rate interest loans can be extended to participants. The system utilizes the auto financing loan applicant's term of employment and / or other employment performance data as the principal credit criteria to qualify the creditworthiness of an applicant versus the applicant's credit score or credit rating. Applicant's driving records are also reviewed as system automobile loan approval credit criteria. Loan applicants provide employment related information and execute a letter of authorization providing the system with authority / rights to contact the applicant's employer to verify said employment information. In order to provide participants with lower interest rates than would otherwise be available through conventional channels, automobiles financed under the system must meet minimum profile criteria, including the year of the auto, the mileage, retail value relative to the wholesale value, and autos financed under the system are covered by extended warranties and have GPS systems installed for asset protection purposes. In utilizing employment term as the principal creditworthiness criteria, the system can to be offered through employers as an employee loyalty reward program.

Owner:KLINKHAMMER KIRK WILLIAM

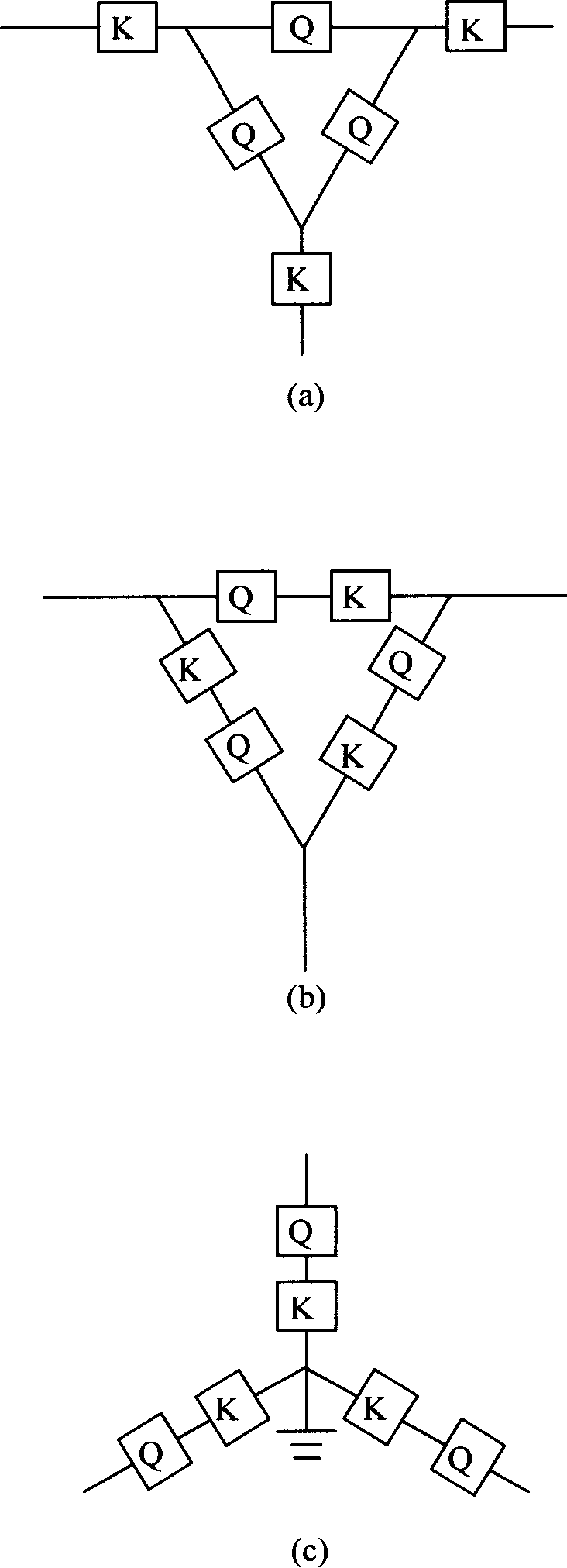

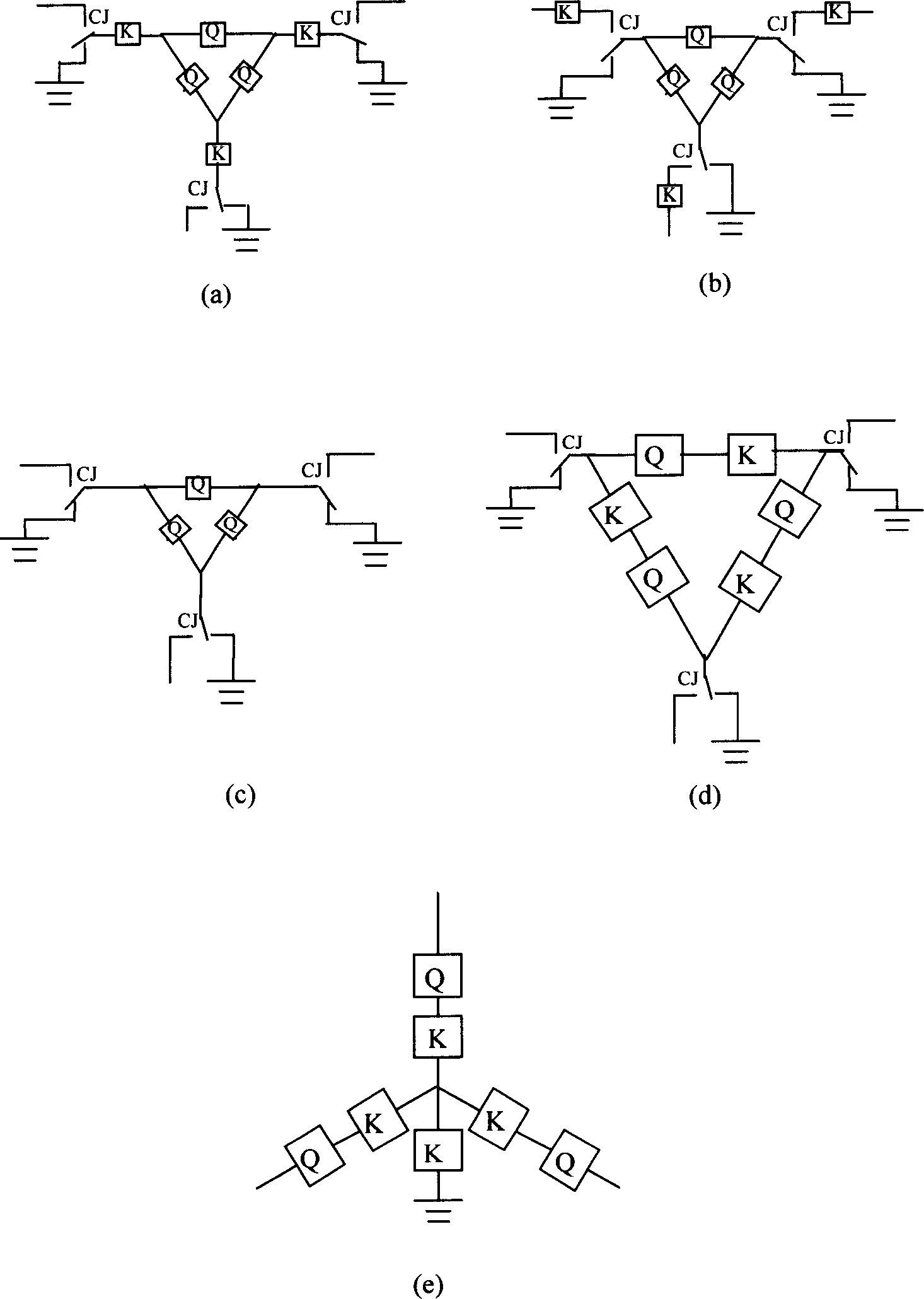

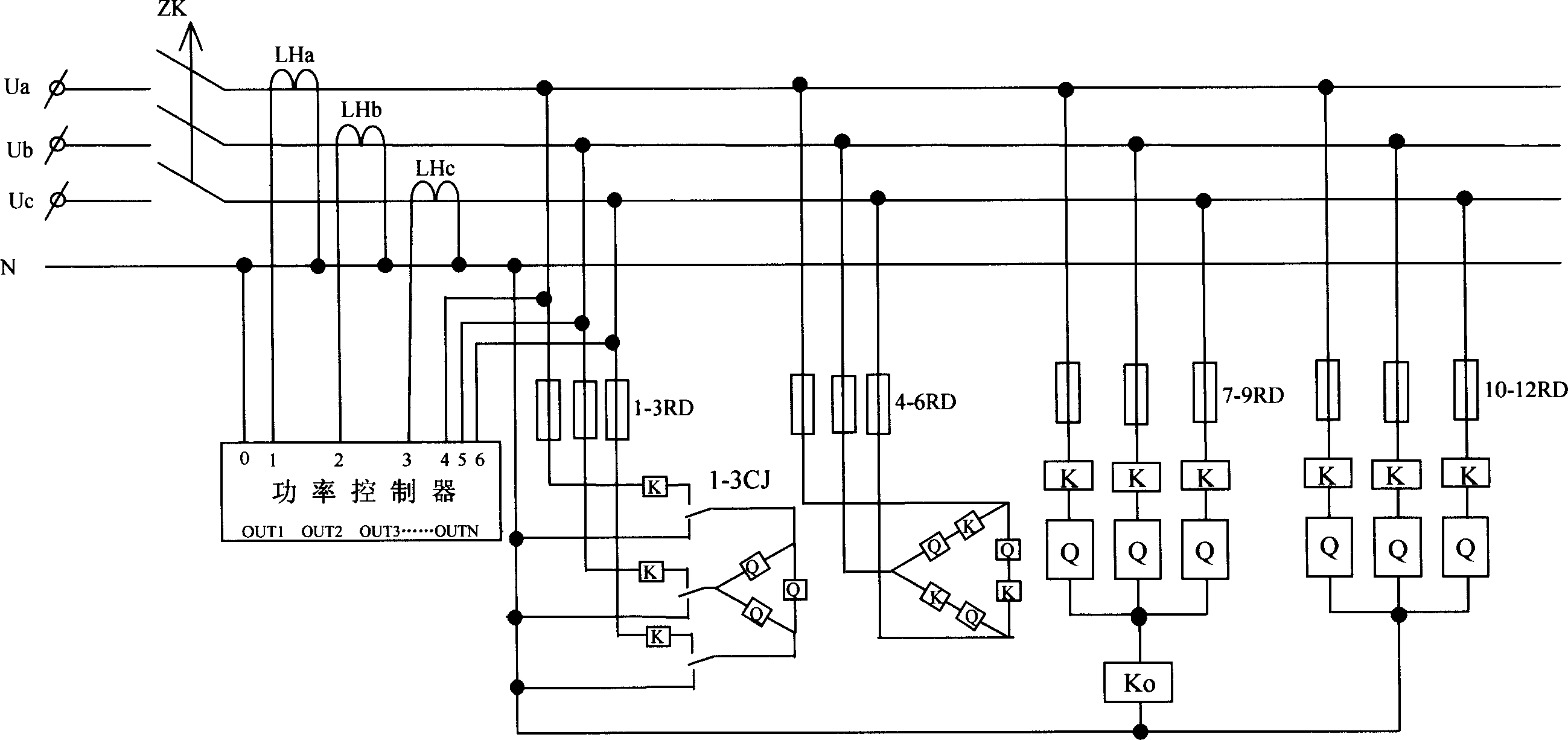

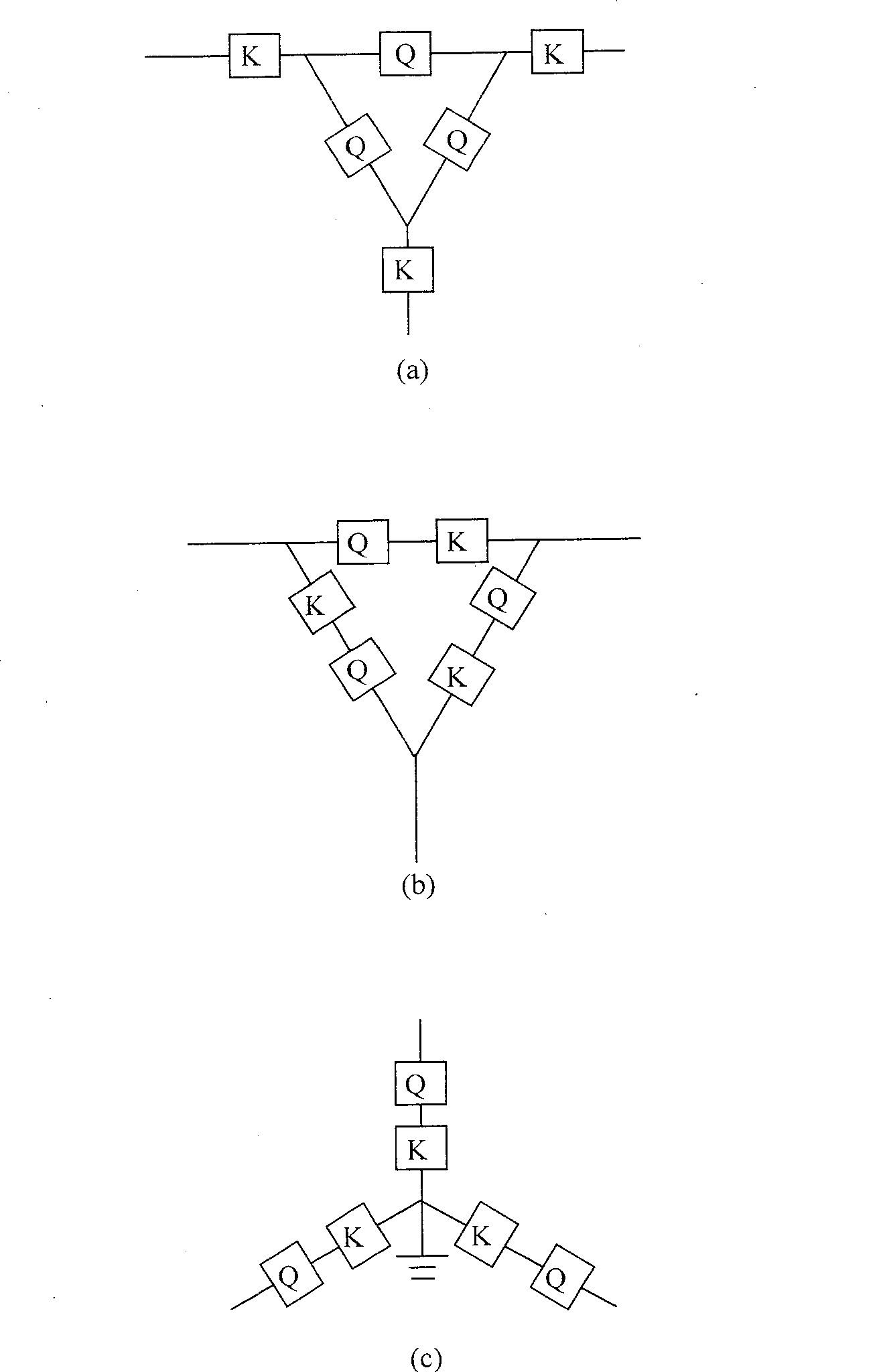

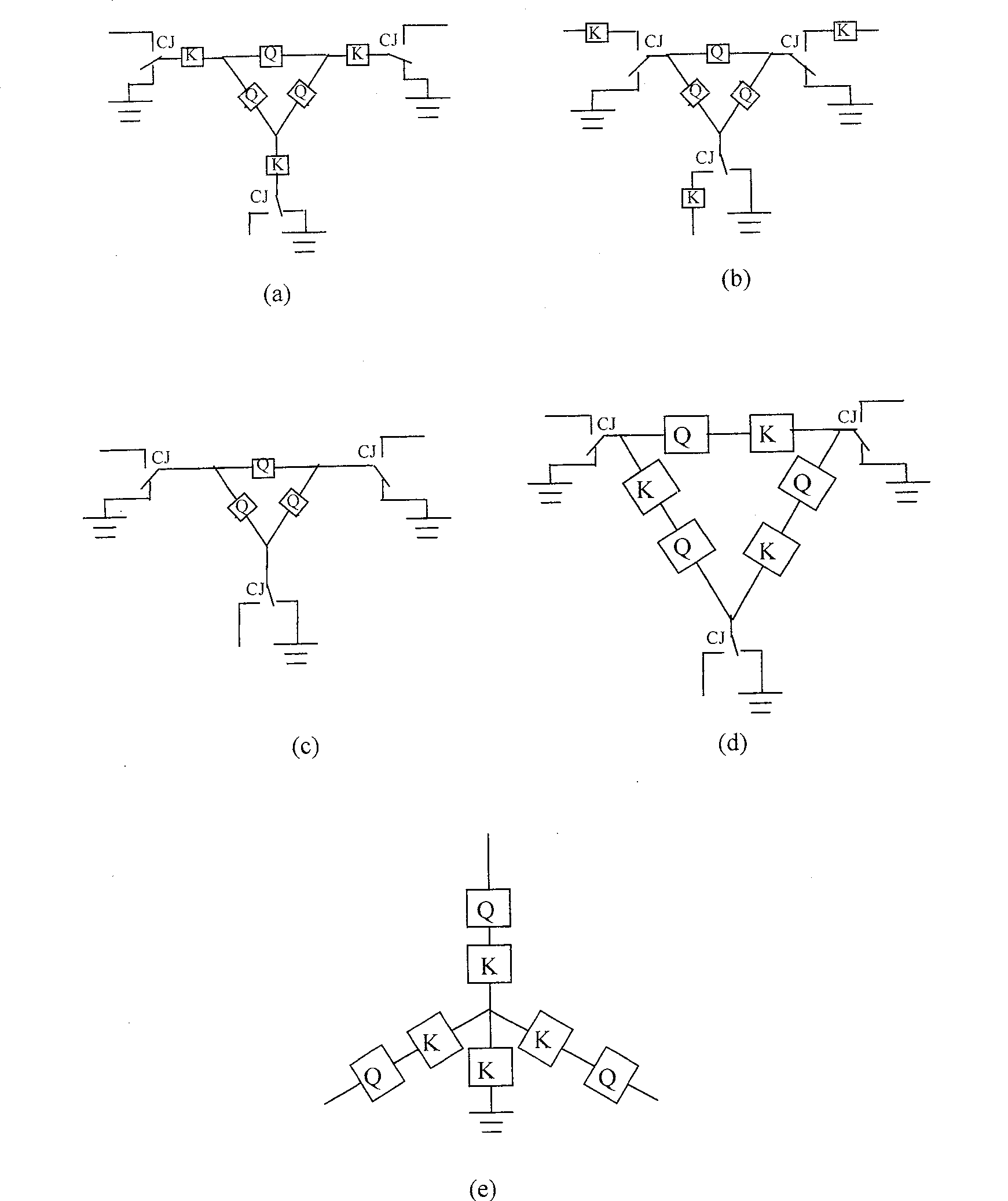

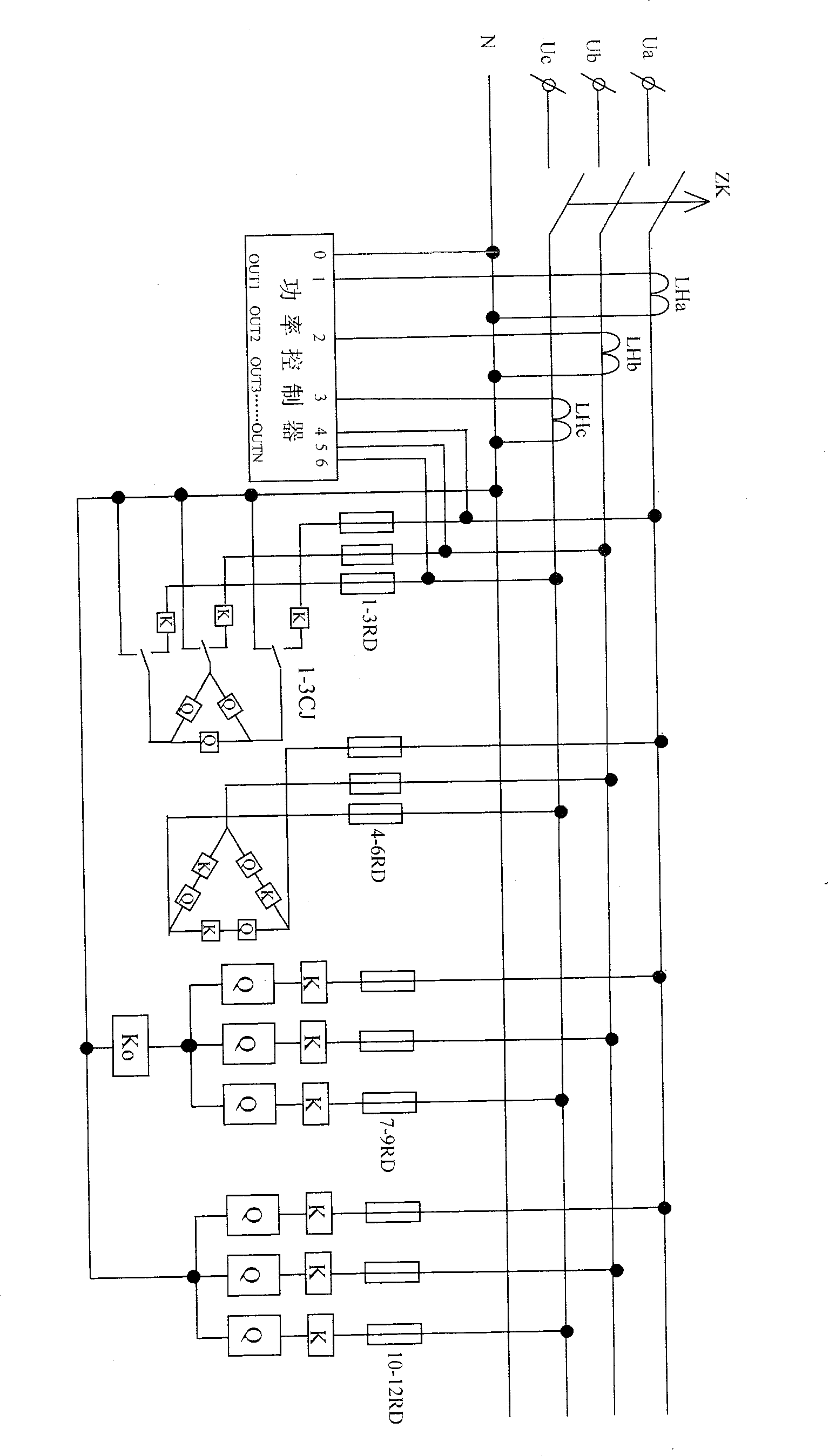

Apparatus for effectively compensating three-phase unbalance load and reactive power

InactiveCN1812219ASolve reactive power compensationSolve balance problemsPolyphase network asymmetry elimination/reductionReactive power adjustment/elimination/compensationPower controllerElectric power system

This invention discloses a kind of high-efficiency compensating three-phase imbalanced load and reactive power apparatus. It concludes: three-phase current of three-phase electric system, three-phase voltage sampling circuit, power controller and different three-phase compensating elements controlled by the power controller. According to the sampling results, the power controller controls each unidirectional switch of three-phase compensating elements of different topological structure respectively. It makes them can either compensate together or compensate solely; it can either compensate reaction or balance action; it can either use for static compensating or use for dynamic compensating; it can either adjust three-phase current of adjust three-phase imbalanced voltage. It can be used for improving and replacing the reactive compensation apparatus of the three-phase-four-line mode imbalanced load electric system.

