Patents

Literature

83results about How to "Use less salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting sodium heparin

The invention relates to a method for extracting sodium heparin, which comprises the following steps: (1) enzymic hydrolyzing intestinal mucosa in a conventional method, and adopting enzyme preparation for the hydrolysis: mixture which is formed by mixing prolease, papain and lipase at a mass ratio of 1 to 4: 1 to 3: 0.1 to 0.3, and selecting the prolease from one of 2709 enzyme, AS1.398 enzyme and pancreatin; (2) resin adsorbing in a conventional method; (3) resin eluenting in a conventional method; (4) settling out the sodium heparin in a conventional method; (5) purifying the sodium heparin in a conventional method; (6) drying the sodium heparin in a conventional method to obtain the pure sodium heparin. An improved solution is characterized in that precipitator is added before filtering and hydrolyzing the mixture in the step 1. The method has simple process, short production period, simple and convenient operation and less investment, and is applicable to the industrialized mass production. The purity of the heparin can reach 100 to 120IU / mg, the extraction efficiency can reach 100 million IU / 1700 to 1800 chatterlings, the extraction efficiency can be improved by 20 to 30 percent, consumed salt can be reduced by 30 to 50 percent, water can be reduced by 50 to 70 percent, energy can be reduced by 30 to 40 percent, and the recycling rate of the crude protein can reach 60 percent.

Owner:GUANGYUAN HAITIAN IND

Manufacturing method of novel semisolid quick-fermentation pickle

PendingCN105394669AIncrease concentrationFull of nutritionClimate change adaptationLactobacillusLeuconostoc mesenteroidesSludge

