Solid-liquid separation method for oil-gas field waste water-based drilling fluid

A water-based drilling fluid, solid-liquid separation technology, applied in mining wastewater treatment, chemical instruments and methods, multi-stage water treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Solid-liquid separation method for waste water-based drilling fluid in eastern Sichuan. In this area, water-based drilling fluid with foam bentonite system is used in the first drilling stage, water-based drilling fluid in polymer system is used in the second drilling stage, and polysulfide is used in the third drilling stage. The system water-based drilling fluid; each stage is mixed with formation materials during the drilling process to form a corresponding system of waste water-based drilling fluid; the solid-liquid separation of the waste water-based drilling fluid at each stage is carried out as follows:

[0037] In the first stage, the waste water-based drilling fluid in the bentonite system adopts the static settlement method to allow the solid phase substances in it to settle naturally to form sludge, and then the filtration method is used to achieve solid-liquid separation.

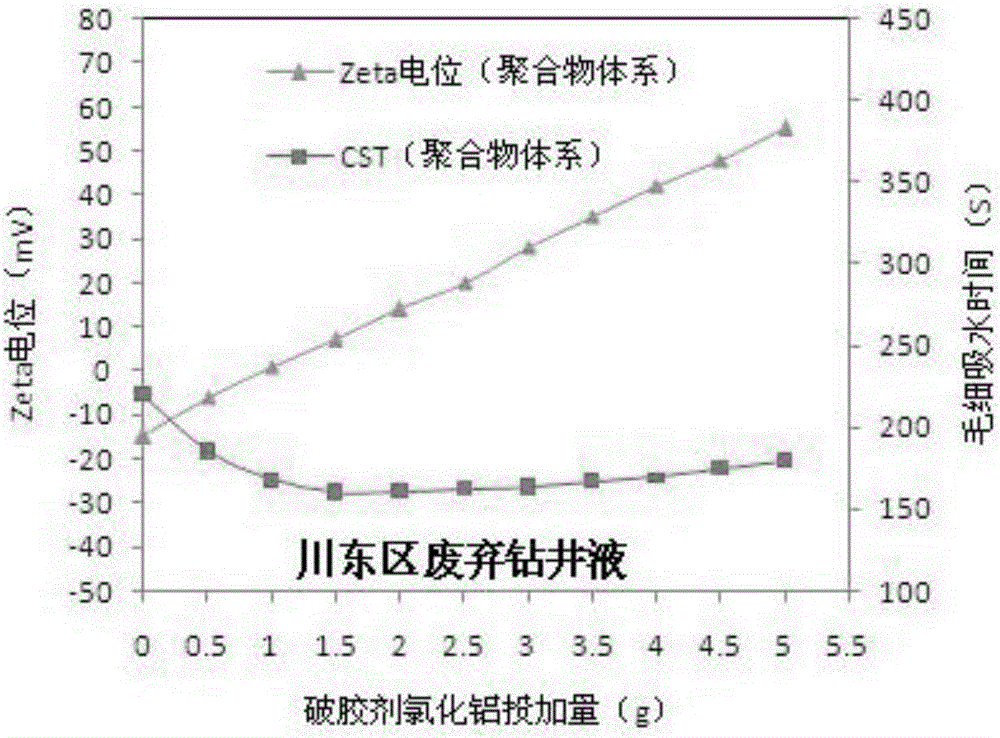

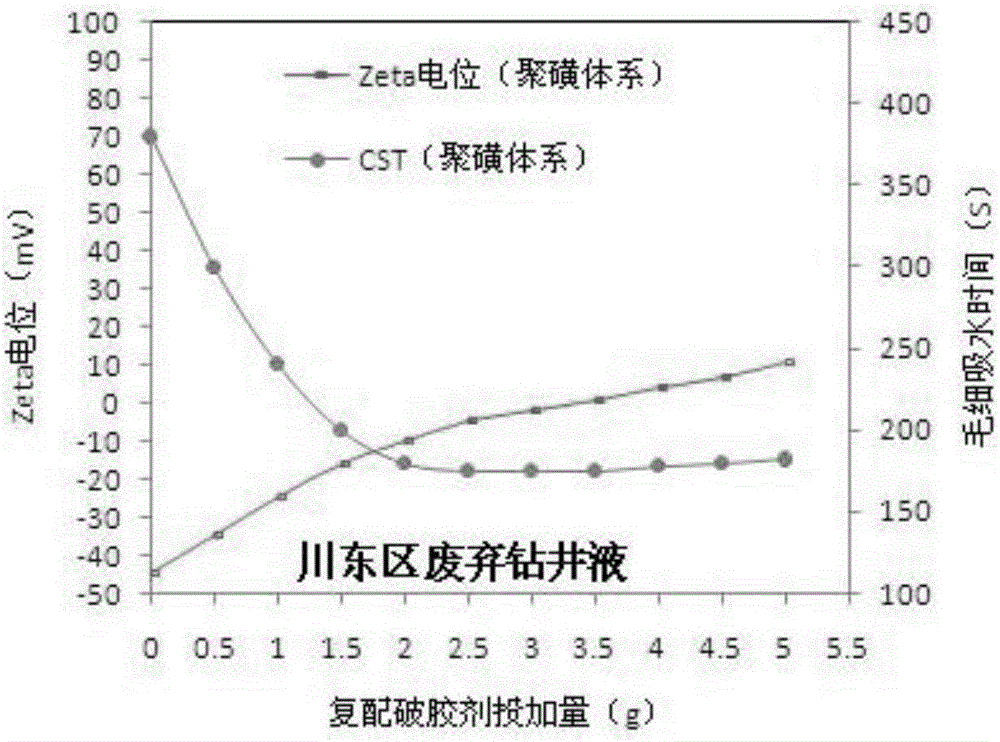

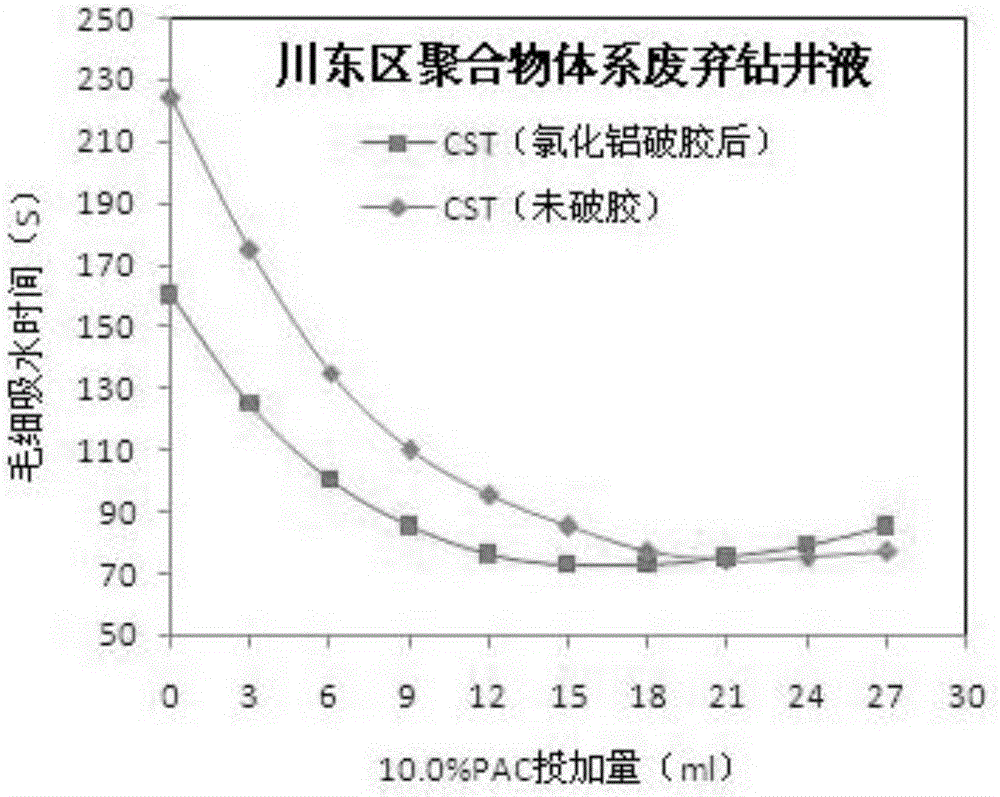

[0038] Waste water-based drilling fluid for polymer system in the second stage, 1m 3 ...

Embodiment 2

[0127] Solid-liquid separation method of waste water-based drilling fluid in Xinjiang area.

[0128] In the first stage, the waste water-based drilling fluid in the bentonite system adopts the static settlement method to allow the suspended solid phase substances to settle naturally to form sludge, and then the filtration method is used to achieve solid-liquid separation;