Owner:齐志江

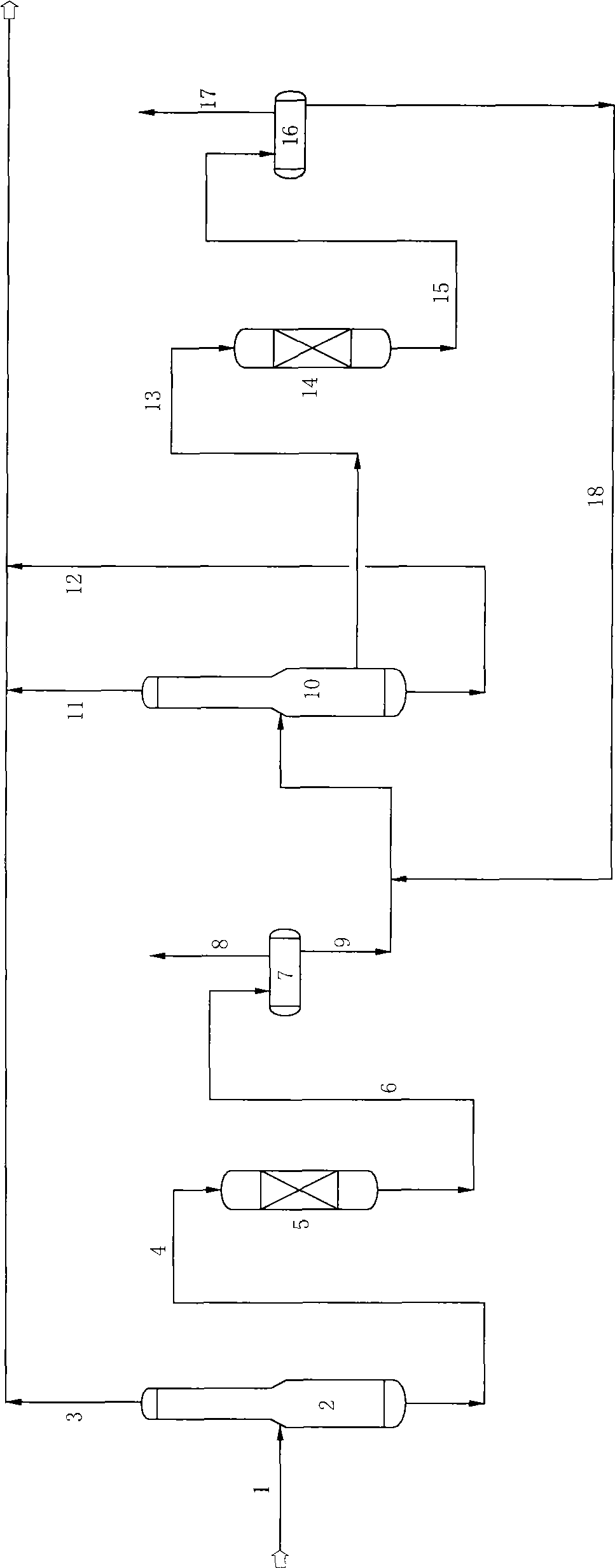

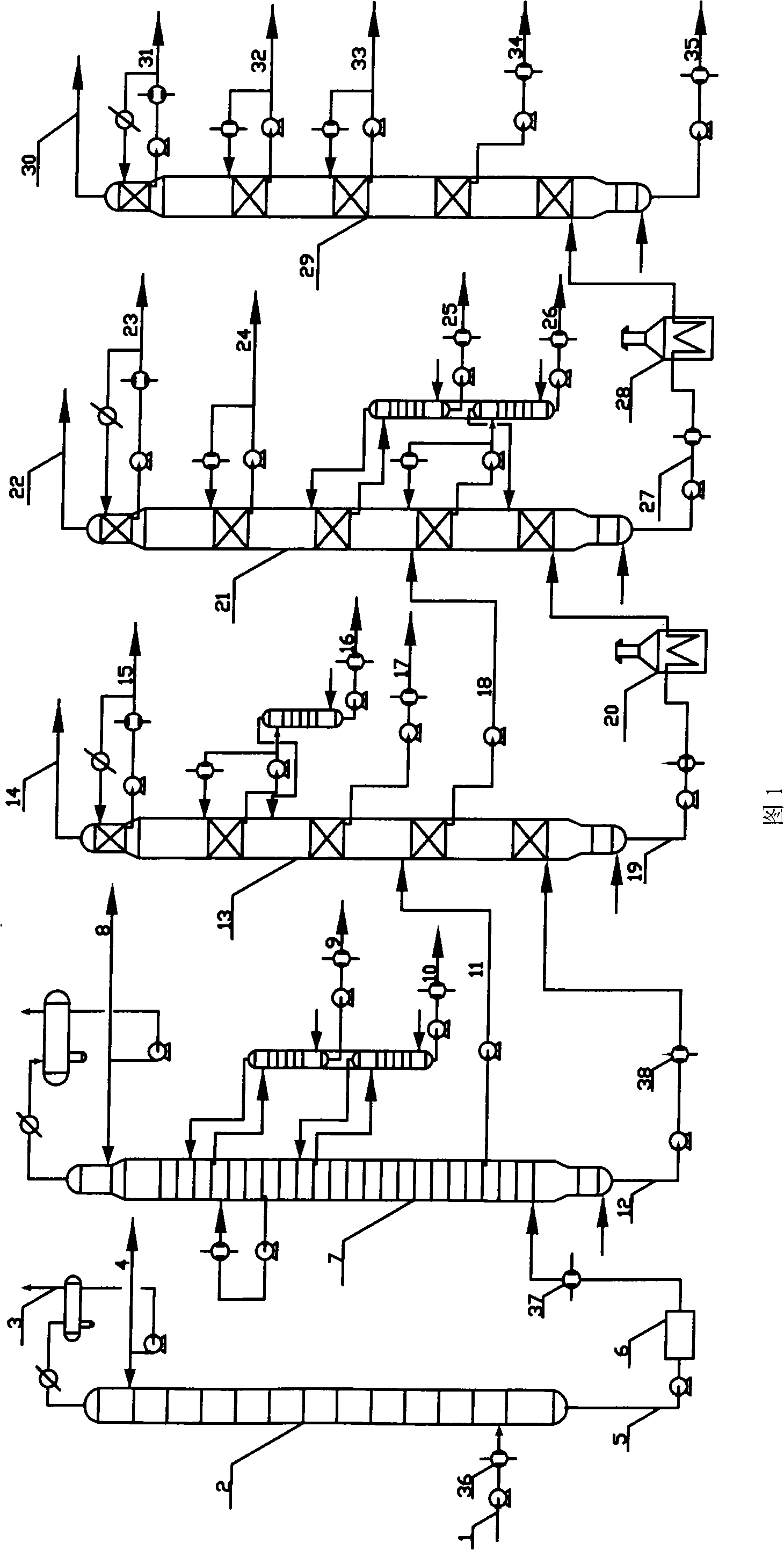

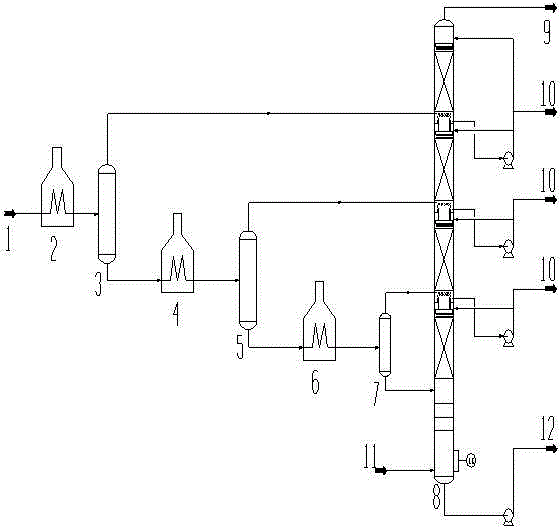

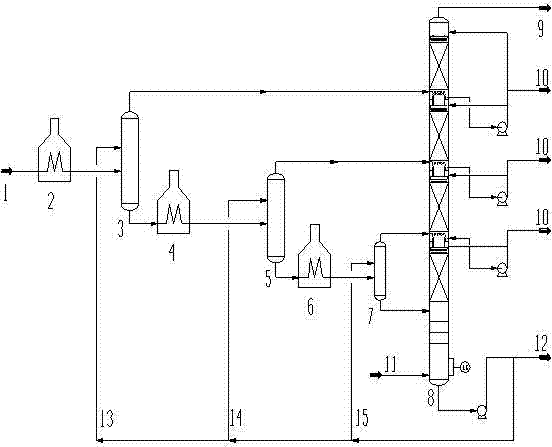

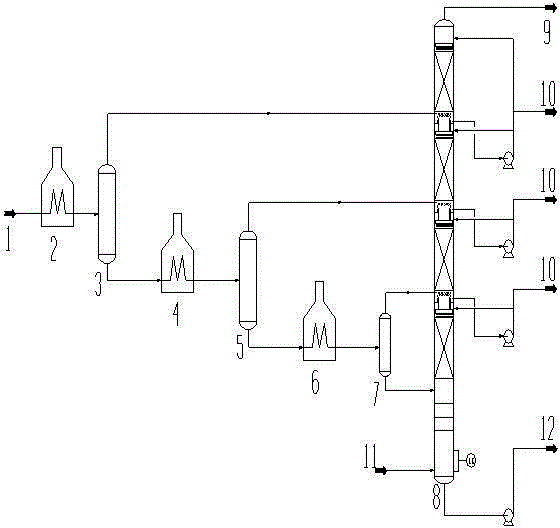

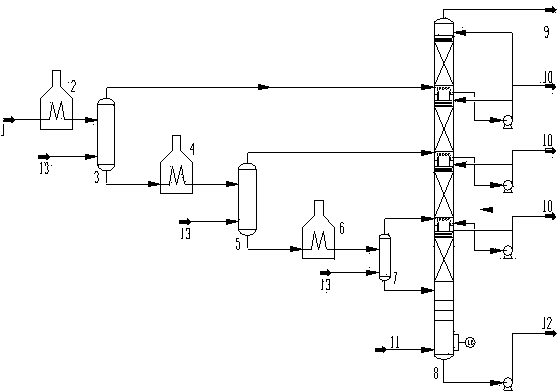

Light hydrocarbon isomerization method

ActiveCN101544905AIncrease the rate of isomerizationGuaranteed isomerization rateHydrocarbon by isomerisationRefining to change hydrocarbon structural skeleton2-methylbutaneIsomerization

The invention relates to a light hydrocarbon isomerization method comprising the following steps: light hydrocarbon materials are firstly separated by a de-isopentane tower, tower top streams are extracted as isomerization products, and tower bottom streams enter a front isomerization reactor to generate isomerization reaction; liquid phase streams obtained by the gas-liquid separation of outlet streams of the front reactor are separated in a de-isohexane tower, and tower top streams and tower bottom streams of the de-isohexane tower are extracted and then mixed with the tower top streams of the de-isopentane tower and are together taken as a gasoline-stripping stabilization system of the isomerization products; siding streams of the de-isohexane tower are extracted into a rear isomerization reactor; and liquid phase streams obtained by the gas-liquid separation of reaction streams of the rear isomerization reactor completely return and are mixed with the liquid phase streams of a gas-liquid separator of the front isomerization reaction system and together taken as feeding materials of the de-isohexane tower. The method has higher normal paraffin isomerization ratio, wherein the C6 normal paraffin realizes the complete isomerization basically, thereby greatly improving the octane number of the light hydrocarbon materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

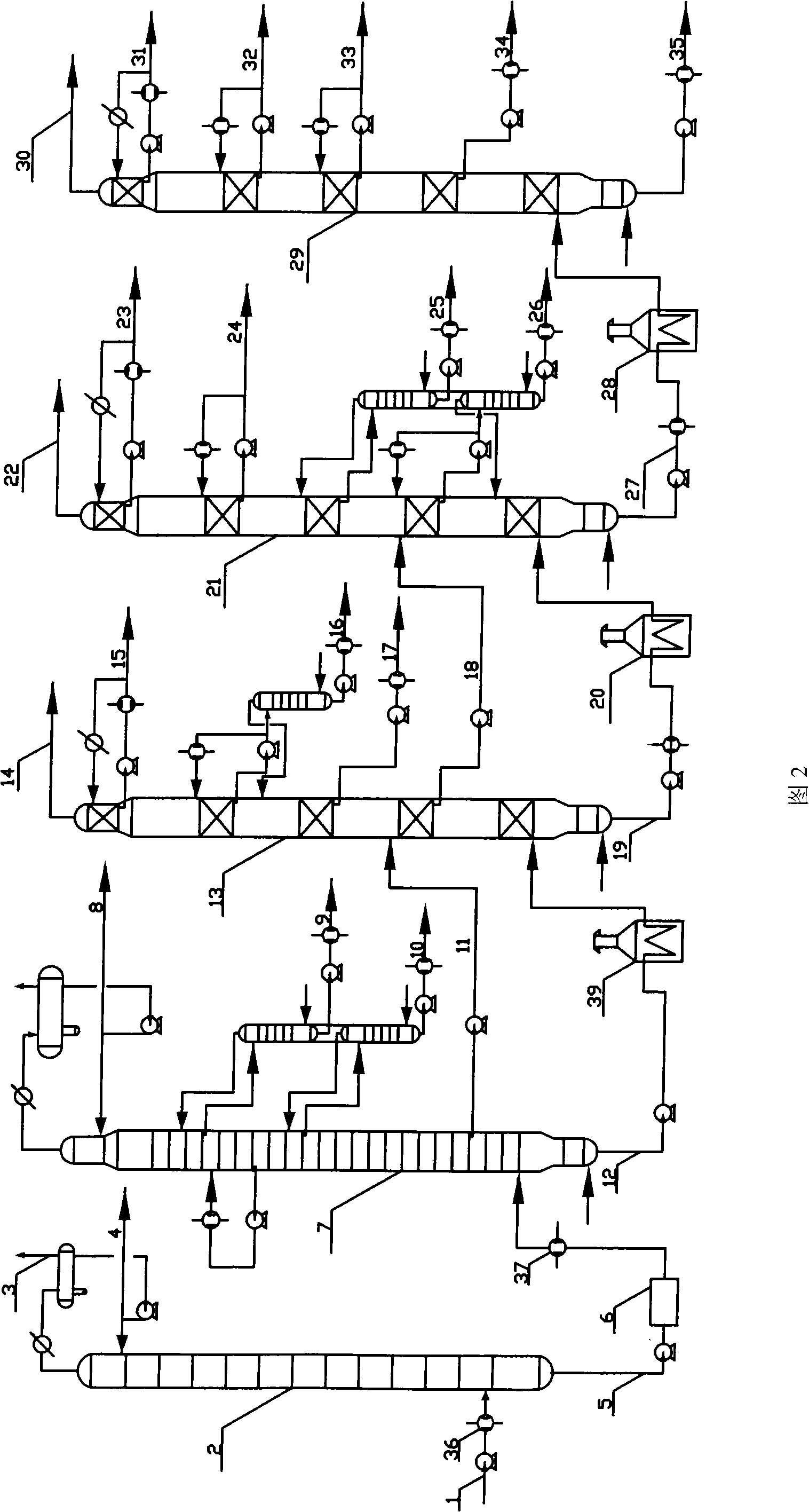

Isomerization method for light hydrocarbon

ActiveCN101497815AGuaranteed isomerization rateImprove liquid yieldRefining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationAlkaneIsomerization

The invention relates to a light hydrocarbon isomerization method. Isomerization reaction is performed for light hydrocarbon raw material in an isomerization reactor at the front part, gas-liquid separation is performed for the outlet stream of the reactor at the front part, the obtained liquid phase stream is separated in an isohexane removing tower, the overhead stream mainly comprising C5 cut fraction and dimethyl C6 alkane is mixed with the bottom stream mainly comprising C7 and cut fractions more than C7 so as to be used as isomate to enter into a gasoline stabilizer, the side stream mainly comprising C6 n-alkane and monomethyl C6 alkane is led into an isomerization reactor at the rear part; after the reaction stream of the isomerization reactor at the rear part is separated, the liquid phase stream all returns and is mixed with the liquid phase stream of a gas-liquid separator of the isomerization reactor at the front part so as to be used as the feeding of the isohexane removing tower. The method has higher n-alkane isomerization ratio and greatly improves the octane number of the light hydrocarbons raw material because the C6 n-alkane basically realizes the full isomerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Crude oil gradual distillation energy saving apparatuses and technological process

The invention belongs to crude oil gradual distillation energy-saving equipment and a process method. According to a connecting mode of crude oil gradual distillation, the equipment comprises a flash distillation tower, a primary distillation tower, a primary decompression tower, a shallow decompression tower and a deep decompression tower; an electrical desalting device and a heat exchange network are arranged between the flash distillation tower and the primary distillation tower; a heat exchange network or a primary decompression furnace is arranged between the primary distillation tower and the primary decompression tower; a shallow decompression furnace is arranged between the primary decompression tower and the shallow decompression tower; and a deep decompression furnace is arranged between the shallow decompression tower and the deep decompression tower. Through gradual heating, crude oil is gradually heated to be close to the condensed temperature and vaporized so as to substantially reduce the nonreversibility of heating and cooling; simultaneously, as light components are gradually drawn out, the residual materials can realize vaporization under the lower pressure; therefore, the materials can enter the decompression and distillation stage after passing through the primary distillation tower; the gradual decompression technology of primary decompression, shallow decompression and deep decompression is adopted to reduce the heating temperature of raw materials, lighten the load of a heating furnace and remarkably improve the processing capacity of the system.

