Air flotation equipment and working method thereof

A working method and equipment technology, applied in flotation water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as poor adhesion, large energy consumption, water disturbance, etc. High pollution efficiency and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

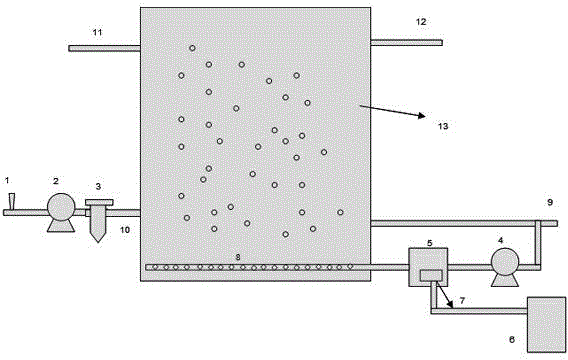

Image

Examples

Embodiment 1

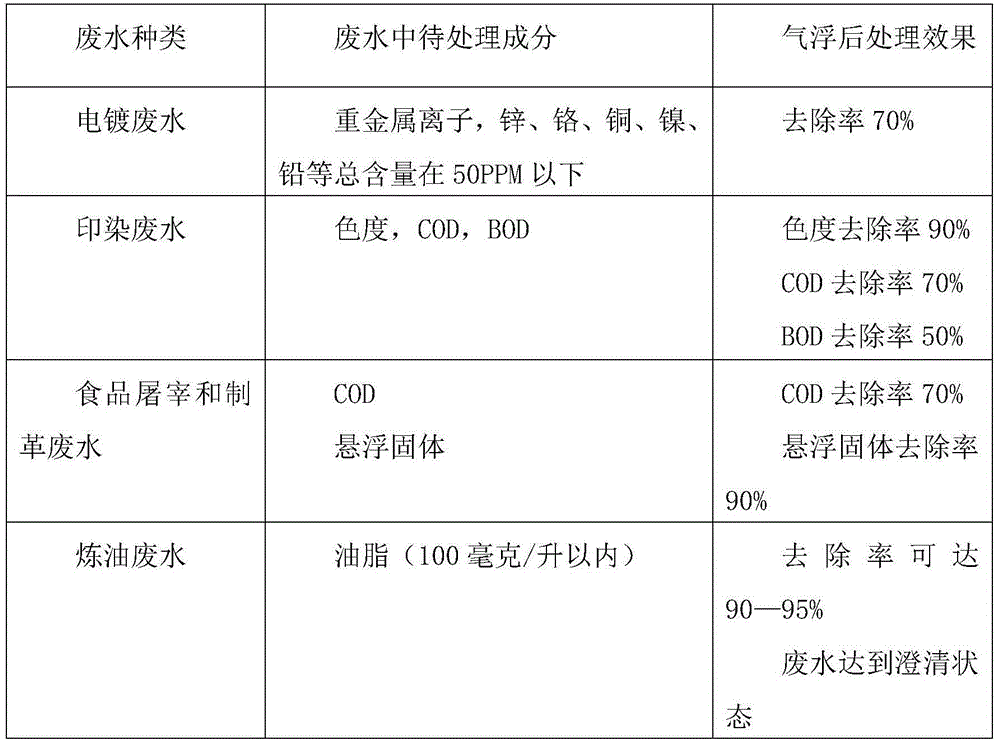

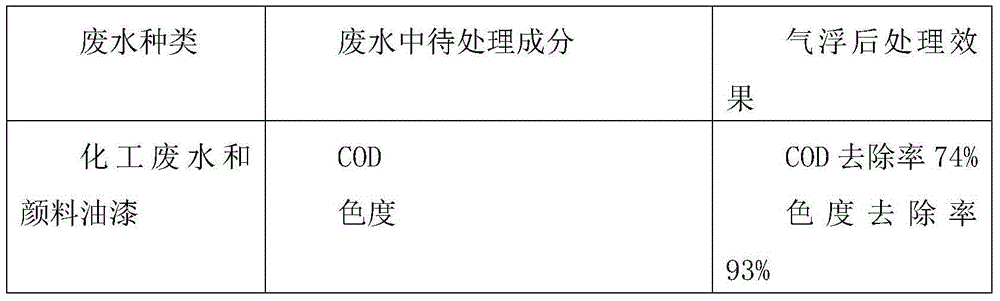

[0029] new type The air flotation is divided into four parts: first, ferric chloride is added in the dosing part, and the added amount accounts for 0.001% of the total waste water to be treated, and it is fully mixed with the sewage in the sewage pump. High-efficiency and energy-saving jet equipment is adopted, and the jet is fully mixed and dissolved with the return water pressurized by the pump after treatment to form dissolved air water. Dosing and coagulation of sewage into new type In the degreasing tank, the dissolved air water is suddenly filled with gas by the release device at the lower part of the inlet pipe, so that the air in the water suddenly releases a large number of microbubbles. The suspended solids all float on the water surface, and then pass through the upper sludge tank, while the bottom of the tank is discharged through the treated clean water. The whole process is automatically controlled by the electric control cabinet.

[0030] The specific opera...

Embodiment 2

[0047] new type The air flotation is divided into four parts: first, ferric chloride is added in the dosing part, and the added amount accounts for 0.002% of the total amount of wastewater to be treated, and it is fully mixed with the sewage in the sewage pump. High-efficiency and energy-saving jet equipment is adopted, and the jet is fully mixed and dissolved with the return water pressurized by the pump after treatment to form dissolved air water. Dosing and coagulation of sewage into new type In the degreasing tank, the dissolved air water is suddenly filled with gas by the release device at the lower part of the inlet pipe, so that the air in the water suddenly releases a large number of microbubbles. The suspended solids all float on the water surface, and then pass through the upper sludge tank, while the bottom of the tank is discharged through the treated clean water. The whole process is automatically controlled by the electric control cabinet.

[0048] The speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com