[0129] Waste water-based drilling fluid for polymer system in the second stage, 1m 3 Add flocculant PAC14~15kg to the waste water-based drilling fluid to coagulate the solid phase substances, and then use filtration method to filter out the solid phase substances to realize solid-liquid separation;

[0130] Waste water-based drilling fluid of polysulfide system in the third and fourth opening stages, 1m 3 Add flocculant PAC 14-15kg and coagulant aid PAM 0.45-0.6kg to the waste water-based drilling fluid; make the solid phase substances in it condense, and then filter out the solid phase substances by filtr...

Embodiment 3

[0133] Solid-liquid separation method of waste water-based drilling fluid in western Sichuan.

[0134] Waste water-based drilling fluid of polymer system in the first stage, 1m 3 Add 10-11kg of gel breaker, 3-5kg of flocculant PAC, and 4-6kg of stabilizer to the waste water-based drilling fluid to break up the colloidal ions, release the liquid-phase substances, and condense the solid-phase substances. Solid-phase substances are released to achieve solid-liquid separation;

[0135] Waste water-based drilling fluid of polysulfide system in the second stage and later stage, 1m 3 Add 20kg of gel breaker, 3-4kg of flocculant PAC, and 10-12kg of stabilizer to the waste drilling fluid to break the colloidal ions, release the liquid phase and condense the solid phase, and then filter out the solid phase by filtration. Realize solid-liquid separation.

[0136] The screening of treatment agents and the determination of dosage are similar to those in Example 1, and will not be repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com