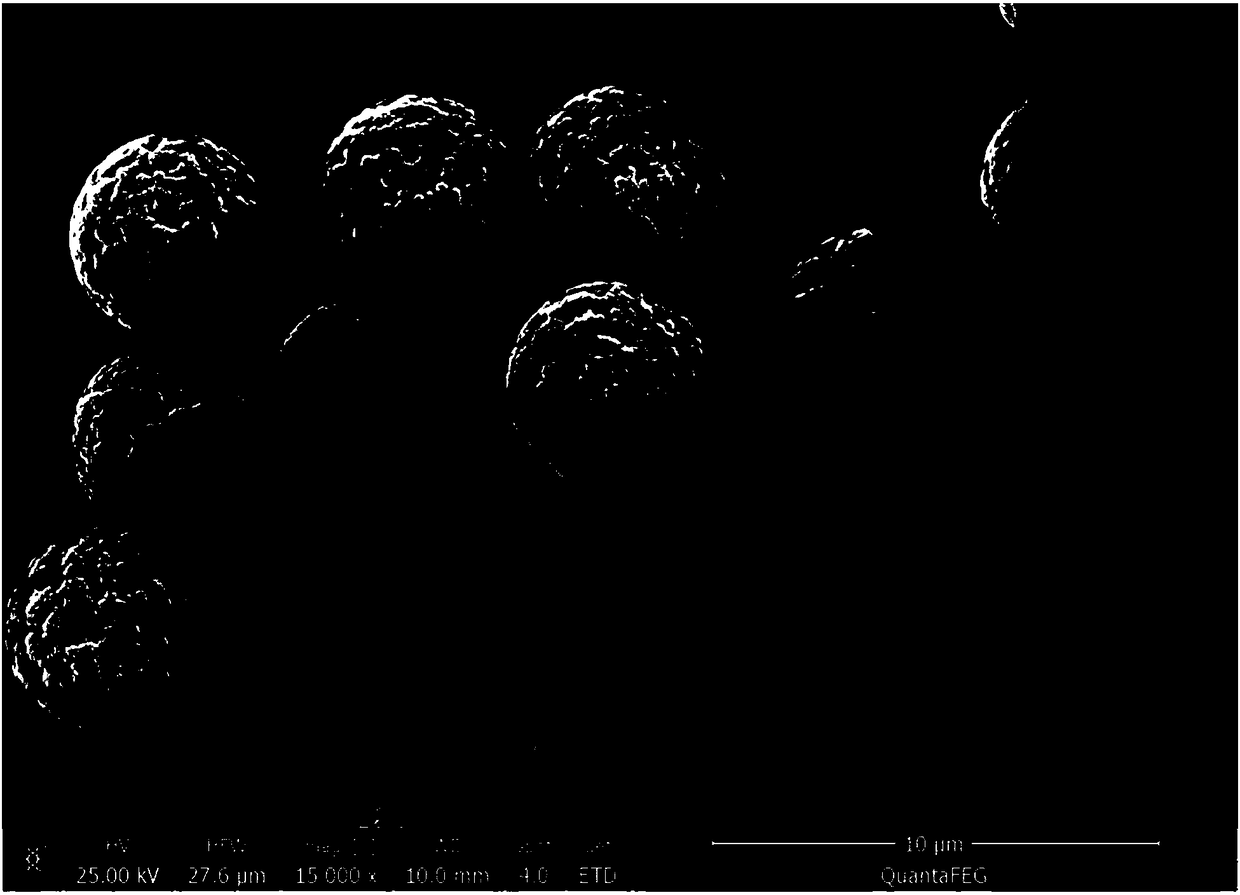

Preparation method of monodisperse agarose superparamagnetic micro-sphere

A superparamagnetic and paramagnetic technology, applied in the field of monodisperse agarose superparamagnetic microsphere preparation, can solve the problems of long incubation time, low purity, lengthy operation steps, etc. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Preparation of Fe 3 o 4 Preparation of magnetic nanoparticles and their surface modification:

[0028] 126g FeCl 2 .4H 2 O, 310g FeCl 3 .6H 2 O was dissolved in 1000g of pure water. Preheat the reaction kettle in a constant temperature water bath at 70°C, replace the air in the reaction kettle with nitrogen, add iron salt solution and stir for 30 minutes, then quickly add 500ml ammonia water for precipitation reaction, after the reaction is carried out for 30 minutes, add 0.1wt% polyethylene Pyrrolidone, after 1hr of surface chemical modification, was heated to 80°C and the reaction system was opened to completely evaporate excess ammonia water. After washing with alcohol and water for many times, it was filtered and concentrated into 30wt% aqueous magnetic fluid for later use. The primary particle size of magnetic nanoparticles is 13-20nm, and they are superparamagnetic.

[0029] 2) Preparation of core-shell magnetic nanoparticles by sol-gel method:

[0030]...

Embodiment 2

[0036] 1) Preparation of Fe 3 o 4 Preparation of magnetic nanoparticles and their surface modification.

[0037] 126g FeCl 2 , 310g FeCl 3 Dissolve in 1000g pure water. Preheat the reaction kettle in a constant temperature water bath at 60°C, replace the air in the reaction kettle with nitrogen, add the iron salt solution and stir for 30 minutes, then quickly add 500ml of ammonia water for precipitation reaction, after the reaction is carried out for 30 minutes, add 2wt% sodium alginate , after 0.5hr of surface chemical modification, the temperature was raised to 65°C and the reaction system was opened to completely evaporate the excess ammonia water. After washing with alcohol and water for several times, it was filtered and concentrated into 50wt% aqueous magnetic fluid for later use. The primary particle size of magnetic nanoparticles is 16-25nm, and they are superparamagnetic.

[0038] 2) Preparation of core-shell magnetic nanoparticles by sol-gel method

[0039] Tak...

Embodiment 3

[0045] 1) Preparation of Fe 3 o 4 Preparation of magnetic nanoparticles and their surface modification.

[0046] 126g FeCl 2 .4H 2 O, 310g FeCl 3 .6H 2 O was dissolved in 1000g of pure water. Preheat the reaction kettle in a constant temperature water bath at 80°C, replace the air in the reaction kettle with nitrogen, add iron salt solution and stir for 30 minutes, then quickly add 500ml of ammonia water for precipitation reaction, after the reaction is carried out for 30 minutes, add 1wt% sodium citrate , after 2 hours of surface chemical modification, the temperature was raised to 90°C and the reaction system was opened to completely evaporate the excess ammonia water. After washing with alcohol and water for several times, it was filtered and concentrated into 10wt% aqueous magnetic fluid for later use. The primary particle size of magnetic nanoparticles is 5-10nm, and they are superparamagnetic.

[0047] 2) Preparation of core-shell magnetic nanoparticles by sol-gel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com