System and method for treating high-salinity wastewater by utilizing high-temperature ash

A technology for high-salt wastewater and ash treatment, which is applied in the field of thermal power plant water treatment, can solve problems such as high cost and low efficiency, and achieve the effects of high equipment utilization rate, good evaporation effect, and low investment and operation and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

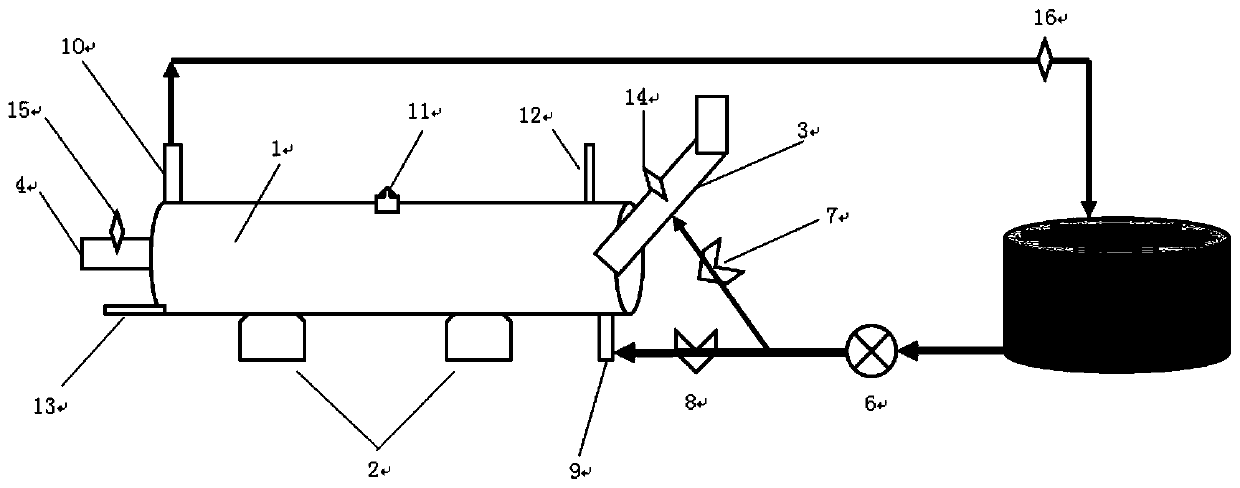

[0024] Such as figure 1 As shown, the present invention provides a method and system for treating high-salt wastewater using high-temperature ash, including a drum slag cooler 1, equipment support 2, slag inlet pipe 3, slag outlet pipe 4, high-salt wastewater storage tank 5, booster Pressure pump 6, first flow adjustment door 7, second flow adjustment door 8, cooling water inlet 9, cooling water outlet 10, safety valve 11, front dust extraction pipe 12, rear dust extraction pipe 13, slag inlet temperature measuring point 14 , slag discharge temperature measuring point 15 and cooling water return water temperature measuring point 16, the cooling water inlet 9 and the cooling water outlet 10 provided on the drum slag cooler 1 are respectively connected with the wastewater outlet and the wastewater inlet on the high-salt wastewater storage tank 5 , forming a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com