Catalyst for preparing ethylene glycol through dimethyl oxalate hydrogenation and preparation method and application of catalyst

A technology of dimethyl oxalate and catalyst, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve problems such as high pressure, high temperature, and large dependence on metal chromium, so as to prolong service life and reduce side effects of reactions. The effect of less product and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

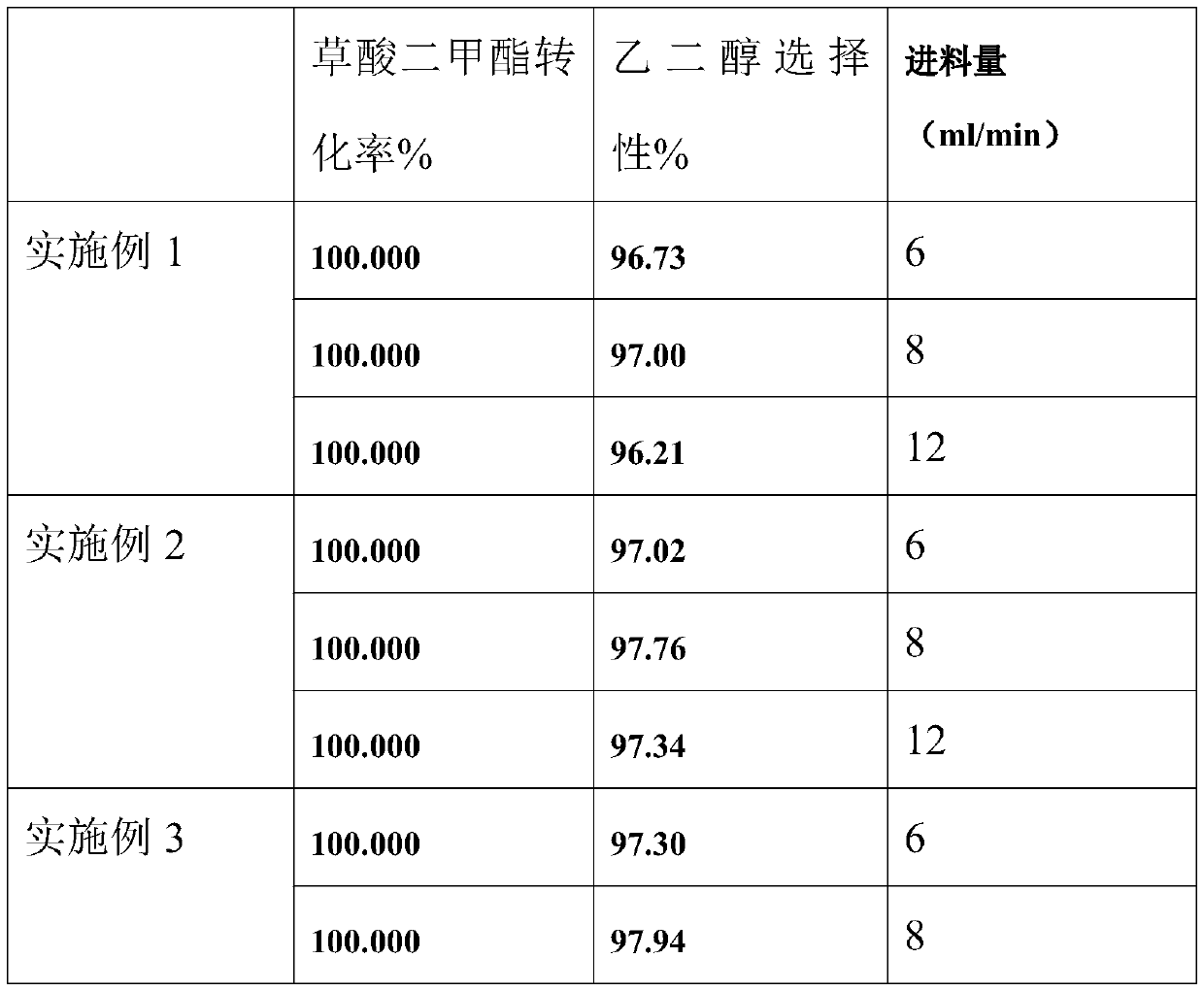

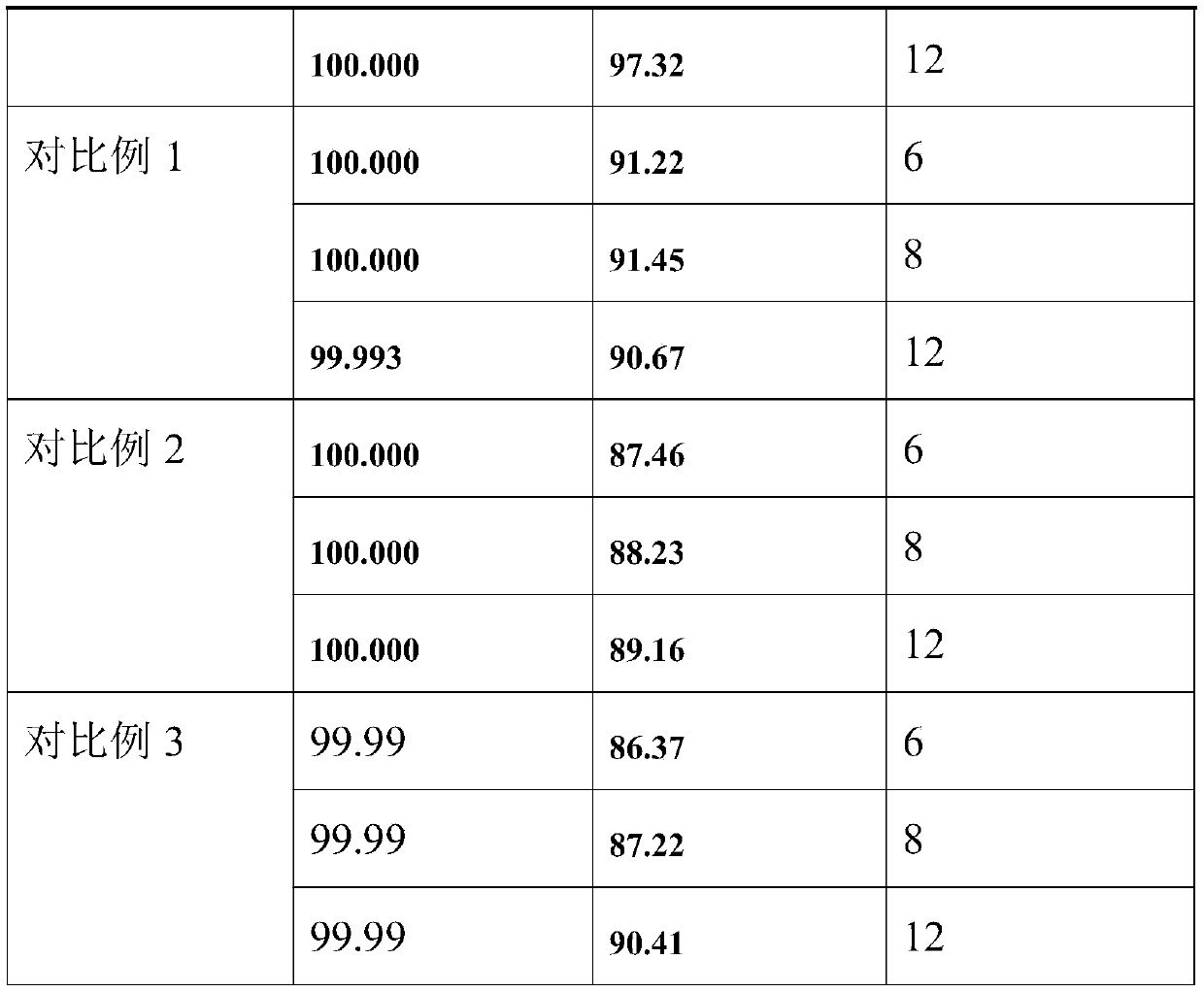

Examples

preparation example Construction

[0040] A method for preparing a catalyst, wherein the method for preparing comprises the steps of:

[0041] 1) According to the weight part of the catalyst composition, the soluble salt of the active component, the soluble salt of the auxiliary metal, and the precipitant are made into the first mixed solution;

[0042]2) adding a carrier to the first mixed solution according to the weight of the carrier contained in the catalyst, aging under stirring conditions, and then removing the ammonia water in the first mixed solution by heating to obtain a catalyst precursor;

[0043] 3) washing, filtering and drying the catalyst precursor;

[0044] 4) calcining the above-mentioned dried catalyst precursor, and finally forming into tablets or extruding strips to obtain the catalyst.

[0045] As yet another embodiment of the present case, wherein the soluble salt of the active metal is one of nitrate, acetate and sulfate.

[0046] As yet another embodiment of the present case, wherein...

Embodiment 1

[0055] A kind of catalyst of dimethyl oxalate hydrogenation ethylene glycol, catalyst is a hollow ring structure, by weight, catalyst comprises following components:

[0056] Active ingredient 20 parts;