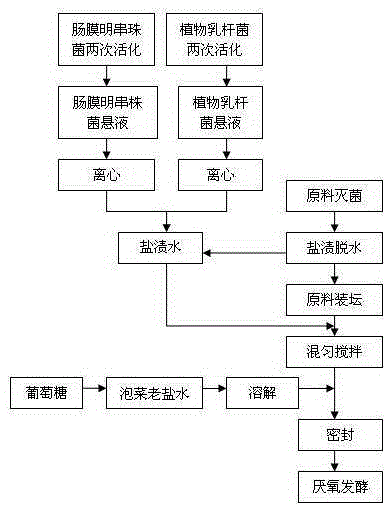

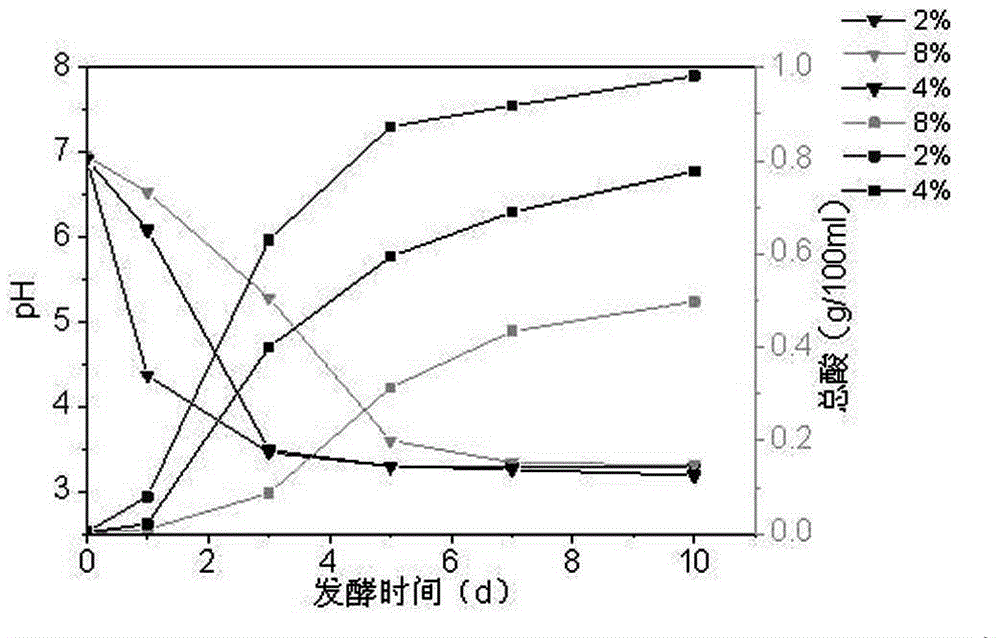

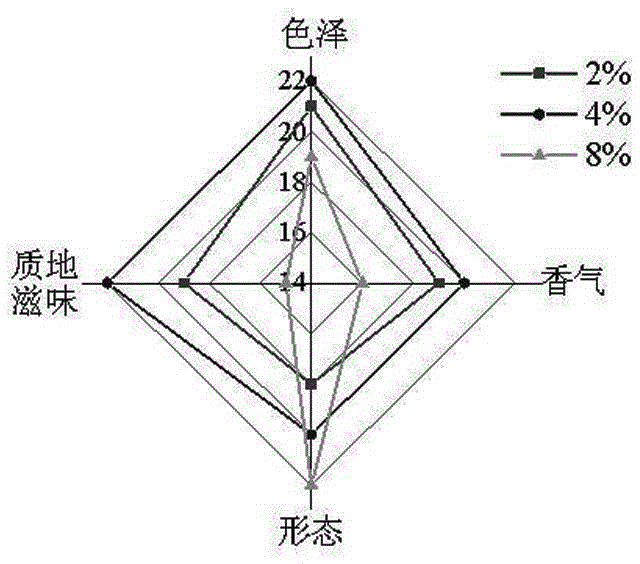

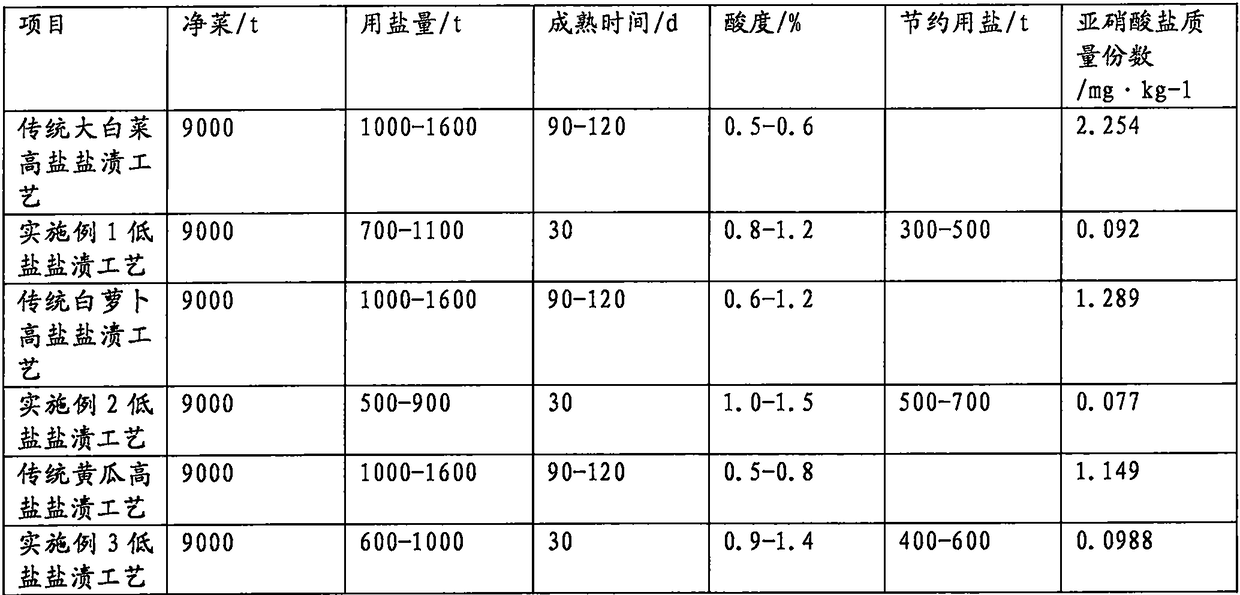

The invention belongs to the field of food processing, and in particular discloses a manufacturing method of a novel semisolid quick-fermentation pickle. The method comprises the following steps: (1) pretreating raw materials; (2) performing disinfection treatment on a pickle jar; (3) salting and dehydrating a pickle; (4) preparing lactobacillus plantarum and leuconostoc mesenteroide bacterial sludge; (5) adding auxiliary materials and a culture; (6) adding pickle old brine and glucose; (7) laying vegetable in the jar flat, adding a layer of film at the opening of the pickle jar, filling up the pickle jar edge water groove with water, thus achieving a double-layer sealing effect, and fermenting under normal temperature. According to the method, the pickle raw materials are firstly salted and dehydrated, and then leuconostoc mesenteroide and the lactobacillus plantarum are added into the pickle jar, so that an obtained pickle substrate is high in concentration, rich in nutrition, and short in fermentation period, and also has the characteristics of preventing pickle mildew, improving pickle taste, and improving pickle quality and safety, and the problem of high cost caused by great salt consumption and water consumption in pickle industrialization can be solved.

Owner:SICHUAN DONGPO CHINESE PAOCAI IND TECH RES INST

Method for preparing industrial fermentation pickled vegetable

ActiveCN101697751AAdd beneficial ingredientsGood antibacterial effectFruits/vegetable preservation using acidsSaline waterIndustrial fermentation

A method for preparing industrial fermentation pickled vegetable relates to a method for preparing fermentation pickled vegetable, solving the problems that pickled vegetable produced by the current large-scale factory is still prepared by traditional technique depending on natural fermentation and the cabbage in the fermentation jar can be easily damaged by other bacteria and be easily rotten and goes bad. The method comprises the following steps: 1, palletizing cabbages; 2, adding pickled vegetable fermentation engineering bacteria; 3, fully injecting brine to the fermentation jar; 4, carrying out fermentation to obtain the product of pickled vegetable. The method uses controllable industrial technique to ferment the pickled vegetable; the added components are known and controllable; thus, the method avoids the pollution of the cabbage by other bacteria, rot and metamorphism.

Owner:HEILONGJIANG UNIV

Process for producing Chinese style fermented meat product with low salt and no nitrate or nitrite

InactiveCN101044906AReduce salt consumptionStrong sauce and ester aromaMeat/fish preservation using chemicalsFood preparationChemistryRaw meat

Owner:SICHUAN UNIV

Method for producing high quality Jinhua ham

InactiveCN101194639AImprove sanitationGood for healthSausage makingFood preparationFlavorProduction rate

The invention discloses a method for manufacturing high-grade kinghua hams, which is processed in a manufacturing shop which is provided with a temperature and moisture control device which leads products to be manufactured under the technological conditions of salination temperature of 2-4DEG C, percentage humidity of 81-95%, pre-salting temperature of 2.5-4 DEG C, percentage humidity of 75-79% or 81-90%, salting temperature of 2.5-4 DEG C, percentage humidity of 71-79%, air-dry temperature of 16-26DEG C, percentage humidity of 66-85%, and further the products are finished by triple-fired maturing. The manufacturing method is promoted to a hermitical manufacturing style from the original open style manufacturing method which completely depends on climate and environment, which improves the sanitary condition of the ham production greatly, thereby the quality of the products are ensured. The invention further has the advantages of short manufacturing period of the products, and high production rate, and the traditional flavor can be maintained.

Owner:HENAN AGRICULTURAL UNIVERSITY

Processing method of clay jar pickled radishes

InactiveCN104000147ABright colorElasticClimate change adaptationFood preparationSaline waterAcid water

A processing method of clay jar pickled radishes comprises nine processes of material selecting and cleaning, peeling and dicing, hardening treatment, salting and infusing, jar sealed pickling, rinsing and desalting, seasoning pickling, jar sealed flavor pickling, and packaging and sterilization. The processing method of the clay jar pickled radishes has the advantages that pickling is conducted twice, first, salt water is used for sealed pickling, after 5-10 days, seasonings are used for pickling, thus nitrite generated by pickles can be effectively evacuated and dispelled after the fastigium, related substances and acid water in the seasonings and special sealing materials in the whole process are combined to lower the nitrite contained in the pickles to the lowest degree. Meanwhile, the salt dosage in the whole process is small, natural quality keeping materials are added in the seasonings, and the expiration date can not be shortened while the salt content of products is small. Accordingly, the produced radish pickles are bright in color, sour and sweet, tasty, aromatic in flavor, high in resilience, crisp and tender. Meanwhile, the salt content is small, the content of the nitrite is very low, and the quality of the pickles is greatly improved.

Owner:CHONGQING YONGQI AGRI DEV

Industrial sauerkraut fermentation process

InactiveCN109349568AShorten the fermentation cyclePromote maturityClimate change adaptationFood scienceCooking & bakingFlavor

The invention discloses an industrial sauerkraut fermentation process. The process comprises the following steps of fresh vegetable acceptance, first low salt high acid salt stain, second low salt stain, shaping, cleaning, cutting, desalting, dehydrating, blending, packaging, bacteria extinction and storage. A reasonable salt pre-baking process reasonablely controls the process parameters such astemperature, acidity, salinity and the like, thereby greatly reducing the nitrite content in a sauerkraut finished product, which satisfies the consumer demand for low-salt and high-acid sauerkraut. The process solves the problems of insufficient fermentation, low nutritional value and poor flavor of the sauerkraut by rationally arranging the dosage of a direct-injection lactic acid bacteria agent, a condiment and a nutrient.

Owner:湖南省香味园食品股份有限公司

Flavor-improved salted chicken egg yolk

InactiveCN107439997AKeep the flavorReduce oxidation rateFood thermal treatmentFood ingredient as taste affecting agentYolkAcetic acid

The invention discloses flavor-improved salted chicken egg yolk. The flavor-improved salted chicken egg yolk is prepared from raw materials including chicken egg yolk, food-grade ethyl acetate, a food-grade osmotic pressure regulator, food-grade acetic acid, food-grade ethanol, a food-grade antioxidant and table salt. Chicken eggs with the freshness higher than or equal to 72 Ha are subjected to separation of egg white and egg yolk, a flavor substance is added to the egg yolk, ultrasonic pretreatment and heat-cold pretreatment are performed sequentially, the egg yolk is added to an isotonic salting solution to be completely immersed, table salt is added multiple times, so that the salting solution has certain concentration gradients, the egg yolk is salted for a period of time and cooked at 70 DEG C, and the flavor-improved salted chicken egg yolk can be obtained. The flavor-improved salted chicken egg yolk has the characteristics of being refreshing in flavor, fine, moderate in saline taste and high oil yield, the process is simple, a little salt is used, and industrial production is easy to realize.

