Different pressure distillation apparatus and process method

A process method and differential pressure technology, applied in hydrocarbon distillation, petroleum industry, etc., can solve the problems of increasing the vapor phase load of the vacuum tower, increasing the cracking tendency of oil products, reducing the decompression extraction rate, etc., so as to reduce the vapor phase Effects of load, improvement of extraction rate, and reduction of heating amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

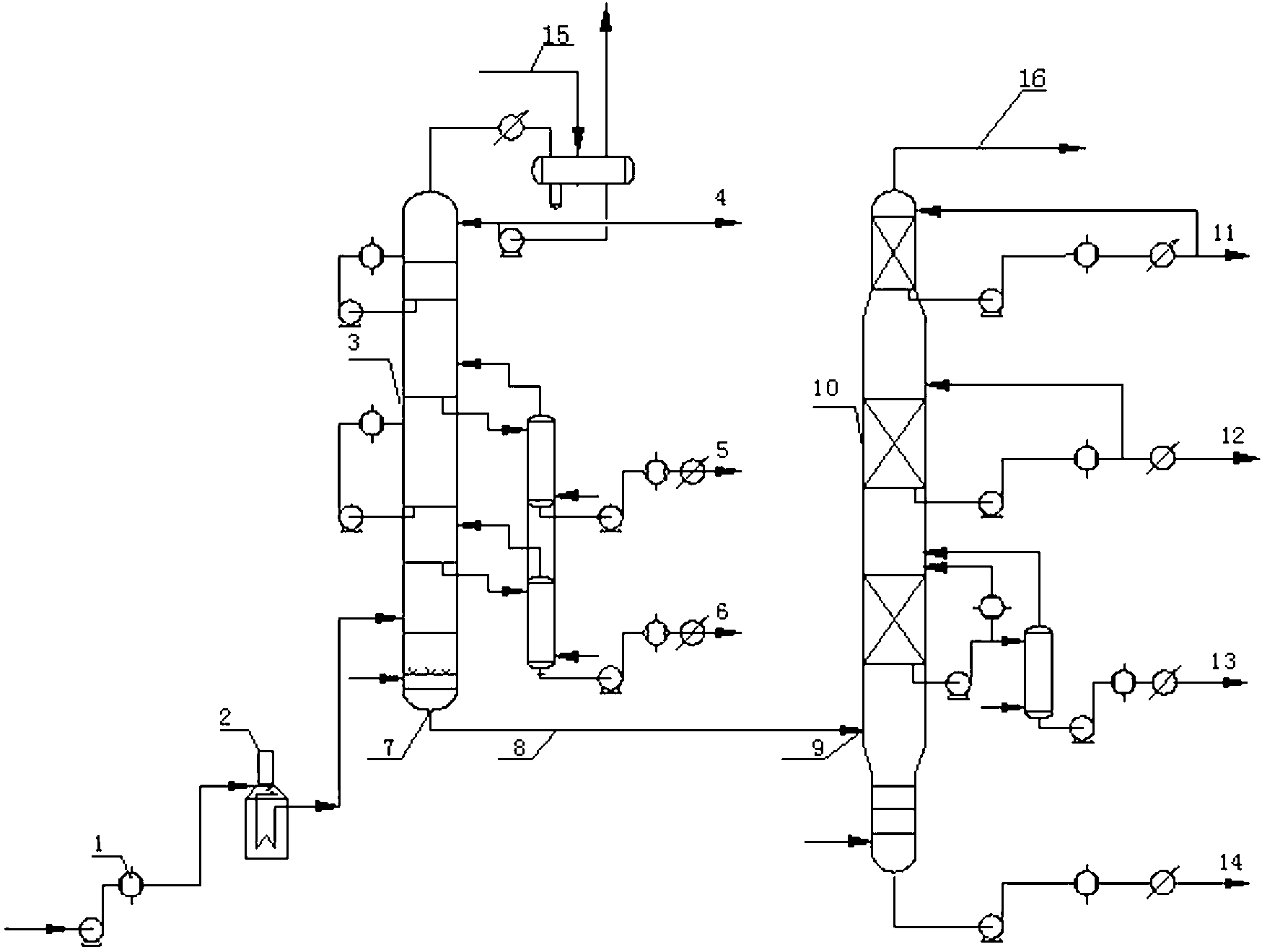

[0020] Embodiment 1: crude oil differential pressure distillation technological process is as figure 1 As shown, the crude oil is heated to about 300°C through the heat exchange network 1 and the heating furnace 2 and enters the supercharging tower 3. A supercharging system 15 is installed on the top of the supercharging tower 3. The absolute pressure at the top of the tower is 250kpa, and gasoline is extracted from the top line 4. , the booster tower 3 is provided with two side lines, increasing the first line 5 to extract kerosene, increasing the second line 6 to extract light diesel oil, and the tower bottom oil is passed through the Unicom pipeline 8 by means of the pressure difference and liquid level difference between the booster tower 3 and the decompression tower 10 Artesian flow enters the decompression tower 10, and the top of the decompression tower 10 is provided with a vacuum system 16, and the absolute pressure at the top of the tower is 9kpa. The decompression t...

