A special natural stone grinding disc for a food grinding machine

A grinding disc, a natural technology, applied in the field of special natural stone grinding discs, can solve problems such as nutrient loss, and achieve the effects of ensuring the quality of abrasives, shortening food processing time, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

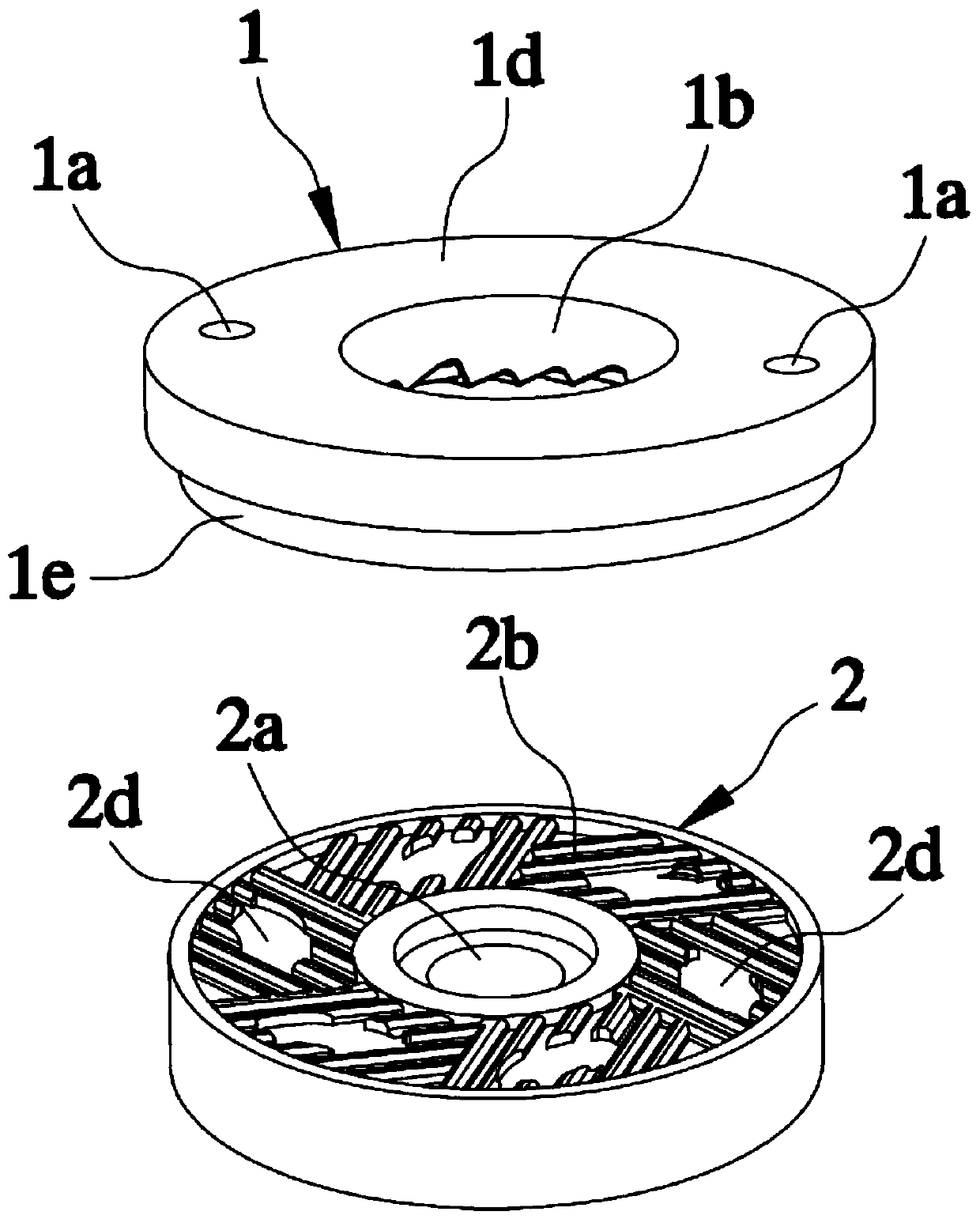

[0031] see figure 1 and figure 2 A special natural stone grinding disc for a food grinding machine comprises an upper grinding disc 1 and a lower grinding disc 2 matched with the upper grinding disc 1 . The upper grinding disc 1 and the lower grinding disc 2 are made of natural stone, which has the advantages of strong hardness, strong wear resistance, and trace elements beneficial to human health. Compared with the existing synthetic grinding discs, its strength is higher , strong wear resistance, so as to ensure that it will not lose sand after long-term use, ensure the quality of food abrasives, and at the same time achieve high-speed work without cracks, improving the service life of the grinding disc . The upper surface of the upper grinding disc 1 is provided with a fixing hole 1a, and the middle part of the upper grinding disc 1 is provided with a feeding hole 1b. The middle part of the lower grinding table 2 is provided with an installation hole 2a, and the bottom ...