Owner:TIANJIN UNIV

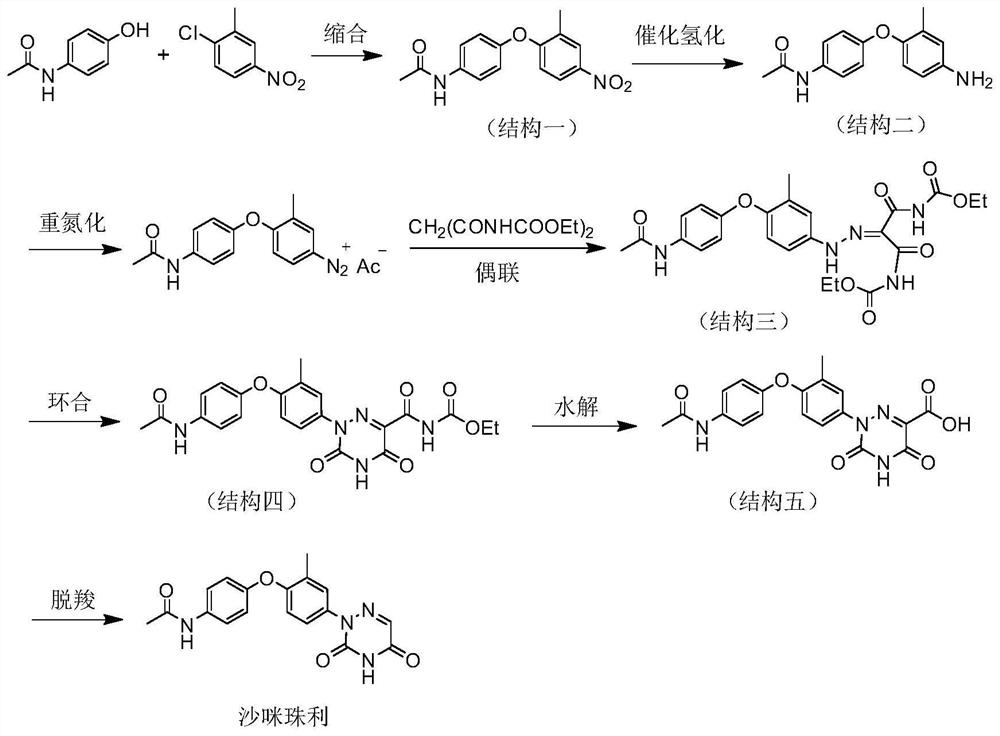

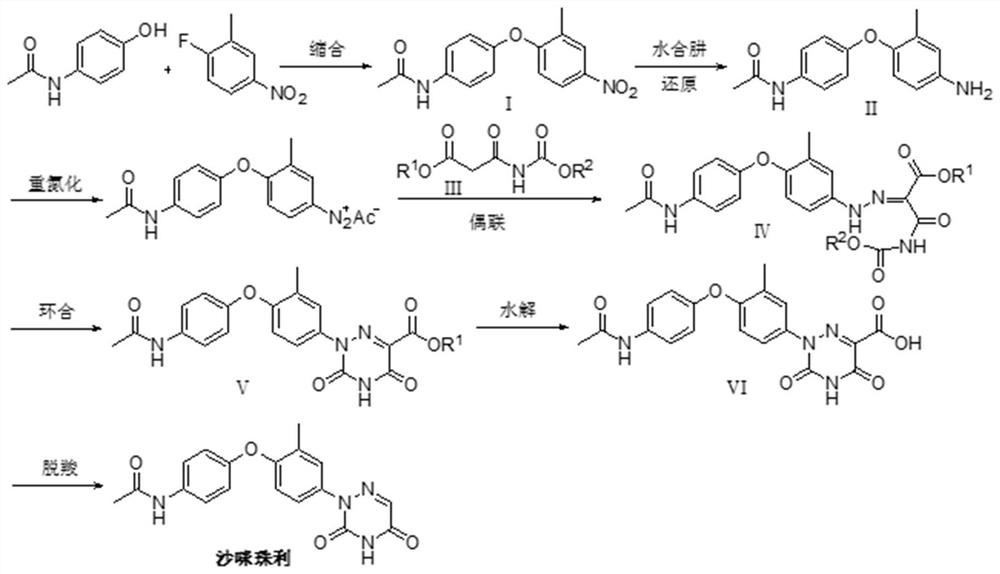

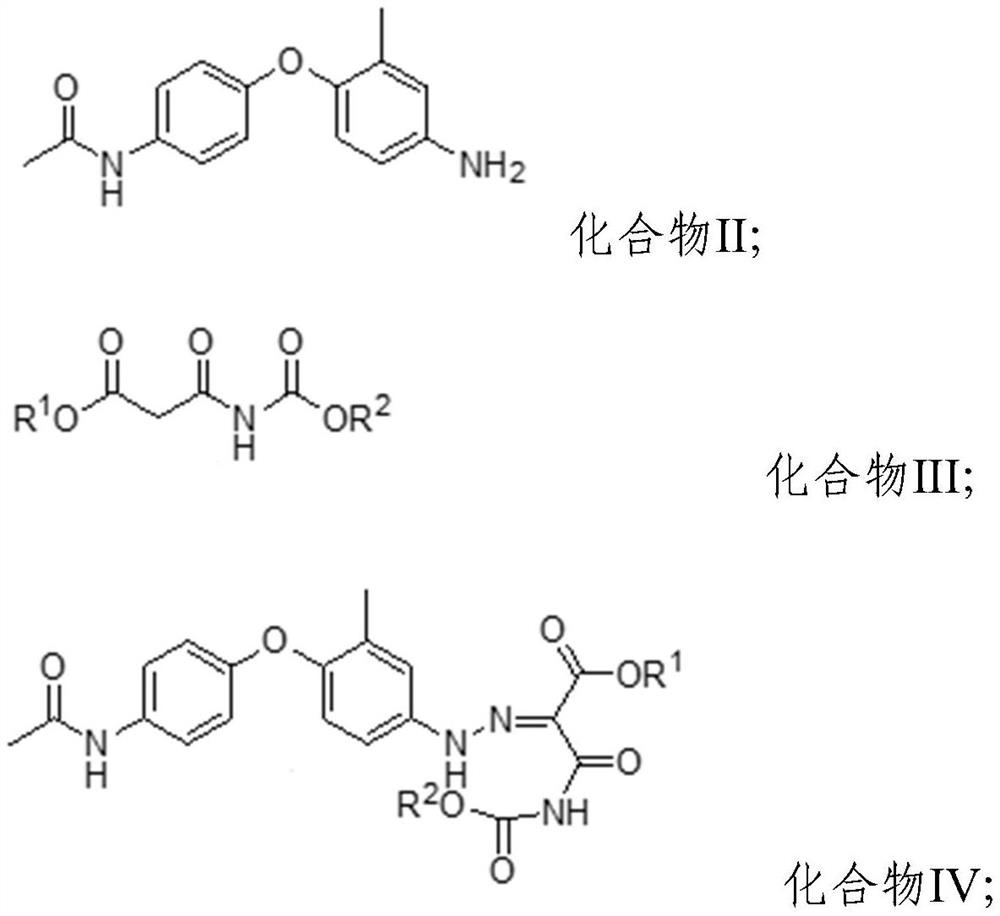

Preparation method of Ethanamizuril bulk drug

The invention provides a preparation method of a Ethanamizuril bulk drug, which comprises the following steps: reacting acetaminophen and 2-fluoro-5-nitrotoluene as initial raw materials to obtain a compound II, and carrying out diazotization coupling reaction to obtain a compound IV, wherein the conjugate adopted in the diazotization coupling reaction is a compound III. According to the preparation method of the Ethanamizuril bulk drug, malonic acid monoester monoamide formate is used as a conjugate, acetaminophen and 2-fluoro-5-nitrotoluene are used as initial raw materials, construction ofa triazine ring can be realized more efficiently and mildly, and the obtained target product samipril is higher in yield and purity.

Owner:HUBEI ZHONGMU ANDA PHARMACEUTICAL CO LTD +1

Light hydrocarbon isomerization method

ActiveCN101544905BIncrease the rate of isomerizationGuaranteed isomerization rateHydrocarbon by isomerisationRefining to change hydrocarbon structural skeleton2-methylbutaneIsomerization

Owner:CHINA PETROLEUM & CHEM CORP +1

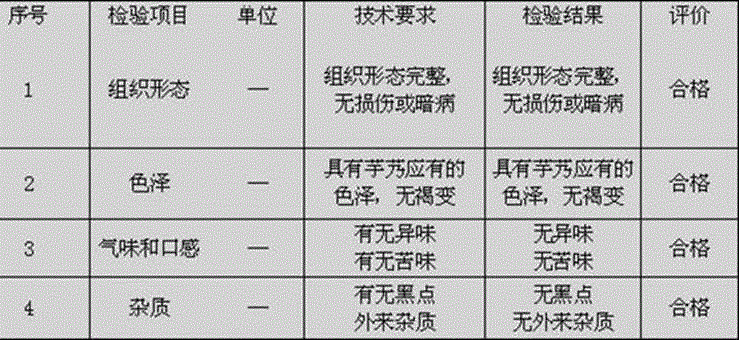

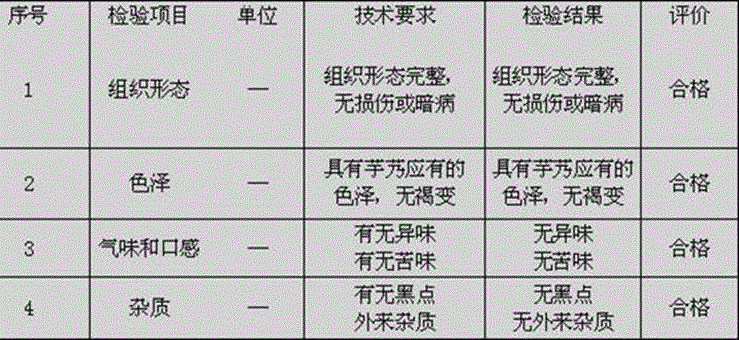

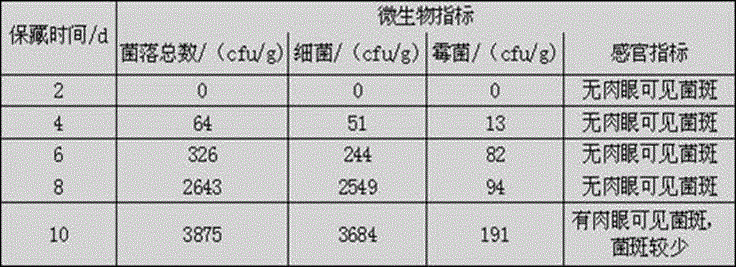

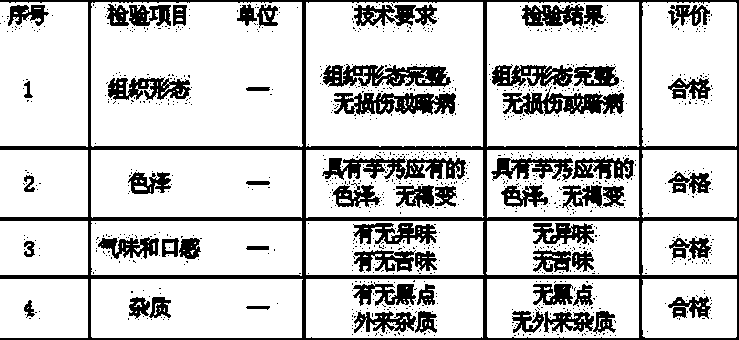

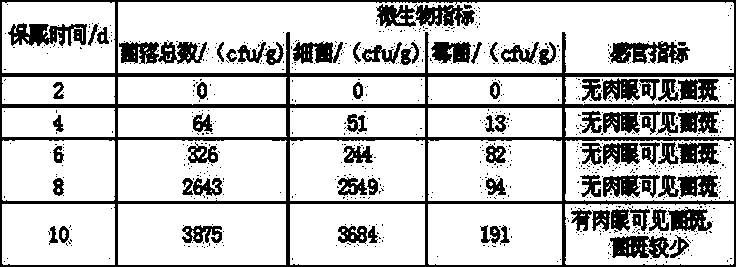

Method for rapidly peeling taros

ActiveCN106174623AReduce dosageImprove efficiencyVegetable peelingTemperature differenceSalt solution

The invention discloses a method for rapidly peeling taros. The method is characterized by including the following specific steps of 1, ripening, wherein a salt solution is heated to 135 DEG C to 160 DEG C, the temperature is kept, and cleaned taros are put into the solution and boiled for 1 min to 3 min; 2, goffering, wherein the taros are rapidly bailed out, put into cold water and soaked for 1 min to 2 min, the temperature is rapidly reduced, it is prevented that taro curing layers are further increased, the huge temperature difference between the insides and the outsides allows peels of the taros to be rapidly wrinkled and fall off, and meanwhile the salt solution attached to the peels of the taros can be removed; peeling, wherein the taros enter a roller-type peeling machine through a conveying belt and are peeled, and the peeled taros are obtained. The method has the advantages that the peeling efficiency is high, losses are small, environment pollution is reduced, the operation cost is low, and the surfaces are smooth and not prone to browning after peeling.

