Flash-strengthened crude oil reduced pressure deep distillation process

A process and flash evaporation technology, applied in the field of petroleum refining, can solve the problems of thermal stress safety design and installation difficulty, unfavorable vacuum distillation column operation, etc., to reduce energy consumption, reduce irreversibility, and improve the extraction rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

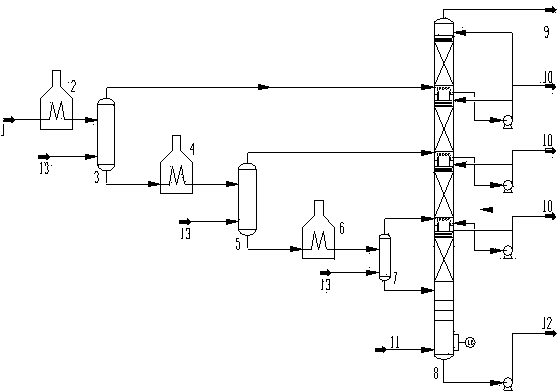

[0055] The method of the present invention is used in the design of a new 10 million tons / year crude oil atmospheric and vacuum distillation unit, and the decompression part process flow and figure 1 Same as shown.

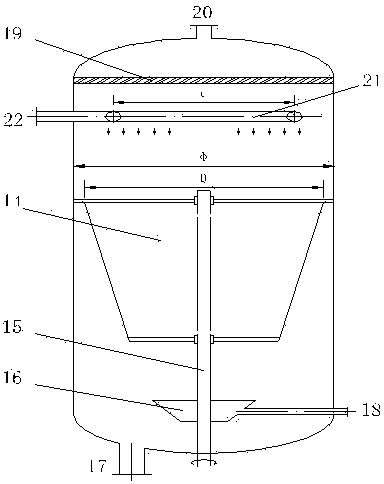

[0056] The processing capacity of the decompression device is 5 million tons per year. The decompression process includes a primary gasifier, a primary decompression flash tank, a secondary gasifier, a secondary decompression flash tank, and a tertiary gasifier , Three-stage vacuum flash tank, vacuum distillation tower. All levels of decompression flash tanks adopt the decompression flash tank with the above-mentioned structure of the present invention, which is a decompression flash tank with a high-gravity rotary evaporator and high-temperature stripping gas. The high-gravity rotary evaporator is composed of wire mesh filled with fillers. The outer diameter D of the upper bottom circle is 90% of the inner diameter φ of the decompression flash tank, and the diam...

Embodiment 2

[0069] The method of the present invention is used for the capacity expansion transformation of a crude oil atmospheric and vacuum device. The normal pressure part is the same as the conventional atmospheric and vacuum device, and the decompression part mainly includes a first-stage gasifier, a first-stage decompression flash tank, and a second-stage gasification Furnace, two-stage vacuum flash tank, three-stage gasifier, three-stage vacuum flash tank, vacuum distillation tower.

[0070] All levels of decompression flash tanks adopt the decompression flash tank with the above-mentioned structure of the present invention, which is a decompression flash tank with a high-gravity rotary evaporator and high-temperature stripping gas. The high-gravity rotary evaporator is composed of metal screens filled with fillers. The outer diameter D of the upper bottom circle is 90% of the inner diameter φ of the decompression flash tank, and the diameter of the lower bottom circle is 50% of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com