A kind of method of industrially fermenting sauerkraut

A kind of sauerkraut and industrial technology, applied in the direction of preserving fruits/vegetables with acid, etc., can solve the problems of deterioration, cabbage pollution, rot, etc., and achieve golden color, enhanced antibacterial effect, and fresh taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

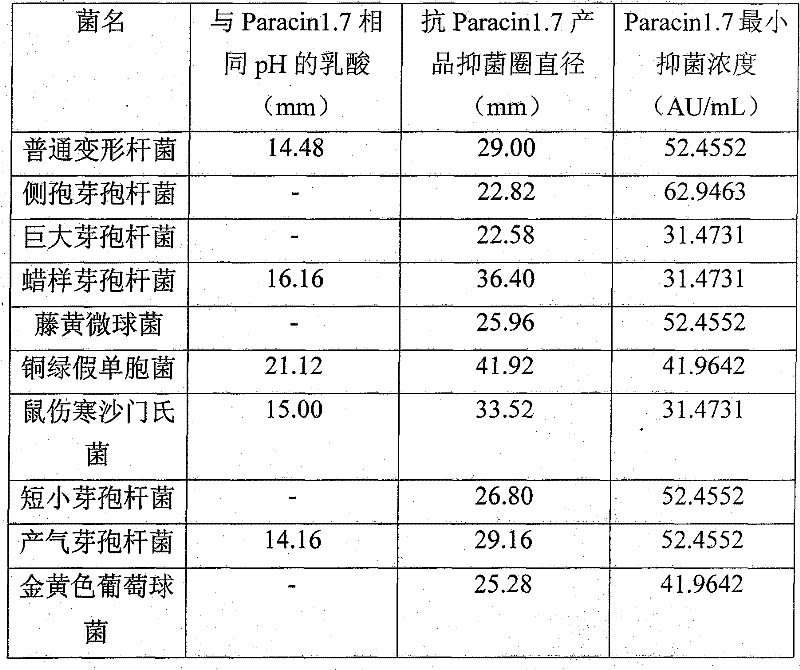

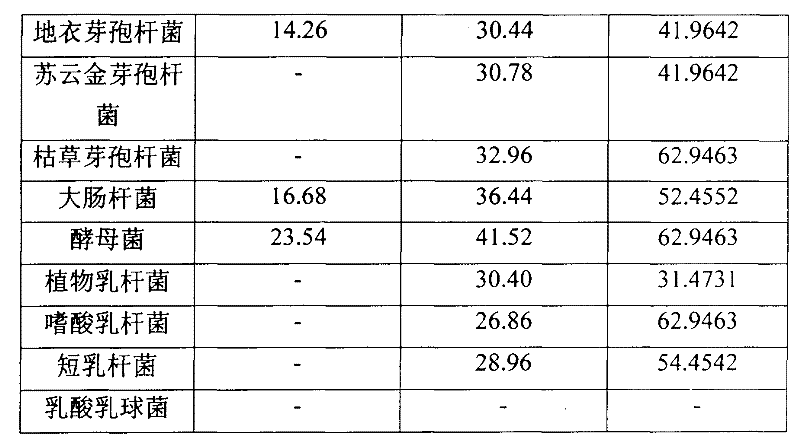

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: the industrial fermented sauerkraut of this embodiment is carried out according to the following steps: one, wash the Chinese cabbage and put it into the fermenter and code it well; two, the sauerkraut fermentation engineering bacteria are added according to the ratio of 1000L per 50 tons of Chinese cabbage; three, add Soybean juice and vegetable juice culture solution with the same volume of sauerkraut fermentation engineering bacteria, and then fill the fermenter with brine with a mass concentration of 1.5%; 4. Fermentation: raise the temperature in the fermenter to 20°C, and keep the temperature at 20°C for 3 days of fermentation , then carry out an internal circulation of the fermentation broth, and then lower the temperature in the fermenter to 18°C for 7 days of fermentation, and then perform an internal circulation of the fermentation broth, after the end of the internal circulation, keep the temperature in the fermenter at 18°C to cont...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the sauerkraut fermentation engineering bacterium in the step 2 is prepared according to the following steps:

[0029] (1) Inoculate Lactobacillus plantarum (Lactobacillus plantarum) HDRS1 and Lactobacillus paracasei (Lactobacillus paracasei) HD1-7 on the slant medium into 10 bean juice and vegetable juice culture solutions with a volume of 500 mL. Static culture for 24 hours, respectively made into first-class strains;

[0030] (2) Add the primary strains of Lactobacillus plantarum (Lactobacillus plantarum) HDRS1 and Lactobacillus paracasei (Lactobacillus paracasei) HD1-7 together to 100 L of bean juice and vegetable juice culture solution, and culture them statically at 30°C for 24 hours , to make secondary strains of fermentation engineering bacteria;

[0031] (3) Add the secondary strain of the fermentation engineering bacteria to 1000 L of bean juice and vegetable juice...

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment two is: in step two, the slant culture medium in the preparation step (1) of sauerkraut fermentation engineered bacteria is MRS medium. Other steps and parameters are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com