Process for pickling low-salt preserved ham

A ham and process technology, applied in the field of ham curing technology, can solve problems such as long production cycle of ham, and achieve the effects of good sterilization, less salt consumption and uniform salt application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

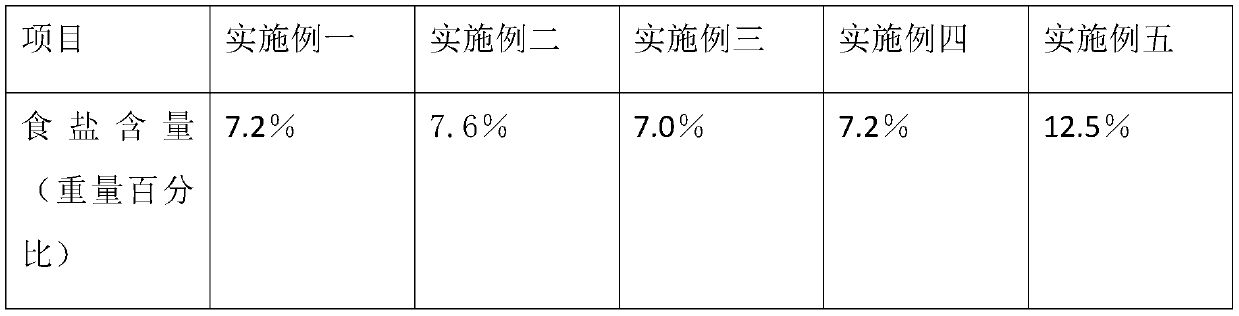

Examples

Embodiment 1

[0017] Use ham salting method of the present invention, concrete steps comprise:

[0018] a. Material selection: choose 6-8 catties of fresh pork legs, cut off the excessively long skin on the sides, flatten the protruding bones, weigh the processed fresh pork legs, and use it as a standard for the amount of salt marinade later, Use a wooden stick to fully beat the shaped ham to loosen the ham meat, and then squeeze the bleeding water from near the pig's feet to the upper part of the ham along the veins.

[0019] b. Salt: Smear and knead with the marinade. The marinade is composed of salt, perilla juice, and pepper powder in a weight ratio of 100:5:1. The perilla juice is obtained by squeezing fresh perilla stems and leaves to remove slag. Add salt in 4 times. For the first salting, the amount of marinade used is 2% of the weight of the fresh pork leg. The kneading direction is selected from near the pig's foot to the upper part of the ham, from the leg bone to the outer skin, ...

Embodiment 2

[0025] All the other steps are the same as the first embodiment, and the difference with the first embodiment is as follows:

[0026] b. Salt: The marinade is composed of table salt, perilla juice, and pepper powder in a weight ratio of 100:10:2. Divide the salt into 5 times, the amount of marinade used for the first salting is 2% of the weight of the fresh pork leg, the amount of the marinade used for the second salting is 1.5% of the weight of the fresh pork leg, rub the salt and pile up for two days; The amount of marinade used for the third salting is 1% of the weight of the fresh pork leg, and the salting method is the same as the first time; the amount of the marinade used for the fourth salting is 0.5% of the weight of the fresh pork leg, and the salt is kneaded and stacked for one day For the fifth salting, the amount of marinade used is 0.5% of the weight of the fresh pork leg, and the salt is kneaded and piled up.

Embodiment 3

[0028] All the other steps are the same as the first embodiment, and the difference with the first embodiment is as follows:

[0029] b. Salt: The marinade is composed of salt, perilla juice, and pepper powder in a weight ratio of 100:4:1.

[0030] e. Heaping: Plant ash is composed of pine wood ash and wormwood ash in a weight ratio of 98:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com