MTBE (methyl tert-butyl ether) device provided with safe automatic control system and used for producing polymerized oil and automatic control method of MTBE device

An automatic control system and superimposed oil technology, applied in the direction of feeding device, separation method, chemical instrument and method, etc., can solve the problems of over-temperature and over-pressure of the burning agent and the reaction system, so as to ensure safety and high equipment utilization rate. , the effect of suppressing the superposition reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

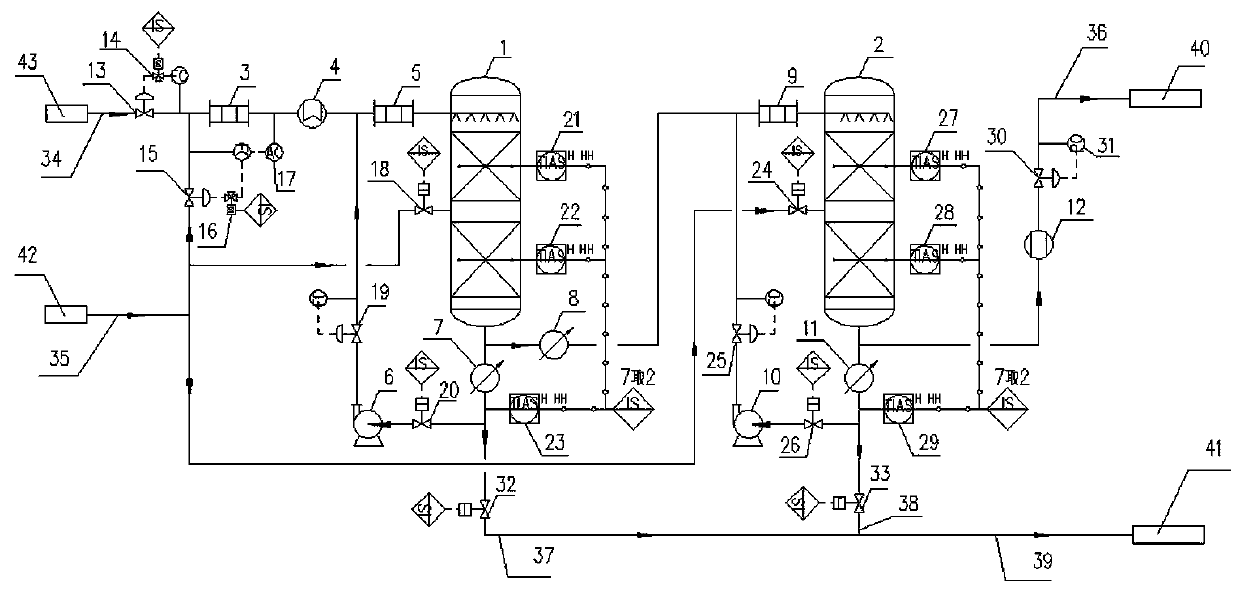

[0042] see figure 1 , a MTBE device with a safety automatic control system for producing composite oil, including a primary composite reactor 1, a secondary composite reactor 2, a safety automatic control system, a primary external circulation heat extraction part and a secondary external circulation extraction hot part.

[0043] Wherein, the C4 feed line 34 communicates with the feed port of the C4-inhibitor mixer 3 , and the C4 feed line 34 is provided with a C4 flow control valve 13 .

[0044] Specifically, the inhibitor main line 35 is divided into three paths, one path is connected with the feed port of the C4-inhibitor mixer 3, and the other two paths are respectively connected with the first-level stacking reactor 1 and the second-level stacking reactor 2 . An inhibitor feed flow control valve 15 is provided on the pipeline between the inhibitor main line 35 and the C4-inhibitor mixer 3 .

[0045] Wherein, the discharge port of the C4-inhibitor mixer 3 communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com