Owner:NINGBO UNIV

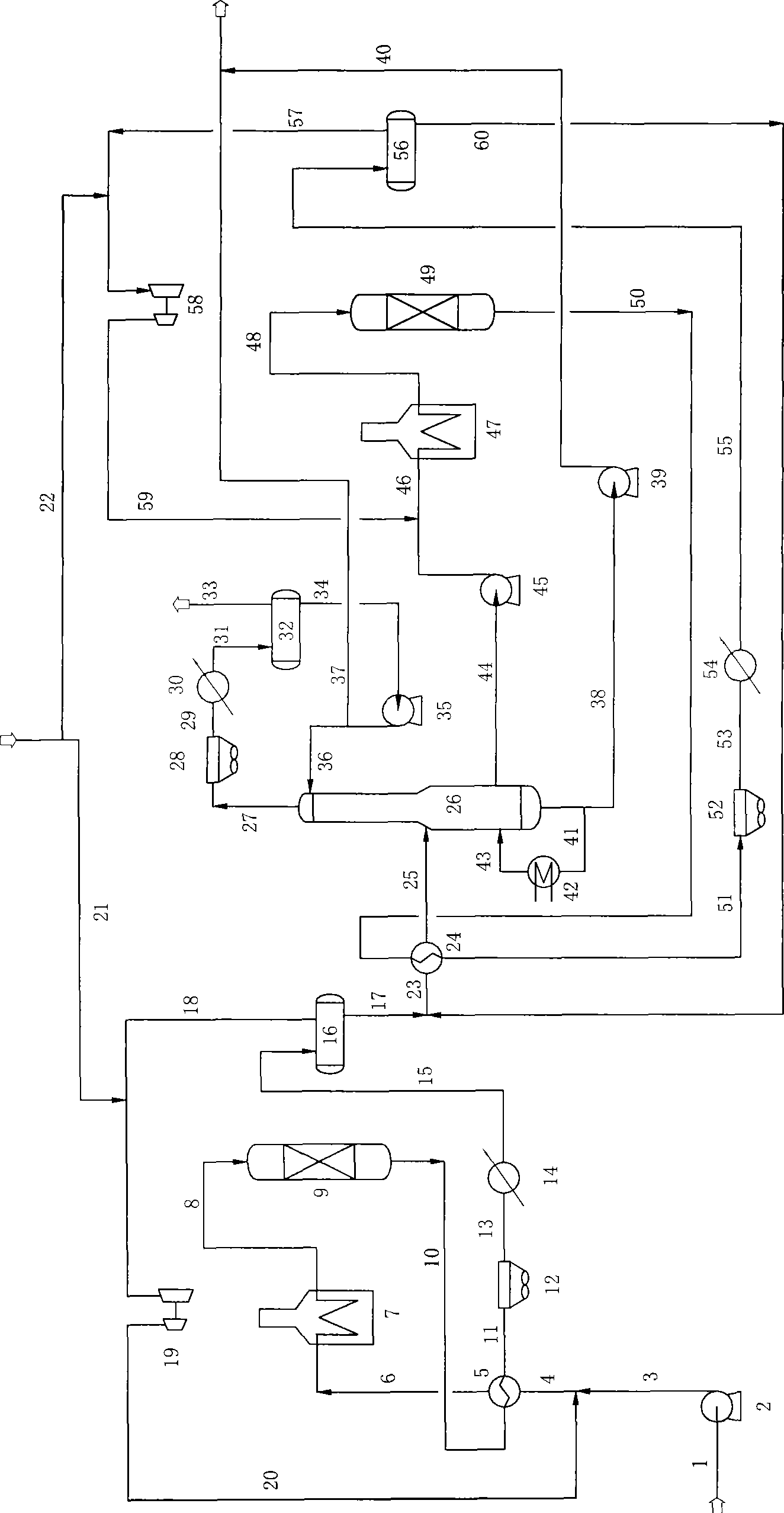

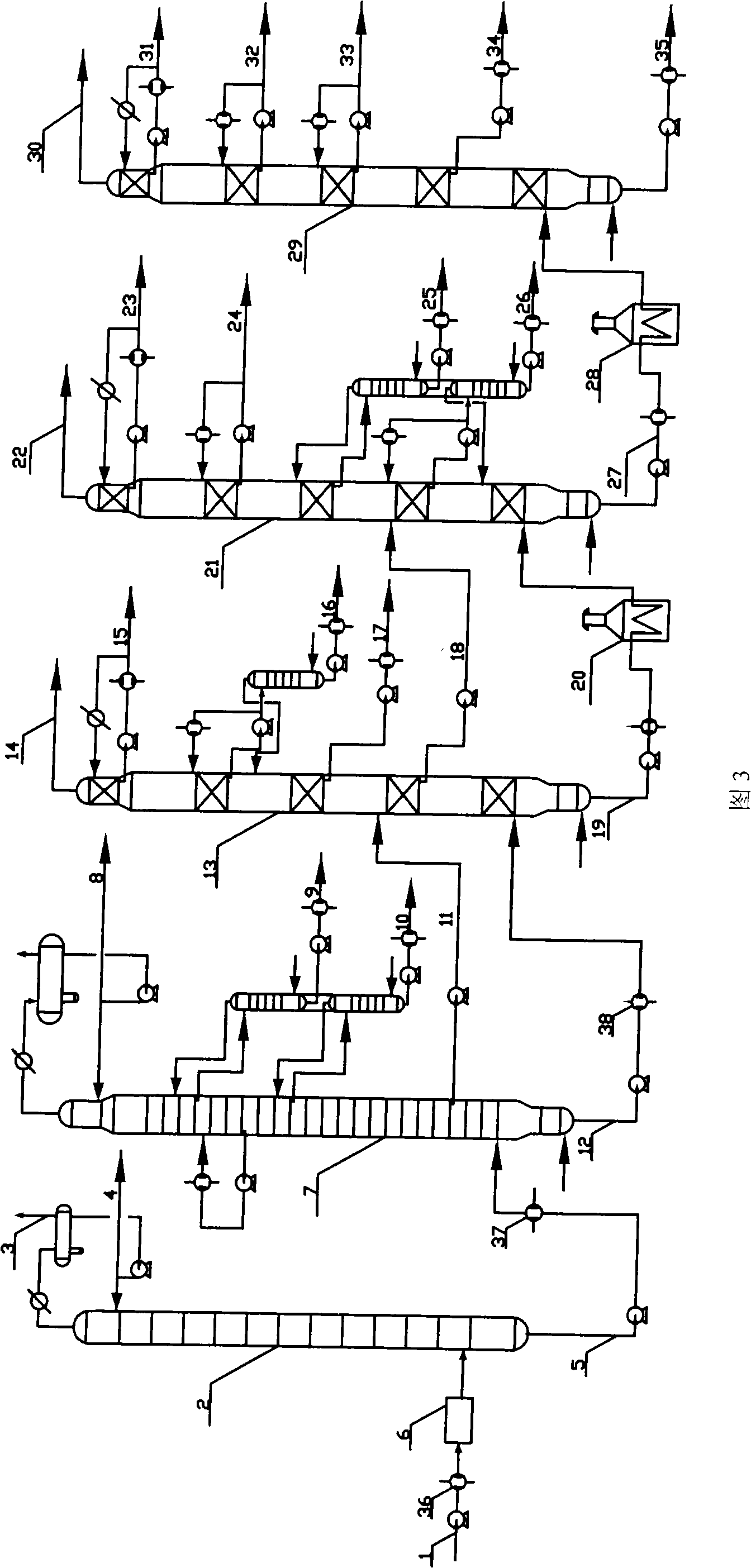

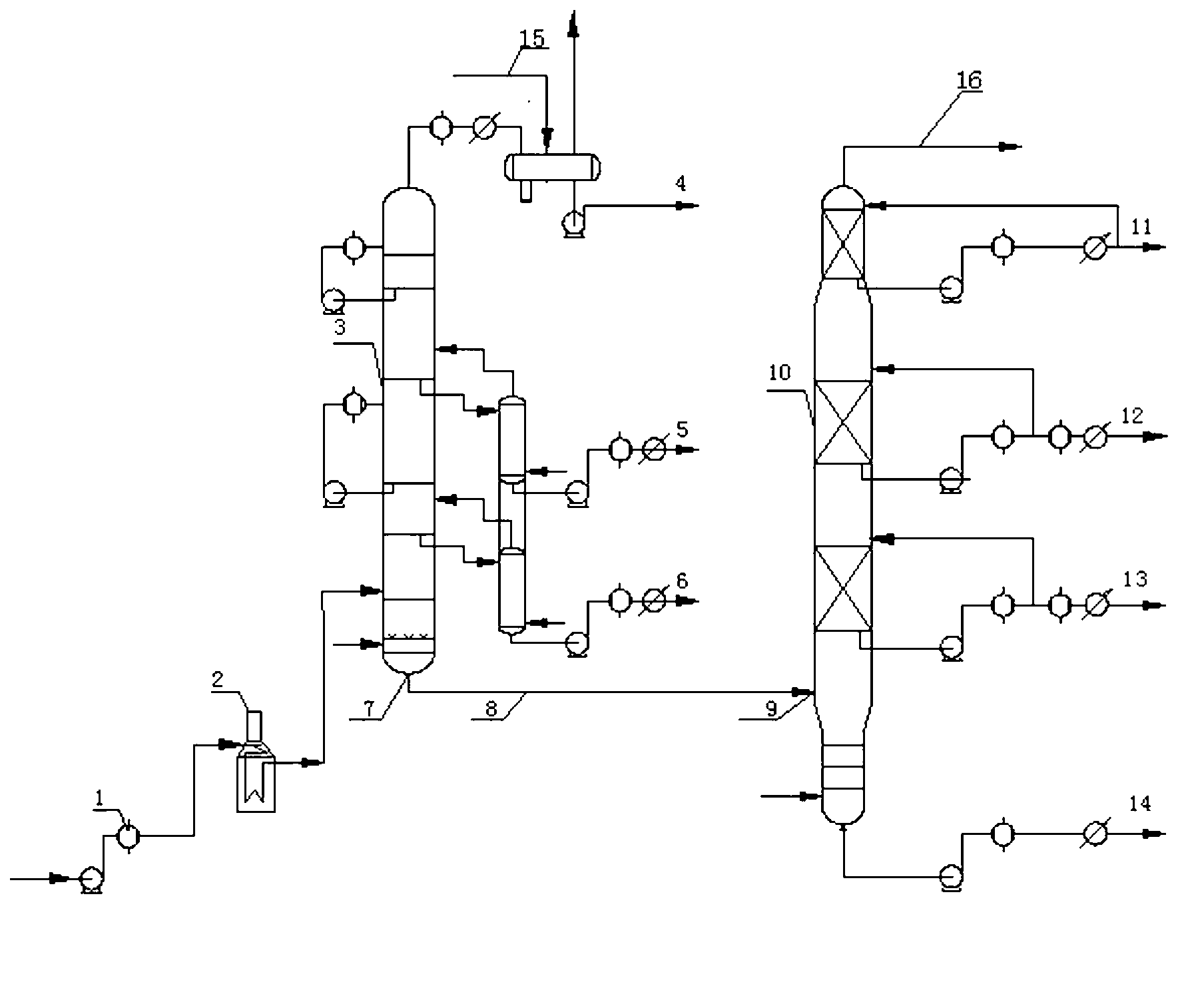

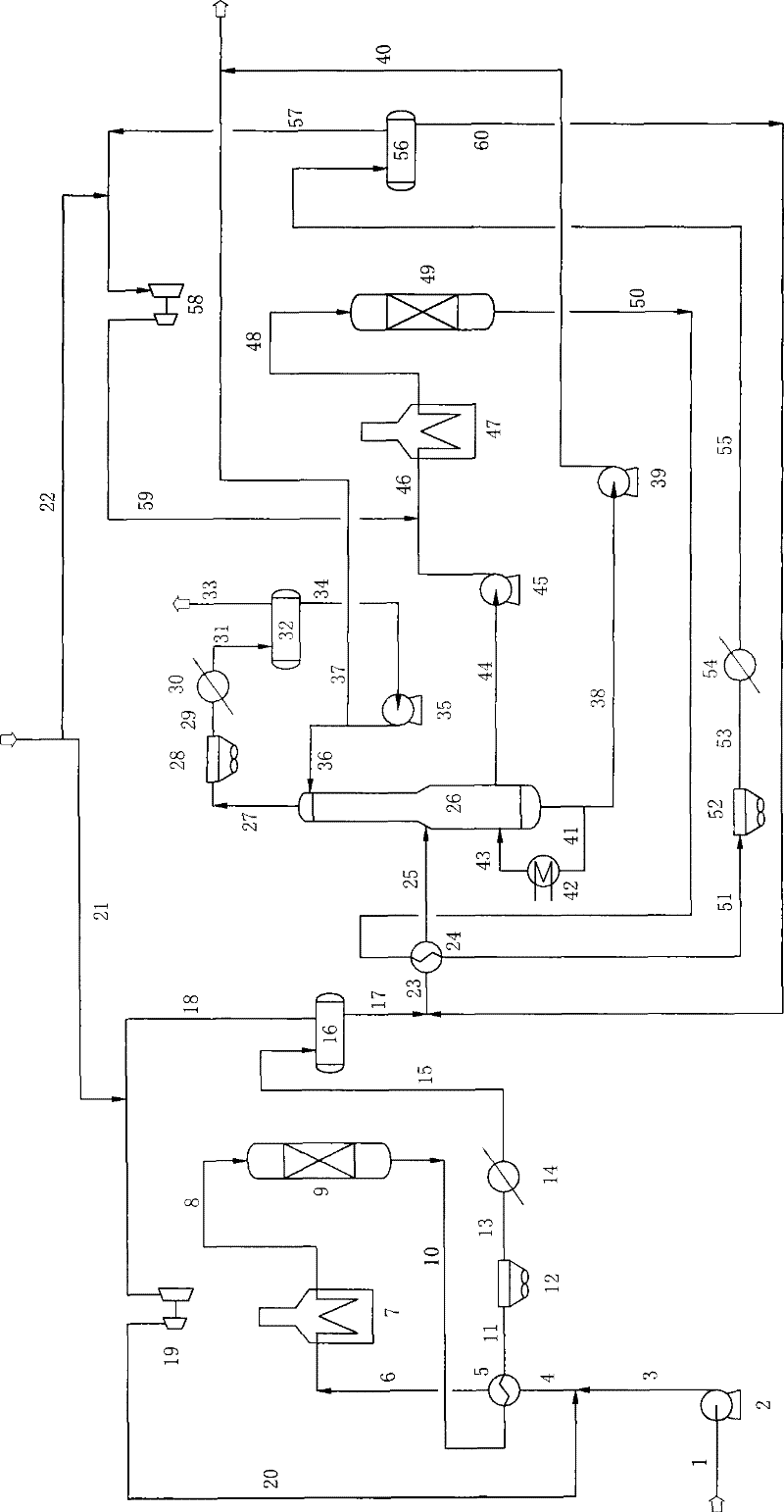

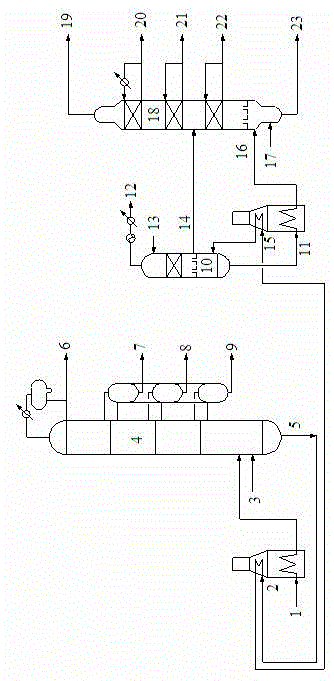

Vacuum distillation method for gradual gasification segmented feed

ActiveCN103059918AIncrease gasification rateRelieve pressureTreatment with plural serial refining stagesFluid phaseProcess engineering

The invention discloses a vacuum distillation method for gradual gasification segmented feed. The method includes: making atmospheric tower bottom oil enter a first stage gasification furnace, conducting heating to make the tower bottom oil enter a first stage flash tank to perform separation, leaving a gas phase to enter an upper fractionation segment of a vacuum tower, and leaving a liquid phase to enter a second stage gasification furnace; heating the liquid phase and making it enter a second stage flash tank, letting the generated gas phase enter a middle fractionation segment of the vacuum tower, and letting the generated liquid phase enter a third stage gasification furnace; heating the liquid phase and making it enter a third stage flash tank, letting the generated gas phase enter a lower fractionation segment of the vacuum tower, and letting the generated liquid phase enter a flash segment of the vacuum tower; and subjecting the feed of each segment to vacuum distillation in the vacuum tower, extracting a lateral line product from a vacuum tower lateral line, and extracting vacuum residue from the tower bottom. The method provided in the invention can substantially enhance the distillate yield of a crude oil vacuum distillation process, reduce equipment energy consumption, increase equipment economic benefits, and save equipment investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

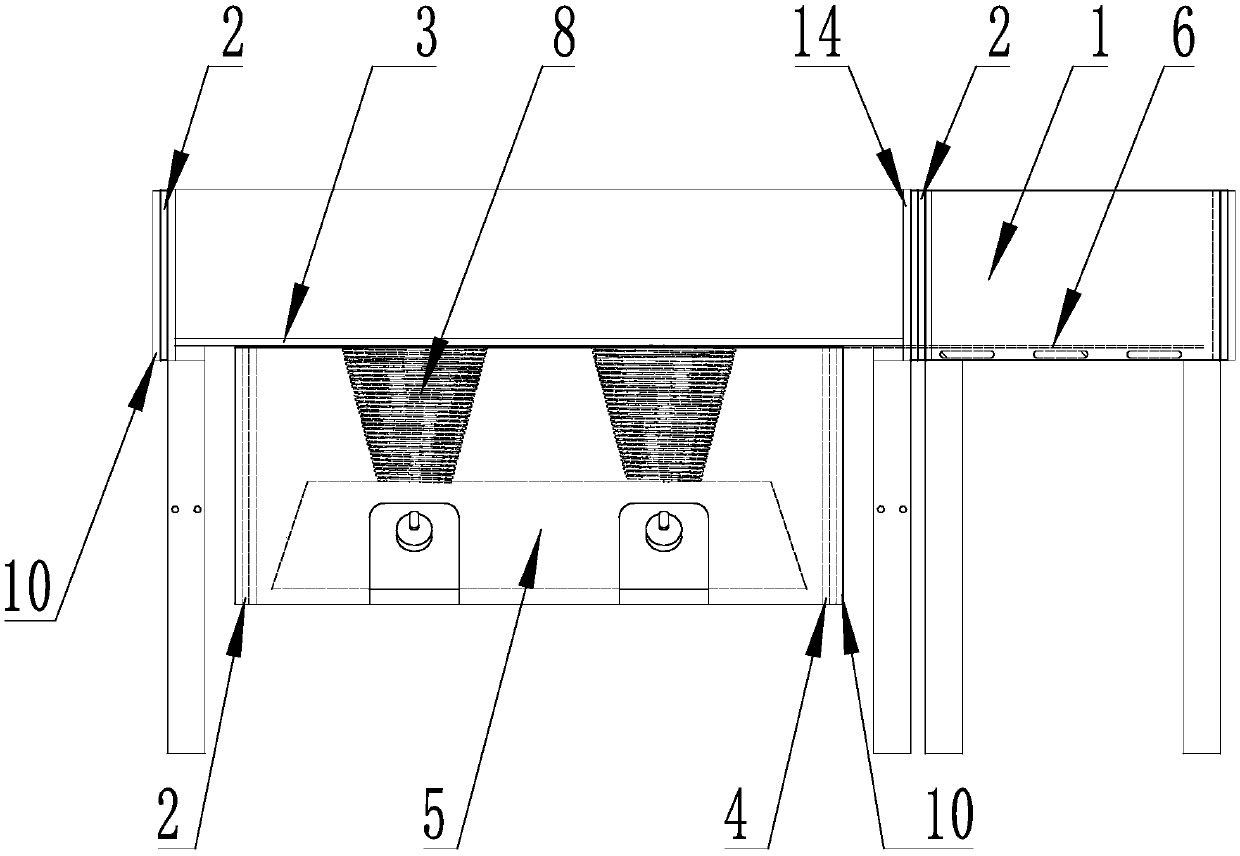

Teppanyaki electric vehicle based on thermoelectric power generation

PendingCN111096688AHigh interest rateGood effect of temperature difference power generationRoasters/grillsGenerators/motorsHeat conductingEngineering

The invention relates to a teppanyaki electric vehicle based on thermoelectric power generation. The teppanyaki electric vehicle comprises an iron plate heating device, an oil temperature heating device and a thermoelectric power generation sheet, the iron plate heating device is characterized in that the iron plate heating device comprises a heating iron plate and a surrounding plate surroundingthe periphery of the bottom of the heating iron plate; a heat source is arranged at the bottom of the heating iron plate; heat conducting wires are spirally wound around the heat source; the heat conduction wire extends into the oil temperature heating device, temperature difference power generation pieces are arranged on the periphery of the surrounding plate and the periphery of the oil temperature heating device and connected with a power source, the power source is connected with the oil temperature heating device, and the hot ends of the temperature difference power generation pieces arearranged inwards. The teppanyaki electric vehicle is high in heat utilization rate, good in temperature difference power generation effect, capable of generating power through heat radiation and heatconduction and capable of achieving self-circulation power generation.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

