Mud resistant slow release type slump retaining agent containing cyclodextrin side group and preparation method thereof

A cyclodextrin and slow-release technology, which is applied in the field of concrete admixture synthesis, can solve the problems of affecting the slump-preserving effect of the water-reducing agent, poor slump-preserving and mud-resistance effects, and the dispersibility of the fast water-reducing agent. Release and disperse effect, good mud resistance and slump protection, weaken the effect of interpenetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

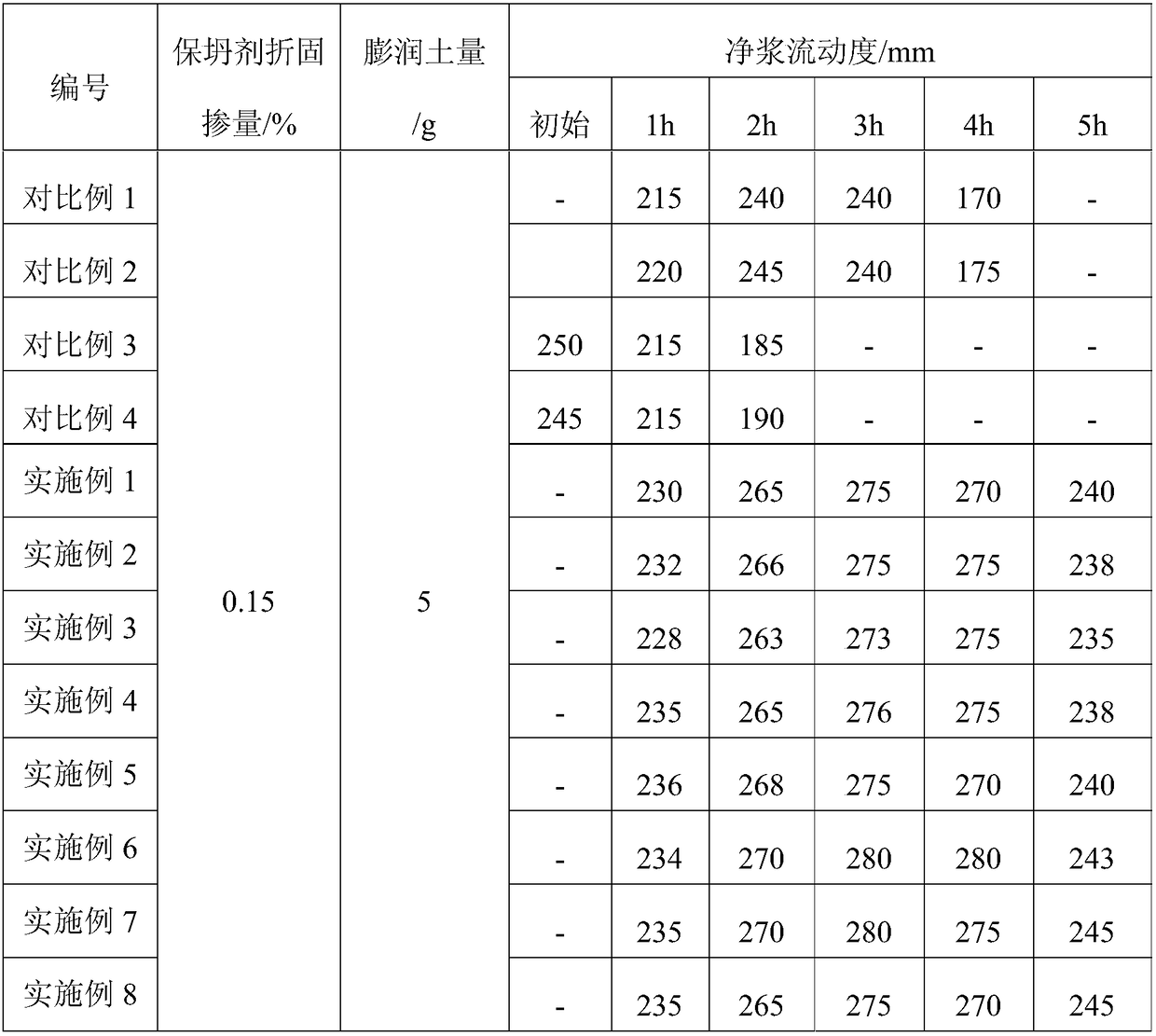

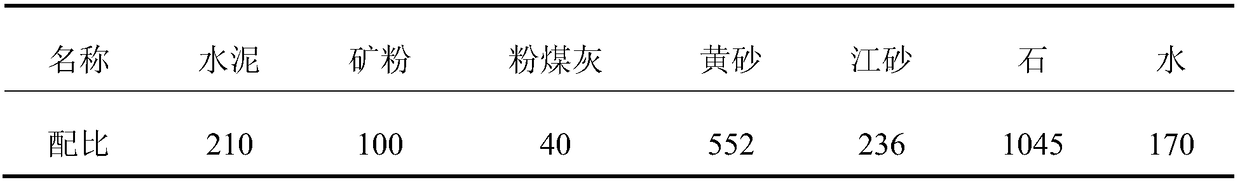

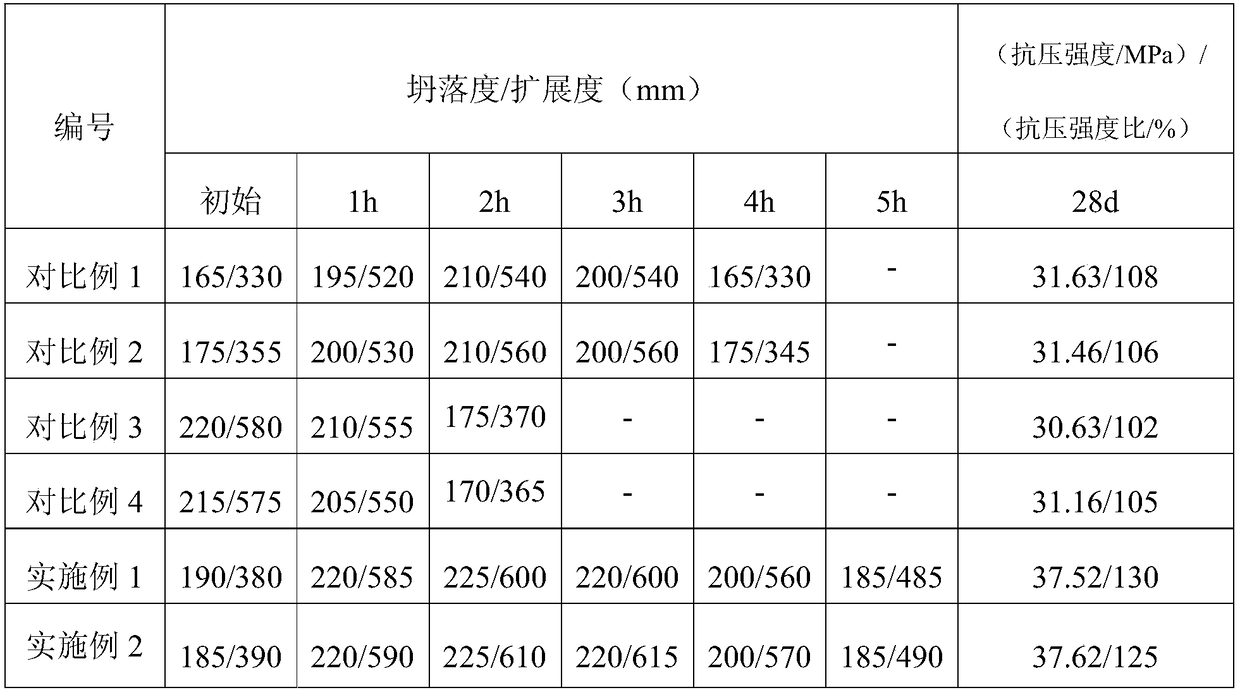

Examples

Embodiment 1

[0030] 1) Preparation of anti-mud ester monomers: Dissolve 9g of fumaric acid and 13g of β-cyclodextrin in N,N dimethylformamide in sequence, then add a certain amount of Vilsmeier-Haack salt solution, at 70°C , and reacted for 10 hours to obtain an anti-mud ester monomer containing cyclodextrin side groups;

[0031] 2) Stir 58g of acetone and 108g of phosphorus trichloride at 30°C for 6 hours in turn according to weight, and continue to add 248g of glacial acetic acid dropwise. Stir for 14 hours to obtain the unsaturated anti-mud monomer isopropenephosphonic acid;

[0032] 3) Preparation of anti-mud slow-release slump retaining agent containing cyclodextrin side groups:

[0033] a) Dissolve 300g of prenol polyoxyethylene ether in 200g of water, stir evenly, add 5g of hydrogen peroxide, and control the temperature at about 34°C;

[0034] b) Dissolve 9g of anti-mud ester monomer synthesized in step 1), 4.5g of isopropenylphosphonic acid, 5g of acrylic acid, 65g of hydroxyethy...

Embodiment 2

[0037] 1) Preparation of anti-mud ester monomers: Dissolve 10g of fumaric acid and 15g of β-cyclodextrin in N,N dimethylformamide in turn, then add a certain amount of Vilsmeier-Haack salt solution, at 70°C Next, react for 10 hours to obtain anti-mud ester monomers containing cyclodextrin side groups;