Owner:马述腾

Flavored fermented chili preparation method

PendingCN106798280AAdd flavor and nutritionStrong adsorptionFood scienceVillosa choctawensisGingerol

The invention relates to a flavored fermented chili preparation method, and belongs to the technical field of foods. Flavored fermented chili is prepared from the following raw materials in parts by weight: 85 to 115 parts of red pepper, 0.3 to 10 parts of raw soybeans, 1 to 10 parts of raw ginger, 1 to 10 parts of garlic, 3 to 7 parts of salt, 2 to 6 parts of rock sugar and 2 to 8 parts of baijiu. The flavored fermented chili preparation method comprises the steps: selecting fresh red pepper, raw soybeans and raw ginger without mildew, washing and filtering for later use; peeling the garlic for later use, and mixing and dissolving the salt, the rock sugar and the baijiu for later use; mixing and chopping the prepared red pepper, ginger and garlic into blocks of 5-10mm, evenly mixing the raw soybeans, a mixed solution of the salt, the rock sugar and the baijiu, and chopped fine chili blocks, canning and sealing. The flavored fermented chili prepared according to the invention has the advantages of being long in shelf life, crisp and tender, sweet and salty, spicy with sour, delicious and nutritious, no any additive is added, and the flavored fermented chili is a green snack and seasoning with excellent mouthfeel and taste.

Owner:贵州长顺八妹农副产品开发有限公司

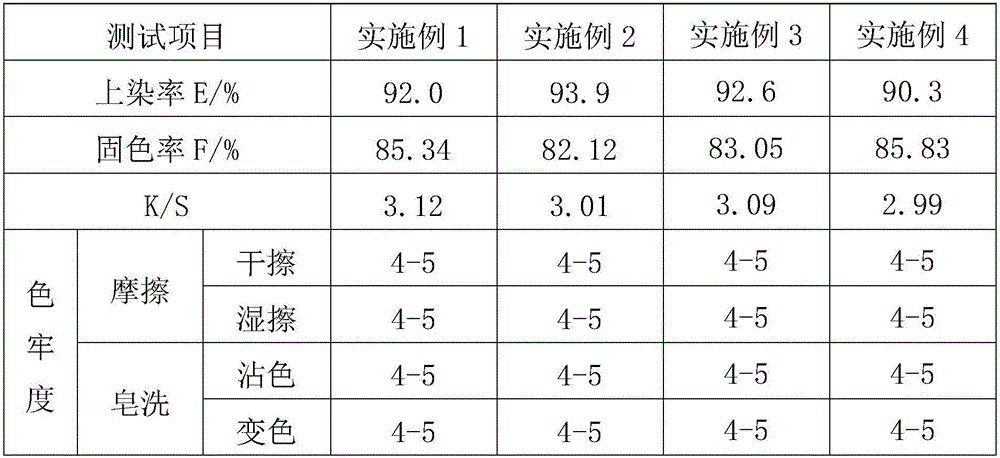

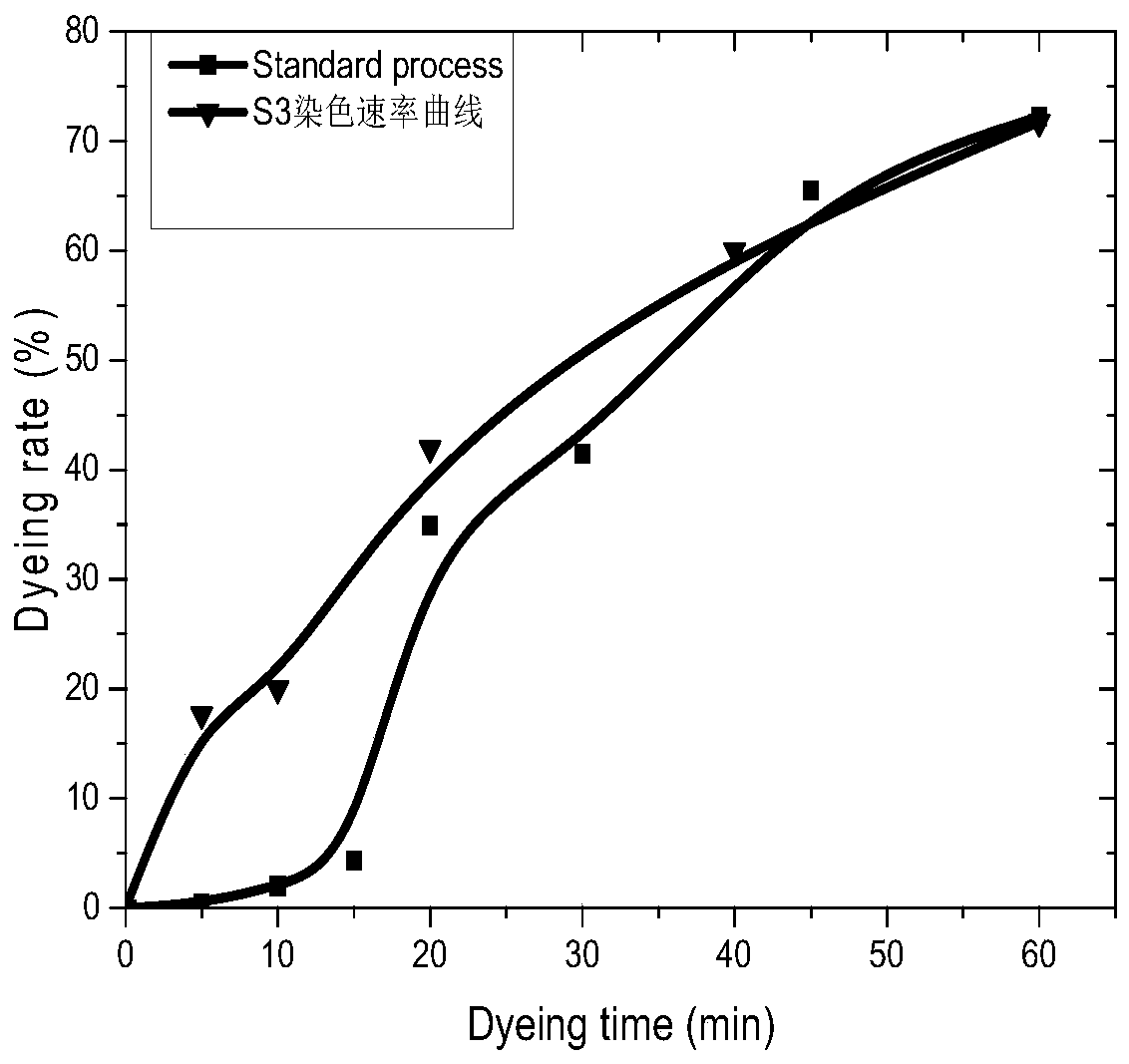

Nylon-cotton fabric one-bath dyeing method with activated dye

InactiveCN106758374ASoft touchImprove the finishDyeing processMicroballoon preparationRare earthSurface-active agents

The invention discloses a nylon-cotton fabric one-bath dyeing method with an activated dye. The method comprises the steps that a nylon-cotton fabric is soaked into a activated dye liquor, dyeing is conducted under the conditions that the bath ratio is adjusted to be 1:(5-20) and the temperature is 20-30 DEG C, the temperature is raised to 55-75 DEG C, heat preservation is conducted for 5-15 min, then the temperature is raised to 105-125 DEG C, heat preservation is conducted for 30-40 min, 1-5 g / L sodium carbonate is added, and heat preservation is conducted for 5-25 min at the fixing temperature of 60-90 DEG C, wherein the activated dye liquor comprises 1-5% owf of rare earth coordinated microencapsulated activated dye, 5-15 g / L of anhydrous sodium sulphate, 0.5-10 g / L of pH lubricating agent, 0.1-0.3 g / L of hydrozybenzene halogenide and 0.01-0.1 g / L of organic fluoride surface active agent. The dyeing method has the advantages of being high in fixation rate and good in leveling property and is simple in technology and short in dyeing time, the consumption of salt in the activated dye is greatly reduced, and environmental protection is achieved.