Embodiment 2

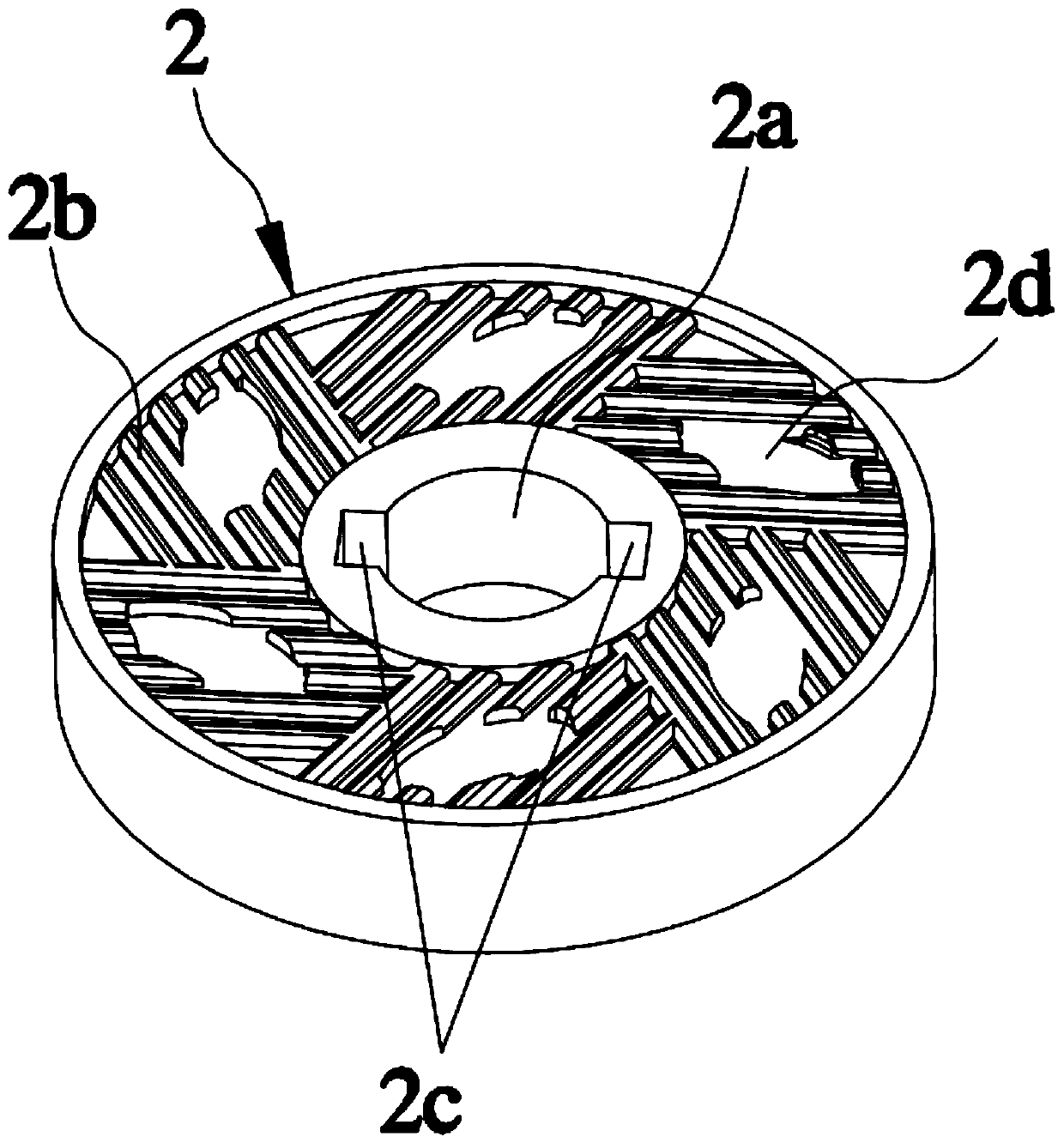

[0039] see image 3 , the lower grinding disc 2 is made of natural stone, which has the advantages of strong hardness and strong wear resistance. Compared with the existing synthetic grinding disc, it has high strength and strong wear resistance, so that it can be used for a long time There will be no sand loss in the end, which ensures the abrasive quality of the food, and at the same time can achieve high-speed work without cracks, which improves the service life of the grinding disc. The grinding surface of the lower grinding disc 2 is divided into 3 to 6 equal sectors along the circumference of the grinding disc, and a plurality of parallel and equal-height lower grinding bars 2b are correspondingly engraved in each sector of the lower grinding disc 2 .

[0040] Specifically, the grinding surface of the lower grinding disc 2 is divided into 6 equal sectors along the circumference of the grinding disc, and the upper grinding bar 1c of the upper grinding disc 1 and the lower...

