Processing technology of green plums

A processing technology, green plum technology, applied in the field of green plum processing technology, can solve the problems of unfavorable health, nutrient loss, impact, etc., and achieve the effect of avoiding a large amount of nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Select the fruit of plum, white powder or longan plum, wash it, and the maturity of the fruit is 8 mature, that is, the fruit is greenish-green with light yellow, and the soluble solid content is 7.0-8.0%.

[0018] (2) Put the washed green plum fruit into the pickling medium for sealing and pickling, and add NaCl gradiently during the pickling process to maintain the constant concentration of NaCl in the pickling medium. After the pickling process is completed, the pickling medium becomes pickled. marinade.

[0019] The pickling medium includes NaCl, white wine, white vinegar and marinade, and the pH value of the pickling medium is adjusted to 3.0-4.0 by adding citric acid. Wherein, the concentration of NaCl is maintained at 12-14% by adding salt intermittently, the consumption of white wine is 5-8% of the pickling medium, and the consumption of white vinegar is 8-10% of the pickling medium. The time of pickling process is 30-90 days.

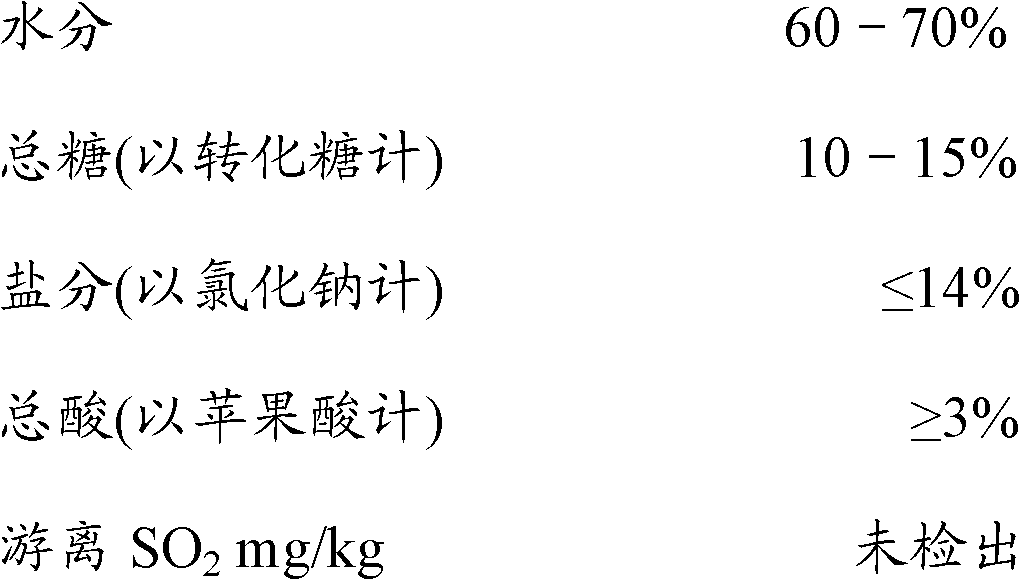

[0020] (3) The pickled gree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com