Acrylic monomer modified polyurethane emulsion as well as preparation method and application thereof

A polyurethane emulsion and acrylic technology, applied in the field of polyurethane emulsion, can solve problems such as incompleteness, easy foaming, and voids in the film, and achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

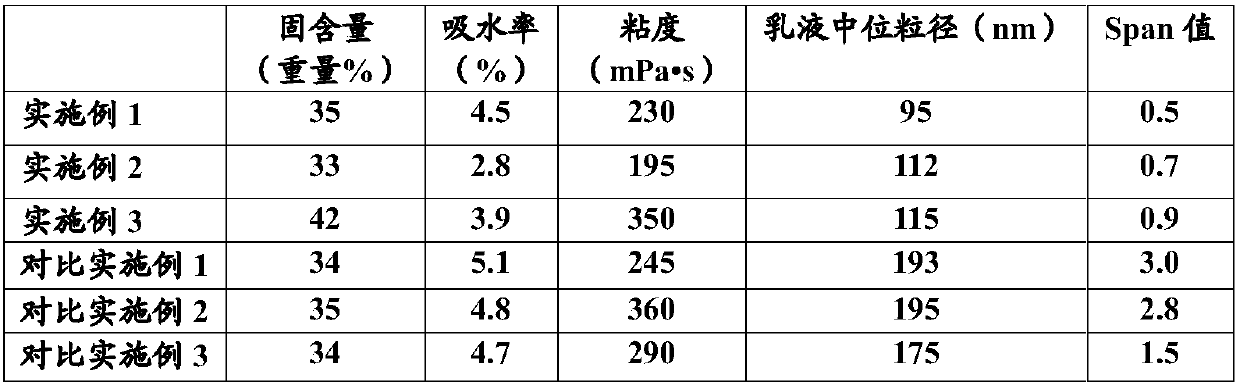

Examples

Embodiment 1

[0064] Put 200g of PEG-1000 (Mn=1000, OH value=115.3mg KOH / g, purchased from Jining Huakai Resin Co., Ltd., the same below) in an oven at 130°C (model DHG-9205A, manufacturer: Shanghai Hecheng Instrument Manufacturing) Co., Ltd.) for 12 hours to remove the moisture in the polyol; reduce its moisture content to 0.01% by weight, wherein the determination of moisture is carried out according to the Karl Fischer method in GB / T11275-2007;

[0065] Add 80g of the above-mentioned dried PEG-1000 into a 1-liter four-necked round-bottomed flask, then add 58g of 4,4'-bis-(isocyanatocyclohexyl)methane, then raise the temperature to 75°C, and react for 2 hours; then Add 12g of 2,2-dimethylolpropionic acid and react at 75°C for 2 hours; then measure the unreacted NCO content (0.040mol in total) in the polyurethane by the acetone-di-n-butylamine method and add 6g of 2-hydroxyethyl methacrylate and 0.12 g of tin dioctoate were reacted at a temperature of 65° C. for 4 hours to obtain a blocked...

Embodiment 2

[0071] Put 200g of POL-3195 (Mn=600, OH value=195mgKOH / g, purchased from Jining Huakai Resin Co., Ltd., the same below) in an oven at 130°C (model DHG-9205A, manufacturer Shanghai Hecheng Instrument Manufacturing Co., Ltd.) Dry in medium for 12 hours to remove the moisture in the polyol; reduce its moisture content to 0.01% by weight, wherein the determination of moisture is carried out according to the Karl Fischer method in GB / T 11275-2007;

[0072] Add 60g of the above dried POL-3195 into a 1-liter four-necked round-bottomed flask, then add 78g of 4,4'-diisocyanatodiphenylmethane, and react at 75°C for 2 hours; then add 5g of 1, 3-propanediol and 8g 2,2-dimethylolbutyric acid were reacted for 2 hours at 80°C; then the unreacted NCO content (0.034mol in total) in the polyurethane was measured by the acetone-di-n-butylamine method and added 4.5 g of 2-hydroxyethyl methacrylate and 0.12 g of tin dioctoate were reacted at a temperature of 70° C. for 4 hours to obtain a blocked ...

Embodiment 3

[0078] 200g of Poly-CD220 (Mn=2000, OH value=53.2mgKOH / g, purchased from Arch Chemical Company, USA) was dried in an oven (model DHG-9205A, manufacturer Shanghai Hecheng Instrument Manufacturing Co., Ltd.) at 130°C for 12 Hours to remove the moisture in the polyol; reduce its moisture content to 0.01% by weight, wherein the determination of moisture is carried out according to the Karl Fischer method in GB / T 11275-2007;

[0079]Add 100 g of the above dried Poly-CD220 into a 1-liter four-neck round-bottomed flask, then add 77 g of isophorone diisocyanate, then heat up to 75 ° C, and react for 2 hours; then add 3.5 g of 1,6 -Hexanediol and 6g 2,2-dimethylolpropionic acid were reacted for 2 hours at 75°C; then the unreacted NCO content in the polyurethane was measured by the acetone-di-n-butylamine method (the content was 0.043mol) and added 6g of 3-hydroxypropyl acrylate and 0.12g of tin dioctoate were reacted at a temperature of 65° C. for 4 hours to obtain a blocked polyuretha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com