Liquefied natural gas recondensation method and device

A technology of liquefied natural gas and re-condensation, applied in liquefaction, refrigeration, liquefaction, solidification and other directions, can solve the problems of unsatisfactory control effect and complicated control method, improve safety and economic benefits, promote condensation recovery, and stabilize inlet pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

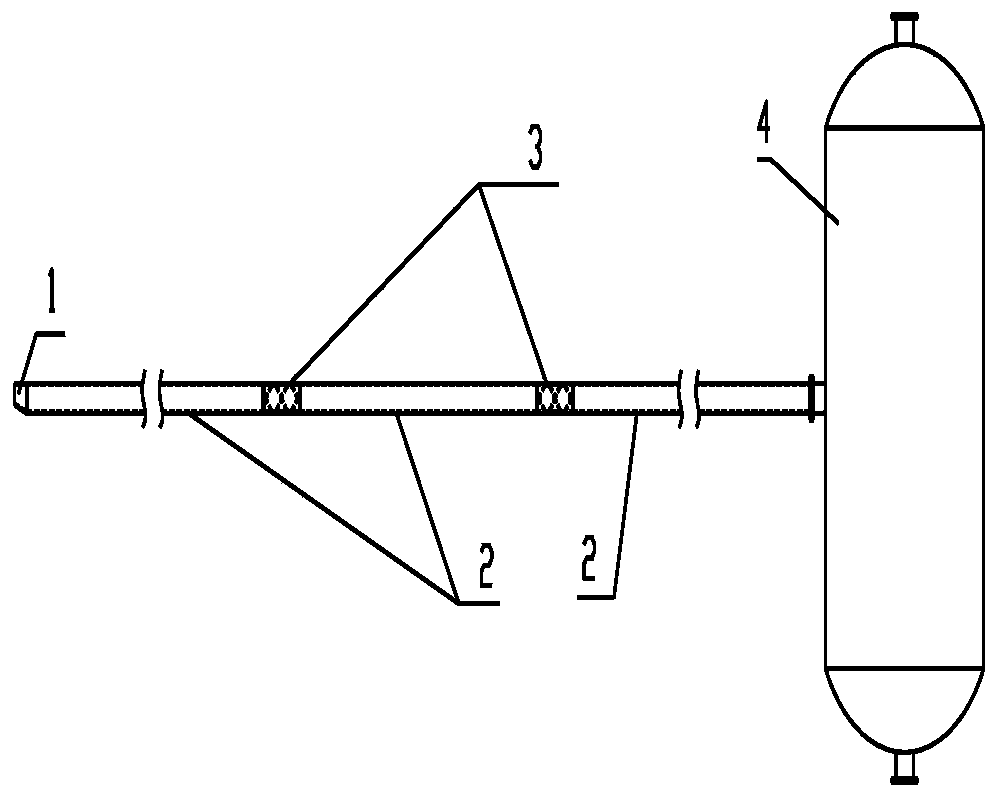

[0023] see figure 1 , the liquefied natural gas recondensation device of the present invention is mainly composed of an inlet expansion pipe 1, a condensing straight pipe 2, a gas-liquid turning device 3 and a buffer tank 4, wherein the gas-liquid turning device 3 and the condensing straight pipe 2 are alternately connected to form a horizontal condensing pipe , the horizontal condensing pipe communicates with the middle part of the buffer tank 4 with a section of straight condensing pipe, and the gas-liquid flipper 3 and the straight condensing pipe 2 can be flanged or welded.

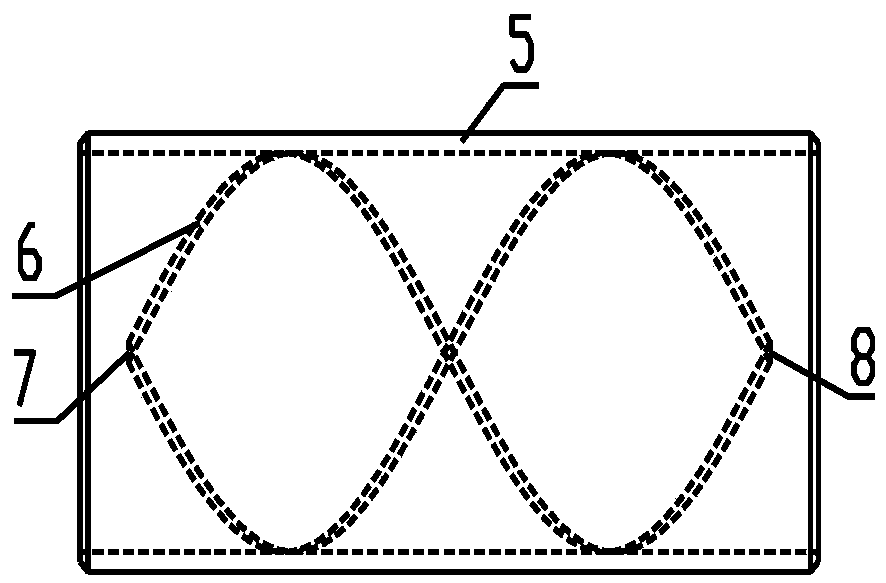

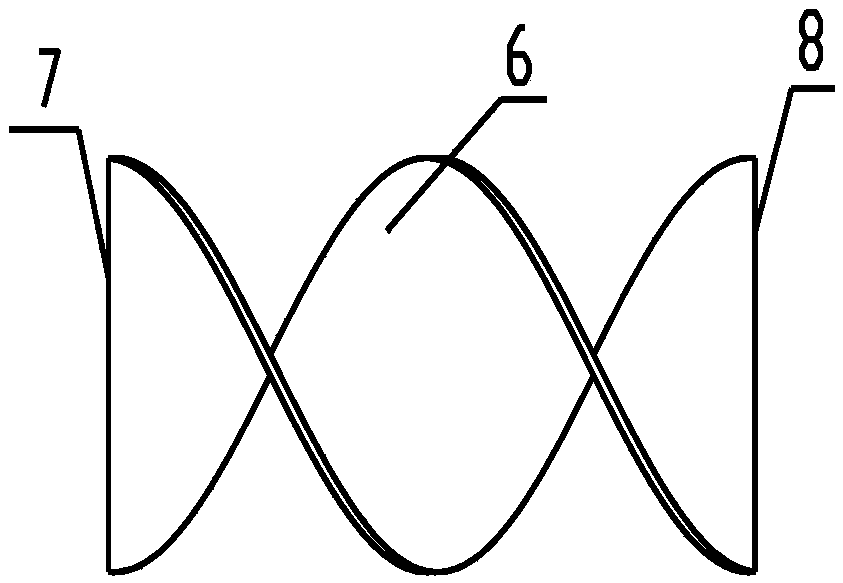

[0024] see Figure 2~4 , the gas-liquid turner is tubular as a whole, mainly composed of a tube shell 5 and a turning blade 6, the tube shell 5 is a round tube; the turning blade 6 is fixed on the inner wall of the tube shell 5 by welding, in a 180° spiral shape, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com