Small intermittent reducing distillation device

A distillation device, batch-type technology, applied in the field of small-scale reduction distillation device, can solve the problems of difficult separation and preparation, and achieve the effects of easy installation and maintenance, improved product yield, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

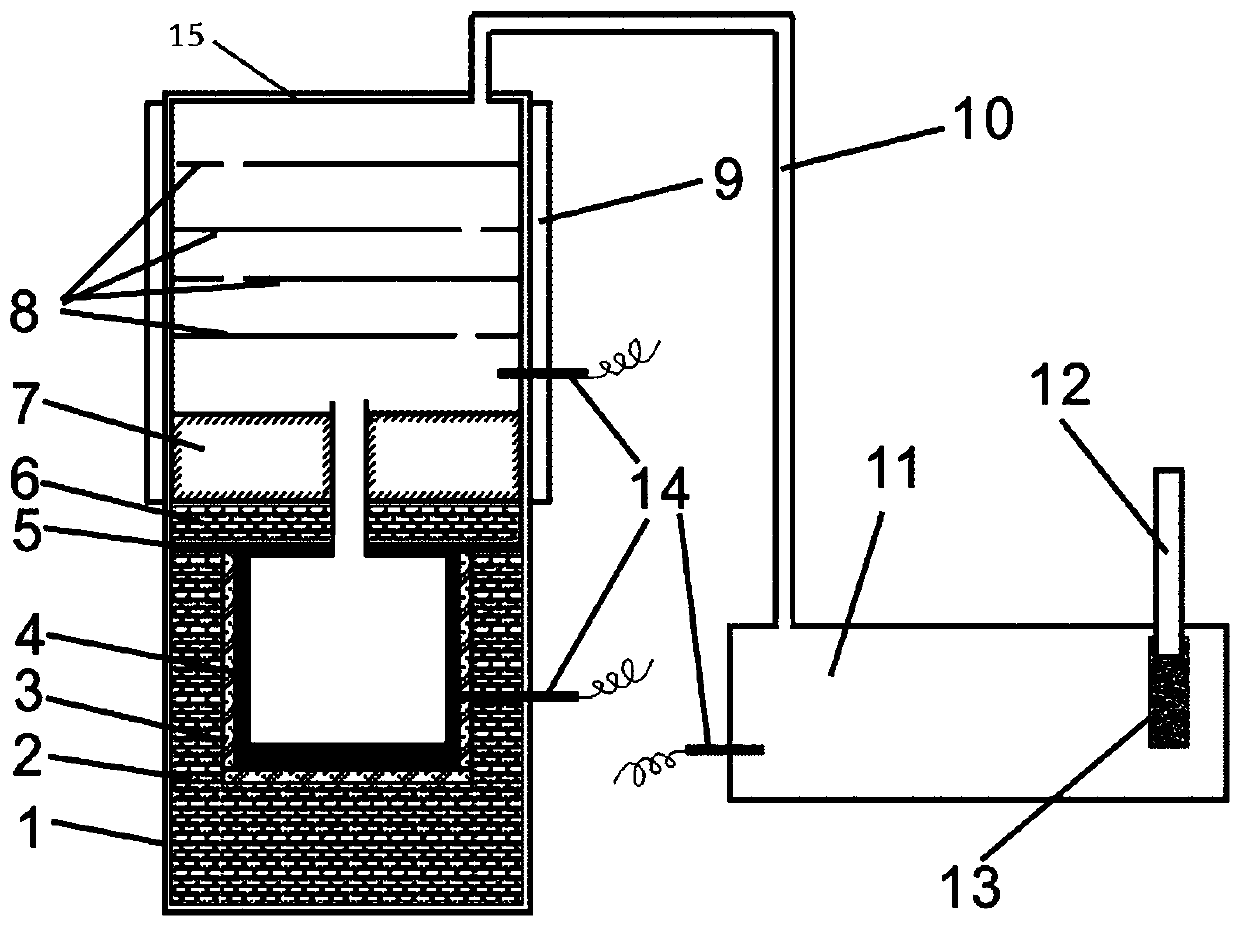

[0031] This embodiment provides a small intermittent reduction distillation device, including a reduction distillation furnace 1, the top opening of the reduction distillation furnace 1, a matching furnace cover 15 is provided at the opening, and a gas outlet is provided on the furnace cover 15. 1 is a hierarchical structure, specifically including:

[0032] The reduction reaction layer at its lower part is provided with a reaction chamber for material reaction, the reaction chamber is provided with an outlet, and the reaction chamber wall is provided with a heating element 3; the reaction chamber is a removable graphite crucible 4 in this embodiment, and the graphite crucible 4 The outlet is the outlet of the reaction chamber, the outlet is covered with a crucible partition 5, and the refractory material 2 is filled between the heating element 3 and the shell of the reduction distillation furnace body;

[0033] The sedimentation layer between the reduction reaction layer and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com