[0057] 1 part of auxiliary metal;

[0058] Carrier 79 parts.

[0059] Wherein, the active component is silver and nickel; the carrier is carbon nanotube.

[0060] The promoter metals include 1 part cesium, 2 parts scandium, 0.5 part yttrium, and 1 part cerium.

[0061] The outer diameter of the catalyst is 10mm, the inner diameter is 5mm, and the height is 2mm;

[0062] A kind of preparation method of catalyst, preparation method comprises the steps:

[0063] (1) 7.8 g AgNO 3 , 15.5 g Ni(NO 3 ) 2 , 0.15g CsNO 3 , 1.13g Sc(NO 3 ) 3 ·6H 2 O, 0.1gY (NO 3 ) 3 ·6H 2 O, 0.3 parts Ce(NO 3 ) 3 ·6H 2 O was dissolved in 1000 milliliters of deionized water, and 35 milliliters of ammonia solution with a mass concentration of 28% was slowly added thereto to form the first...

Embodiment 2

[0070] A kind of catalyst of dimethyl oxalate hydrogenation ethylene glycol, catalyst is a hollow ring structure, by weight, catalyst comprises following components:

[0071] Active ingredient 30 parts;

[0072] 5 parts of auxiliary metal;

[0073] Carrier 65 copies.

[0074] Among them, the active components are silver and nickel; the carrier is HMS.

[0075] The promoter metals include 2 parts cesium, 3 parts scandium, 1 part yttrium, and 2 parts cerium.

[0076] The outer diameter of the catalyst is 8mm, the inner diameter is 4mm, and the height is 5mm.

[0077] A kind of preparation method of catalyst, preparation method comprises the steps:

[0078] (1) 15.6g AgNO 3 , 15.5g Ni(NO 3 ) 2 , 0.89g CsNO 3 , 4.77g Sc (NO 3 ) 3 ·6H 2 O, 1.33gY (NO 3 ) 3 ·6H 2 O, 1.92g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 1000 milliliters of deionized water, and 40 milliliters of ammonia solution with a mass concentration of 28% was slowly added dropwise to form the first mixed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com