Preparation method of drug-loading Pickering emulsion

An emulsion and drug-loading technology, which is applied in the field of preparation of drug-loaded Pickering emulsions, can solve problems such as sudden release, fast release speed, and obstacles to the application of drug controlled release, so as to achieve the effect of expanding application and improving sustained release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of preparation method of drug-loaded Pickering emulsion, its method step comprises:

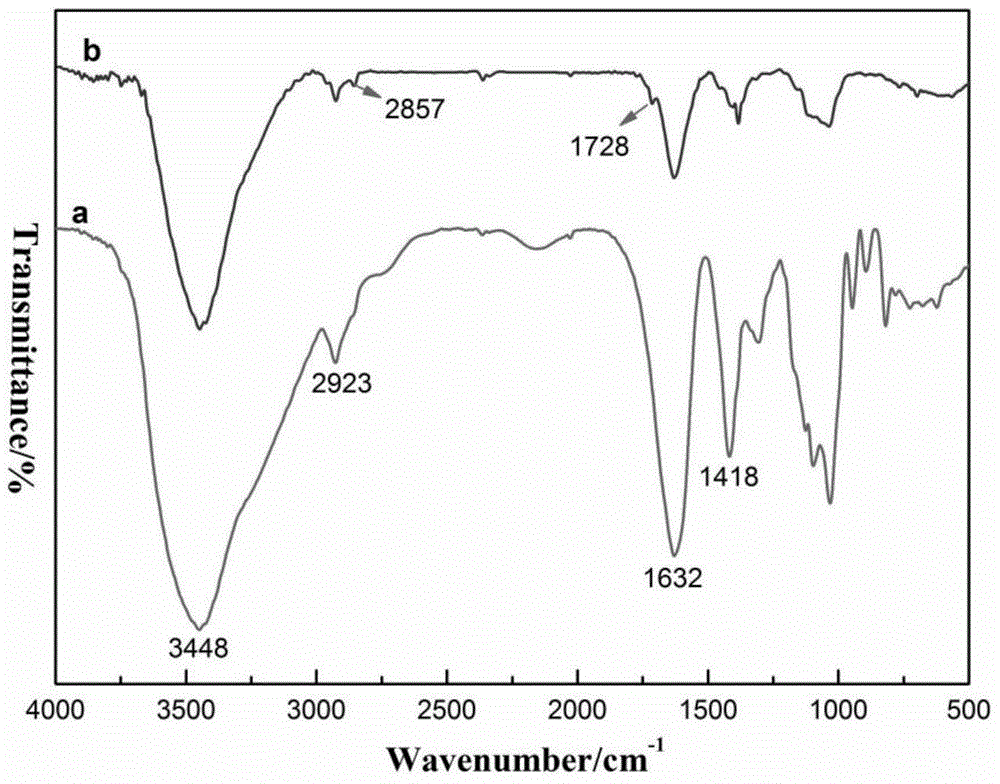

[0037](1) Take 70mL of formamide / dimethylformamide solution with a volume ratio of 10:9, weigh 1.0g of p-toluenesulfonic acid, add 2.0g of sodium alginate raw material, and stir evenly at 40°C for 20-40min to carry out partial Protonation; Weigh 0.76g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 0.95g 4-dimethylaminopyridine as the catalytic system of esterification, add 8.0 gram of lauryl alcohol, stirred at 40°C for 20-30 hours, the carboxyl group on the protonated sodium alginate reacted with the hydroxyl group on the lauryl alcohol; the reaction product was precipitated with 4-6 times the volume of ethanol, and the precipitate was taken for high-speed centrifugation Separation, washing with absolute ethanol, dissolving the precipitate with deionized water, neutralizing the product with 1.5% sodium carbonate solution to neutrality; finally, dialysis and sep...

Embodiment 2

[0040] A kind of preparation method of drug-loaded Pickering emulsion, its method step comprises:

[0041] (1) Take 70mL of formamide / dimethylformamide solution with a volume ratio of 9:8, weigh 1.0g of p-toluenesulfonic acid, add 1.0g of sodium alginate raw material, and stir evenly at 60°C for 20-40min for part Protonation; Weigh 0.8g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 1.0g 4-dimethylaminopyridine as the catalyst system for esterification, add 5.0g Lauryl alcohol, stirred at 50°C for 20-30h, the carboxyl group on the protonated sodium alginate reacted with the hydroxyl group on the lauryl alcohol; the reaction product was precipitated with 4-6 times the volume of propanol, and the precipitate was subjected to high-speed centrifugation Separation, washing with anhydrous propanol, dissolving the precipitate with deionized water, neutralizing the product with 5% sodium bicarbonate to neutrality; finally, dialysis and separation of the solution for 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com