Industrial sauerkraut fermentation process

A fermentation process and kimchi technology, which is applied in the field of industrialized kimchi fermentation technology, can solve problems affecting the development of the kimchi industry, achieve the effects of shortening the fermentation cycle, increasing varieties, and solving insufficient fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

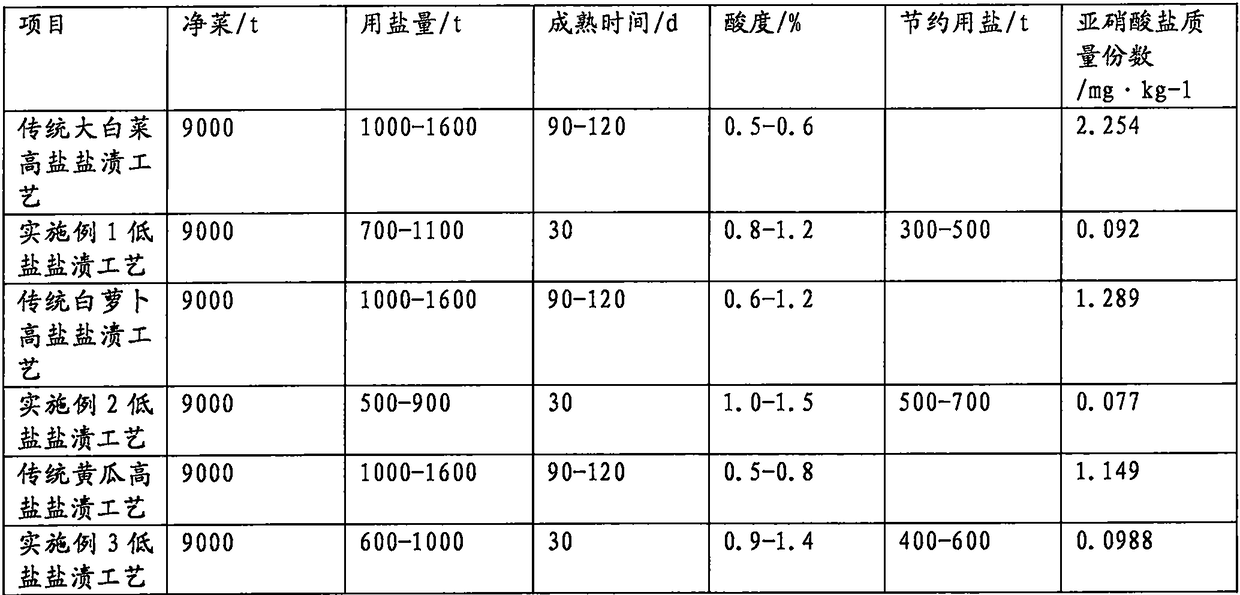

Embodiment 1

[0036] A kind of industrialization kimchi fermentation process, comprises the following steps:

[0037] (1) Acceptance of fresh vegetables

[0038] Select fresh Chinese cabbage, ensure that it is free from disease, rot, and mildew, remove the silt on the surface of the Chinese cabbage, the yellow and rotten leaves of the Chinese cabbage, and the stalks of the cabbage, then wash and drain;

[0039] (2) Salted

[0040] One low-salt and high-salt pickling: Put the fresh Chinese cabbage in step (1) into the fermentation tank one by one, put the Chinese cabbage and edible salt into the tank and add according to the salting process of "one layer of salt and one layer of vegetables", and eat Salt accounts for 6% of the total amount of Chinese cabbage, operate sequentially, and compact the Chinese cabbage layer by layer until the mouth of the fermentation tank is about 20cm; The amount of inoculum must reach 105CFU / g according to the amount of fresh Chinese cabbage), and add it to t...

Embodiment 2

[0051] A kind of industrialization kimchi fermentation process, comprises the following steps:

[0052] (1) Acceptance of fresh vegetables

[0053] Select fresh white radish, make sure it is free from disease, rot, and mildew, remove the silt and pedicles on the surface of the white radish, then wash and drain;

[0054] (2) Salted

[0055] One low-salt and high-salt pickling: Cut the fresh white radish in step (1) into pieces and put them into the fermentation tank one by one. Add, edible salt accounts for 4% of the total amount of white radish, operate sequentially, and compact the white radish layer by layer until the mouth of the fermentation tank is about 20cm; The inoculum amount of lactic acid bacteria agent must reach 108CFU / g according to the amount of white radish) and add it into the salted water with a brine pump circulation. Reach the quantitative standard, that is: after the white radish is 90% of the weight of the water in the salt pond, the surface of the white...

Embodiment 3

[0066] A kind of industrialization kimchi fermentation process, comprises the following steps:

[0067] (1) Acceptance of fresh vegetables

[0068] Select fresh cucumbers to ensure that they are free from disease, rot and mildew, remove the sediment on the surface of cucumbers, then wash and drain;

[0069] (2) Salted

[0070] One low-salt and high-salt pickling: put the fresh cucumbers in step (1) into the fermentation tank layer by layer, fresh cucumbers and edible salt are loaded and added according to the salting process of "one layer of salt and one layer of vegetables", and edible salt Accounting for 5% of the total amount of cucumbers, operate sequentially to compact the cucumbers layer by layer until about 20cm from the mouth of the fermentation tank; Cucumber meter must reach 110CFU / g) Use a brine pump to circulate and add to the salted water. During the salting process, take out the salted water after inoculation from the bottom of the fermentation tank and spray i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com