Method for increasing dispersity of rubber vulcanization accelerator TMTD (Tetramethyl Thiuram Disulfide)

A technology of rubber vulcanization and accelerator, applied in the field of improving the dispersibility of rubber vulcanization accelerator TMTD, can solve the problems of great influence on the quality of rubber products, non-dispersion of rubber processing enterprises, quality problems of rubber products, etc., and achieve physical and chemical properties and vulcanization reaction. Good, the amount of dust is reduced, and the effect of overcoming the excellent particle strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

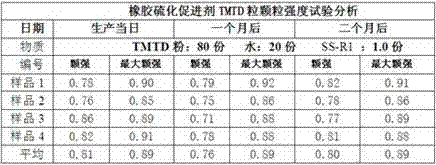

[0022] Select the raw materials according to the following table, and put all the additives into the kneader according to the ratio of 1.5% of the total amount of dry TMTD powder and water. Extrude uniform cylindrical pellets with a diameter of 1.5 ± 0.1 mm. Then dry in the range of 100-130°C by fluidized bed blast, separate the granules and powder with a vibrating screen, and pack the finished granules directly, and return the powder to the kneader for re-kneading with the next batch.

[0023]

[0024] 4 groups of samples were taken out from each batch, and compared by placing them at intervals for a period of time, it can be seen that only the strength of the particles added with MOA-9 hardly changed, and the others all hardened. The experimental results are shown in the table below.

[0025]

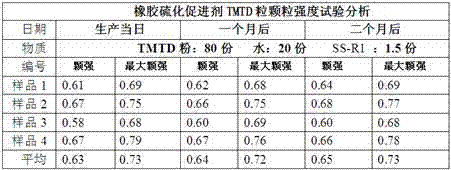

Embodiment 2

[0027] Select raw materials according to the following table: TMTD powder, water, MOA-9, MOA-9 is added according to the ratio of 1.0% of the total amount of dry TMTD powder and water, put into the kneader for kneading, after kneading evenly, add The granulator is used to extrude uniform cylindrical granules with a diameter of 1.5±0.1mm from the orifice plate of the machine head through screw conveying. Then dry in the range of 100-130°C by fluidized bed blast, separate the granules and powder with a vibrating screen, and pack the finished granules directly, and return the powder to the kneader for re-kneading with the next batch. Four groups of samples were taken out and placed at intervals for a period of time. It can be seen that the strength of the particles added with MOA-9 is uniform and hardly changes after being placed for a long time.

[0028]

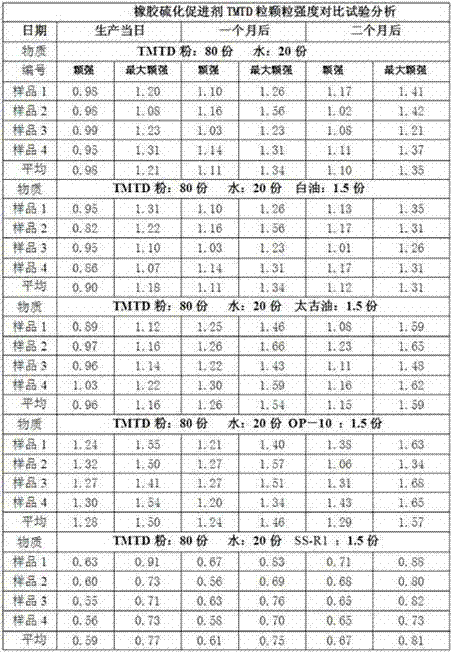

Embodiment 3

[0030] Select raw materials according to the following table: TMTD powder, water, MOA-9, MOA-9 is added according to the ratio of 1.2% of the total amount of dry TMTD powder and water, put into the kneader for kneading, after kneading evenly, add The granulator is used to extrude uniform cylindrical granules with a diameter of 1.5±0.1mm from the orifice plate of the machine head through screw conveying. Then dry in the range of 100-130°C by fluidized bed blast, separate the granules and powder with a vibrating screen, and pack the finished granules directly, and return the powder to the kneader for re-kneading with the next batch. Four groups of samples were taken out and placed at intervals for a period of time. It can be seen that the strength of the particles added with MOA-9 is uniform and hardly changes after being placed for a long time.

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com