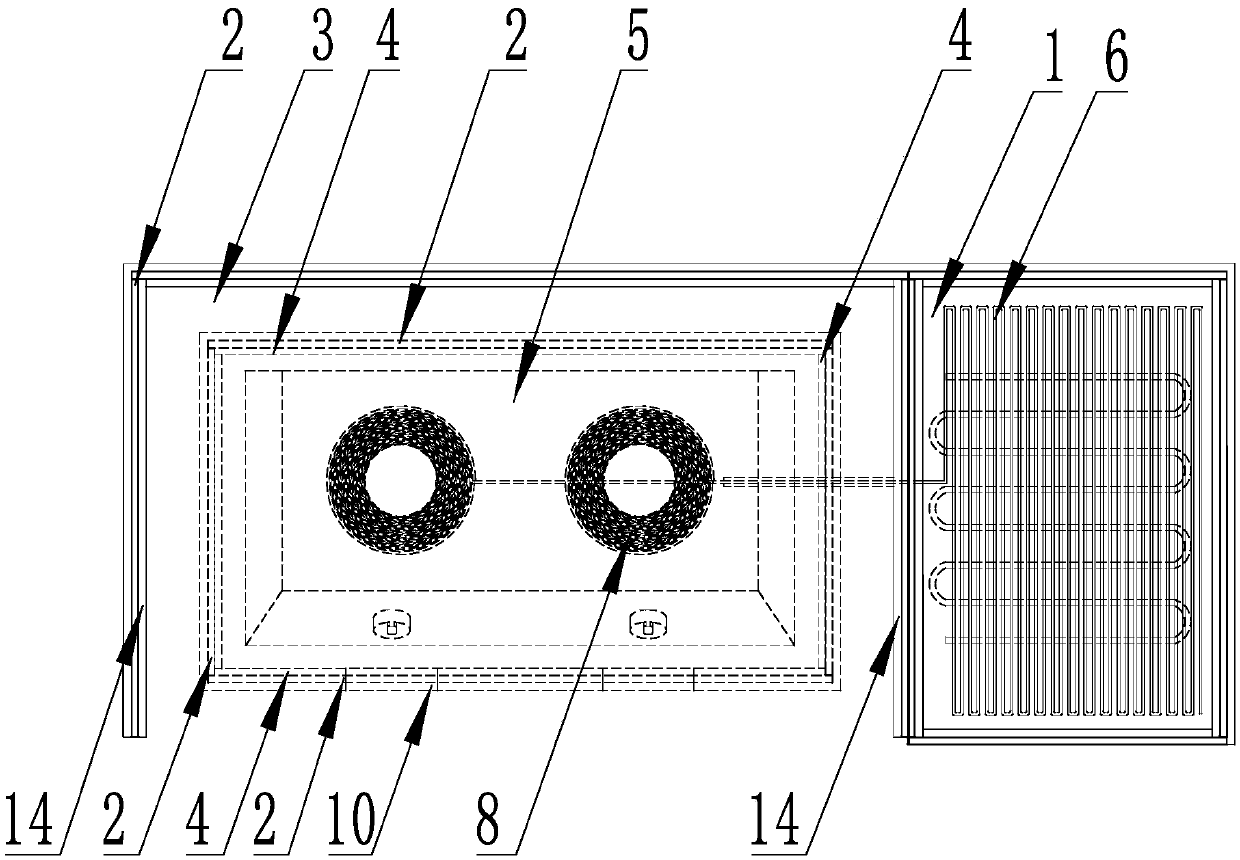

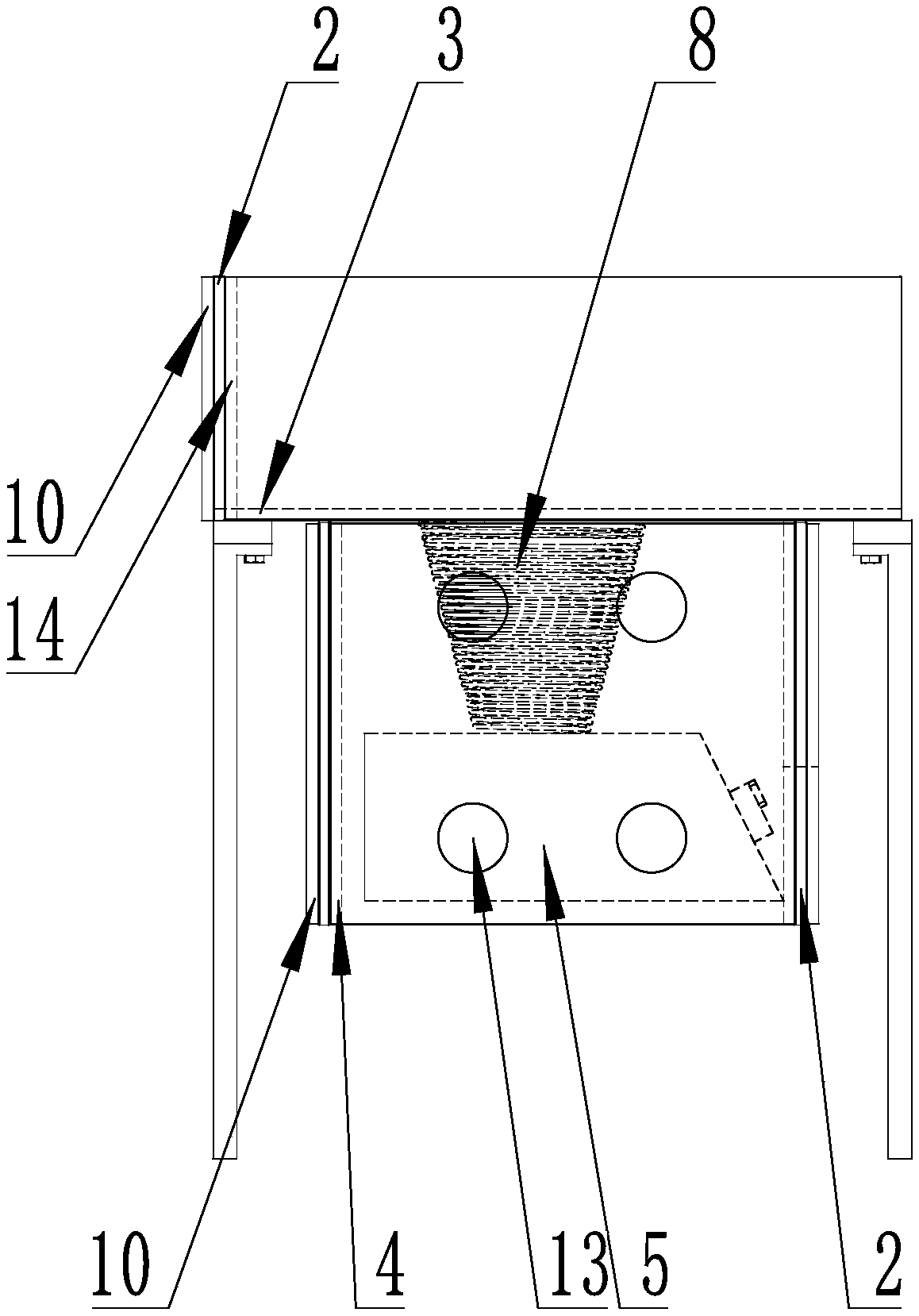

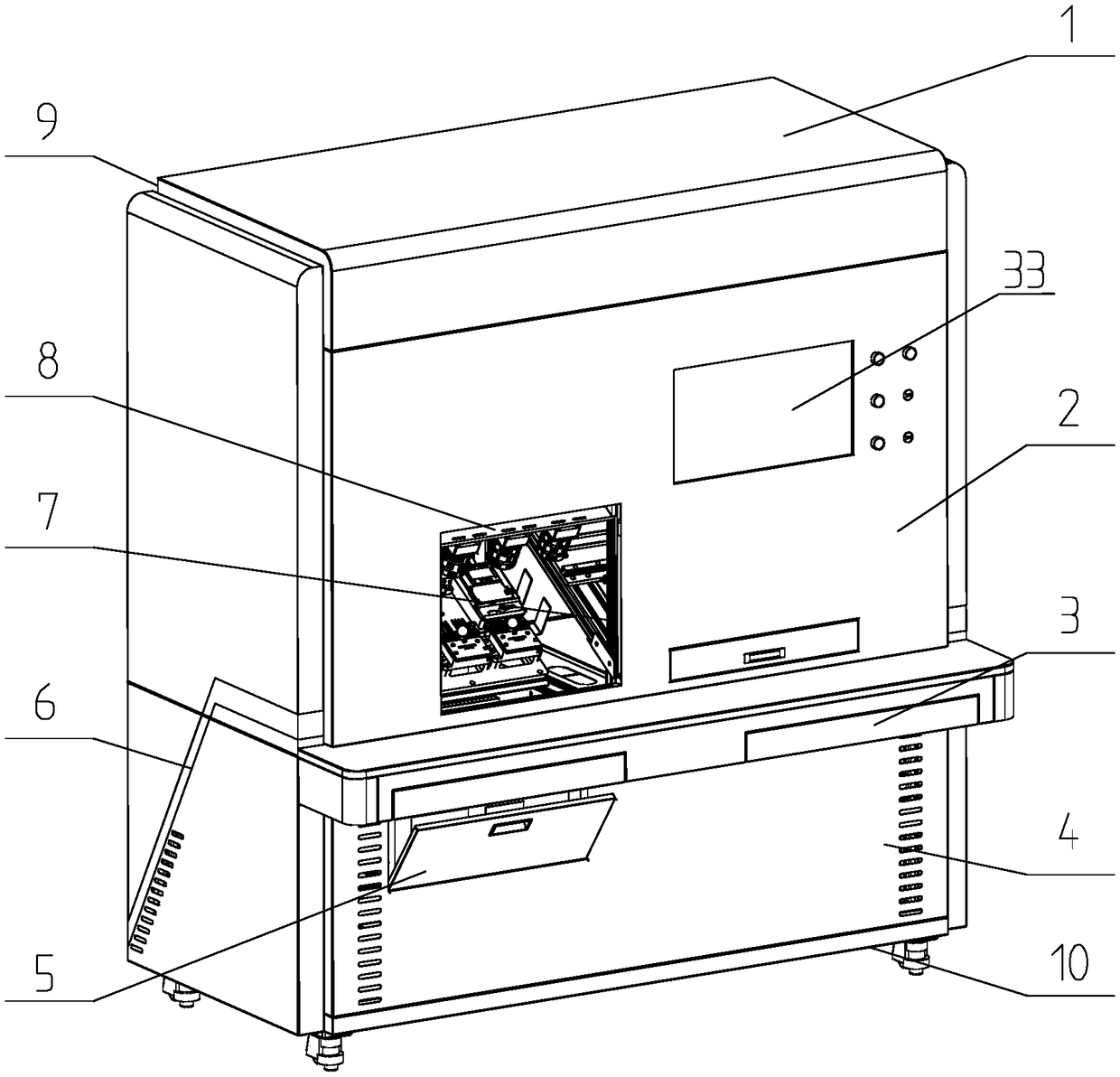

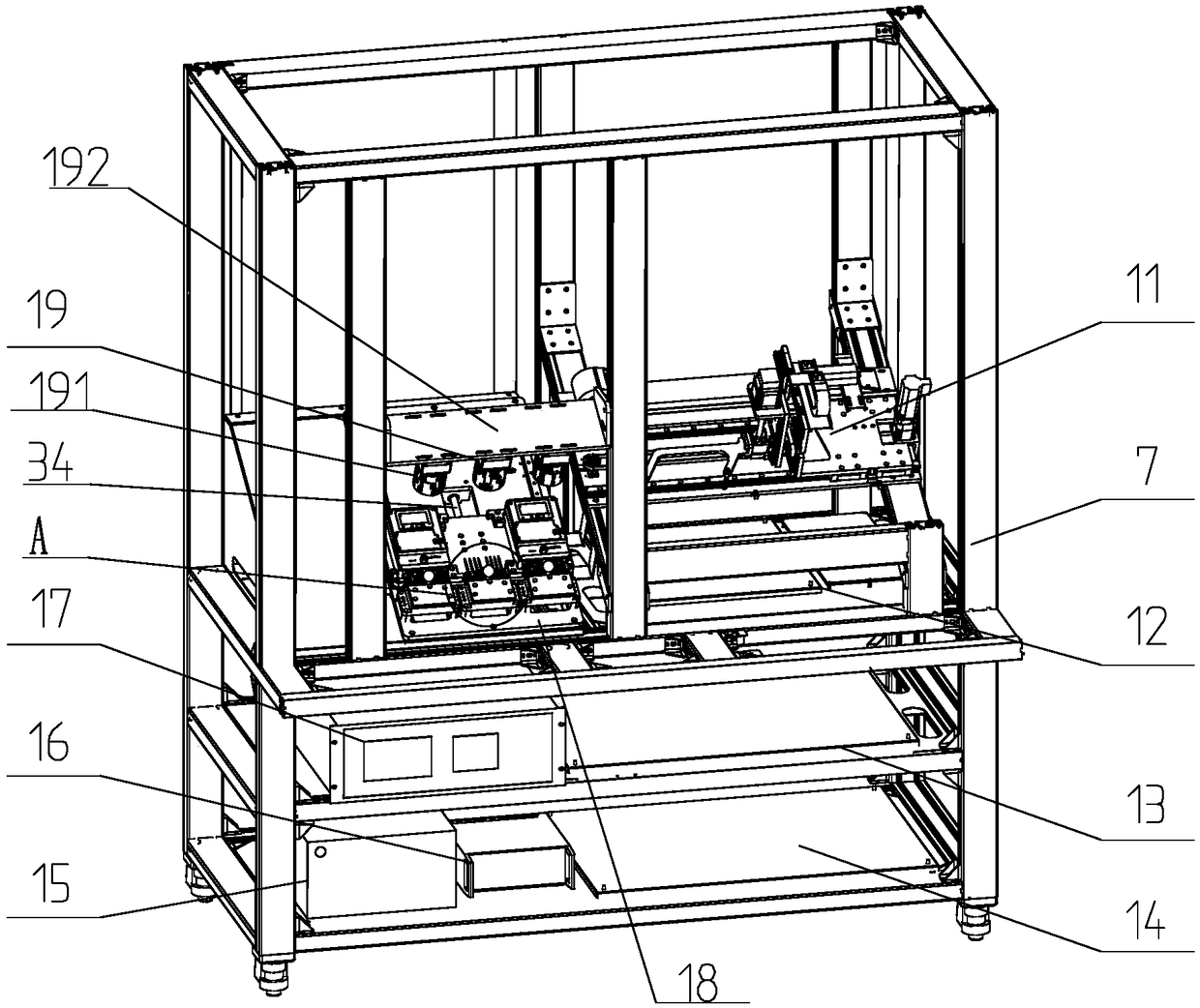

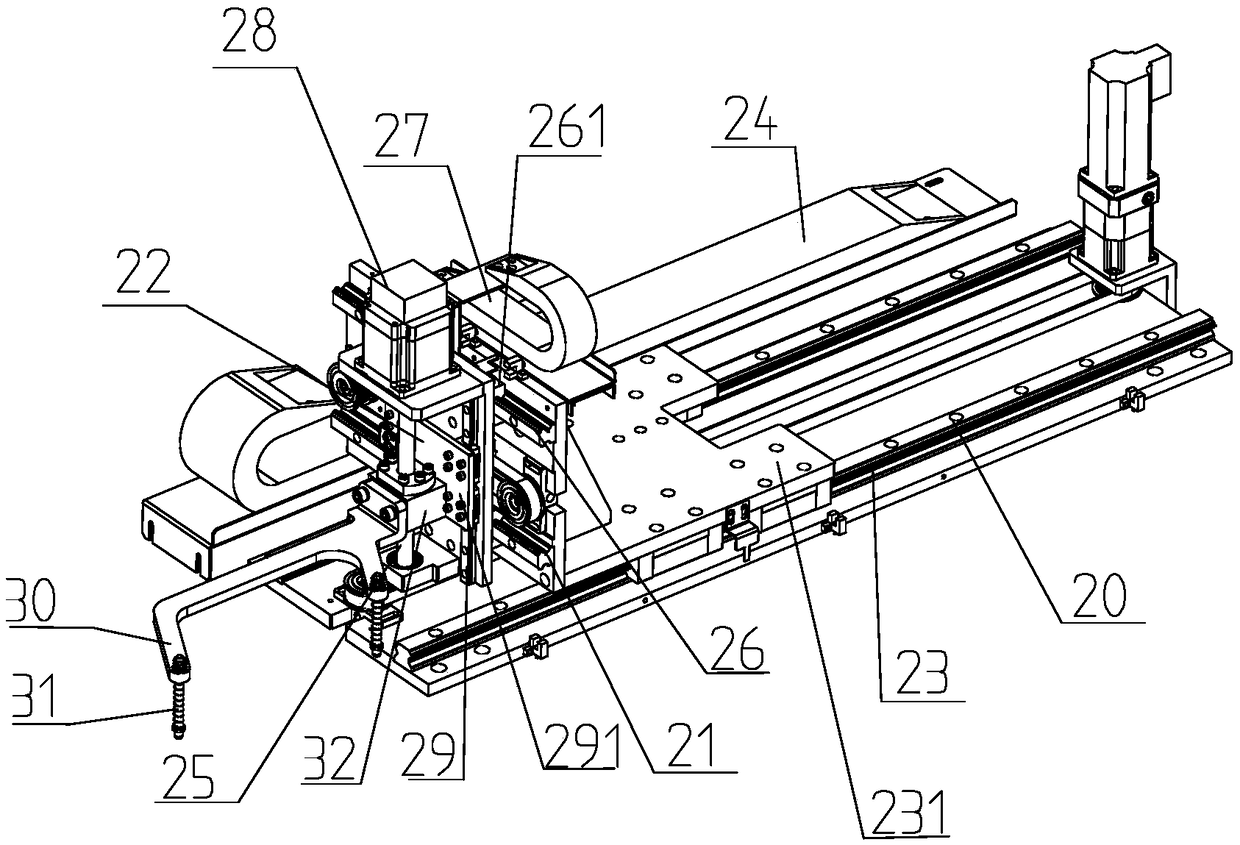

Device and method for intelligent sorting and checking of dismounted single-phase electric energy meters

ActiveCN109465208AImprove accuracyReliable and effective verification of sorting methodsSortingPersonal computerManipulator

The invention discloses a device and a method for intelligent sorting and checking of dismounted single-phase electric energy meters. The device comprises a frame; a checking module, a pressing module, an image identifying module and a mechanical screen overturning module are arranged in the frame; the checking module comprises a checking source, a forward and reverse meter detecting sensor, an industrial personal computer, a PLC and an isolation CT; the checking module is connected with a clock, and is connected with the industrial personal computer through a serial port wire; the forward andreverse meter detecting sensor is directly connected with the PLC; the pressing module comprises a pressing socket and an insertion pin; the pressing socket can move in the axial direction of the insertion pin; the image identifying module comprises an industrial camera; the industrial camera is connected with the PLC; and the mechanical screen overturning module comprises an XTZ three-axis manipulator. The device has the advantages of capability of finishing automatic checking and sorting of the dismounted electric energy meters, improvement of the sorting accuracy of the electric energy meters, improvements of the recycling rate of the dismounted single-phase electric energy meters and provision of more reliable and effective checking and sorting modes to electric power measuring properties.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD

