Method for rapidly peeling taros

A taro and fast technology is applied in the field of fast peeling of taro, which can solve the problems of serious environmental pollution, high labor intensity and rough pulp surface, and achieve the effects of reducing salt consumption, low labor intensity and good peeling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A method for quickly peeling taro, specifically comprising the following steps:

[0013] (1) Ripening: Heat the salt solution to 145°C and keep it at a constant temperature; then put the washed taro into the solution and cook for 2 minutes; the components and their mass fractions in the salt solution are composed of 65wt% food-grade chlorine Calcium chloride, 0.04wt% food-grade sodium polyphosphate, 0.06wt% food-grade sodium gluconate, and all the other ingredients are water;

[0014] (2) Wrinkling: quickly remove the taro and soak in cold water for 1.5 minutes;

[0015] (3) Peeling: Use the conveyor belt to put the taro into the drum peeling machine for peeling, and through the friction between the taro and the taro, and between the taro and the peeling machine (manual peeling can also be used), the peeled taro can be obtained.

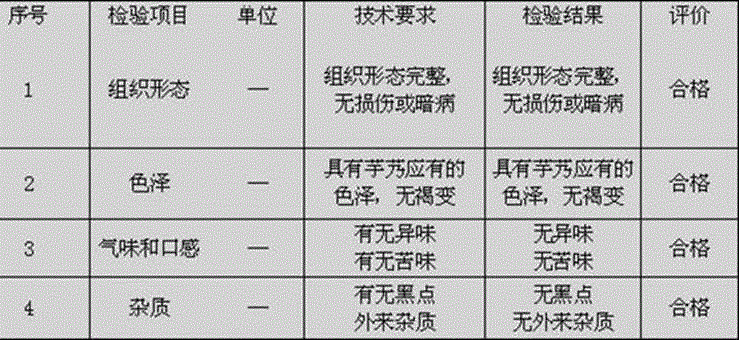

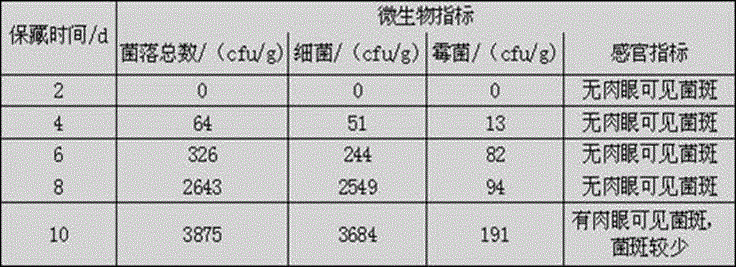

[0016] Carry out sensory evaluation and microbial index evaluation on the peeled taro: 10 experienced personnel form an evaluation team to e...

Embodiment 2

[0022] With above-mentioned embodiment 1, its difference is:

[0023] Step (1) During ripening: heat the salt solution to 135°C and keep it at a constant temperature; then put the washed taro into the solution and cook for 3 minutes; the components and their mass fractions in the salt solution consist of 20wt% food-grade calcium chloride, 0.01wt% food-grade sodium polyphosphate, 0.01wt% food-grade sodium gluconate, and all the other ingredients are water;

[0024] Step (2) Wrinkling: Quickly remove the taro and soak in cold water for 1 minute.

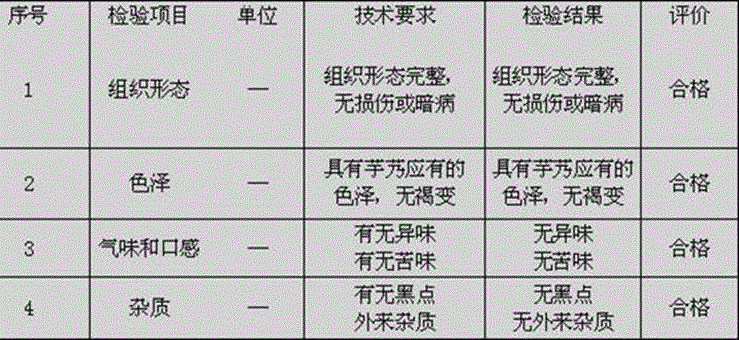

[0025] Carry out sensory evaluation and microbial index evaluation on the peeled taro: 10 experienced personnel form an evaluation team to evaluate the appearance, color and taste of the peeled taro. See Table 2.1 for sensory evaluation results, Table 2.2 for microbial testing results, Table 6 for peeling rate, yield rate, and loss rate, and Table 7 for color evaluation.

[0026] Table 2.1 Sensory evaluation results

[0027]

[0...

Embodiment 3

[0031] With above-mentioned embodiment 1, its difference is:

[0032] Step (1) During aging: heat the salt solution to 160°C and keep it at a constant temperature; then put the washed taro into the solution and cook for 1 min; the components and their mass fractions in the salt solution are composed of 70wt% food-grade calcium chloride, 0.10wt% food-grade sodium polyphosphate, 0.10wt% food-grade sodium gluconate, and all the other ingredients are water;

[0033] Step (2) Wrinkling: Remove the taro quickly and soak it in cold water for 1-2 minutes.

[0034] Carry out sensory evaluation and microbial index evaluation on the peeled taro: 10 experienced personnel form an evaluation team to evaluate the appearance, color and taste of the peeled taro. See Table 3.1 for sensory evaluation results, Table 3.2 for microbial testing results, Table 6 for peeling rate, yield rate, and loss rate, and Table 7 for color evaluation.

[0035] Table 3.1 Sensory evaluation results

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com