Improved delayed coking process for raising yield of gasoline and diesel oil

A delayed coking and diesel technology, applied in the delayed coking field, can solve the problems of increasing the yield of gasoline and diesel, and achieve the effects of increasing the processing capacity, being easy to implement and popularizing, and having less investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

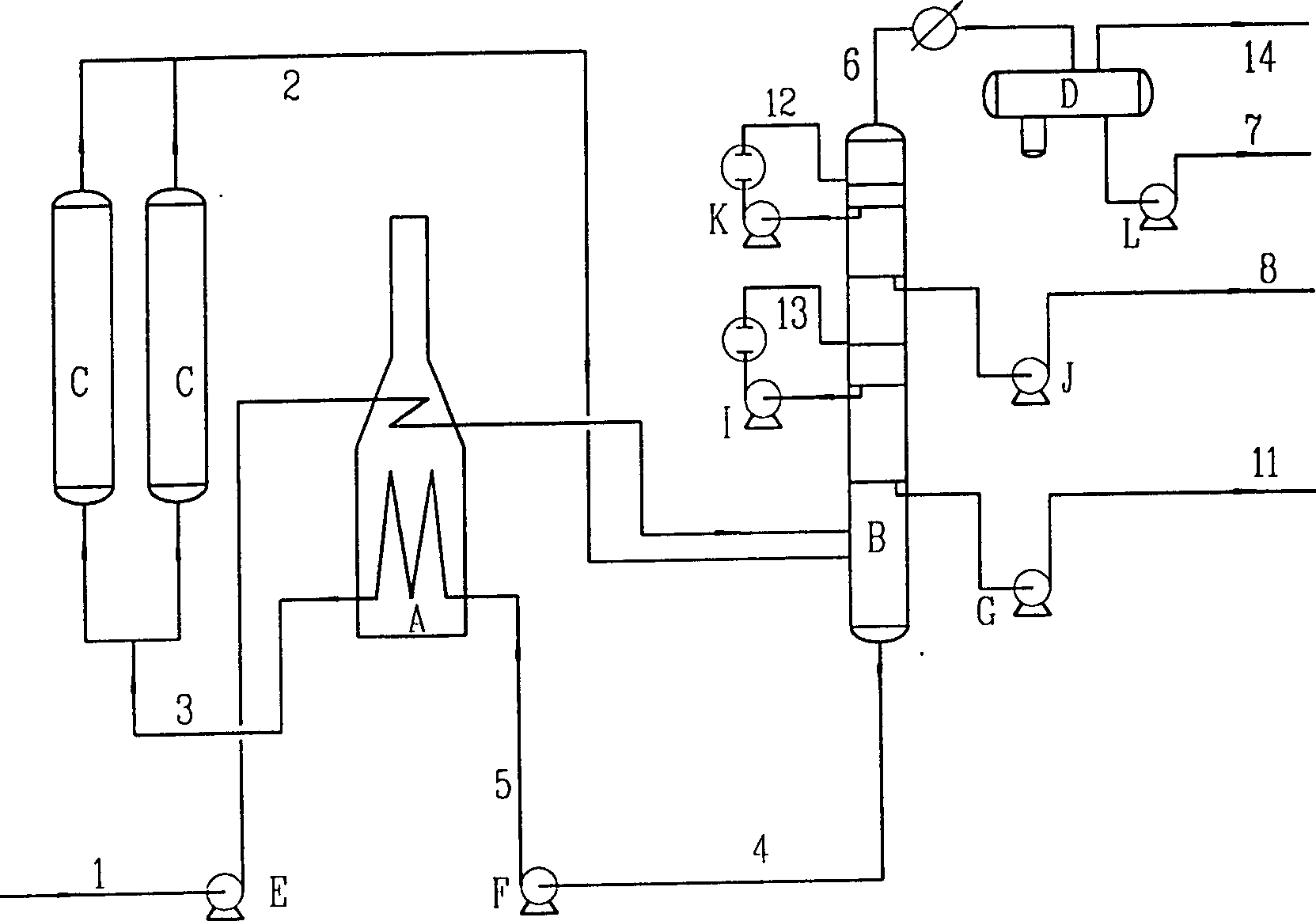

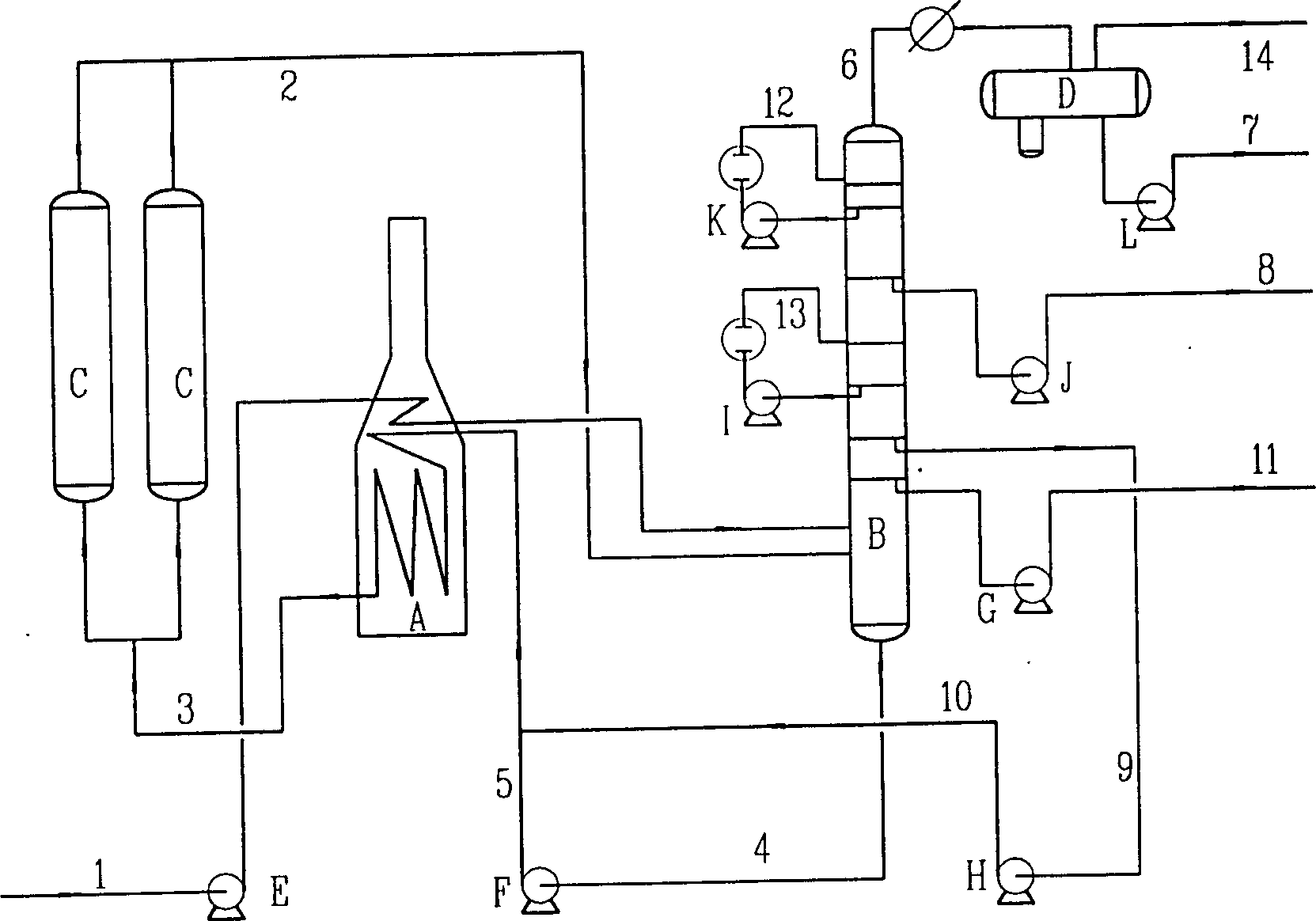

Image

Examples

Embodiment 1

[0017] Embodiment 1 is in the conventional delayed coking process, in the lower part of the coking fractionation column B, between the diesel oil extraction line 8 and the wax oil extraction line 11, a light cycle oil extraction line 9 is added, and the extracted light cycle oil is used for light cycle oil extraction. The outlet pipeline 5 of the feed pump F of the circulating oil pump H to the coking heating furnace A is mixed with the bottom oil of the fractionation tower from the feed pump F. Among them: the oil and gas are heated to 495°C or 496°C by the coking heating furnace and then enter the coke tower; the extraction amount of light cycle oil is 5% or 7% or 9% of the relative vacuum residue raw material amount by weight percentage; except for the addition of light fraction In addition to the oil circulation, it is better to increase the residence time of the mixed feed oil in the coking heating furnace in the heating furnace tube. There are more than 2 to 3 rows of fu...

Embodiment 2

[0021] Embodiment 2 differs from Embodiment 1 in that: Embodiment 2 is a production scheme mainly increasing diesel oil. During the operation of embodiment 2, the furnace tube arrangement and structure of the coking heating furnace, the equipment and process flow such as coke tower and fractionation tower are the same as in embodiment 1, that is, the equipment and process flow of the device after transformation can adapt to the conditions of example 1 and example 2 Production requirements, but the process and operating parameters of the device need to be adjusted accordingly. When producing according to the scheme of increasing diesel oil production, the coking reaction depth is relatively low, and the outlet temperature of the radiant section of the heating furnace only needs to be 493°C or 494°C or 495°C, which is lower than that of Example 1. 2 to 3°C, the extraction amount of light cycle oil is 10% or 12% or 15% of the relative vacuum residue raw material amount by weight p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com