Low-carbon alkane isomerization method

A low-carbon alkane, isomerization technology, applied in the treatment of hydrocarbon oil, refined hydrocarbon oil, petroleum industry, etc., can solve the problems of high isomerization activity, easy loss, and can not be directly replenished, so as to improve the isomerization rate , increase octane number, improve the effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

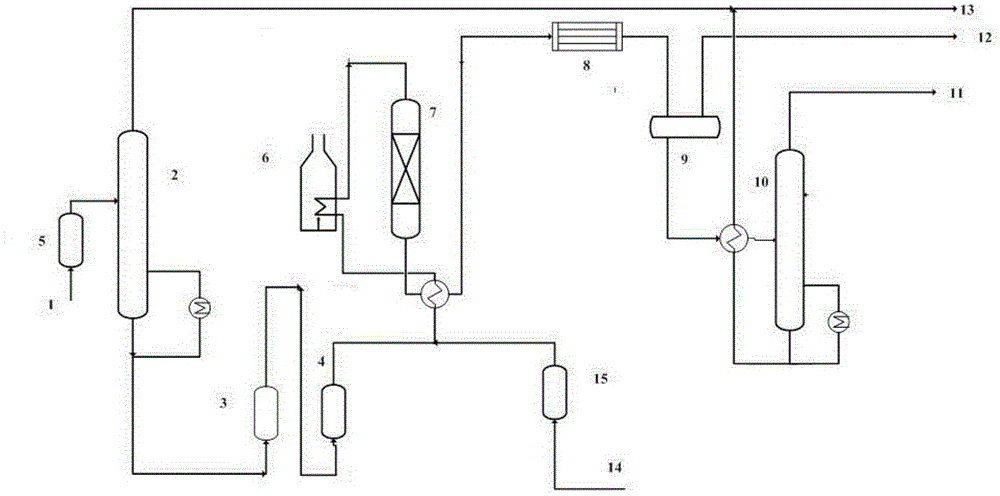

Method used

Image

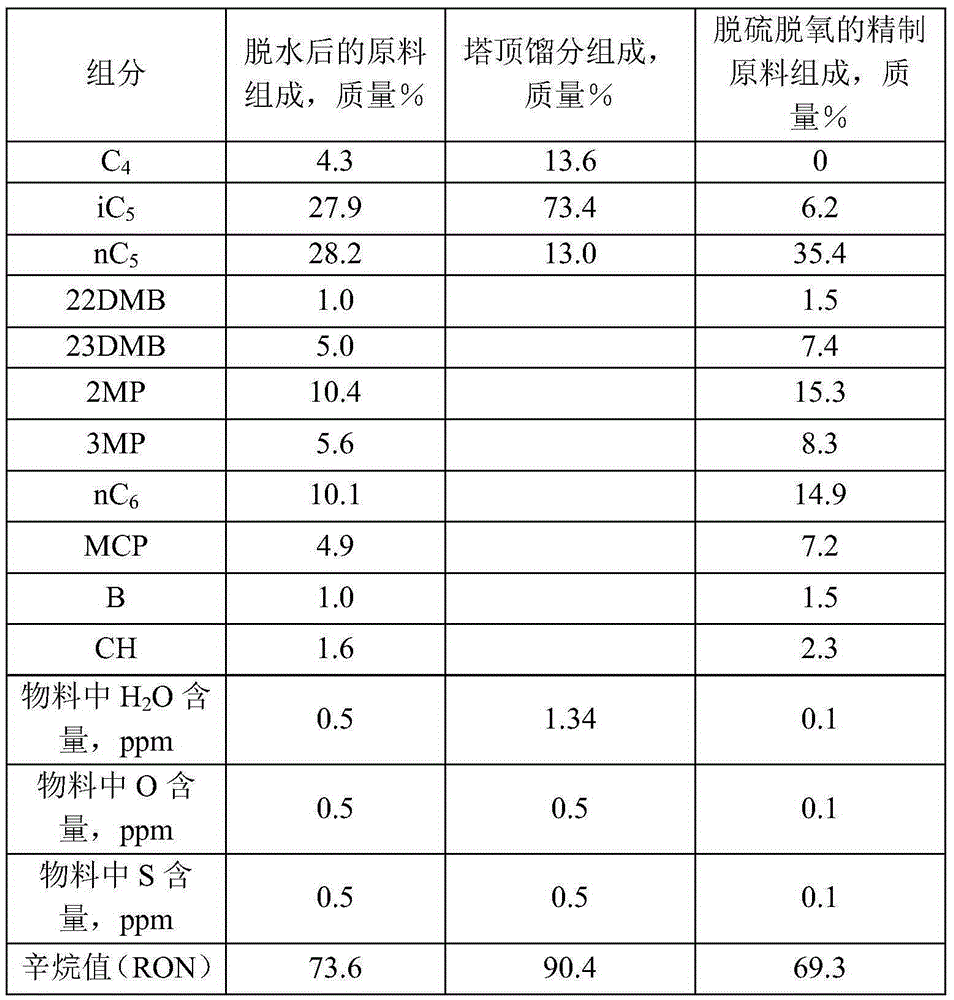

Examples

specific Embodiment approach

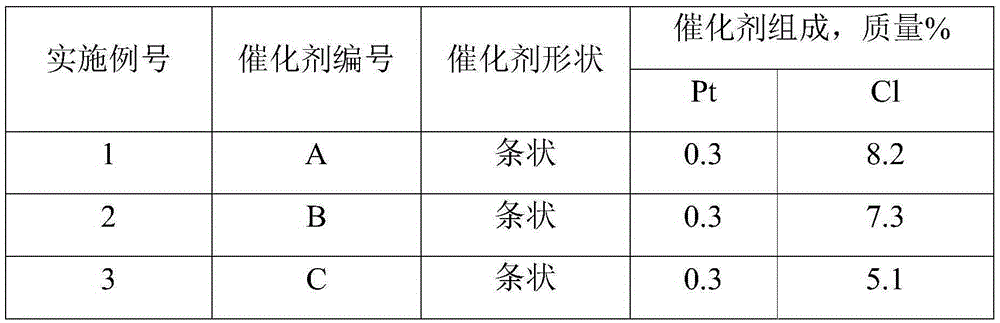

[0037] According to a specific embodiment of the preparation of the catalyst of the present invention, the preparation method of the chlorine-containing aluminum oxycatalyst may include: (1), the alumina carrier is first impregnated with a solution containing a Group VIII metal compound and then dried to obtain impregnated alumina; (2), impregnating the impregnated alumina obtained in step (1) with an alkane solution containing alkylaluminum chloride for a second impregnation to obtain the chlorine-containing aluminum oxide catalyst; preferably, the chlorine-containing The preparation method of the alumina-type catalyst may also include: performing the second impregnation in the step (2) after the impregnated alumina obtained in the step (1) is subjected to water chlorine treatment; wherein, the conditions of the water chlorine treatment may be The atmosphere that water chlorine handles is oxygen or air, and the temperature that water chlorine handles is 450-700 ℃, and the mol ...

Embodiment 1

[0049] Preparation of Chloride-Containing Aluminum Oxygen Catalyst

[0050] (1), preparation of alumina carrier

[0051] Mix 100 grams of SB aluminum hydroxide powder (produced by Condea in Germany, with an alumina content of 75% by mass) and an appropriate amount of deionized water to make the liquid / solid weight ratio 1:1.6, stir, add water and 68% by mass of concentrated The volume ratio of nitric acid is 7mL of dilute nitric acid of 1:1, extrusion molding, drying at 120°C for 2 hours, and calcining at 550°C for 4 hours to obtain alumina carrier.

[0052] (2), the introduction of platinum components

[0053] The alumina carrier prepared in the previous step is impregnated with a mixture of chloroplatinic acid, hydrochloric acid and trichloroacetic acid prepared in a predetermined amount as an impregnating solution, and the platinum content in the impregnating solution is 0.3% by mass. The amounts are 1.2% and 5.0% respectively (all relative to the mass of the alumina carr...

Embodiment 2

[0057] Prepare the catalyst according to the method of Example 1, except that the impregnating solution prepared in step (2) does not contain hydrochloric acid and trichloroacetic acid, and the composition of the prepared catalyst B is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com