Method for salifying or recrystallization of rupatadine fumarate

A technology of rupatadine fumarate and fumaric acid, which is applied in the field of salt formation or recrystallization of anti-allergic drugs, can solve the problems of being unsuitable for large-scale industrial production, affecting product quality and yield, and low solubility. Achieve good crystal stability and fluidity or bulk density, good quality, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 16 grams of free base rupatadine and 320ml of the solution (acetone:water=9:1, volume ratio) into a 500ml three-necked flask, turn on mechanical stirring, heat up to 40°C, and add 4.48 grams of fumaric acid, after the addition, stir at 40°C for 30 minutes, then cool to about 0°C and stir to crystallize overnight, filter, wash the solid with cold acetone, and dry in vacuum at 60-70°C for 8 hours to obtain 17.5 grams of fumaric acid The white powder of patadine has a yield of 85.4%.

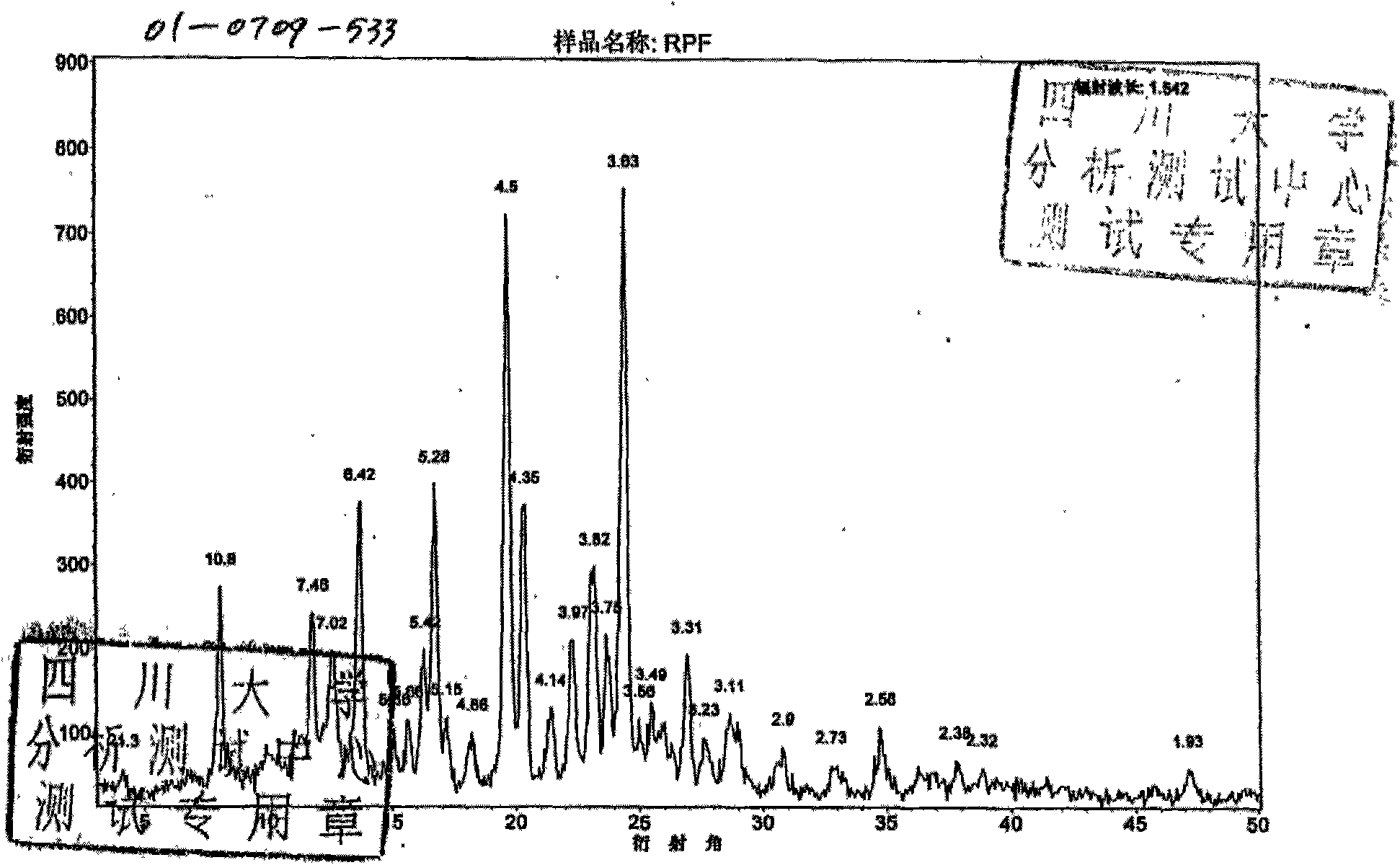

[0021] By the X-ray diffraction method, the product obtained in the embodiment is placed on a powder diffractometer for scanning and X-ray radiation, and the measured results are expressed at about 8.0 (10.8), about 11.6 (7.46), about 12.5 (7.02), There are characteristic peaks at about 13.7 (6.42), about 16.8 (5.28), about 19.6 (4.5), about 20.2 (4.35), and about 24.3 (3.63). Such as figure 1 shown.