[0038] 2) Stir 55g of acetone and 105g of phosphorus trichloride at 30°C for 6 hours according to weight, and continue to add 236g of glacial acetic acid dropwise. Stir for 12 hours to obtain the unsaturated anti-mud monomer isopropenephosphonic acid;

[0039] 3) Preparation of anti-mud slow-release slump retaining agent containing cyclodextrin side groups:

[0040] a) Dissolve 400g of prenol polyoxyethylene ether in 350g of water, stir well, add 8g of hydrogen peroxide, and control the temperature at about 34°C;

[0041] b) 12g of anti-mud ester monomer synthesized in step 1), 3g of isopropenylphosphonic acid, 7g of methacrylic acid, 63g of hydroxypropyl acrylate and 3g of N...

Embodiment 3

[0044] 1) Preparation of anti-mud ester monomer: Dissolve 12g fumaric acid and 20g β-cyclodextrin in N,N dimethylformamide in sequence, then add a certain amount of Vilsmeier-Haack salt solution, at 80°C , and reacted for 12 hours to obtain an anti-mud ester monomer containing cyclodextrin side groups;

[0045] 2) Stir 60g of acetone and 110g of phosphorus trichloride at 30°C for 6 hours according to weight, and continue to add 258g of glacial acetic acid dropwise. Stir for 16 hours to obtain the unsaturated anti-mud monomer isopropenephosphonic acid;

[0046] 3) Preparation of anti-mud slow-release slump retaining agent containing cyclodextrin side groups:

[0047] a) Dissolve 200g of prenol polyoxyethylene ether in 200g of water, stir evenly, add 6g of hydrogen peroxide, and control the temperature at about 34°C;

[0048] b) 6g of anti-mud ester monomer synthesized in step 1), 9g of isopropenylphosphonic acid, 7g of acrylic acid, 53g of methyl acrylate and 4g of acrylamide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com