Oil cooling system

An oil cooling system and coolant technology, applied in the direction of gear lubrication/cooling, transmission parts, components with teeth, etc., can solve problems such as increased power loss, increased radiator pressure drop, secondary heating, etc., to avoid Pressure drop, avoidance of elevation, effect of simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

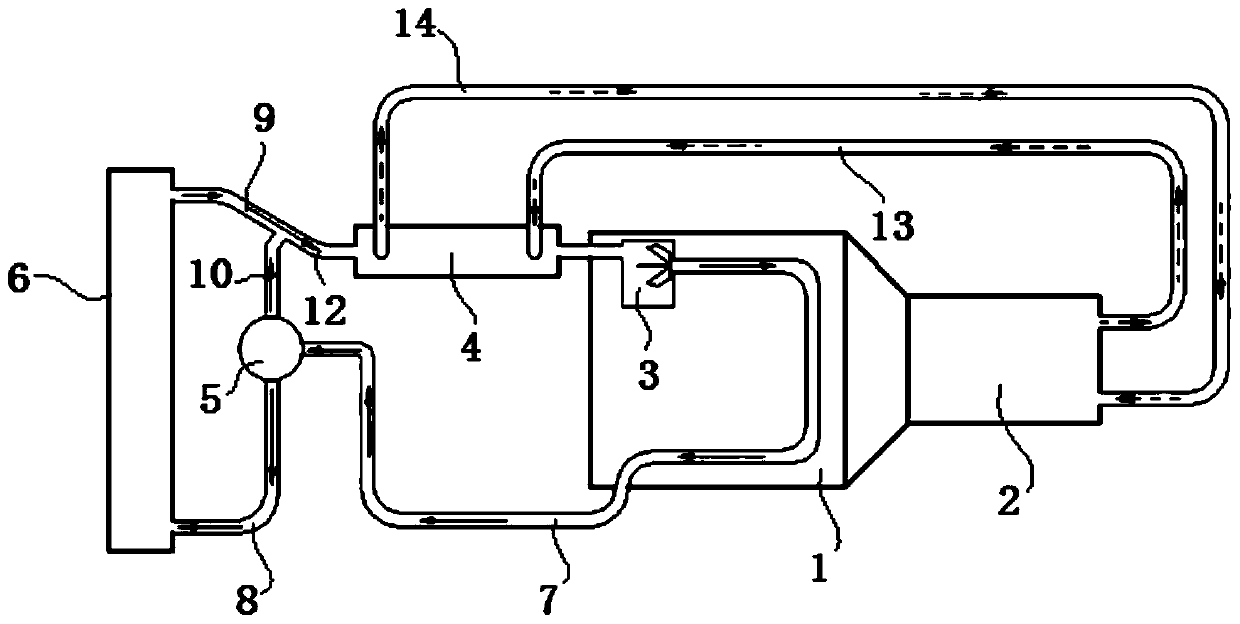

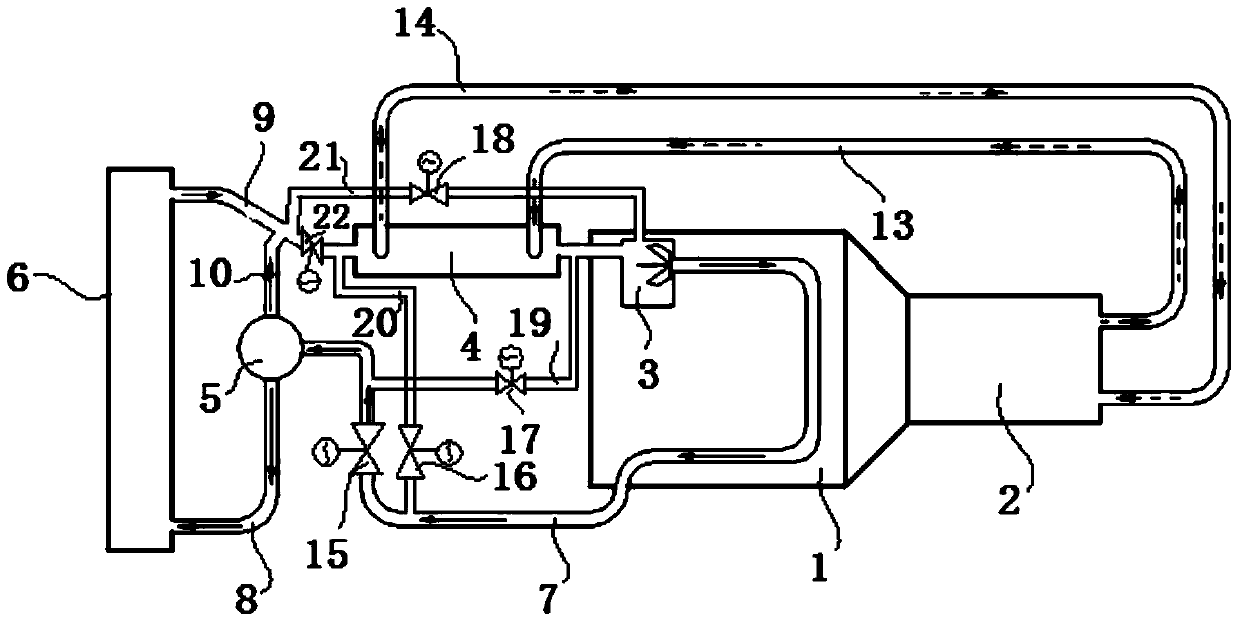

[0033] In the following description, the flow direction of coolant is represented by a solid line with arrows, and the flow direction of oil is represented by a dotted line with arrows. Moreover, although the following embodiments are described by taking an automatic transmission as an example, the described oil cooling system can also be applied to hydraulic actuators such as hydraulic retarders that require heat dissipation.

[0034] refer to figure 1, In the first embodiment, the oil cooling system includes the coolant circulation circuit of the engine, the oil circulation circuit of the hydraulic actuator and the oil cooler 4 . Specifically, in the coolant circulation circuit of the engine, the pump 3 provides flow power for the coolant, the coolant flows in the engine 1 to absorb heat, and then enters the oil cooler 4 through the pipeline 7, and the oil cooler 4 completes and After the heat exchange of the oil, the coolant enters the thermostat 5 through the pipeline 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com