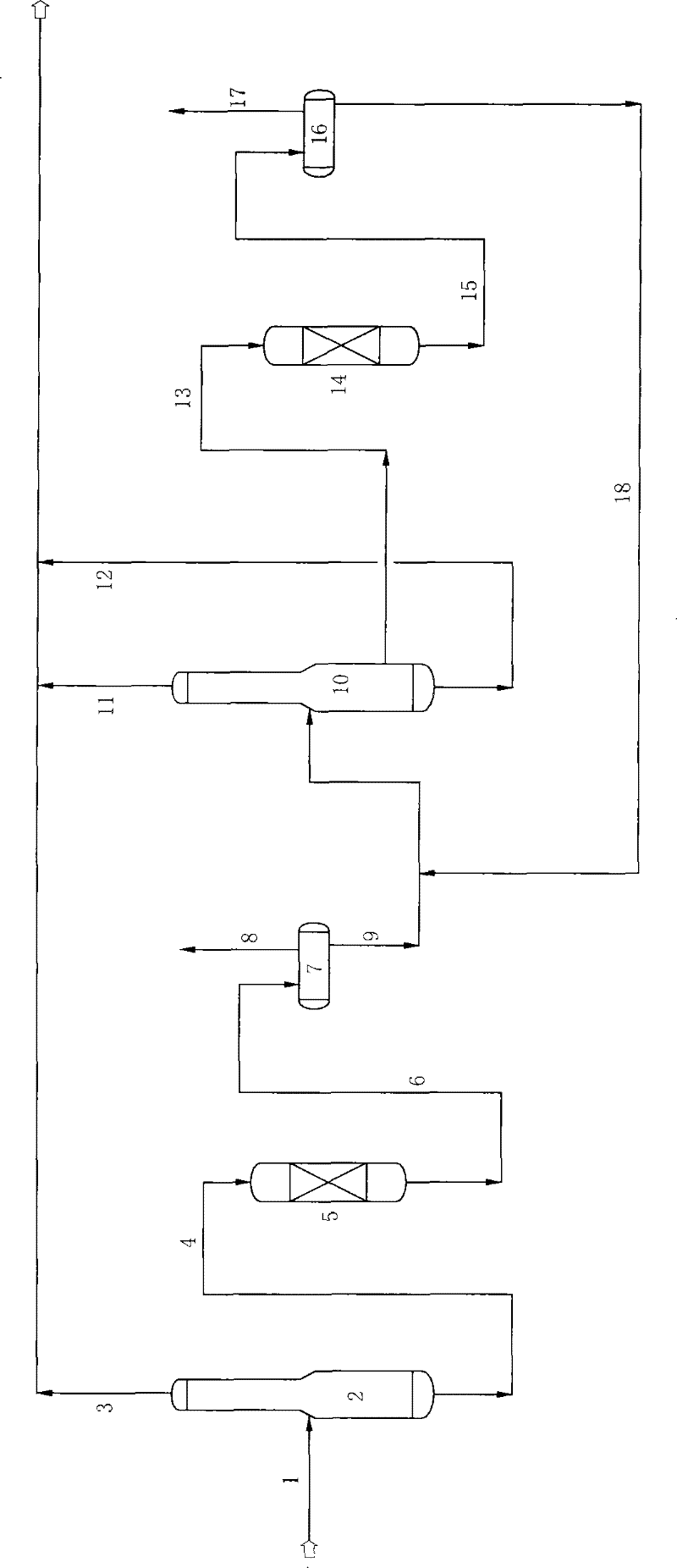

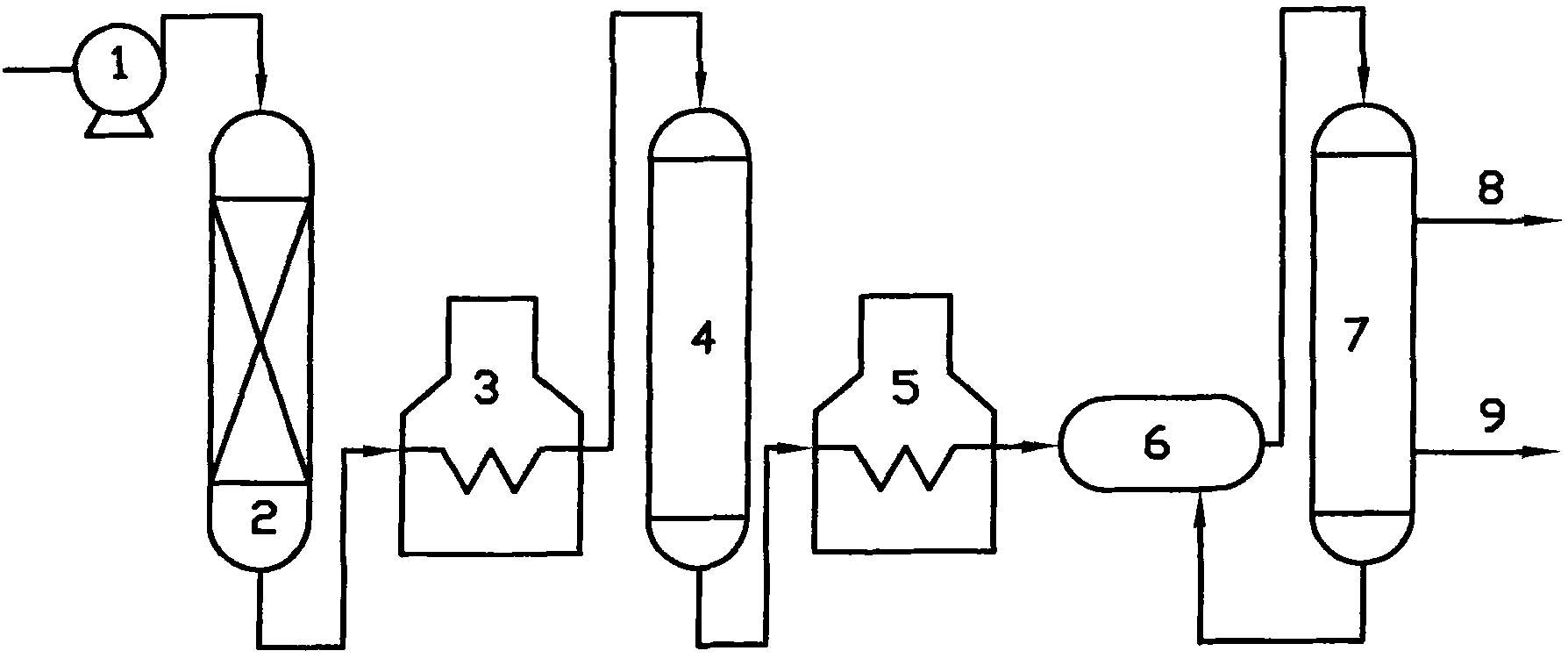

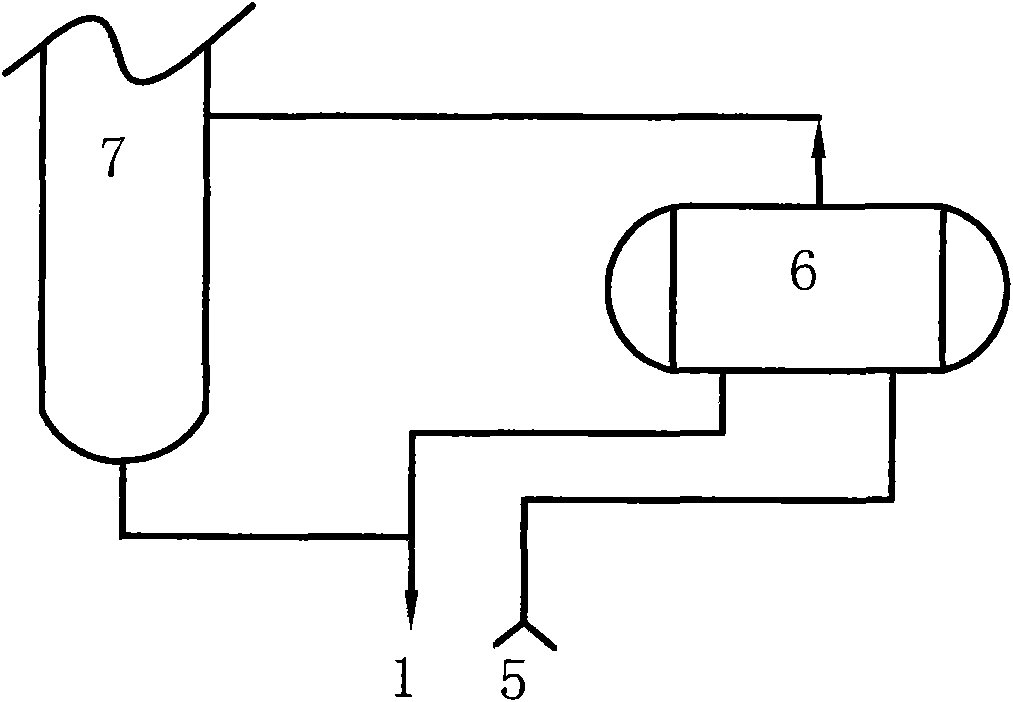

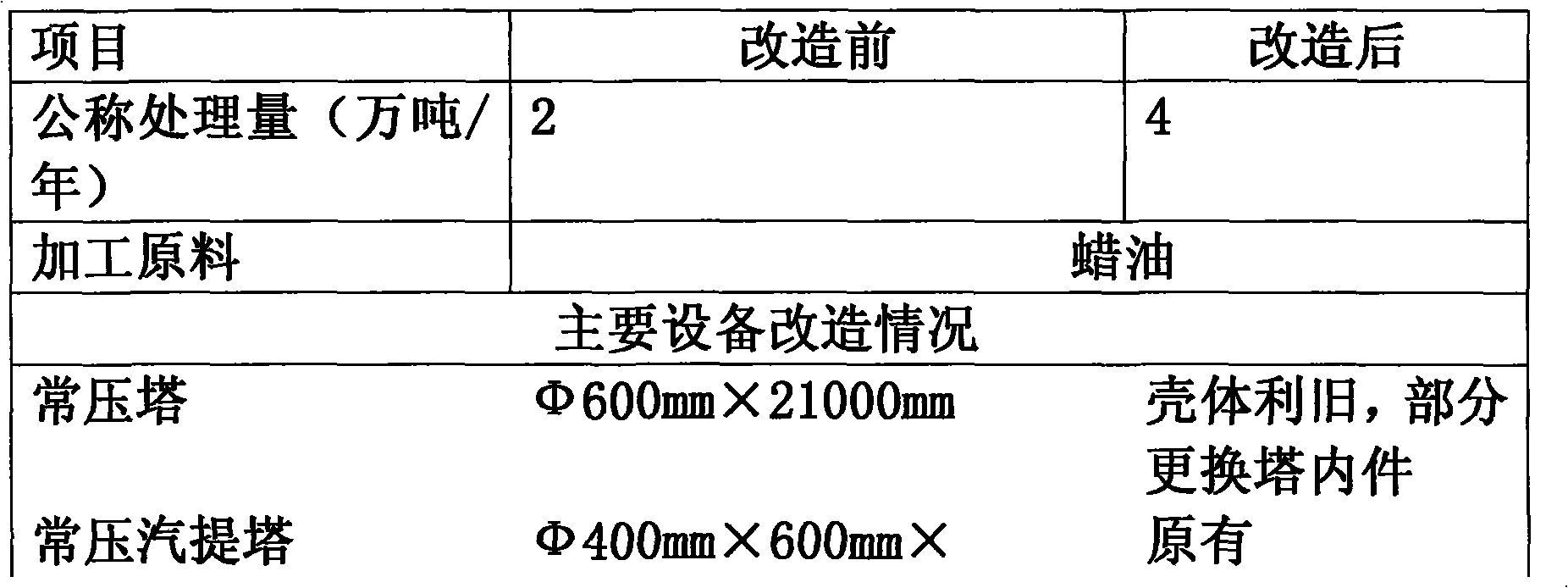

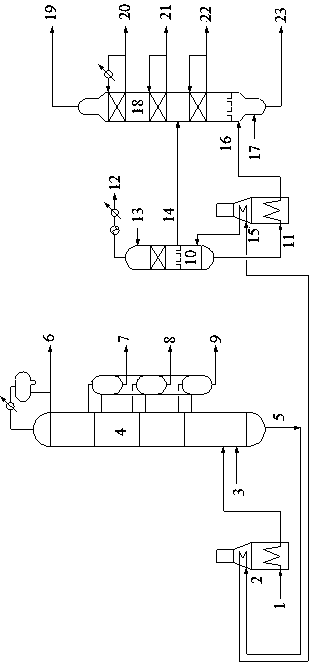

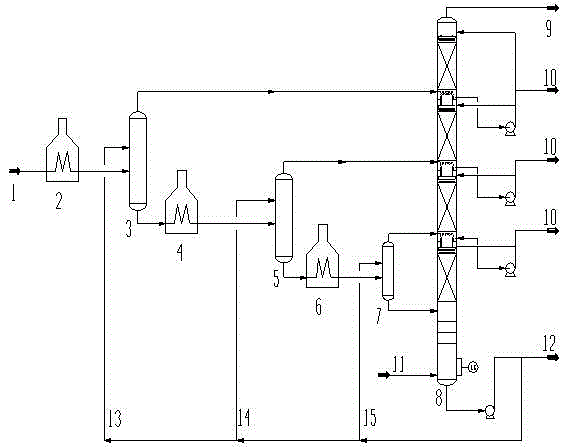

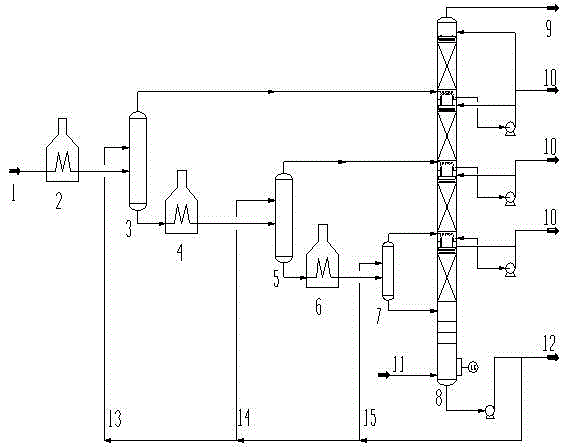

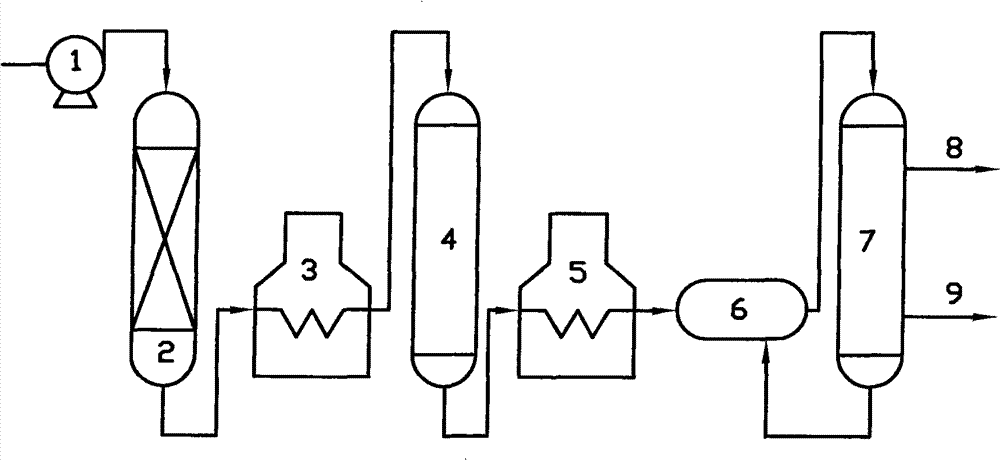

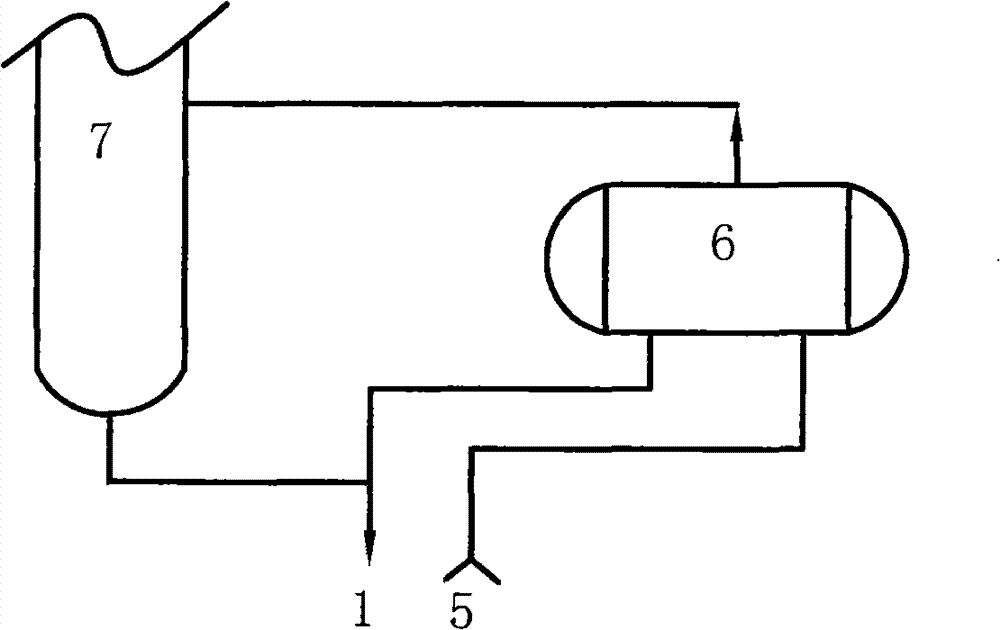

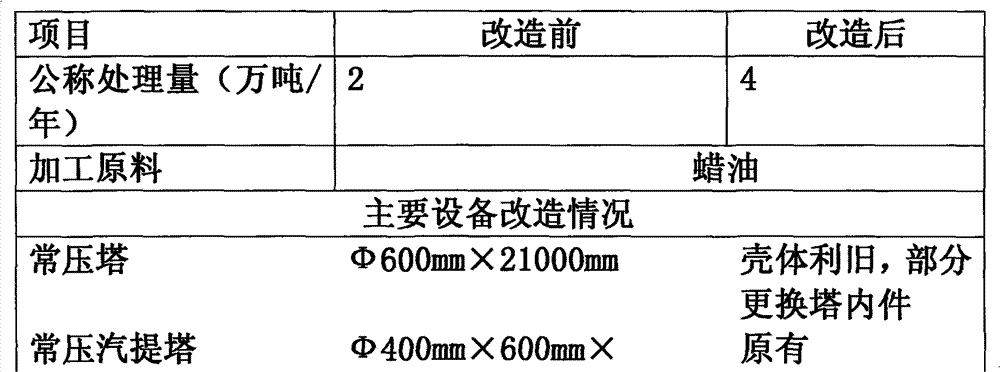

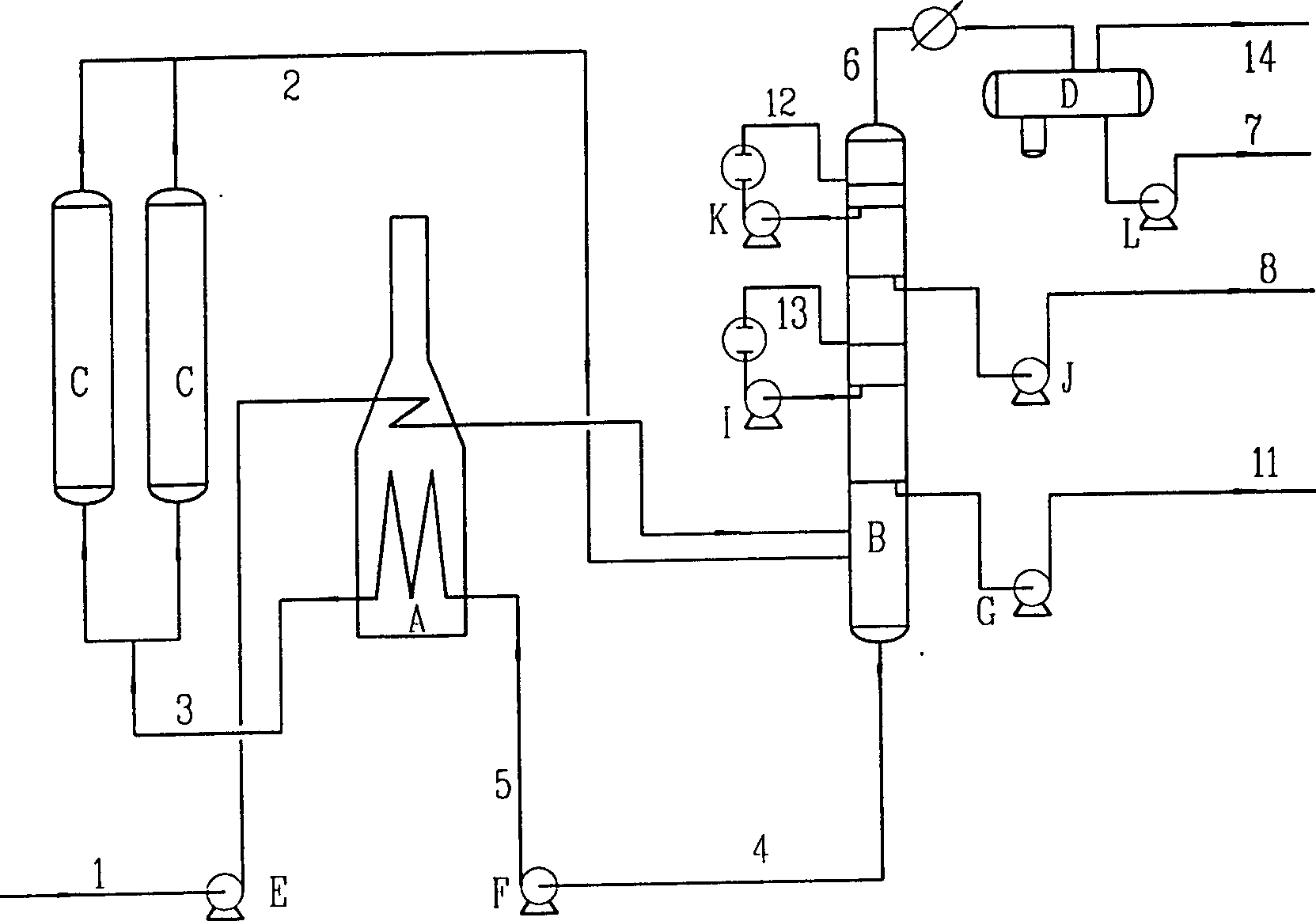

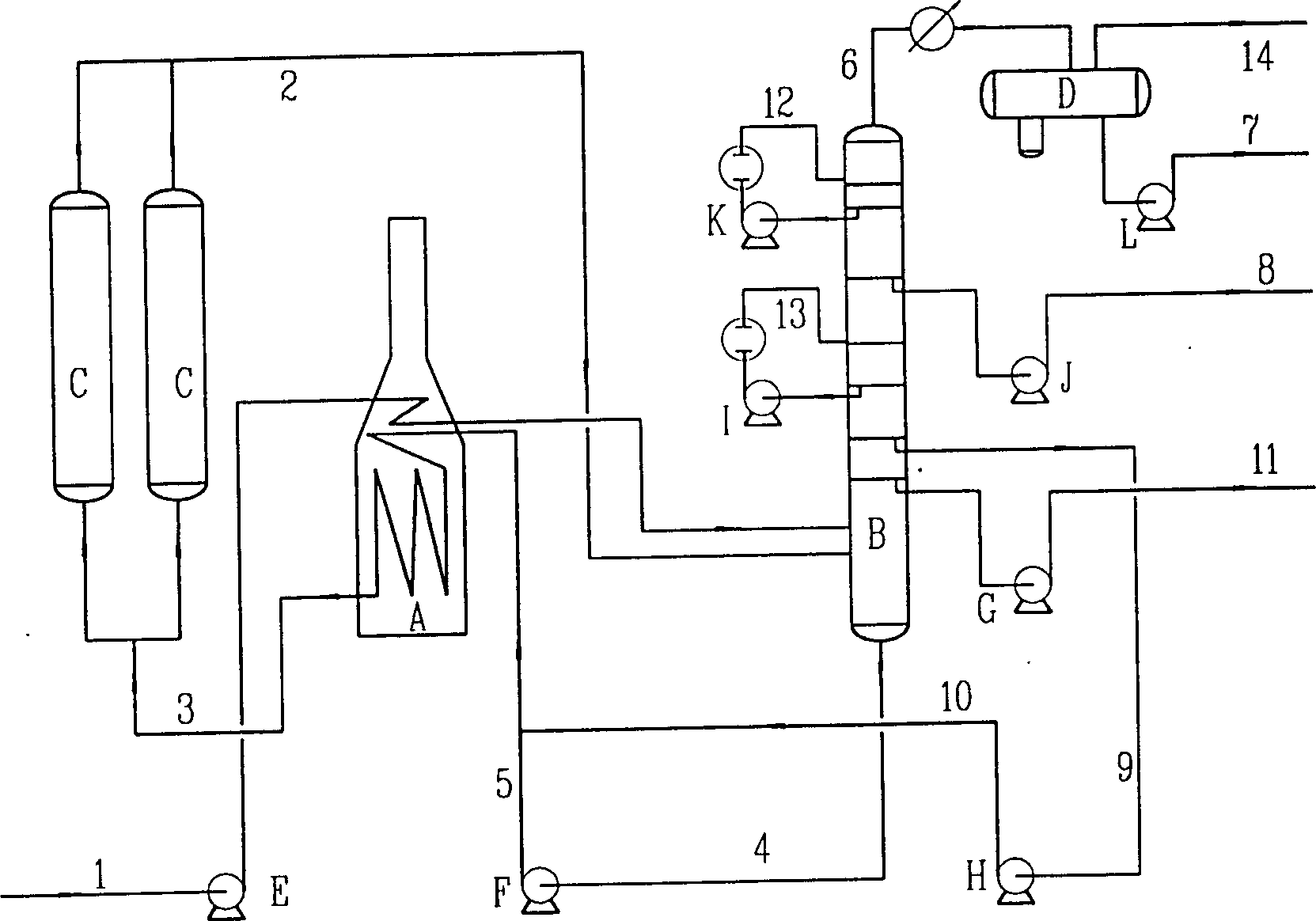

Non-hydrogen dewaxing depressurizing distillation process and device

InactiveCN101798526ADoes not damage the organizational structureHigh flash pointBase-materialsHydrocarbon oils treatmentWaxHydrogen

The invention discloses non-hydrogen dewaxing depressurizing distillation process and device. The process has the following steps of: using wax oil as the raw material, carrying out non-hydrogen dewaxing, atmospheric distillation, flash evaporation and depressurizing distillation, and then producing a lube base oil. The device comprises a raw material oil pump (1), a reactor (2), an atmospheric furnace (3), an atmospheric tower (4), a depressurizing furnace (5), a flash evaporating tank (6) and a depressurizing tower (7). The depressurizing tower is provided with a side line, and the lube base oil can be pumped from the side line. The heavy lube base oil can be pumped from the bottom of the depressurizing tower. When used for reforming the old device, the invention has the advantages of high utilization rate of the old equipment, investment saving, large operation flexibility and short idle time, obviously enhances the production separation effect, and optimizes the product quality.

Owner:新疆五家渠现代石油化工有限公司

Different pressure distillation apparatus and process method

InactiveCN103224806AReduce pump shaft powerReduce total pressure dropHydrocarbon distillationExchange networkPetrochemical

The invention belongs to the field of petrochemical industry, and provides a different pressure distillation apparatus and a process method. The different pressure distillation apparatus main body comprises a pressure increase tower and a pressure reduction tower, wherein a tower bottom oil outlet of the pressure increase tower and a material inlet of the pressure reduction tower are connected through a communication pipeline, and the tower bottom oil outlet is higher than the material inlet. During a different pressure distillation process, raw material oil is heated to a set temperature through a heat exchange network and a heating furnace, and then enters the pressure increase tower, a light distillate oil product is extracted, the tower bottom oil enters the pressure reduction tower through the communication pipeline in a nature flow manner by adopting pressure difference and liquid level difference of the pressure increase tower and the pressure reduction tower, a heavy distillate oil product is extracted, and heavy oil or residue oil is extracted through bottom reduction. Compared to atmospheric and vacuum distillation, the crude oil different pressure distillation has the following characteristics that: the light component is sequentially subjected to vaporization and condensation under pressure increase and pressure reduction operation conditions so as to substantially reduce a crude oil heating temperature, reduce heating, reduce energy consumption, improve an extraction rate, and improve oil product quality; and compared to atmospheric and vacuum distillation, the heavy oil different pressure distillation has the following characteristics that: the light component in the heavy oil is extracted through the pressure increase tower so as to substantially reduce a vapor phase load of the pressure reduction tower, reduce energy consumption, and improve an extraction rate.

