Crude oil gradual distillation energy saving apparatuses and technological process

A technology of energy-saving equipment and process methods, applied in the direction of vacuum distillation, etc., can solve the problems of high energy consumption in crude oil processing, and achieve the effects of improving product quality, reducing scale, and reducing heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

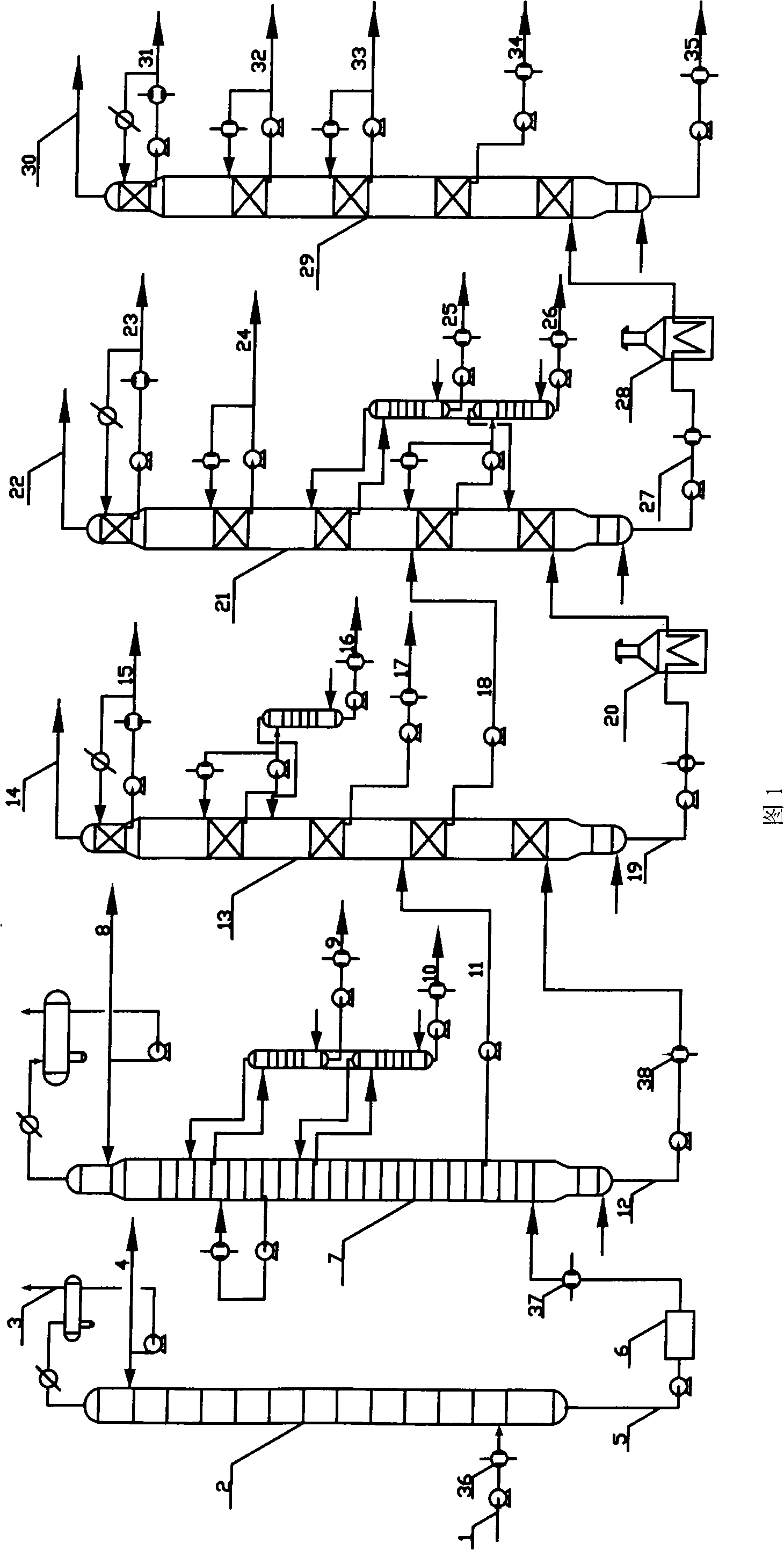

[0029] Embodiment 1: use the method of the present invention for the transformation of a certain crude oil distillation unit. The original flow process mainly includes the initial distillation tower, atmospheric furnace, atmospheric tower, decompression furnace, and decompression tower. The original processing capacity of the device is 3.5 million tons / day annual crude oil. The flow chart is shown in Figure 1, mainly including a flash distillation tower, an initial distillation tower, an initial decompression tower, a shallow decompression furnace, a shallow decompression tower, a deep decompression furnace, and a deep decompression tower. After the transformation, the design and processing capacity of the device will be increased to 6 million tons / year, and the maximum can reach 7 million tons / year.