Owner:无为竟成服饰有限公司

Preparation method of clean type pure cotton yarn sizing agent

The invention discloses a preparation method of a clean type pure cotton yarn sizing agent. The preparation method comprises the following steps: firstly, preparing a glutin dissolved liquid and a monomer pre-emulsion; then, under the effect of an initiator, carrying out reaction with an acrylic acid monomer to prepare a protein derivative assistant; and finally, preparing a positive ion crosslinking modifier WLS and carrying out reaction with the protein derivative assistant to obtain the clean type pure cotton yarn sizing agent. The invention relates to the preparation method of the clean type pure cotton yarn sizing agent. The sizing agent not only has the characteristics of improving the strength of the yarn, reducing yarn hairiness, improving the abrasive resistance of the yarn, having good compatibility with other slurry, replacing PVA (Polyvinyl Acetate) slurry and effectively reducing the breakage of the cotton yarn during weaving and the like, but also the dyeing performance of the sizing fabric is improved by means of the structural characteristic of the slurry, so that the use level of salt for dyeing is reduced and the use level of dyes is saved, and slurry on the fabric is not completely removed, so that the environmental pollution is effectively alleviated and the waste protein resources are effectively used.

Owner:ZHEJIANG YUBO TEXTILE CO LTD

Curing method of flavored tea-scented cured beef

The invention discloses a curing method of flavored tea-scented cured beef. The curing method comprises the following steps: (1) by the weight of fresh beef, weighing the seasonings such as 3-3.5% of salt, 0.5-1.0% of pu'er tea powder and 1% of white sugar; (2) rubbing: preparing the three seasonings and spreading the seasonings on the surface of the beef in sequence to rub repeatedly; (3) curing: stacking the beef to cure indoors at a constant temperature of 5-8 DEG C for no less than 30 days, and drying by cold air at 8-18 DEG C under a hanging condition until the weight of the beef is reduced to 58-61% of the weight of the fresh beef; and (4) fermentation: fermenting in a fermentation room in which the temperature is 20 DEG C and the relative humidity is 71% for 3 months, and by the weight of 100kg of fresh beef, obtaining the flavored tea-scented cured beef after the beef is cured and fermented to 55+ / -2kg. The cured beef has unique tea scent and is sweet in taste after being fried.

Owner:YUNNAN BAILEKAI AGRI & ANIMAL HUSBANDRY DEV CO LTD

Processing method of snakeheaded fishes

The invention relates to a processing method of snakeheaded fishes. The processing method particularly comprises the following steps of 1) performing acceptance check on the snakeheaded fishes and selecting the checked snakeheaded fishes: performing hygienic general investigation on the snakeheaded fishes in fishing waters, and performing detection on heavy metal and pesticide residues; when selecting a fish source, rejecting dead fishes and all the impurities; 2) culturing the snakeheaded fishes with clean water: putting the selected snakeheaded fishes in a culturing tank with clean water for culturing the snakeheaded fishes with clean water for 2-3 days; 3) removing fishy smell and performing disinfection: putting fresh and living snakeheaded fishes after being cultured with clean water culturing in clean water for soaking for 30-50 minutes; 4) cutting and pickling the soaked snakeheaded fishes: removing internal organs from the snakeheaded fishes after fishy smell removal and disinfection, thoroughly cleaning the snakeheaded fishes without the internal organs, cutting fish meat into slices, and cutting fish bones into segments; 5) compounding pickled materials; 6) putting fish meat slices into a container, weighing the pickled materials in proportion, uniformly mixing the weighed pickled materials, putting the fishes and the pickled fishes in a manner of staggered arrangement of a layer of the fishes and a layer of the pickled materials, uniformly sprinkling the pickled materials on the fishes, after the container is filled with the fishes, compressing the fishes, and sealing a cover; after the cover is sealed, putting the container in a freezer of 0-4 DEG C for standing pickling for 72 hours, and turning over the fishes and the pickling materials up and down every 6 hours so that products in the same batch are uniformly pickled; and 7) putting the pickled fish meat slices into a pot for steaming, and matching the steamed fish meat slices with condiments for eating.

Owner:陈玉海

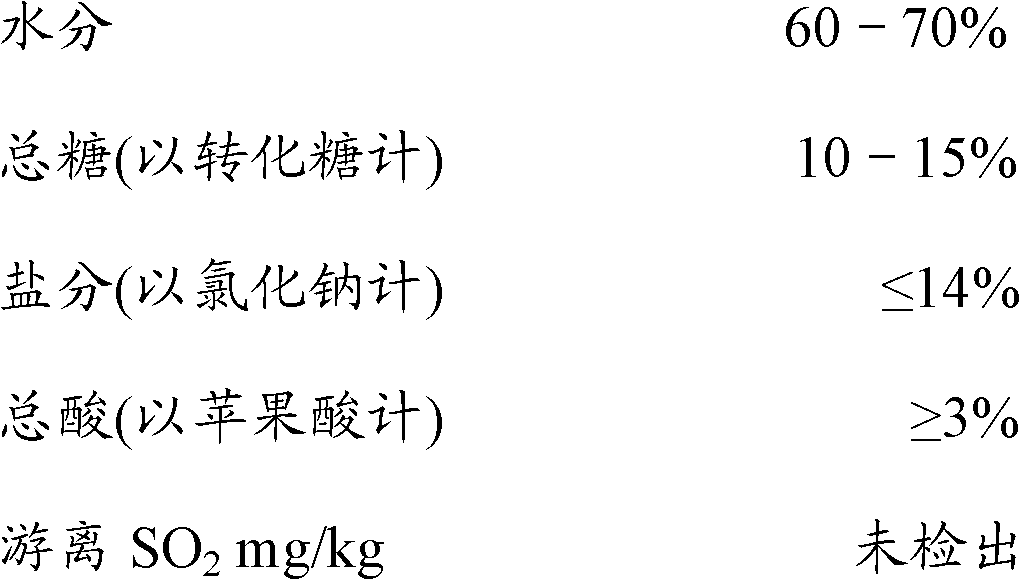

Processing technology of green plums

InactiveCN102613515AAvoid Nutrient LossUse less saltClimate change adaptationFood preparationFlavorAlcohol

The invention discloses a processing technology of green plums. According to the technology of the invention, cleaned green plums are put into a pickling medium for sealed pickling, and in the pickling process, NaCl is added gradiently to maintain a constant NaCl concentration in the pickling medium. When the pickling process is finished, the pickling medium becomes pickling marinade that can be used repeatedly. The technology of the invention is characterized by less salt consumption and fast flavor forming, and after pickling, the marinade can be reused or can be subjected to distillation to recover alcohol for processing green plum wine, thus overcoming the problem of substantial emission of harmful brine in traditional plum product processing; a lot of nutrient loss caused by traditional nonintact processing can be avoided, and meanwhile, the processing process adopts synergistic corrosion prevention of salt, wine, vinegar, and oxygen separation, and is free of SO2 and staining (no pigment).