Owner:PANJIN XINGDA ASPHALT

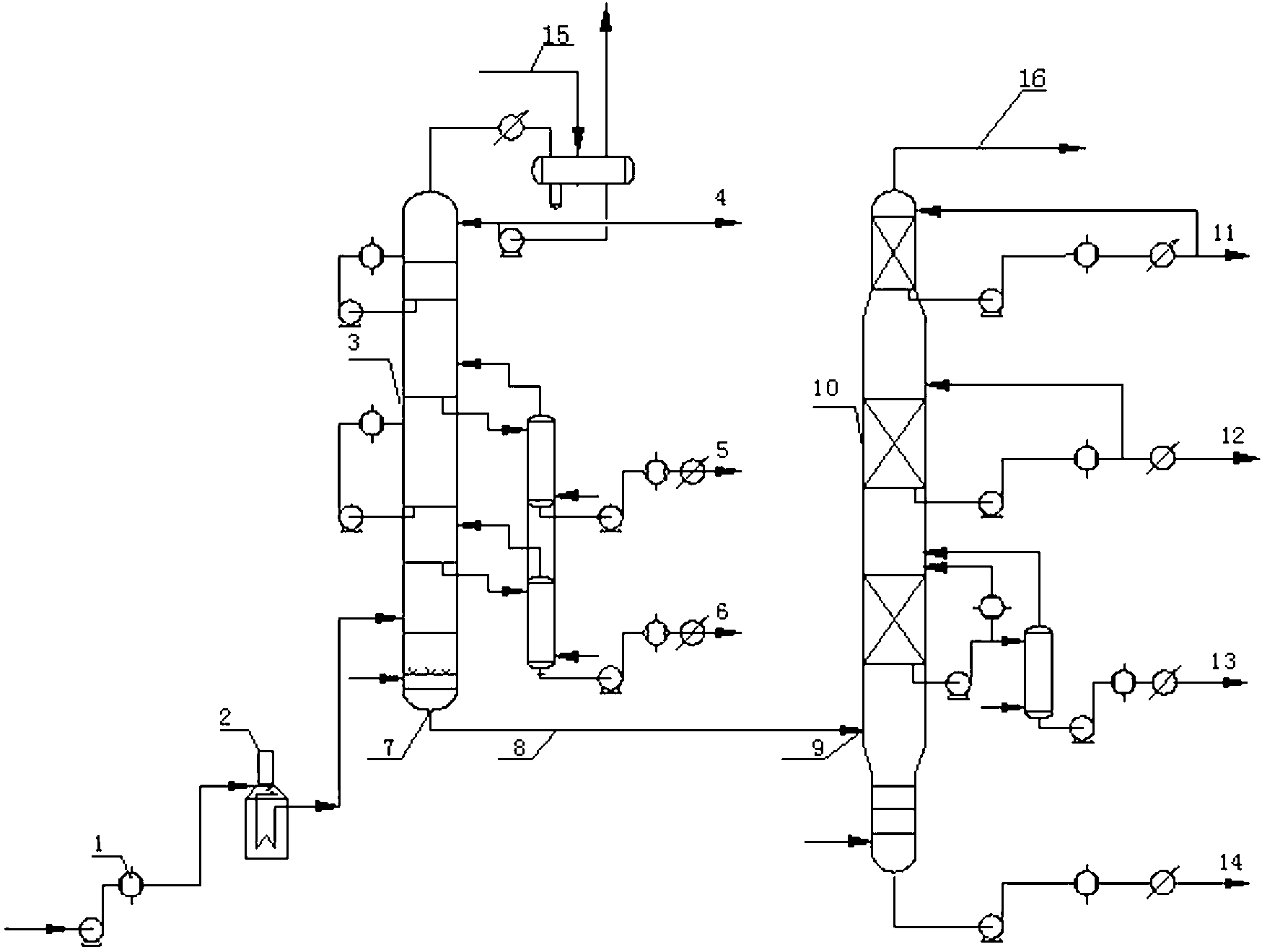

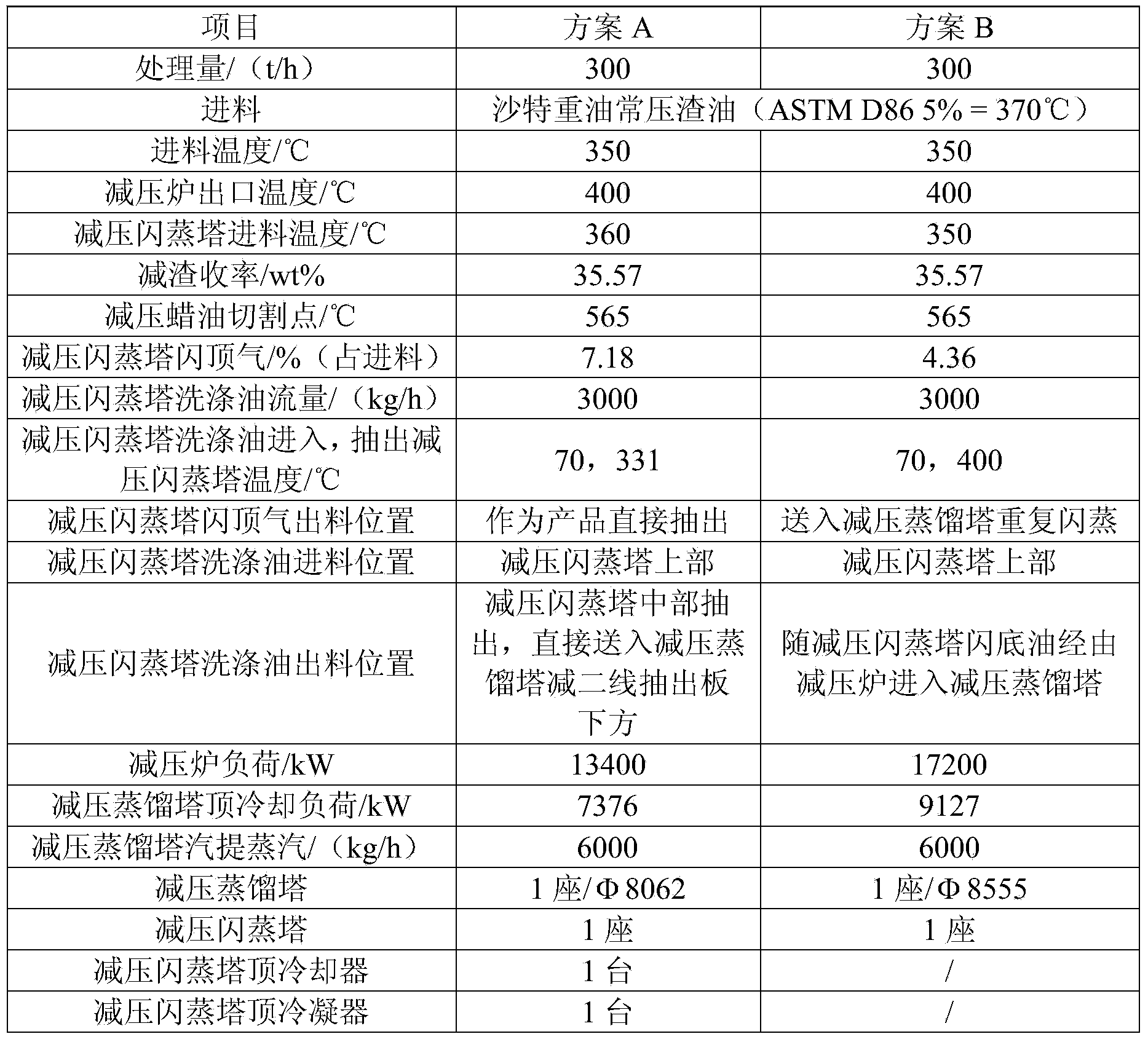

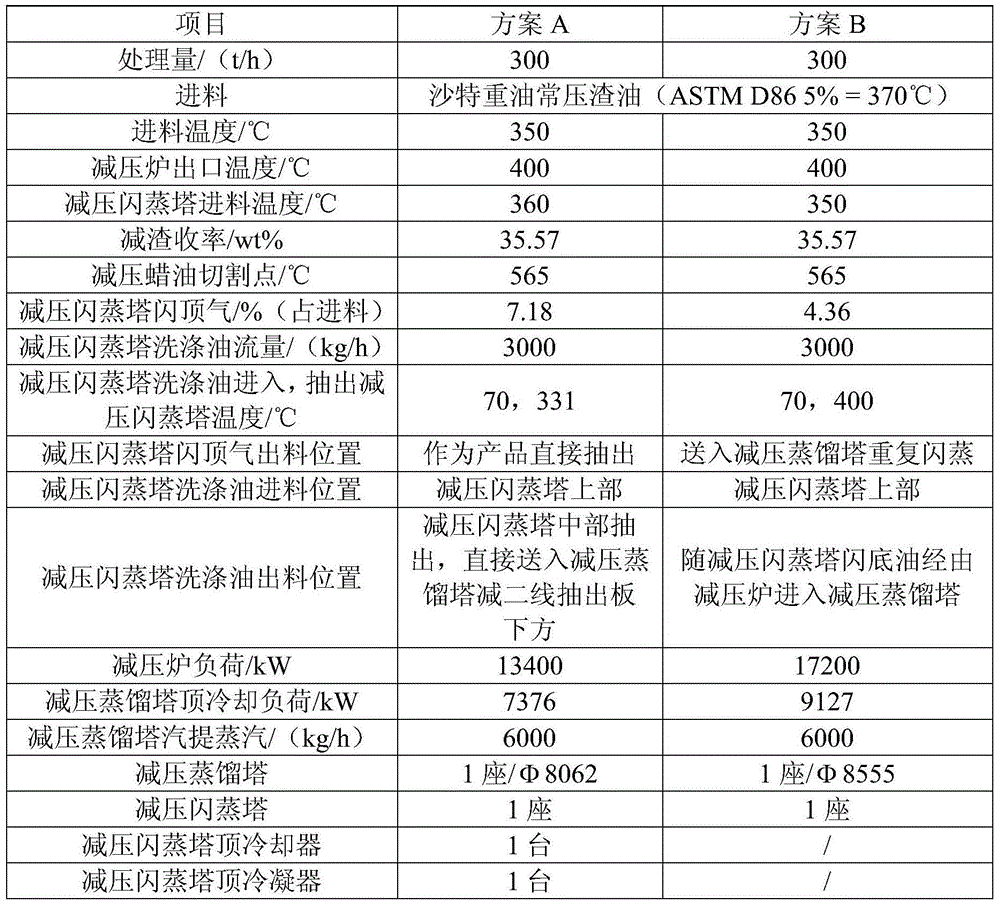

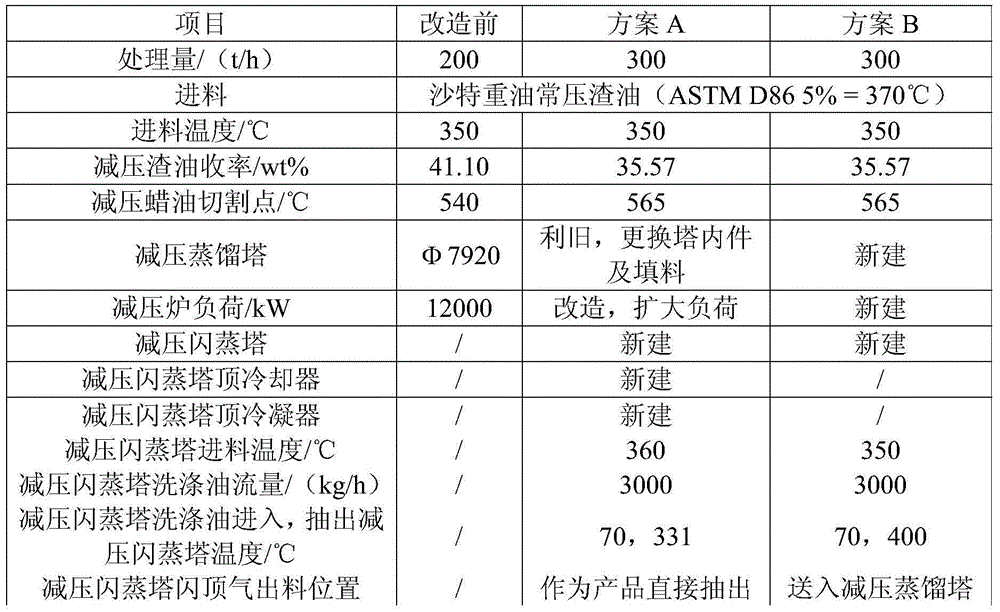

Crude oil reduced pressure distillation method for eliminating choke point in pressure reduction process

InactiveCN103865565AIncrease temperatureIncrease top flash volumeVacuum distillationFractionationEconomic benefits

The invention discloses a crude oil reduced pressure distillation method for eliminating a choke point in a pressure reduction process. The method comprises the following steps: firstly, performing heat exchange on atmospheric pressure residual oil through an atmospheric pressure furnace convection section and a reduced pressure furnace convection section, raising the temperature by 5-20 DEG C, then feeding the residual oil into a reduced pressure flash column, operating the reduced pressure flash column at 5-30kPa, at the same time, introducing reduced pressure flash column light lube oil as washing oil from the upper part of a reduced pressure distillation column, performing heat exchange on a gas on the top of the reduced pressure flash column, condensing, cooling and directly extracting the gas as a product, extracting the washing oil in the middle of the reduced pressure flash column, feeding the washing oil below a light lube oil extracting plate of the reduced pressure flash column, feeding the flash base oil of the reduced pressure flash column into a reduced pressure furnace, heating to be 370-410 DEG C, feeding into the reduced pressure distillation column through an oil transfer line, performing reduced pressure fractionation, and then extracting products of different fractions from a side line of the reduced pressure distillation column. The method improves the crude oil reduced pressure distillation process, eliminates the choke points of the reduced pressure furnace and the reduced pressure distillation column, reduces energy consumption, improves the treatment capacity and increases the economic benefits of a device.

Owner:SUN YAT SEN UNIV

Method and device for crude oil deep vacuum distillation

ActiveCN103059920AIncrease gasification rateRelieve pressureTreatment with plural serial refining stagesFluid phaseResidual oil

The invention discloses a method and a device for crude oil deep vacuum distillation. The method disclosed in the invention includes: introducing atmospheric tower bottom oil into a primary gasification furnace, conducting heating and leaving the oil to enter a primary flash tank to undergo separation, making the obtained gas phase enter a vacuum tower upper fractionation section, and letting the liquid phase enter a second stage gasification furnace; heating the liquid phase and making it enter a second-stage flash tank, leaving the obtained gas phase to enter a vacuum tower middle fractionation section, and making the obtained liquid phase enter a third-stage gasification furnace; heating the liquid phase and making it enter a third-stage flash tank, letting the obtained gas phase enter a vacuum tower lower fractionation section, and leaving the obtained liquid phase to enter a vacuum tower flash section; subjecting the feed of each section to vacuum distillation is the vacuum, extracting a lateral line product from a vacuum tower lateral line, and extracting vacuum residual oil from the tower bottom; and introducing part of the vacuum residual oil into the flash tanks of different stages respectively. The method provided in the invention can significantly improve the distillate yield of the crude oil in the distillation process, reduce device energy consumption, increase device economic benefits, and save device investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Comprehensive filtering, sterilization and purification treatment technology for industrial wastewater

InactiveCN107986523AEffective toxicityImprove physical strengthSemi-permeable membranesWater/sewage treatment by irradiationActivated carbonIndustrial effluent

The invention discloses a comprehensive filtering, sterilization and purification treatment technology for industrial wastewater. The technology comprises the following steps: (1) putting wastewater to be treated into a separation container; adding a flocculating agent and stirring for 5 to 8min; then carrying out solid-liquid separation to obtain filtrate A; (2) conveying the filtrate A into a sterilization container; adsorbing through sulfur-loaded activated carbon; then carrying out ultraviolet radiation and disinfection to obtain filtrate B; (3) conveying the filtrate B to a membrane filtering container A and filtering to obtain filtrate C; (4) conveying the filtrate C to a membrane filtering container B and filtering to obtain filtrate D; (5) discharging the filtrate D out of the container and washing a separation membrane in the membrane filtering container for one time. According to the comprehensive filtering, sterilization and purification treatment technology for the industrial wastewater, disclosed by the invention, substances, which have influences on the separation membrane, in sewage can be effectively removed and the separation membrane is washed in time so that damages, caused by pollutants, on the separation membrane are reduced and the service life of the separation membrane is easy to prolong; a sterilization procedure can be used for effectively removing toxic substances in the wastewater and the toxicity of the wastewater is greatly removed.

Owner:苏州雷沃克环保科技有限公司

Apparatus for effectively compensating three-phase unbalance load and reactive power

InactiveCN100533909CIncrease profitCost-effectivePolyphase network asymmetry elimination/reductionReactive power adjustment/elimination/compensationPower compensationPower controller

The invention discloses a device for efficiently compensating three-phase unbalanced loads and reactive power, which includes: three-phase current and three-phase voltage sampling circuits of a three-phase power system, a power controller and different three-phase compensation unit. It is characterized in that the power controller controls each single-phase switch in the three-phase compensation unit with different topological structures separately according to the sampling results, so that it can realize both common compensation and single compensation; it can not only compensate reactive power, but also balance Active power; it can be used as both static compensation and dynamic compensation; it can not only adjust the ability of three-phase current, but also adjust the three-phase unbalanced voltage. The invention is suitable for the transformation and updating of the existing reactive power compensation device of the three-phase four-wire unbalanced load power system.

Owner:齐志江

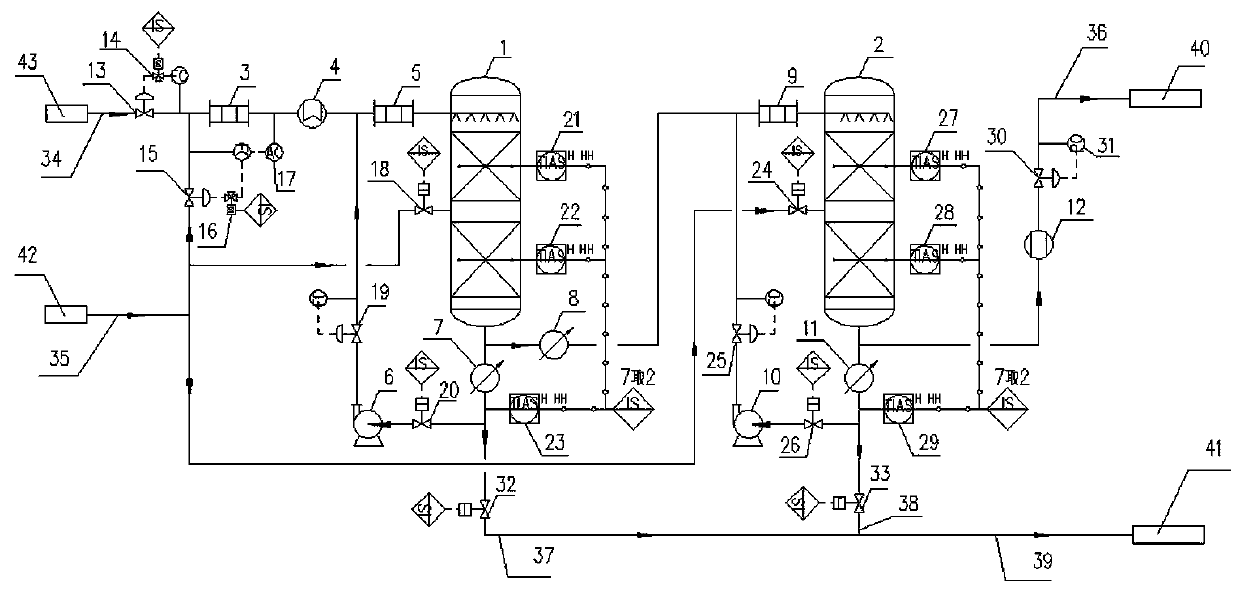

MTBE (methyl tert-butyl ether) device provided with safe automatic control system and used for producing polymerized oil and automatic control method of MTBE device

PendingCN110075774AHigh interest rateLow costProcess control/regulationChemical industryAutomatic controlProcess engineering

The invention discloses an MTBE (methyl tert-butyl ether) device provided with a safe automatic control system and used for producing polymerized oil and an automatic control method of the MTBE device. The MTBE device comprises a primary polymerization reactor, a secondary polymerization reactor, the safe automatic control system, a primary external circulation heat taking part and a secondary external circulation heat taking part. An old original MTBE device can be used, the utilization rate of equipment is high, and the transformation cost of the device is lower; the primary polymerization reactor and the secondary polymerization reactor are both provided with multipoint remote temperature indicators, and real-time and accurate temperature alarm linkage value can be realized; in the automatic control method, safety measures such as quick cutting-off, timely supplement of inhibitors and emergency tapping of reaction materials during accidents are taken, and the safety of the MTBE device is guaranteed. The primary external circulation heat taking part and the secondary external circulation heat taking part are also newly added, reaction heat is timely removed, and overtemperature of a catalyst bed layer is prevented. The MTBE device is worth popularizing and applying in a polymerized oil device of an MTBE device of a refinery plant.

Owner:CHANGLING PETRO CHEM ENG DESIGN

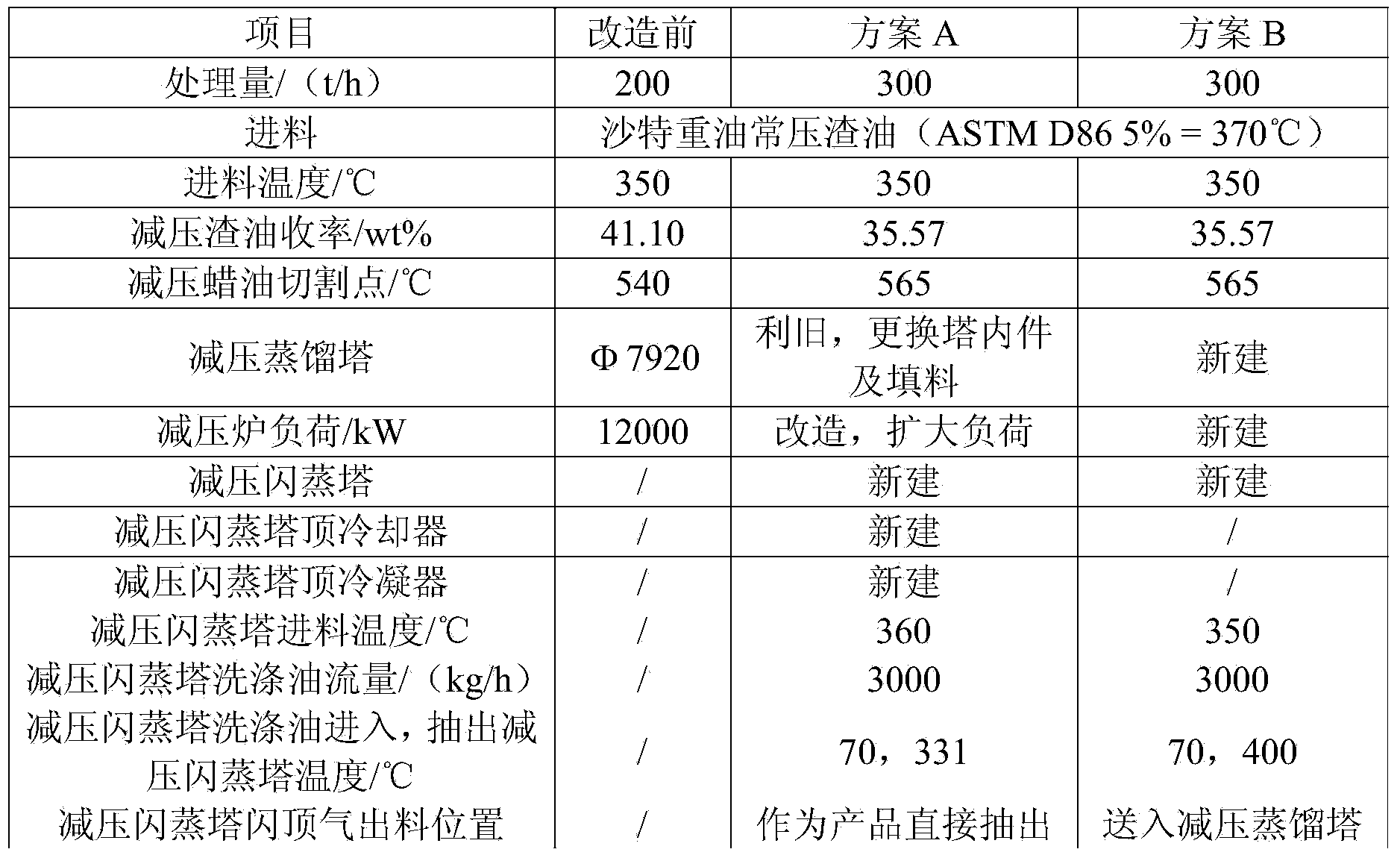

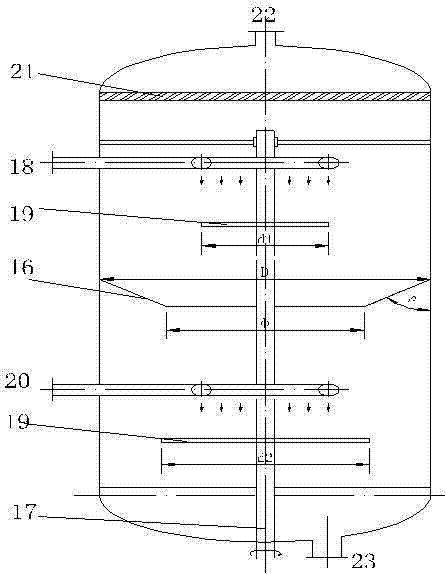

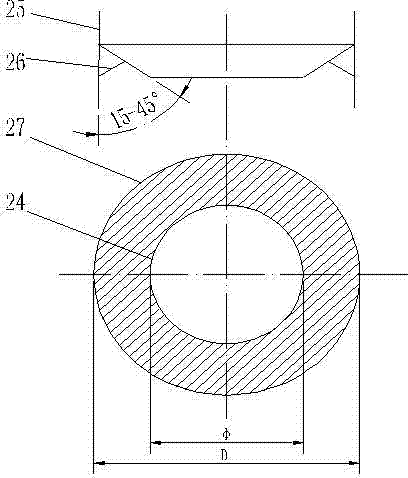

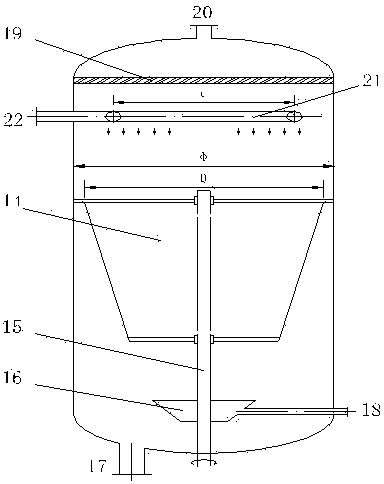

Crude oil reduced pressure distillation method and apparatus for reducing yield of residual oil

The invention discloses a crude oil reduced pressure distillation method for reducing yield of residual oil. Atmospheric tower bottom oil is introduced into a first stage flash tank for separation after being heated in a first stage gasifier; a liquid phase is introduced to a second stage gasifier and then to a second stage flash tank after being heated; the liquid phase is introduced to a third stage gasifier and then to a third stage flash tank after being heated; the liquid phase is introduced to a reduced pressure flash section; gas phases obtained in various stages are introduced to the upper, the middle and the lower fractional distillation sections of reduced pressure tower; lateral line products are pumped out from lateral lines of the reduced pressure tower; a part of residues at the bottom of the tower is introduced to the flash tanks in the various stages, wherein at least two rotary evaporation coils are arranged in a gas phase zone in the upper part of the reduced pressure flash tower; tank walls between the two rotary evaporation coils are provided with baffle plates for preventing wall flows; and the rotary evaporation coils are fixed on a rotary shaft at a longitudinal shaft center position of the tank body. The method provided by the invention can obviously reduce the yield of the reduced pressure residual oil, increase economic benefits of the apparatus, reduce energy consumption of the apparatus, and save investment for the apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

