Gas heating stove

A technology of gas heating and central processing unit, which is applied in the direction of lighting and heating equipment, fluid heaters, water heaters, etc., to achieve the effect of effective recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

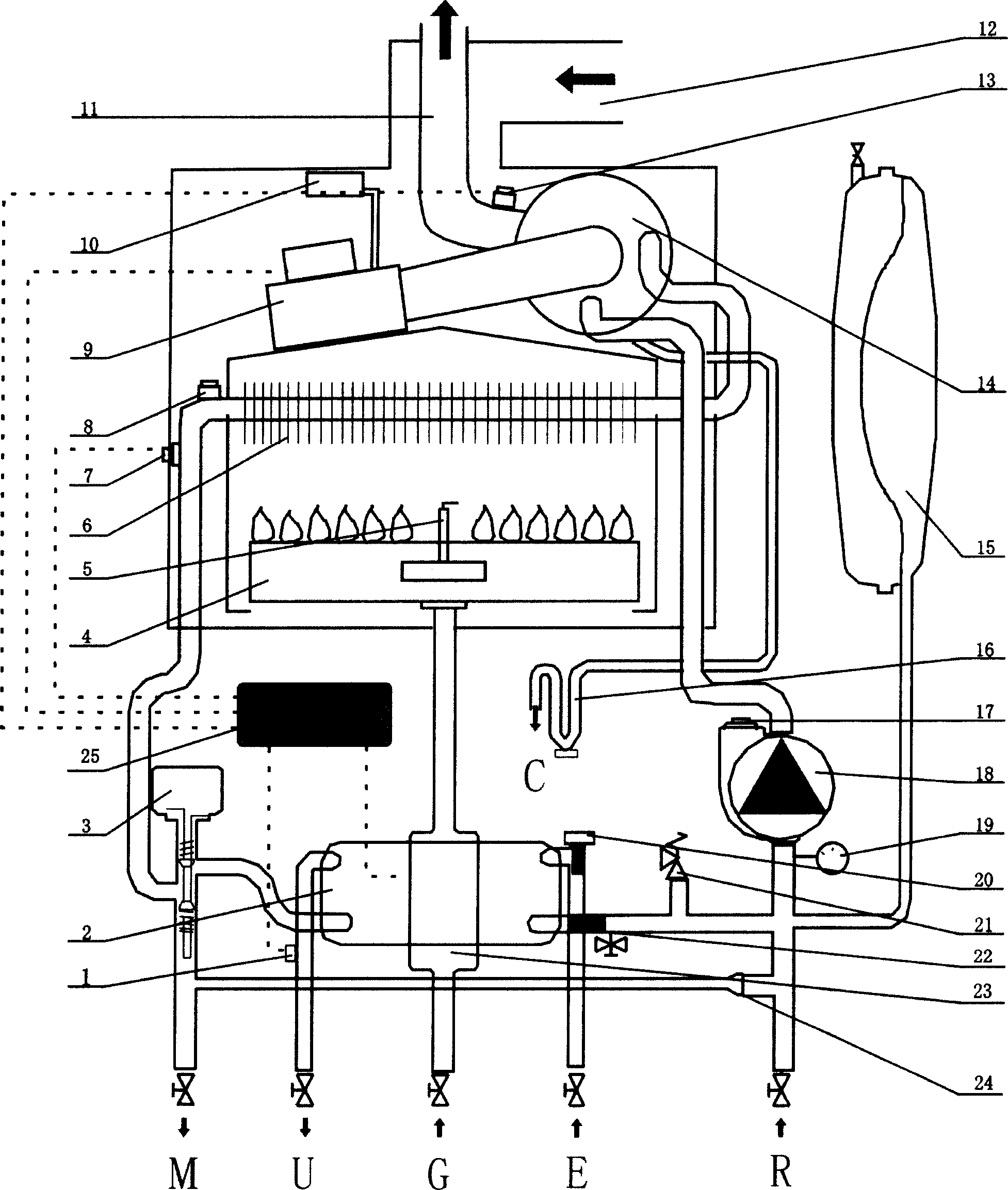

[0020] The invention provides a gas heating furnace, which realizes that the water vapor in the flue gas discharged from the gas heating furnace is fully condensed, and the heat is effectively recovered and utilized.

[0021] see figure 1 , which is a structural diagram of the gas heating furnace of the present invention.

