Concrete and mortar slump-retaining anti-mud stabilizing agent and preparation method thereof

A concrete and steady-state technology, which is applied in the field of concrete and mortar additives and its preparation, can solve the problems of concrete slump retention, poor workability, failure to meet concrete quality requirements, and lack of good-quality sand and gravel materials, and achieve enhanced wrapping ability , Decrease in viscosity, improve mud resistance and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

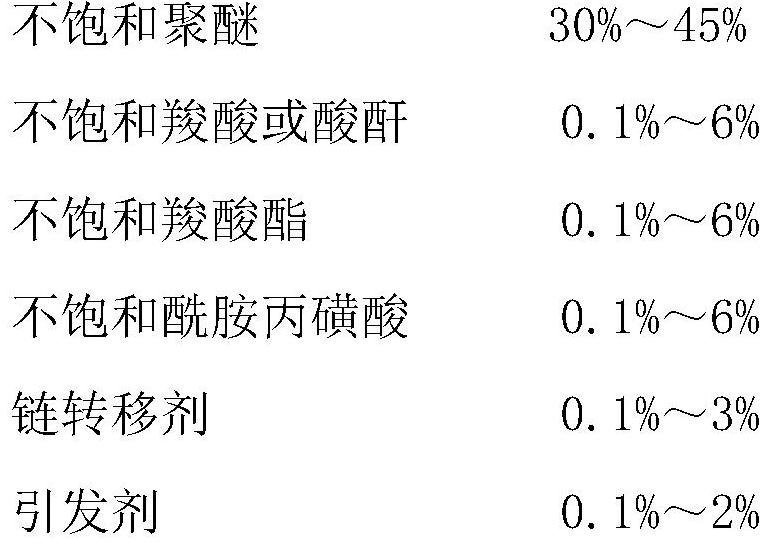

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of concrete and mortar slump-preserving and mud-resisting stabilizer:

[0032] First, add 200g of new polyether (EPEG) and 250g of water into a four-necked flask, start stirring until dissolved, and then add 1.02g of hydrogen peroxide as a base material;

[0033] Then add 7.62g of acrylic acid, 3.09g of 2-hydroxyethylmethacrylic acid and 4.78g of 2-acrylamide-2-methylpropanesulfonic acid to the beaker and stir until dissolved, forming the first solution;

[0034] Then add 1.03g of mercaptopropionic acid and 0.65g of ascorbic acid in turn in the beaker and stir until dissolved to form the second solution;

[0035] Finally, the first solution and the second solution were added dropwise at the same time, the first solution was added dropwise for 2.5 hours, the second solution was added dropwise for 3 hours, the temperature was kept constant for one hour after the dropwise addition, and the pH value was adjusted to 5.5-6.5 after the constant temperatu...

Embodiment 2

[0037] First, add 200g of new polyether (TPEG2400) and 250g of water into a four-necked flask, start stirring until dissolved, and then add 6.85g of ammonium persulfate as a base material;

[0038] Then add 10.62g of acrylic acid, 3.09g of 2-hydroxyethyl methacrylate and 3.05g of 2-acrylamide-2-methylpropanesulfonic acid into the beaker and stir until dissolved, forming the first solution;

[0039] Then add 0.89 g of thioglycolic acid and 0.65 g of ascorbic acid successively in the beaker, stir until dissolved, and form the second solution;

[0040] Finally, the first solution and the second solution were added dropwise at the same time. The first solution was added dropwise for 2.0 hours, and the second solution was added dropwise for 2.1 hours. After the dropwise addition, the temperature was kept constant for one hour, and the pH value was adjusted to 5.5-6.5 after the constant temperature was completed.

Embodiment 3

[0042] First, add 200g of new polyether (GPEG3000) and 250g of water into a four-necked flask, start stirring until dissolved, then add 0.5g of hydrogen peroxide and 3.3g of ammonium persulfate as the base material;

[0043] Then add 8g of acrylic acid, 6.09g of hydroxyethylmethacrylic acid and 3.05g of 2-acrylamide-2-methylpropanesulfonic acid to the beaker and stir until dissolved, forming the first solution;

[0044] Then, add 0.89 g of thioglycolic acid and 0.65 g of thioglycollate successively in the beaker, stir until dissolved, and form the second solution;

[0045]Finally, add the first solution and the second solution dropwise at the same time. The first solution is added dropwise for 2.5 hours, and the second solution is added dropwise for 3 hours. While adding the polyhydroxy compound aqueous solution dropwise, the dropwise addition is completed within half an hour, and the temperature is kept constant for half an hour. After the reaction is completed, a high-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com