Condensing device for distilling procedure in wine brewing

A condensing device and process technology, which is applied in the field of condensing devices in the wine distillation process, can solve the problems of difficulty in guaranteeing the recovery effect, poor sealing, complex structure, etc., and achieve the effects of high recovery rate, backflow prevention, and full condensation recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

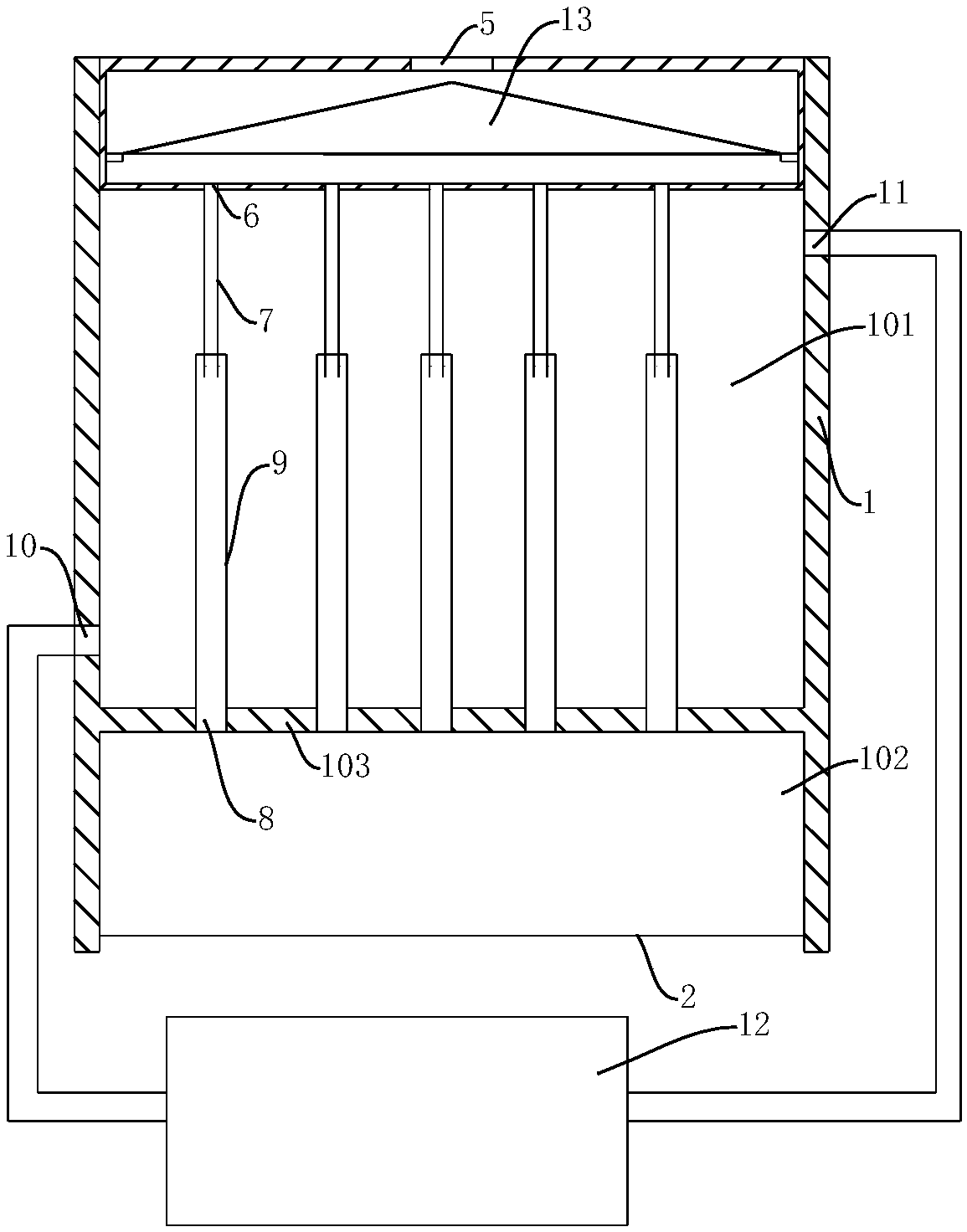

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 , the condensing device in the wine distillation process in this embodiment includes a condensing chamber 1, an air intake chamber 3 and a recovery tank 2, the condensing chamber 1 is a cavity structure with openings at both ends, and the condensing chamber 1 is located at the lower part of the middle of the condensing chamber The position is provided with a sealing partition 103, and the sealing partition 103 divides the condensation chamber 1 into two independent chambers, which are respectively the condensation chamber 101 and the pre-cooling chamber 102, and the upper opening of the condensation chamber 101 is provided with an air inlet The cross section of the chamber 3 and the air inlet chamber 3 match the cross section of the condensation chamber 101, and the two are sealed at the connecting position.

[0014] An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com