Embodiment 3

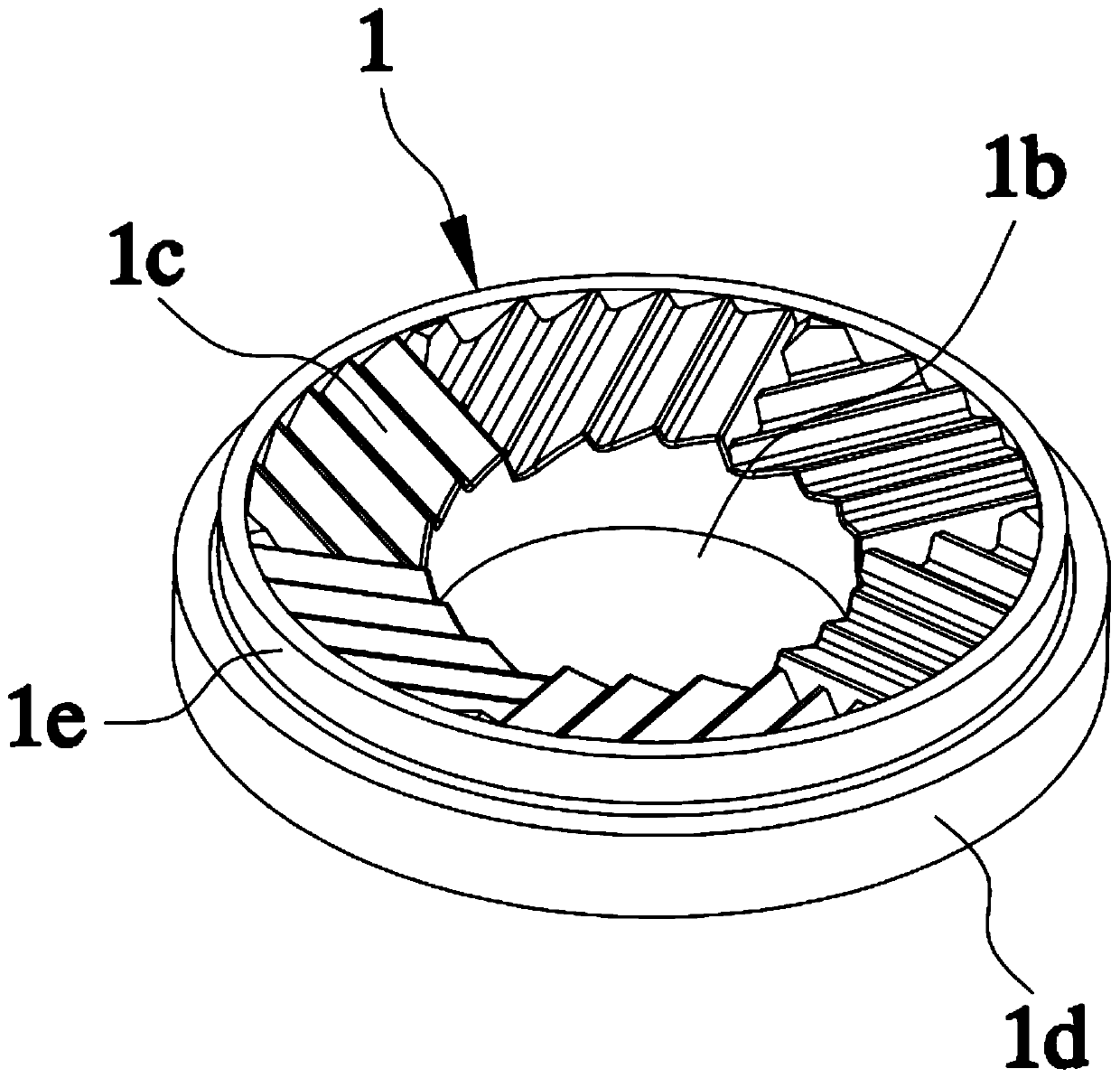

[0048] see Figure 4 , the upper surface of the upper grinding disc 1 is provided with a fixing hole 1a, and the middle part of the upper grinding disc 1 is provided with a feeding hole 1b. The upper grinding disc 1 is made of natural stone, which has the advantages of high hardness and strong wear resistance. Compared with the existing synthetic grinding discs, it has high strength and strong wear resistance, so that it can ensure that it is durable after long-term use. There will be no sand loss, which ensures the abrasive quality of food and improves the service life of the grinding disc. The grinding surface of the upper grinding disc 1 is divided into 6 equal fan-shaped areas along the circumference of the grinding disc, and the upper grinding bar 1c of the upper grinding disc 1 is designed to be inclined at a certain inclination angle in the fan-shaped area, and each of the upper grinding disc 1 The inclination angles of the upper grinding bars 1c in two adjacent fan-sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com