Owner:漳浦县小城水产养殖场

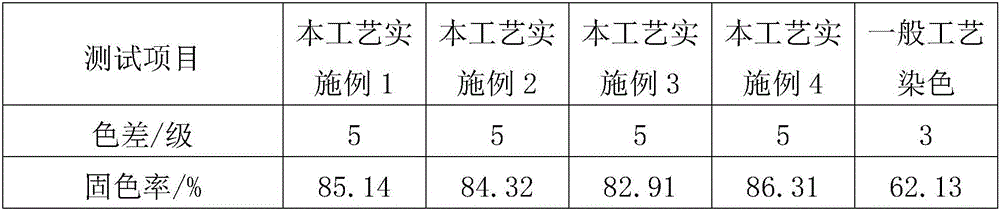

Polyester cotton dispersing and reactive dye one bath process dyeing technology

ActiveCN106758328AIncrease productivityReduce distractionsDyeing processMicroballoon preparationMicroencapsulationsReactive dye

The invention discloses a polyester cotton dispersing and reactive dye one bath process dyeing technology. The technology comprises the steps that dye liquor is prepared at room temperature, the dye liquor pH is adjusted to be 4-6, polyester cotton is immersed in the dye liquor according to the bath ratio of 1:(10-30), heating is conducted to be at 45-55 DEG C, heat preservation is conducted for 8-12 min, heating is conducted to be at 135-145 DEG C, heat preservation is conducted for 35-45 min, isolated disperse dye microcapsule continuous dyeing is conducted for 15-25 min, cooling is conducted to be at 75-85 DEG C, and initial washing, soaping, after-washing and drying are conducted; the dye liquor is prepared from 1-3%(owf) of reactive dye, 2-5%(owf) of rare earth complex microencapsulation disperse dye, 5-15 g / L of anhydrous sodium sulphate, 1.5-3.5 g / L of a pH buffering agent, 0.1-0.3 g / L of organic phenol haloid and 0.01-0.05 g / L of organic fluorine surfactant. The dyeing technology is high in fixation rate, good in levelling property, simple and short in cycle.

Owner:宣城加特林机械有限公司

Flavor-improved salted goose egg yolk

The invention discloses flavor-improved salted goose egg yolk which comprises the following raw materials: goose egg yolk, food-grade ethyl acetate, a food-grade osmotic pressure regulator, food-grade acetic acid, food-grade ethanol, a food-grade antioxidant and edible salt. The flavor-improved salted goose egg yolk is prepared by the following steps: separating egg white from egg yolk of a goose egg of which the production time is within 2d; adding flavor substances to the egg yolk, carrying out ultrasonic pretreatment, and then carrying out heating-cooling pretreatment; adding and completely soaking the egg yolk into an isotonic pickling liquid; adding the edible salt many times to enable the pickling liquid to have certain gradient concentration; pickling the egg yolk for a certain time; and after curing at 70 DEG C, removing the flavor in vacuum so as to obtain the flavor-improved salted goose egg yolk. The flavor-improved salted goose egg yolk disclosed by the invention has the characteristics of large size, fresh flavor, small smell, fineness, moderate salty taste and more egg yolk oil; and the production process is simple and convenient in technology, low in usage amount of table salt, low in energy consumption, more friendly to the environment, and more likely to realize industrial production.

Owner:马述腾

Pickling and storing method of low salt semi-product of pickled cabbage

InactiveCN103053974AReduce pollutionUse less saltClimate change adaptationFood preparationFlavorDesalination

The invention discloses a pickling and storing method of a low salt semi-product of pickled cabbage, and belongs to the technical field of vegetable salting and fermenting foods. The method comprises the following steps of: (1) dehydration and softening of fresh pickled cabbages; (2) preparation of a combined gas replacement pickling device; (3) pickling and compacting of pickled cabbages; (4) sealing of EVOH (Ethylene-Vinyl Alcohol Copolymer) and replacement of gas in a bag; (5) storage and management at normal temperature and the like. Compared with the conventional pickling and storing method of a high salt vegetable semi-product, the use level of salt can be reduced by about 50%, and in further product manufacturing process, processes such as desalination and dehydration can be simplified, so that loss of original flavor and nutrition of pickled cabbage is reduced, the production cost is lowered, and pollution of high salt brine discharged to the environment is reduced. The method provided by the invention can be popularized and applied to related vegetable salting processing enterprises.