Embodiment 2

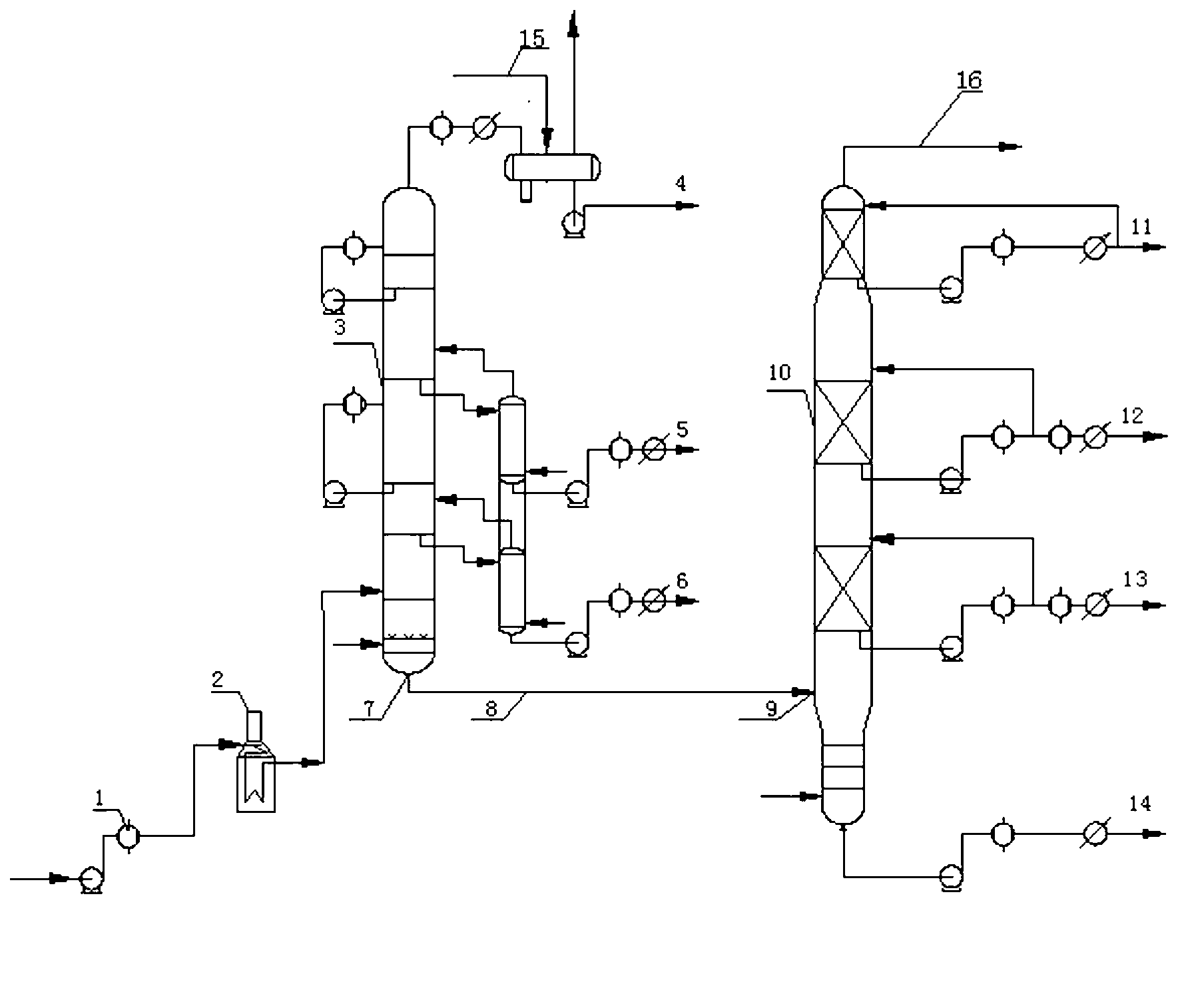

[0021] Embodiment 2: heavy oil differential pressure distillation technological process such as figure 2 As shown, the heavy oil is heated to about 400°C through the heat exchange network 1 and the heating furnace 2 and enters the supercharging tower 3. A supercharging system 15 is installed on the top of the supercharging tower 3, and the absolute pressure at the top of the tower is 250kpa. Diesel, booster tower 3 is provided with two side lines, the first line 5 is added to produce heavy diesel oil, the second line 6 is added to produce wax oil, and the bottom oil is obtained by the pressure difference and liquid level difference between the booster tower 3 and the decompression tower 10 through the China Unicom The pipeline 8 enters the decompression tower 10 by gravity, and the vacuum system 16 is arranged on the top of the decompression tower 10, and the absolute pressure on the top of the tower is 7kpa. The third line 13 produces wax oil, and the bottom-reducing extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com