Isomerization method for light hydrocarbon

A technology for isomerization and light hydrocarbons, applied in the field of isoparaffins, can solve the problems of products that are not easy to isomerize, cannot solve the problem of accumulation of heavy components, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

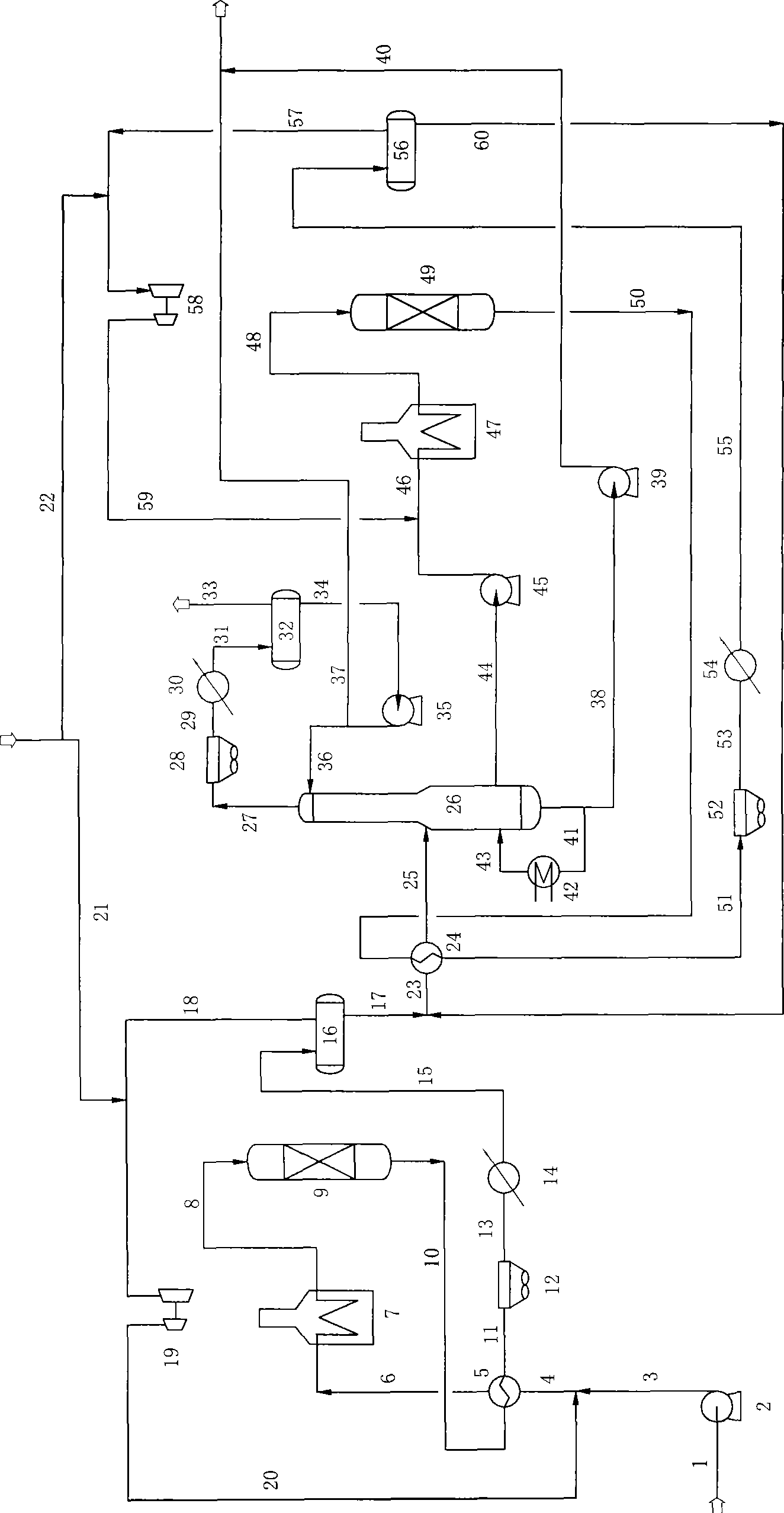

[0037] This embodiment adopts the technological process shown in the accompanying drawing. The composition and properties of light hydrocarbon raw materials, the main reaction conditions of isomerization and the composition and properties of isomerization products are explained below:

[0038] 1. Composition and properties of light hydrocarbon feedstock

[0039] The weight composition of light hydrocarbon feedstock is as follows:

[0040] n-butane, wt% 2.60

[0041] Isobutane, wt% 0.30

[0042] n-Pentane, wt% 23.54

[0043] Isopentane, wt% 9.56

[0044] Cyclopentane, wt% 1.39

[0045] n-Hexane, wt% 32.66

[0046] Isohexane, wt% 22.13

[0047] Cyclohexane and methylcyclopentane, wt% 4.15

[0048] Benzene, wt% 1.65

[0049] C7 and above hydrocarbons, wt% 2.02

[0050] The research octane number for the light hydrocarbon feedstock was 59.4. Due to the relatively high octane number requirements for gasoline products, generally above 90, if light hydrocarbon raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com