Owner:YIWU NANSHAN FOOD FACTORY +1

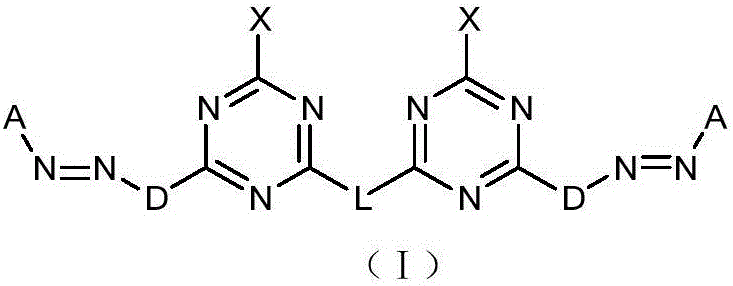

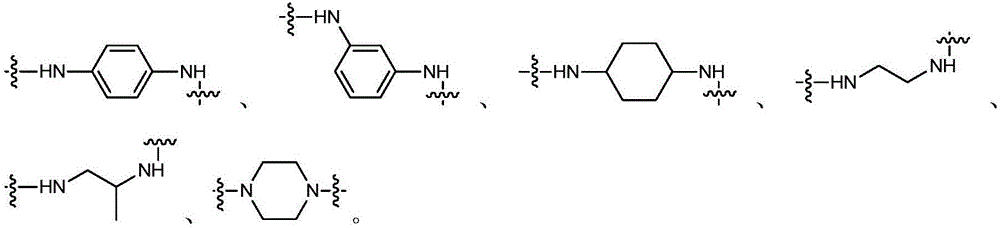

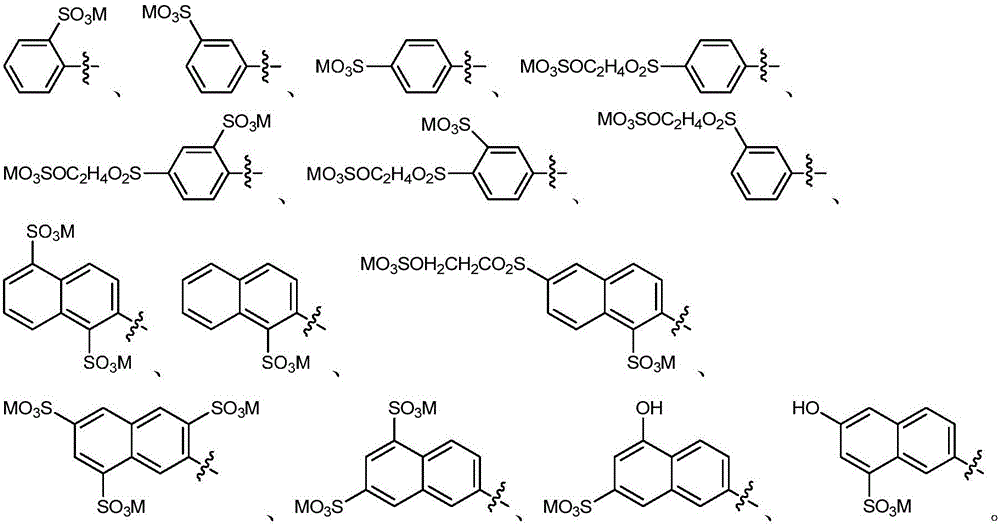

Active yellow dye and preparation and application thereof

The invention discloses an active yellow dye and preparation and application thereof. The active yellow dye has a structure shown in formula (I). The active yellow dye has the advantages that the structure of monomer compound is novel, the property is excellent, the color fixation rate is good, and the color fastness rate is high; the stability is realized, the washing-resistant, abrasion-resistant and sun exposure-resistant property are good, and the binding stability with fibers is good; during dyeing, the usage amount of water is reduced, the dying duration is short, the consumption of energy sources is decreased, and the usage amount of salt is reduced; a finished product has excellent colorful degree, the production cost is low, and the active yellow dye can be popularized and applied in a large scale way.

Owner:TAIXING JINYUN DYESTUFF

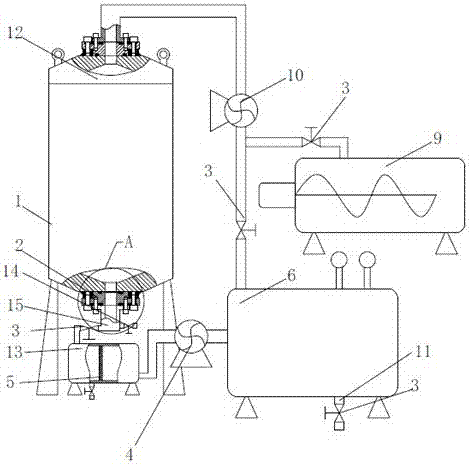

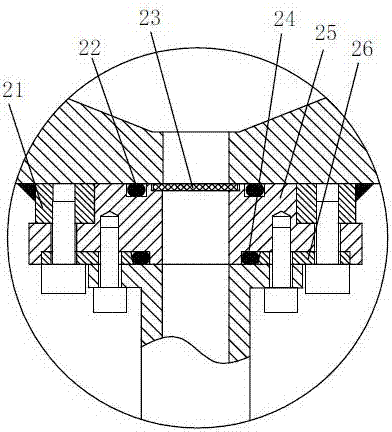

Device and method for cyclically utilizing pickled vegetable pickling liquid

The invention discloses a device for cyclically utilizing a pickled vegetable pickling liquid. The device comprises a tank body, a filter tank, a front circulating pump, a pickling liquid storage tank, a rear circulating pump and a sealing tank cover, wherein a water inlet is formed in the sealing tank cover, and the sealing tank cover is hermitically connected to the upper end of the tank body; a water outlet is formed in the lower end of the tank body; a sealing device is arranged at the water outlet; a water discharging pipe is connected between an inlet of the filter tank and a water outlet of the tank body; a manual valve is arranged on the water discharging pipe; the water discharging pipe is further connected with a water drainage pipe; a manual water drainage valve is arranged on the water drainage pipe; a filter net is arranged inside the filter tank; an outlet of the filter tank is communicated with an inlet of the pickling liquid storage tank through a pipeline of the front circulating pump. The device has the beneficial effects that by cyclic utilization of the pickled vegetable pickling liquid, the taste of pickled vegetables can be fully guaranteed, and the quality of the pickled vegetables is improved; furthermore, the water use amount and the salt use amount are effectively lowered; limited resources are saved, the environmental pollution is relieved, and the preparation period of the pickling liquid is shortened.