Isomerization method for light hydrocarbon

ActiveCN101497815BGuaranteed isomerization rateImprove liquid yieldRefining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationAlkaneIsomerization

The invention relates to a light hydrocarbon isomerization method. Isomerization reaction is performed for light hydrocarbon raw material in an isomerization reactor at the front part, gas-liquid separation is performed for the outlet stream of the reactor at the front part, the obtained liquid phase stream is separated in an isohexane removing tower, the overhead stream mainly comprising C5 cut fraction and dimethyl C6 alkane is mixed with the bottom stream mainly comprising C7 and cut fractions more than C7 so as to be used as isomate to enter into a gasoline stabilizer, the side stream mainly comprising C6 n-alkane and monomethyl C6 alkane is led into an isomerization reactor at the rear part; after the reaction stream of the isomerization reactor at the rear part is separated, the liquid phase stream all returns and is mixed with the liquid phase stream of a gas-liquid separator of the isomerization reactor at the front part so as to be used as the feeding of the isohexane removing tower. The method has higher n-alkane isomerization ratio and greatly improves the octane number of the light hydrocarbons raw material because the C6 n-alkane basically realizes the full isomerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

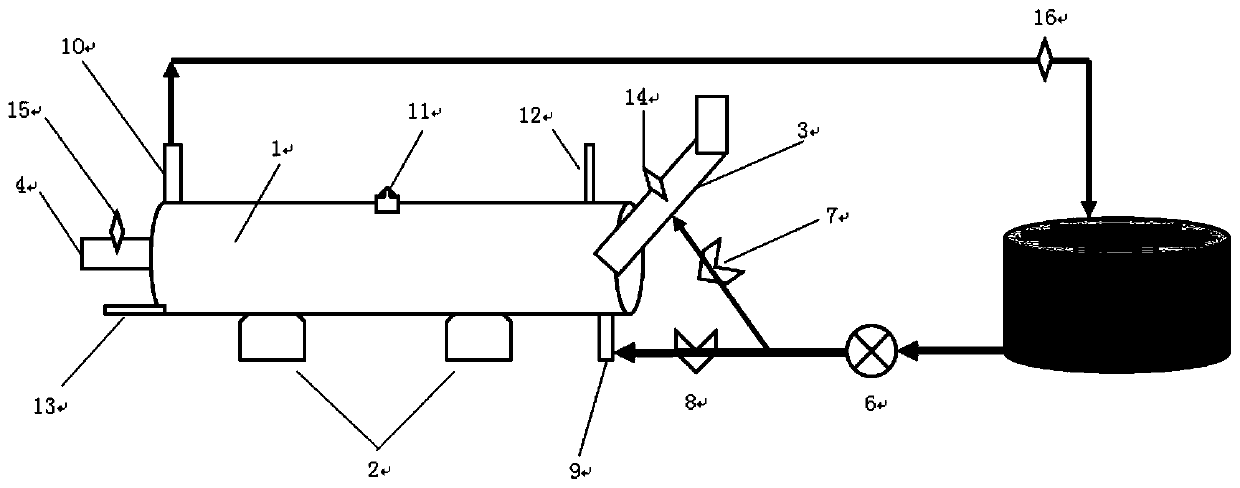

System and method for treating high-salinity wastewater by utilizing high-temperature ash

PendingCN110877918AEvaporate quicklyHigh interest rateWater/sewage treatment by heatingSlagControl valves

The invention provides a system for treating high-salinity wastewater by using high-temperature ash. The system comprises a roller slag cooler, a slag inlet pipe, a slag outlet pipe, a high-salinity wastewater storage tank, a first flow control valve, a second flow control valve, a cooling water inlet, a cooling water outlet, an inlet slag temperature measuring point, an outlet slag temperature measuring point and a returned cooling water temperature measuring point. Waste heat of high-temperature bottom slag is fully utilized, and a part of high-salinity wastewater (the treatment capacity isrelated to the slag discharge capacity) is treated without affecting the boiler efficiency and the boiler running condition, so the system is a beneficial supplement of a traditional zero-discharge process, and has the advantages of good evaporation effect, high device utilization rate and low investment, operation and maintenance cost.

Owner:HUANENG CLEAN ENERGY RES INST

Vacuum distillation method for gradual gasification segmented feed

ActiveCN103059918BIncrease gasification rateRelieve pressureTreatment with plural serial refining stagesFluid phaseProcess engineering

The invention discloses a vacuum distillation method for gradual gasification segmented feed. The method includes: making atmospheric tower bottom oil enter a first stage gasification furnace, conducting heating to make the tower bottom oil enter a first stage flash tank to perform separation, leaving a gas phase to enter an upper fractionation segment of a vacuum tower, and leaving a liquid phase to enter a second stage gasification furnace; heating the liquid phase and making it enter a second stage flash tank, letting the generated gas phase enter a middle fractionation segment of the vacuum tower, and letting the generated liquid phase enter a third stage gasification furnace; heating the liquid phase and making it enter a third stage flash tank, letting the generated gas phase enter a lower fractionation segment of the vacuum tower, and letting the generated liquid phase enter a flash segment of the vacuum tower; and subjecting the feed of each segment to vacuum distillation in the vacuum tower, extracting a lateral line product from a vacuum tower lateral line, and extracting vacuum residue from the tower bottom. The method provided in the invention can substantially enhance the distillate yield of a crude oil vacuum distillation process, reduce equipment energy consumption, increase equipment economic benefits, and save equipment investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for crude oil deep vacuum distillation

ActiveCN103059920BIncrease gasification rateRelieve pressureTreatment with plural serial refining stagesFluid phaseResidual oil

The invention discloses a method and a device for crude oil deep vacuum distillation. The method disclosed in the invention includes: introducing atmospheric tower bottom oil into a primary gasification furnace, conducting heating and leaving the oil to enter a primary flash tank to undergo separation, making the obtained gas phase enter a vacuum tower upper fractionation section, and letting the liquid phase enter a second stage gasification furnace; heating the liquid phase and making it enter a second-stage flash tank, leaving the obtained gas phase to enter a vacuum tower middle fractionation section, and making the obtained liquid phase enter a third-stage gasification furnace; heating the liquid phase and making it enter a third-stage flash tank, letting the obtained gas phase enter a vacuum tower lower fractionation section, and leaving the obtained liquid phase to enter a vacuum tower flash section; subjecting the feed of each section to vacuum distillation is the vacuum, extracting a lateral line product from a vacuum tower lateral line, and extracting vacuum residual oil from the tower bottom; and introducing part of the vacuum residual oil into the flash tanks of different stages respectively. The method provided in the invention can significantly improve the distillate yield of the crude oil in the distillation process, reduce device energy consumption, increase device economic benefits, and save device investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

A crude oil vacuum distillation method for eliminating the bottleneck of the vacuum process

InactiveCN103865565BIncrease temperatureIncrease top flash volumeVacuum distillationFractionationPressure reduction

The invention discloses a crude oil reduced pressure distillation method for eliminating a choke point in a pressure reduction process. The method comprises the following steps: firstly, performing heat exchange on atmospheric pressure residual oil through an atmospheric pressure furnace convection section and a reduced pressure furnace convection section, raising the temperature by 5-20 DEG C, then feeding the residual oil into a reduced pressure flash column, operating the reduced pressure flash column at 5-30kPa, at the same time, introducing reduced pressure flash column light lube oil as washing oil from the upper part of a reduced pressure distillation column, performing heat exchange on a gas on the top of the reduced pressure flash column, condensing, cooling and directly extracting the gas as a product, extracting the washing oil in the middle of the reduced pressure flash column, feeding the washing oil below a light lube oil extracting plate of the reduced pressure flash column, feeding the flash base oil of the reduced pressure flash column into a reduced pressure furnace, heating to be 370-410 DEG C, feeding into the reduced pressure distillation column through an oil transfer line, performing reduced pressure fractionation, and then extracting products of different fractions from a side line of the reduced pressure distillation column. The method improves the crude oil reduced pressure distillation process, eliminates the choke points of the reduced pressure furnace and the reduced pressure distillation column, reduces energy consumption, improves the treatment capacity and increases the economic benefits of a device.

Owner:SUN YAT SEN UNIV

Non-hydrogen dewaxing depressurizing distillation process and device

InactiveCN101798526BDoes not damage the organizational structureHigh flash pointBase-materialsHydrocarbon oils treatmentWaxHydrogen

The invention discloses non-hydrogen dewaxing depressurizing distillation process and device. The process has the following steps of: using wax oil as the raw material, carrying out non-hydrogen dewaxing, atmospheric distillation, flash evaporation and depressurizing distillation, and then producing a lube base oil. The device comprises a raw material oil pump (1), a reactor (2), an atmospheric furnace (3), an atmospheric tower (4), a depressurizing furnace (5), a flash evaporating tank (6) and a depressurizing tower (7). The depressurizing tower is provided with a side line, and the lube base oil can be pumped from the side line. The heavy lube base oil can be pumped from the bottom of the depressurizing tower. When used for reforming the old device, the invention has the advantages of high utilization rate of the old equipment, investment saving, large operation flexibility and short idle time, obviously enhances the production separation effect, and optimizes the product quality.

Owner:新疆五家渠现代石油化工有限公司

Flash-strengthened crude oil reduced pressure deep distillation process

ActiveCN103242885BEasy to separateIncrease evaporation rateVacuum distillationRotary evaporatorFluid phase

The invention discloses a flash-strengthened crude oil reduced pressure deep distillation process. Atmospheric tower bottom oil is introduced into a first stage flash tank for separation after being heated in a first stage gasifier; a gas phase is introduced to an upper fractional distillation section of a reduced pressure tower; a liquid phase is introduced to a second stage gasifier and then to a second stage flash tank after being heated; the liquid phase is introduced to a third stage gasifier and then to a third stage flash tank after being heated; the gas phase is introduced to a lower fractional distillation section of the reduced pressure tower; the liquid phase is introduced to a flash section of the reduced pressure tower; feeding materials in various stages are introduced to the reduced pressure tower for reduced pressure distillation; lateral line products are pumped out from lateral lines of the reduced pressure tower; and residual oil is pumped from the bottom of the tower, wherein the upper gas phase zone of the reduced pressure flash tower is provided with a reduced pressure tower rotary evaporator; and the lower liquid phase zone of the reduced pressure flash tower is provided with a stripping gas distributor for introducing a high temperature stripping gas. The process provided by the invention can obviously increase distillation rate during a crude oil reduced pressure distillation process, reduce energy consumption of the apparatus, increase economic benefits of the apparatus, and save investment of the apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

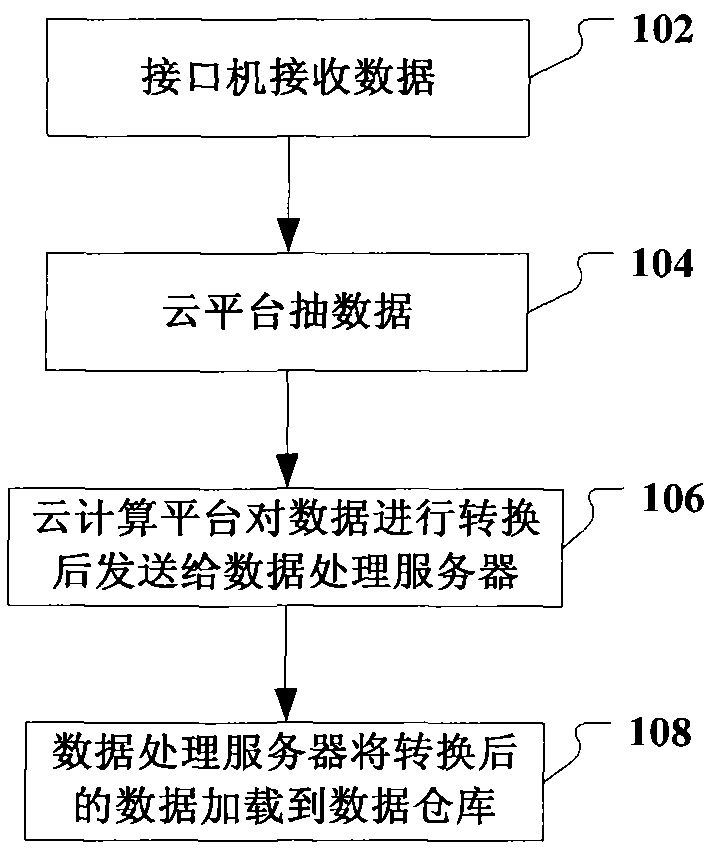

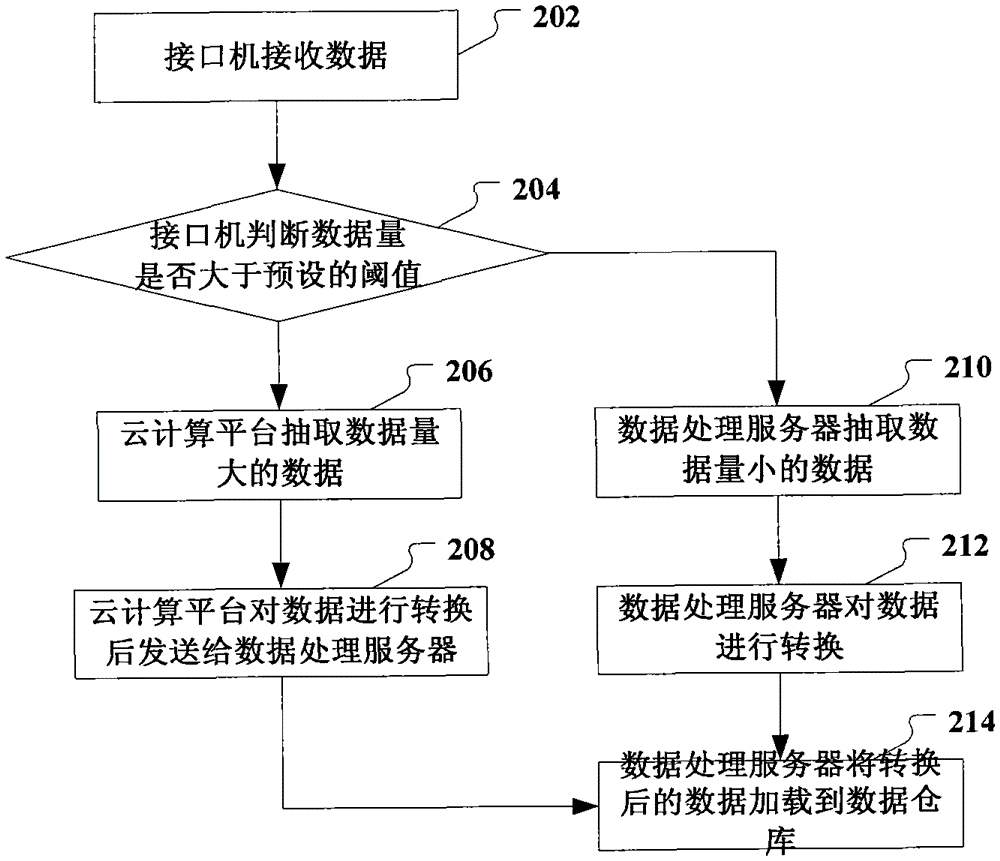

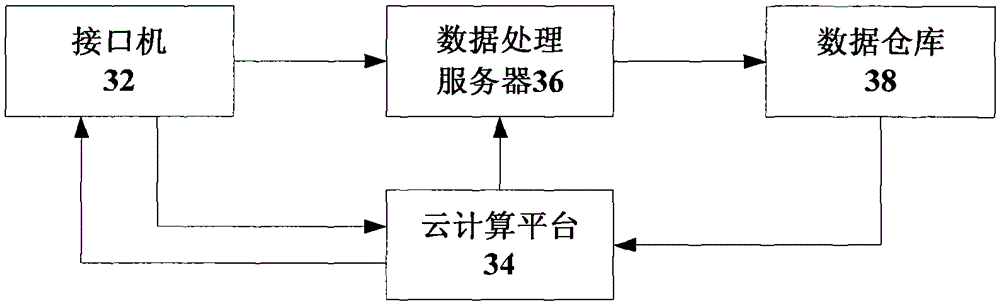

Data processing method, device and system

The invention discloses a data processing method, device and system. The data processing method includes: the cloud computing platform processes the acquired data, and sends the processed data to a data processing server; the data processing server transmits the data processed by the cloud computing platform to a data warehouse. The data processing method, device and system of the present invention extract and process data through the cloud computing platform, and the data processing server transmits the processed data to the data warehouse, thereby increasing the amount of data processing and realizing massive data processing, and will not Make too many changes to the existing architecture, maintain the relative independence of the cloud platform, and be easy to transform. The cloud computing platform has low cost, small investment, and high interest rate, which can relieve the pressure of system expansion and reduce system cost.

Owner:CHINA MOBILE COMM GRP CO LTD

Improved delayed coking process for raising yield of gasoline and diesel oil

The present invention relates to an improved delayed coking process for increasing yield of gasoline and diesel oil, and is characterized by that in the conventional delayed coking process, in the lower portion of coking fractionating tower and between the diesel-oil extracting line and wax-oil extracting line a light cycle oil extracting line is added, then the extracted light cycle oil can be pumped into the outlet pipeline of feeding pump of the coking heating furnace by using light cycle oil pump and mixed with coking fractionating tower bottom oil discharged from feeding pump.

Owner:新疆寰球工程公司

A method for quickly peeling taro

ActiveCN106174623BReduce dosageImprove efficiencyVegetable peelingTemperature differenceSalt solution

The invention discloses a method for rapidly peeling taros. The method is characterized by including the following specific steps of 1, ripening, wherein a salt solution is heated to 135 DEG C to 160 DEG C, the temperature is kept, and cleaned taros are put into the solution and boiled for 1 min to 3 min; 2, goffering, wherein the taros are rapidly bailed out, put into cold water and soaked for 1 min to 2 min, the temperature is rapidly reduced, it is prevented that taro curing layers are further increased, the huge temperature difference between the insides and the outsides allows peels of the taros to be rapidly wrinkled and fall off, and meanwhile the salt solution attached to the peels of the taros can be removed; peeling, wherein the taros enter a roller-type peeling machine through a conveying belt and are peeled, and the peeled taros are obtained. The method has the advantages that the peeling efficiency is high, losses are small, environment pollution is reduced, the operation cost is low, and the surfaces are smooth and not prone to browning after peeling.

Owner:NINGBO UNIV

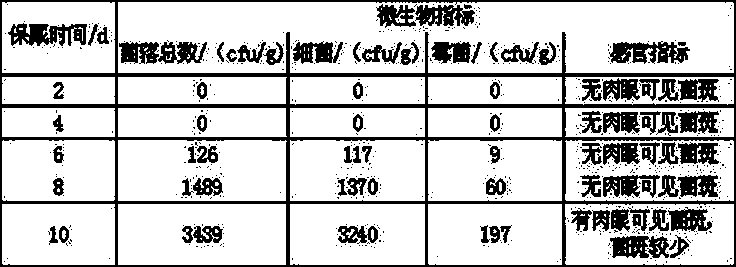

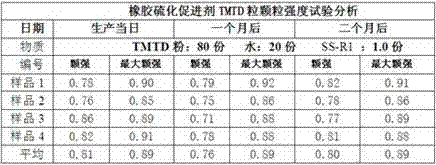

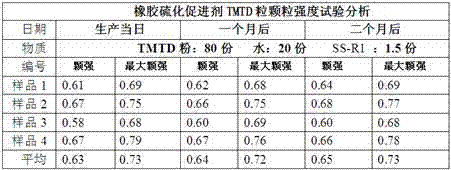

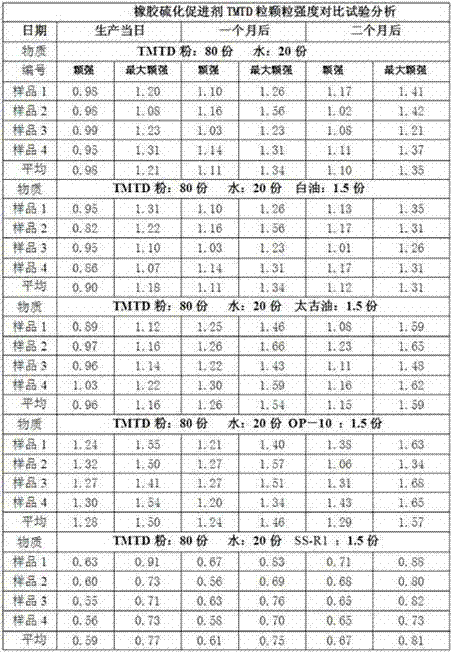

Method for increasing dispersity of rubber vulcanization accelerator TMTD (Tetramethyl Thiuram Disulfide)

The invention relates to the technical field of production of rubber vulcanization accelerators, and in particular to a method for increasing the dispersity of a rubber vulcanization accelerator TMTD (Tetramethyl Thiuram Disulfide). The method for increasing the dispersity of the rubber vulcanization accelerator TMTD takes TMTD powder as a treatment object and is characterized by comprising the following steps of adding the TMTD powder into a kneading machine, then adding water and MOA-9 (Fatty Alcohol Polyoxyethylene Ether), adding a mixture into a pelletizer for pelletizing after uniformly kneading, then drying, separating particles and powder by using a vibrating screen, and using the separated particles as finished products. According to the method for increasing the dispersity of the rubber vulcanization accelerator TMTD, disclosed by the invention, the operation is simple, the granulation rate is high, the strength is uniform, the dispersity of TMTD particles in rubber can be effectively improved, and the problems that the particle strength is too hard, dispersion of granular products during a rubber machining process is non-uniform, the dispersion is difficult and the like are solved.

Owner:SHANDONG SUNSINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com