A kind of preparation method of ester anti-mud and slump-preserving polycarboxylate water reducer

A slump-preserving polycarboxylate technology, which is applied in the field of concrete water-reducing agent, can solve the problems of lower compressive strength ratio, poor slump-preserving effect, and reduced strength of hardened concrete, so as to improve the mud resistance of the product and weaken the interpenetrating effect , Improve the effect of branch chain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

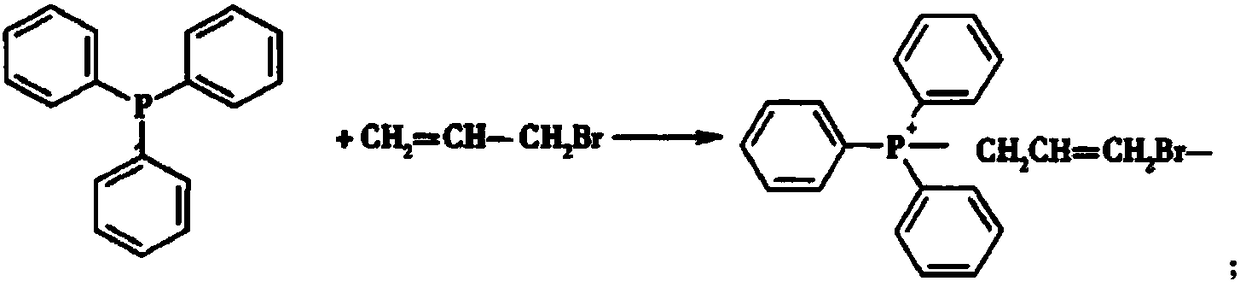

[0027] (1) Preparation of unsaturated amphoteric quaternary phosphorus salt: Weigh a certain amount of triphenylphosphine and allyl bromide in a molar ratio of 1:1.0. Add 20g of triphenylphosphine and 30g of carbon tetrachloride into a 100mL three-necked flask, and stir magnetically to dissolve. After the dissolution is completed, 9.3 g of allyl bromide is added dropwise (1 drop / 5 seconds). During the dropwise addition, magnetic stirring is carried out, and the reaction temperature is kept at about 40° C. After a period of reaction, a yellow-brown precipitate will precipitate out. After 4 hours, the precipitated product was recrystallized with acetone, and the recrystallized product was dried in a vacuum oven at 80° C. to finally obtain a white powder, which was an unsaturated amphoteric quaternary phosphonium salt.

[0028] (2) Esterification reaction: in parts by weight, 100.00 parts of polyethylene glycol monomethyl ether with a molecular weight of 1000, 51.65 parts of meth...

Embodiment 2

[0031] (1) Preparation of unsaturated amphoteric quaternary phosphorus salt: Weigh a certain amount of triphenylphosphine and allyl bromide in a molar ratio of 1:1.2, add 20g of triphenylphosphine and 30g of carbon tetrachloride into 100mL three ports In the flask, stir magnetically to dissolve. After the dissolution is completed, 11.07 g of allyl bromide is added dropwise (1 drop / 4 seconds). During the dropwise addition, magnetic stirring is carried out, and the reaction temperature is maintained at 45° C. After a period of reaction, a yellow-brown precipitate will precipitate out. After 5 hours, the precipitated product was recrystallized with acetone, and the recrystallized product was dried in a vacuum oven at 80° C. to finally obtain a white powder, which was an unsaturated amphoteric quaternary phosphonium salt.

[0032] (2) Esterification reaction: in parts by weight, 120.00 parts of molecular weight are 1200 polyethylene glycol monomethyl ether, 43.05 parts of methacry...

Embodiment 3

[0035] (1) Preparation of unsaturated amphoteric quaternary phosphonium salt: Weigh a certain amount of triphenylphosphine and allyl bromide in a molar ratio of 1:1.3. Add 20g of triphenylphosphine and 30g of carbon tetrachloride into a 100mL three-necked flask, and stir magnetically to dissolve. After the dissolution is completed, 12 g of allyl bromide is added dropwise (1 drop / 3 seconds). During the dropwise addition, magnetic stirring is carried out, and the reaction temperature is maintained at about 48° C. After a period of reaction, yellowish-brown precipitates will precipitate out. After 6 hours, the precipitated product was recrystallized with acetone, and the recrystallized product was dried in a vacuum oven at 80° C. to finally obtain a white powder, which was an unsaturated amphoteric quaternary phosphonium salt.

[0036] (2) Esterification reaction: in parts by weight, 200.00 parts of molecular weight are 2000 polyethylene glycol monomethyl ether, 34.44 parts of ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com