Owner:成都古味觉食品有限公司

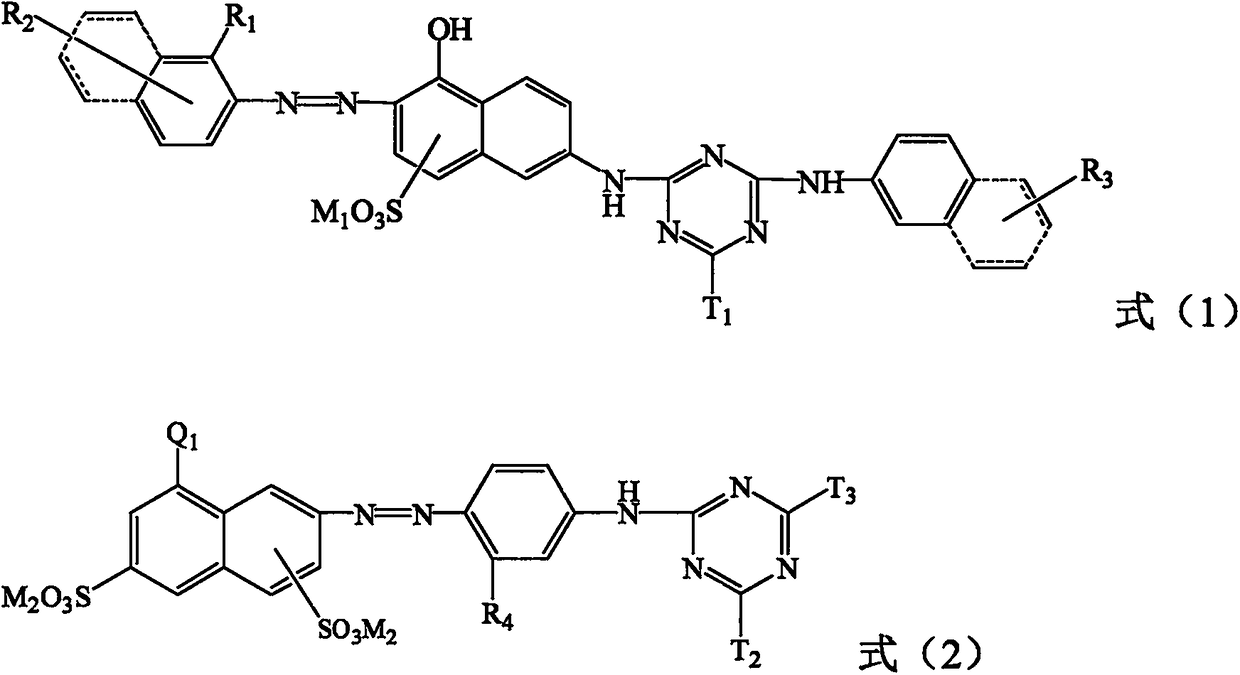

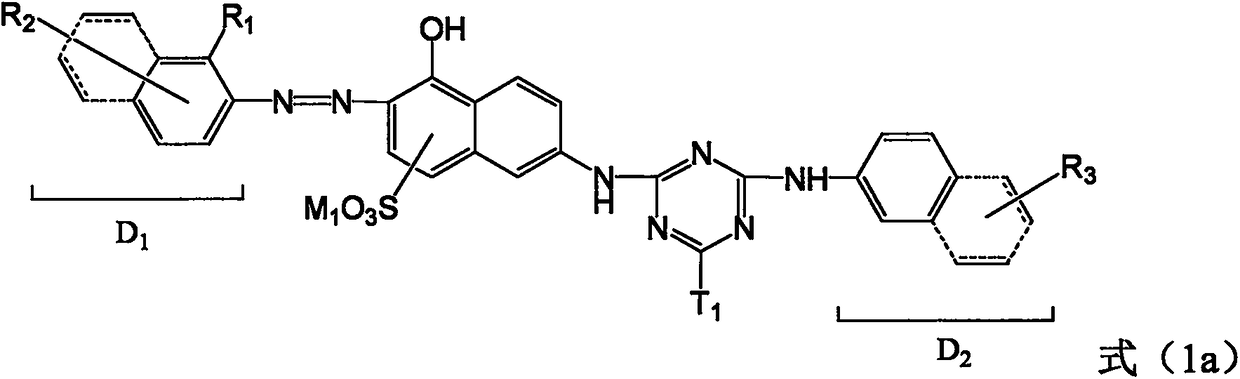

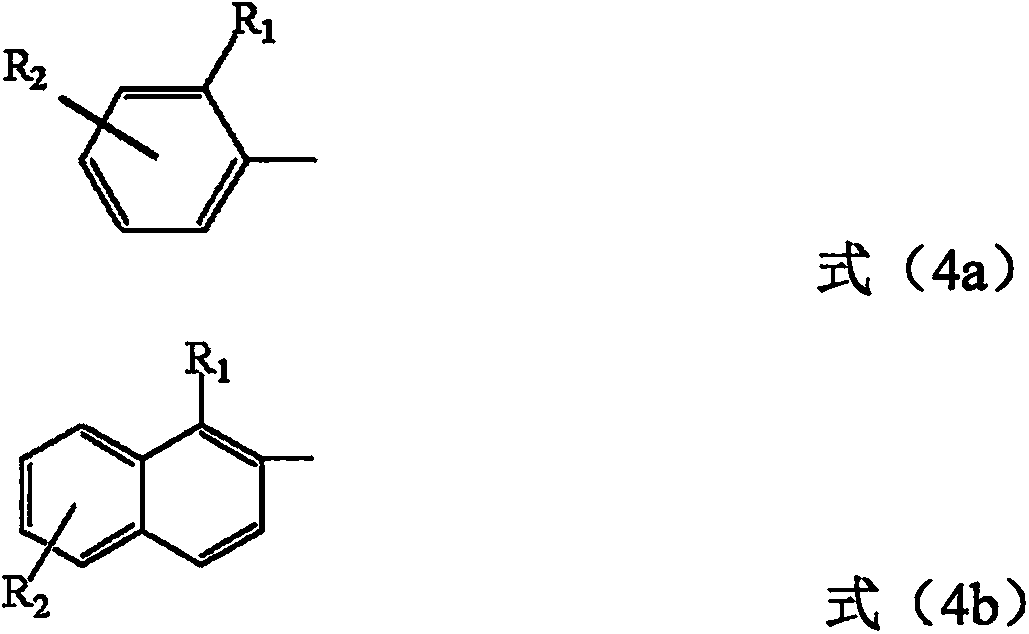

Orange inkjet printing dye mixture, as well as preparation method and application thereof

The invention provides an orange inkjet printing dye mixture, which is characterized by at least comprising two dye compounds as shown in the below general formula (1) and general formula (2). In thegeneral formula (1) and general formula (2), Q1 represents a group selected from H, OH, NH2, COOH, SO3H or metal salt forms thereof; M1 and M2 are respectively independent H in a free acid form or sodium or potassium in a metal salt form; R1, R2, R3 and R4 are independently fiber active groups; T1, T2 and T3 represent same or different components selected from at least one of halogen, C1 to C4 alkyl groups, C1 to C4 alkoxy groups, carboxyl and sulfonyl. The orange inkjet printing dye mixture provided by the invention is the orange dye mixture with a high levelling property, high fixation rateand high dissolvability, and is the environmental-friendly inkjet printing dye with an excellent combination property.

Owner:TAIXING JINYUN DYESTUFF

Method for rapidly peeling taros

ActiveCN106174623AReduce dosageImprove efficiencyVegetable peelingTemperature differenceSalt solution

The invention discloses a method for rapidly peeling taros. The method is characterized by including the following specific steps of 1, ripening, wherein a salt solution is heated to 135 DEG C to 160 DEG C, the temperature is kept, and cleaned taros are put into the solution and boiled for 1 min to 3 min; 2, goffering, wherein the taros are rapidly bailed out, put into cold water and soaked for 1 min to 2 min, the temperature is rapidly reduced, it is prevented that taro curing layers are further increased, the huge temperature difference between the insides and the outsides allows peels of the taros to be rapidly wrinkled and fall off, and meanwhile the salt solution attached to the peels of the taros can be removed; peeling, wherein the taros enter a roller-type peeling machine through a conveying belt and are peeled, and the peeled taros are obtained. The method has the advantages that the peeling efficiency is high, losses are small, environment pollution is reduced, the operation cost is low, and the surfaces are smooth and not prone to browning after peeling.

Owner:NINGBO UNIV

Quaternary ammonium polyether solution and preparation method thereof

The invention discloses a quaternary ammonium polyether solution used for carrying out non-ionic or weak cationic modification on water-soluble anionic dyes for dyeing of cellulosic fiber textiles and a preparation method thereof. The preparation method comprises the following steps: dewatering polyether glycol; reacting the dewatered polyether glycol with diisocyanate under the catalytic action of a catalyst to prepare a primary polymer of the diisocyanate and the polyether glycol; reacting the primary polymer of the diisocyanate and the polyether glycol with tertiary amine to prepare polyether amine; reacting the polyether amine with a quaternary ammonium reagent to prepare quaternary ammonium polyether; mixing and dispering the quaternary ammonium polyether with a diluents, a neutralizer and water to prepare the quaternary ammonium polyether solution. After the quaternary ammonium polyether solution prepared in the invention is used for modifying water-soluble anionic dyes, the salt dosage of the water-soluble anionic dyes for dyeing cellulosic fibers is decreased by more than 30%, and the color depths of the dyed textiles are not reduced.

Owner:DONGGUAN BAOLIMEI CHEM +1

Sweet potato leaf kale borecole and making method thereof

The invention discloses sweet potato leaf kale borecole. The sweet potato leaf kale borecole is made from the following raw materials in parts by weight: 100 parts of sweet potato leaves, 35-55 partsof olive, 35-55 parts of sesame oil, 40-60 parts of a soy sauce and 10-20 parts of garlic oil. The invention further discloses a making method of the sweet potato leaf kale borecole. According to thesweet potato leaf kale borecole and the making method thereof, provided by the invention, the sweet potato leaves and the olive are used as the raw materials for making the kale borecole, the sweet potato leaf kale borecole is rich in nutrition and unique in flavor, and the kinds of the kale borecole can be greatly enriched; and besides, the fermentation period of the kale borecole can be effectively shortened, the product quality is improved, the salt consumption is reduced, and the product quality is stabilized.

Owner:湖南轻工研究院有限责任公司

A kind of method of industrially fermenting sauerkraut

ActiveCN101697751BAdd beneficial ingredientsGood antibacterial effectFruits/vegetable preservation using acidsSaline waterBiotechnology

Owner:HEILONGJIANG UNIV

Sauced common cattail and processing method thereof

The invention discloses a sauced common cattail and a processing method thereof. The common cattail is prepared through specific conditions and steps of preserving, saucing and disinfecting. The sauced common cattail is unlike as previous products, oil, chicken soup and the like are not added to be cooked, the color of the common cattail can be kept for a long time, the mouth feel of the common cattail is fluffy and crisp, brown stains are not generated, the sauced common cattail is fresh, tender and delicious, and the sauced common cattail is convenient to transport, store and sell.