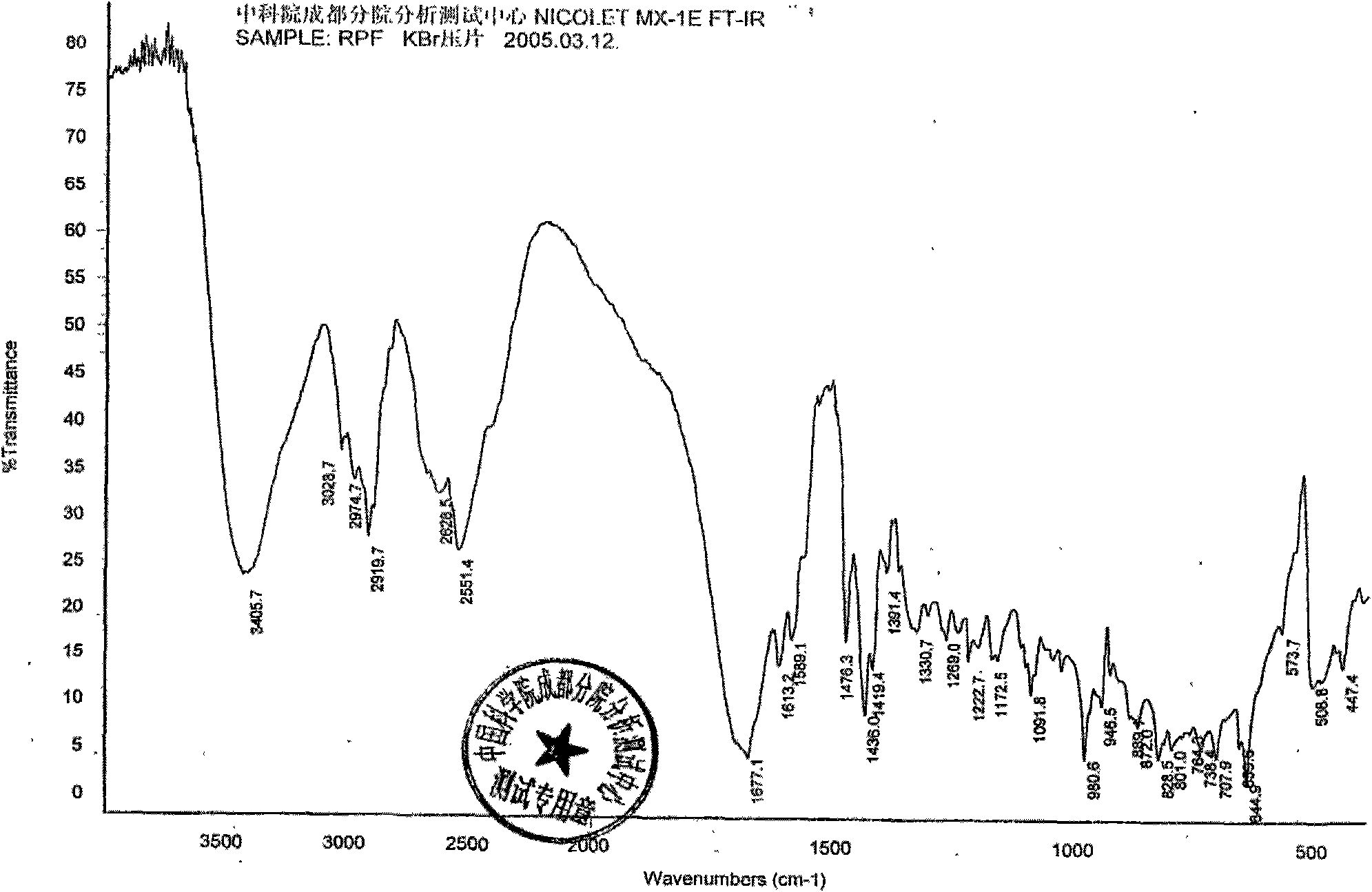

[0022] Check the infrared absorption spectrum of the product with a spectrophotomet...

Embodiment 2

[0025] Add 16 grams of free base rupatadine and 320 ml of the solution (acetone: water = 5: 1, volume ratio) into a 500 ml three-necked flask, turn on mechanical stirring, raise the temperature to 40 ° C, and add 4.48 grams of fumaric acid, after the addition, stir at 40°C for 30 minutes, then cool to about 0°C and stir to crystallize overnight, filter, wash the solid with cold acetone, and dry in vacuum at 60-70°C for 8 hours to obtain 16.4 grams of fumaric acid The white powder of patadine has a yield of 80.1%.

Embodiment 3

[0027] Add 16 grams of free base rupatadine and 320 ml of the solution (acetone: water = 15: 1, volume ratio) into a 500 ml three-necked flask, turn on mechanical stirring, heat up to 40 ° C, and add 4.48 grams of fumaric acid, after the addition, stir at 40°C for 30 minutes, then cool to about 0°C and stir to crystallize overnight, filter, wash the solid with cold acetone, and dry in vacuum at 60-70°C for 8 hours to obtain 17.6 grams of fumaric acid The white powder of patadine has a yield of 86.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com