High-efficiency and low-resistance dust remover for gas separation and purification

A technology of gas separation and dust collector, applied in the direction of separation method, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of large energy loss, large pressure drop, complex structure, etc., and achieve reduced energy consumption and small pressure drop , the effect of high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

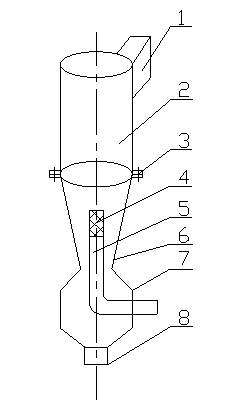

[0027] like figure 1 Shown: when the dust collector of the present invention is in use, the gas containing dust particles enters the tangential inlet 1 of the DC cyclone separator, and the dust particles are thrown to the wall of the device under the action of centrifugal force, move spirally along the cyclone separation wall, and finally It falls into the ash hopper 7 below and is discharged from the discharge port 8; at the same time, the gas separated by the cyclone moves downward along the center of the cavity of the DC cyclone and enters the exhaust pipe 5, and the gas is installed through the upper end of the exhaust pipe 5 The filter element 4 enters into 5 to further purify the gas. When pulse recoil is used, the dust deposited on the filter element 4 will also fall into the ash hopper 7 below and be discharged from the discharge port 8 . At the same time, in order to facilitate disassembly and replacement of the filter element 4, the cylindrical body 2 of the DC cycl...

Embodiment 2

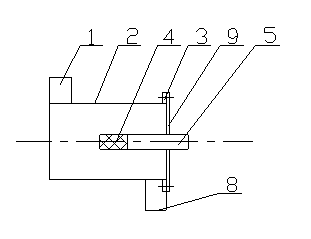

[0029] like figure 2 Shown: when the dust collector of the present invention is in use, the gas containing dust particles enters the tangential inlet 1 of the DC cyclone separator, and the dust particles are thrown to the wall of the device under the action of centrifugal force, move spirally along the cyclone separation wall, and finally It is discharged from the discharge port 8; at the same time, the gas separated by the cyclone moves horizontally along the center of the cavity of the DC cyclone into the exhaust pipe 5, and the gas enters into the exhaust pipe 5 through the filter element 4 installed at the inlet end of the exhaust pipe 5, and further Purified gas. When pulse recoil is used, the dust deposited on the filter element 4 will also be discharged from the discharge port 8 . In order to facilitate disassembly and replacement of the filter element 4 , the cylindrical body 2 of the DC cyclone separator is designed as a detachable connection structure between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com