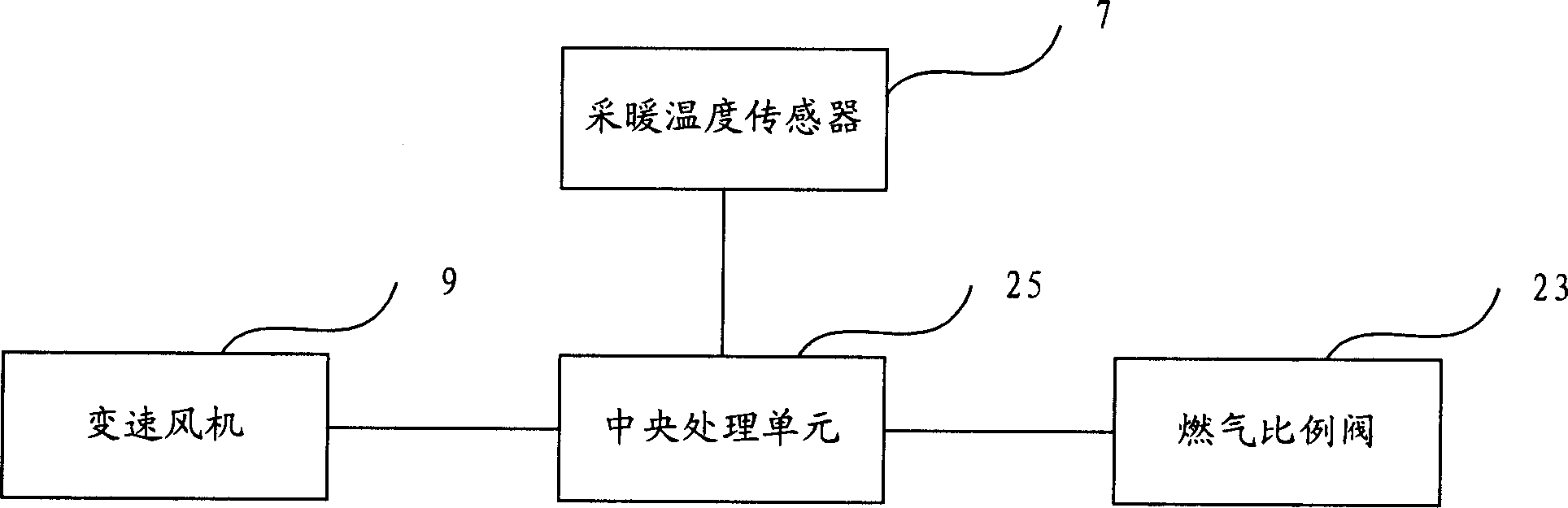

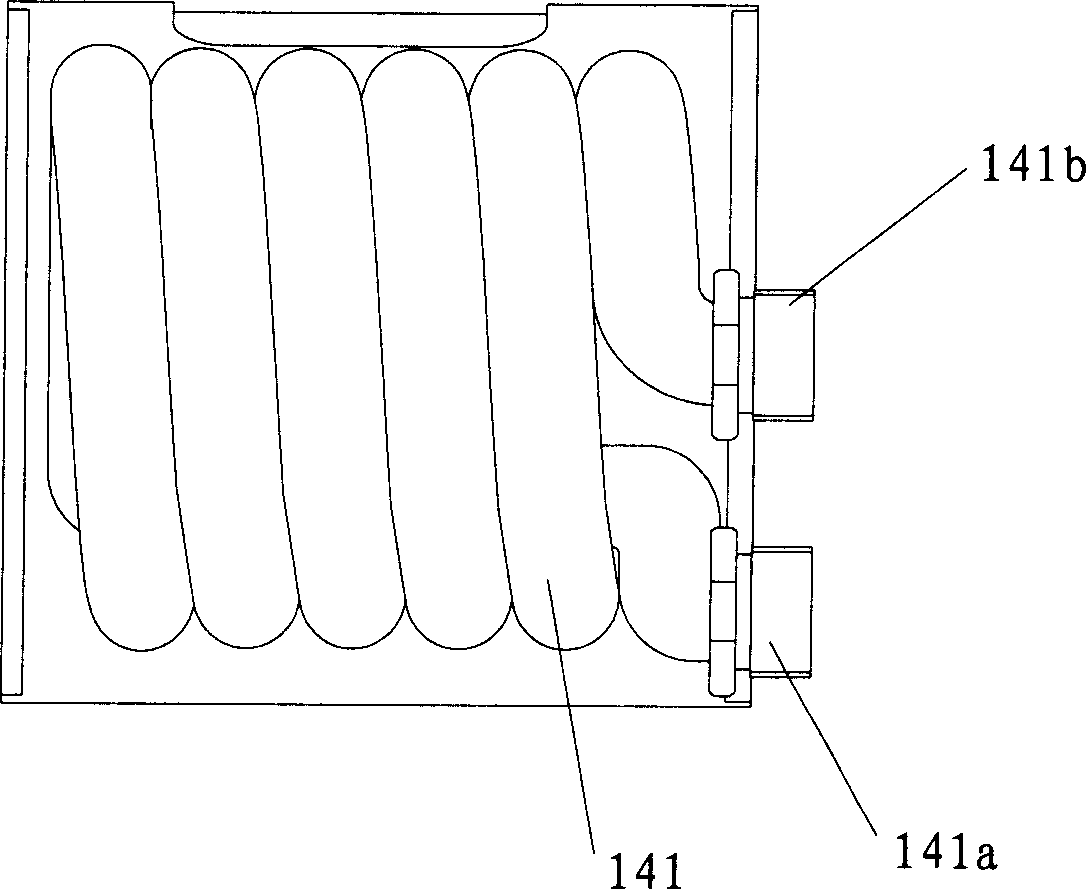

[0022] 1 is the hot water temperature sensor; 2 is the plate heat exchanger; 3 is the three-way valve motor; 4 is the burner; 5 is the ignition / detection electrode; 6 is the main heat exchanger; 7 is the heating temperature sensor; 8 is the limit temperature Switch; 9 is variable speed fan; 10 is air pressure difference switch; 11 is flue gas discharge pipe; 12 is air inlet pipe; 13 is temperature sensor; 14 is condensing heat exchanger; 15 is closed expansion water tank; 16 is condensing Water drainage pipe; 17 is an automatic exhaust valve; 18 is a circulating water pump; 19 is a water pressure gauge; 20 is a water flow sensor; 21 is a safety valve; 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com