[0030] The crude oil 1 is heated to 150° C. through the heat exchange network 36 and enters the flash tower 2 . The gas 3 and part of the light gasoline 4 are extracted from th...

Embodiment 2

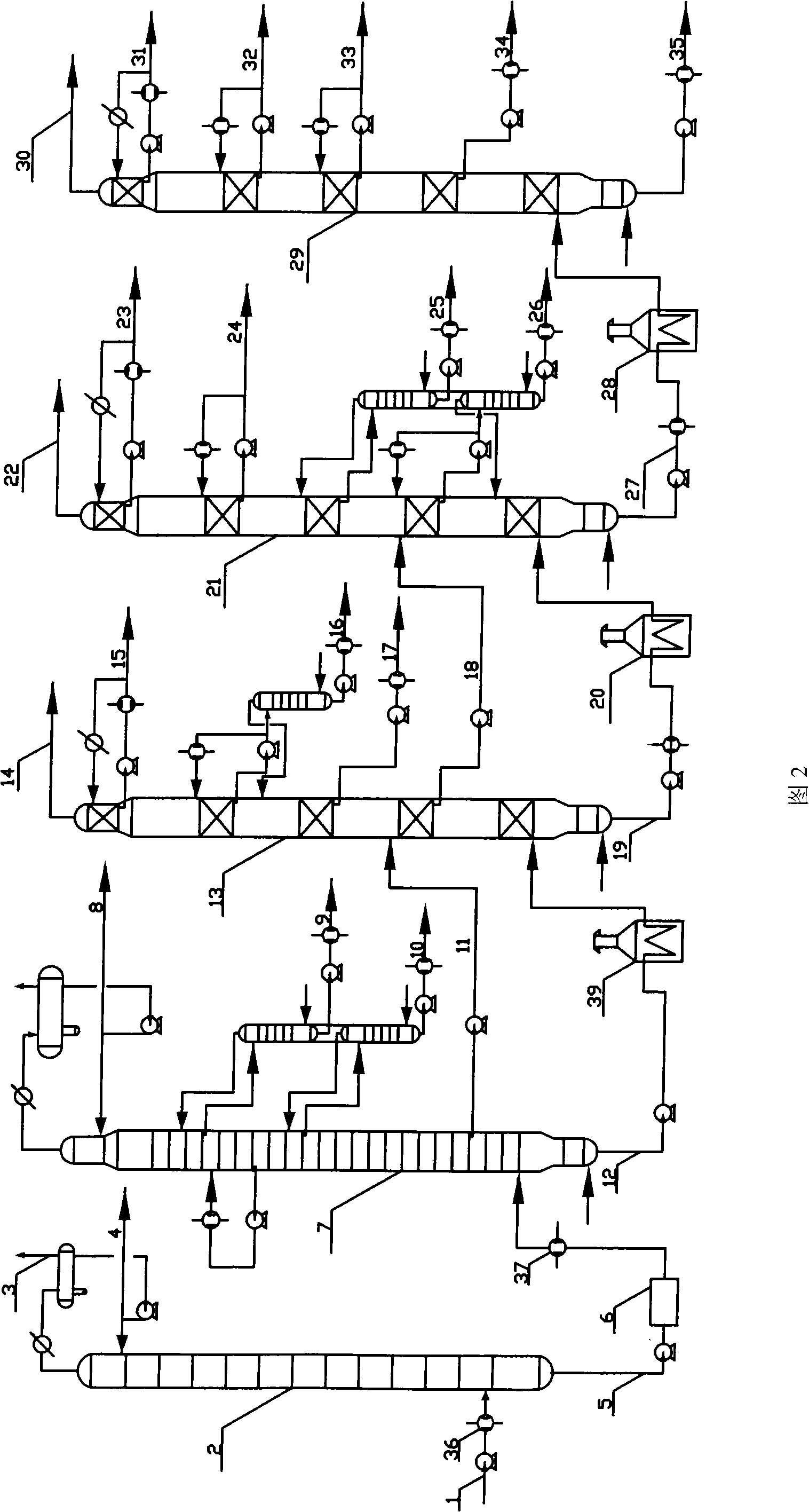

[0032] Embodiment 2: the present invention can also be realized through the following technical solutions:

[0033] The flow chart is shown in Figure 2, which mainly includes a flash tower, an initial distillation tower, an initial decompression furnace, an initial decompression tower, a shallow decompression furnace, a shallow decompression tower, a deep decompression furnace, and a deep decompression tower.

[0034] The crude oil 1 is heated to about 150° C. through the heat exchange network 36 and enters the flash tower 2 . The gas 3 and part of the light gasoline 4 are extracted from the top of the flash tower, and the flash bottom oil 5 enters the electric desalination device 6 . The crude oil after electric desalination, desalination and dehydration is about 135°C, and it passes through the heat exchange network 37 to exchange heat to about 275°C and enters the initial distillation tower 7; the gasoline component 8 is extracted from the top of the initial distillation to...

