Anionic and nonionic mixed aqueous polyurethane dispersion body and preparation method thereof

A water-based polyurethane and non-ionic technology, applied in the field of polymer resin, can solve the problems of poor water resistance of mixed water-based polyurethane dispersion, poor water resistance of sulfonate, poor water resistance, etc., and achieve excellent mechanical properties, dispersion Easy, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

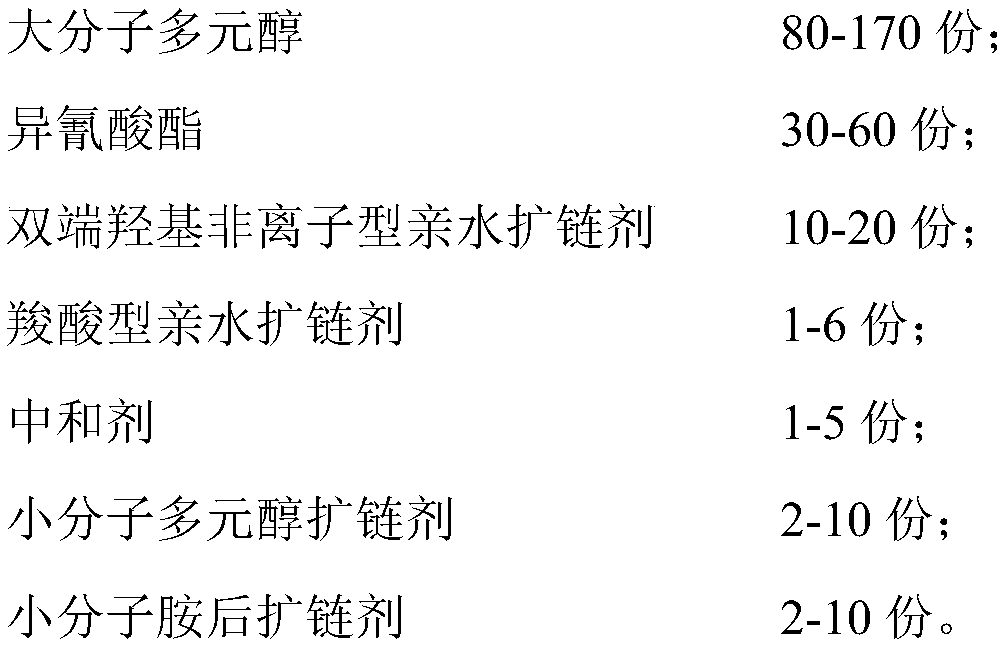

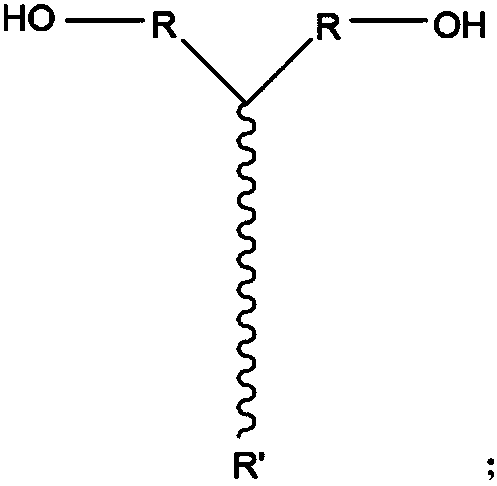

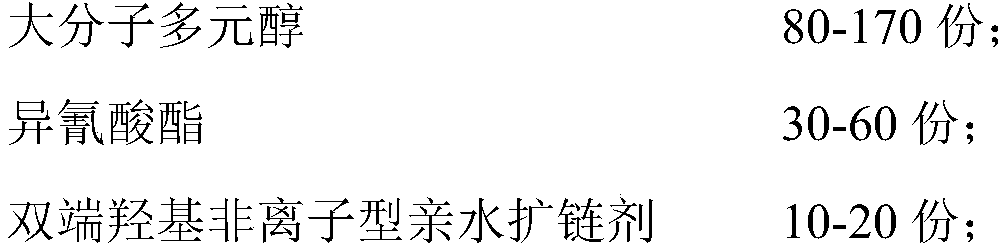

Method used

Image

Examples

Embodiment 1

[0038] Take by weighing 120g polypropylene oxide (PPG3000, relative molecular mass is 3000) and 20g double-terminated hydroxyl polyethylene oxide (relative molecular mass is 1000), put into reactor, add 40g diphenylmethane diisocyanate under stirring , keep the temperature at 85°C, and stir for 2 hours. Cool down to 50°C, add 3g of dimethylolpropionic acid (DMPA), 2g of trimethylolpropane, raise the temperature to 70°C, and keep stirring at 70°C for 4 hours to prepare a waterborne polyurethane prepolymer.

[0039] Cool the water-based polyurethane prepolymer to 5°C, add 1.5g of triethylamine, stir for 10 minutes, then transfer to a high-speed emulsifier, add 300g of deionized water at a speed of 1400r / min, and slowly add 4g of ethylamine after phase transition Diamine post-chain extender to prepare anionic and nonionic mixed waterborne polyurethane dispersions.

Embodiment 2

[0041] Take by weighing 160g polypropylene oxide (PPG3000, relative molecular mass is 3000) and 15g double-terminated hydroxyl polyethylene oxide (relative molecular mass is 1500), put into reactor, add 35g isophorone diisocyanate under stirring , keep the temperature at 90°C, and stir for 2 hours. Cool down to 50°C, add 2.5g DMPA, 1.5g butylene glycol, and 2g trimethylolpropane, raise the temperature to 70°C, and keep stirring at 70°C for 5 hours to prepare a waterborne polyurethane prepolymer.

[0042] Cool the water-based polyurethane prepolymer to 30°C, add 1.25g of triethylamine, stir for 10 minutes, then transfer to a high-speed emulsifier, add 400g of deionized water at a speed of 1400r / min, and slowly add 3.6g after phase transition Ethylenediamine post-chain extender to prepare anionic and nonionic mixed waterborne polyurethane dispersions.

Embodiment 3

[0044] Weigh 100g polytetrahydrofuran diol (PTMEG2000, relative molecular mass is 2000) and 10g double-terminated hydroxyl polyethylene oxide (relative molecular mass is 800), put them into the reactor, add 30g toluene diisocyanate, 5g six methylene diisocyanate, keep the temperature at 85°C, and stir for 2 hours. Cool down to 50°C, add 3.2g DMPA, 2g cyclohexanedimethanol, and 1g trihydroxypropane, raise the temperature to 70°C, and keep stirring at 75°C for 5 hours to prepare a water-based polyurethane prepolymer.

[0045] Cool the water-based polyurethane prepolymer to 10°C, add 1.62g of triethylamine, stir for 10 minutes, then transfer to a high-speed emulsifier, add 320g of deionized water at a speed of 1400r / min, slowly add 6g of iso Fluorone diamine post-chain extender to prepare anionic and nonionic mixed waterborne polyurethane dispersions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com