Owner:淮安康得乐食品有限公司

Method for preparing pickled tender shoots of mulberry twigs

InactiveCN106666568ANot destroyedNo pollution in the processClimate change adaptationFood scienceCelluloseShoot

The invention belongs to the technical field of food processing and particularly relates to a method for preparing pickled tender shoots of mulberry twigs. The method includes: picking the tender shoots of the mulberry twigs, cleaning, keeping crispness, spreading for airing, and marinating in brine, wherein brine concentration is not lower than 3%. By the method for preparing the pickled tender shoots of the mulberry twigs, sugar, proteins, celluloses, vitamins, mineral substances and bioactive substances in pickled tender shoots of the mulberry twigs can be completely absorbed and used by human bodies; by preservation of the tender shoots of the mulberry twigs under the preservative action of added salt and spices and lactic acid generated in fermentation, low salt consumption, recyclability of prepared brine, low production cost, low energy consumption and freeness of environmental pollution are realized; in addition, the proteins in the tender shoots of the mulberry twigs are gradually decomposed into amino acids under actions of microorganisms and proteases during pickling to generate unique aroma which covers an original bitter and astringent taste; moreover, by pickling of the tender shoots of the mulberry twigs under the condition of low-salt concentration, nutrient damages are avoided.

Owner:SICHUAN ACAD OF AGRI SCI SERICULTURE INST

Low-salt dyeing method of reactive dye

ActiveCN111005245AHigh affinityIncrease color depthDyeing processCotton fibrePulp and paper industry

The invention relates to a low-salt dyeing method of a reactive dye. The dyeing method does not change the conventional dyeing equipment and basic dyeing process of cotton textiles, and is easy to implement and control. Compared with a traditional dyeing method of a reactive dye to cotton textiles, the dyeing method can reduce the dosage of a dyeing electrolyte by 50% or above, and the cotton textile dyed by adopting the low-salt dyeing method of the reactive dye disclosed by the invention has obviously higher color rendering depth, high dyeing fastness and excellent dyeing reproducibility, and can be used for reactive dye dyeing processing of various cotton fibers and products thereof, so that the use amount of the dyeing electrolyte is remarkably reduced, the environment is protected, and the dyeing method has good application effect and bright market prospect.

Owner:WUHAN TEXTILE UNIV

Process for pickling low-salt preserved ham

InactiveCN110810739ANot perishableReduce salt contentFood ingredient as taste affecting agentAnimal repellantsBiotechnologyLean meat

The invention provides a process for pickling a low-salt preserved ham. The process comprises steps of material selection, salt application, jar preservation, hanging and piling. Compared with a conventional process, the process emphasizes discharge of blood water in a fresh ham and uniform salt application since a pickling material used in the salt application step is composed of edible salt, purple perilla juice and Chinese prickly ash in a weight ratio of 100:(10-2):(3-1), and in the hanging step, the ham is wrapped by using a cloth bag which is soaked into Chinese prickly ash water and isdried naturally. On premise that the ham made by using the low-salt preserved ham processing method provided by the invention is not rotten or deteriorated, the salt content tested in lean is remarkably lower than that of a ham made by using the conventional process.

Owner:LIJIANG SANCHUAN IND GRP

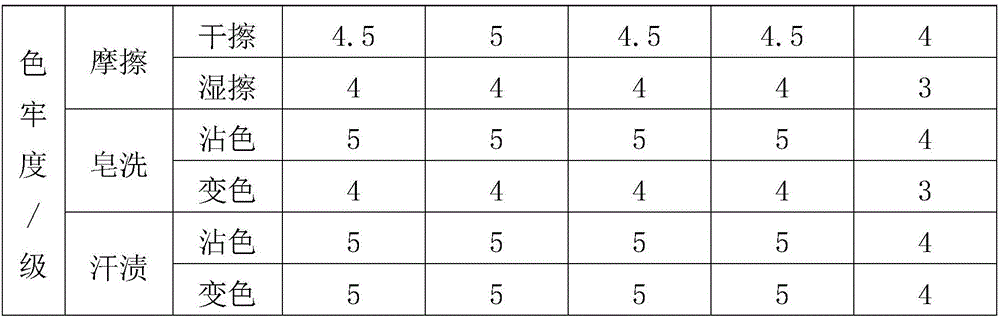

Low-salt and low-alkali dyeing process of cellulose fiber fabrics with medium-temperature reactive dyes

ActiveCN103556498BIncrease dye seatFacilitated DiffusionDyeing processVegetal fibresCellulose fiberPolymer chemistry

The invention relates to a low-salt and low-alkali dyeing process with a mesothermal type active dye of a cellulosic fiber fabric. The low-salt and low-alkali dyeing process comprises the following steps: modifying a cellulosic fiber fabric to be dyed by a fiber modifying agent to prepare a partially-aminated modified cellulosic fiber fabric to be dyed; modifying the mesothermal type active dye by a dye modifying agent to prepare an activated and modified mesothermal type active dye; and carrying out low-salt and low-alkali dyeing on the cellulosic fiber fabric, namely carrying out the low-salt and low-alkali dyeing on the partially-aminated modified cellulosic fiber fabric to be dyed by the activated and modified mesothermal type active dye in the presence of neutral electrolyte, inorganic alkalis and water. According to the dyeing technology, the use amount of the neutral electrolyte and the inorganic alkalis can be reduced and the dyeing temperature can be reduced by about 10 DEG C; the dyed cellulosic fiber fabric has high coloring depth, good dyeing fastness and excellent dyeing reproducibility; the low-salt and low-alkali dyeing process can be used for dyeing various cellulosic fiber fabrics by the mesothermal type active dye.

Owner:佛山市马大生纺织有限公司

Processing method for soil jar pickled cowpeas

InactiveCN104068349ABright colorStrong fragranceClimate change adaptationFood preparationSaline waterNitrite

The invention provides a processing method for soil jar pickled cowpeas. The processing method is finished by nine procedures including selecting materials and washing, slitting, carrying out hardening treatment, salting and pickling, sealing a jar and pickling, rinsing and desalting, infusing by seasonings, sealing the jar and pickling, and packaging and sterilizing. The processing method has the beneficial effects that the pickling is carried out by two times; firstly, salt water is used for sealing and pickling and the seasonings are used for pickling so that nitrite produced by pickled vegetables can be effectively dispersed and digested after the highest peak period; relative substances and acid water in the seasonings are combined and a full-process specially-made sealing material is utilized so that nitrite in the pickled vegetables can be reduced to the lowest degree; meanwhile, the salt amount in a whole process is less and natural quality-guaranteeing materials are used so that the product has low salt content and meanwhile, the guarantee period is not shortened; the pickled cowpeas produced by the processing method are bright in color and luster, are sour and sweet, and tasty, have an aromatic flavor, have high resilience and have a crispy and tender mouth feel; meanwhile, the salt content is low and the content of the nitrite is very low; the quality of the pickled vegetables is greatly improved.

Owner:CHONGQING YONGQI AGRI DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com