Embodiment 3

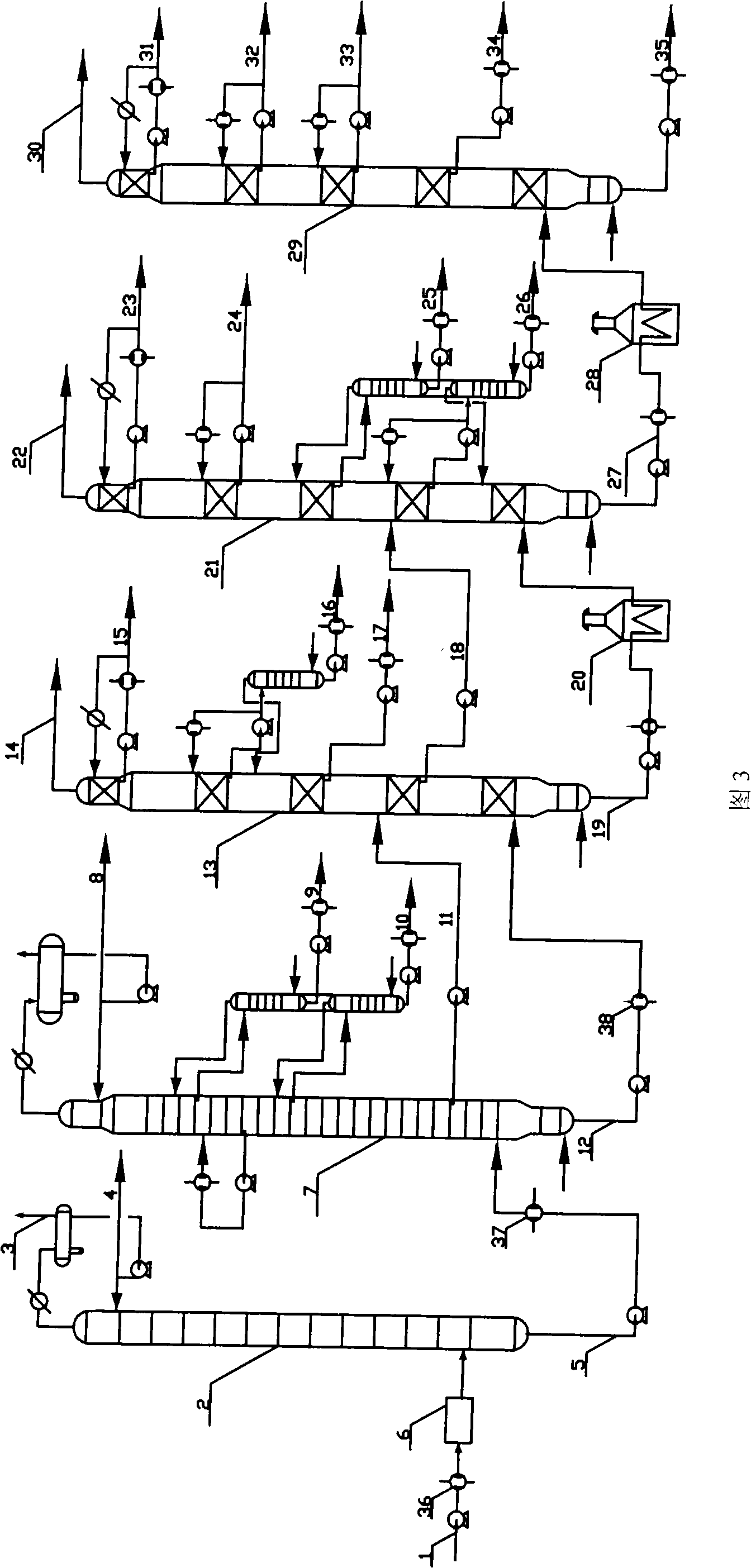

[0036] Embodiment 3: the present invention can also be realized through the following technical solutions:

[0037] The flow chart is shown in Figure 3, mainly including flash tower, initial distillation tower, initial decompression tower, shallow decompression furnace, shallow decompression tower, deep decompression furnace and deep decompression tower.

[0038] The crude oil 1 is heated to 150° C. through the heat exchange network 36 and enters the electric desalination device 6 . The crude oil after desalination and dehydration from the electric desalination is about 135° C. and enters the flash tower 2 . The gas 3 and some light gasoline 4 are extracted from the top of the flash distillation tower, and the flash bottom oil 5 passes through the heat exchange network 37 to exchange heat to about 275°C and enters the primary distillation tower 7; the gasoline component 8 is extracted from the top of the primary distillation tower, and the initial The distillation tower is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com