Pre-quenching recovery mechanism for steel plate conveying mechanism

A technology of conveying mechanism and recycling mechanism, applied in the field of pre-quenching and recycling mechanism, can solve the problems of easy generation of dead corners and loopholes, inability to preprocess steel plates, low resource utilization, etc., so as to avoid splashing of spray water and improve the scope of spraying , to avoid the effect of spray leaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

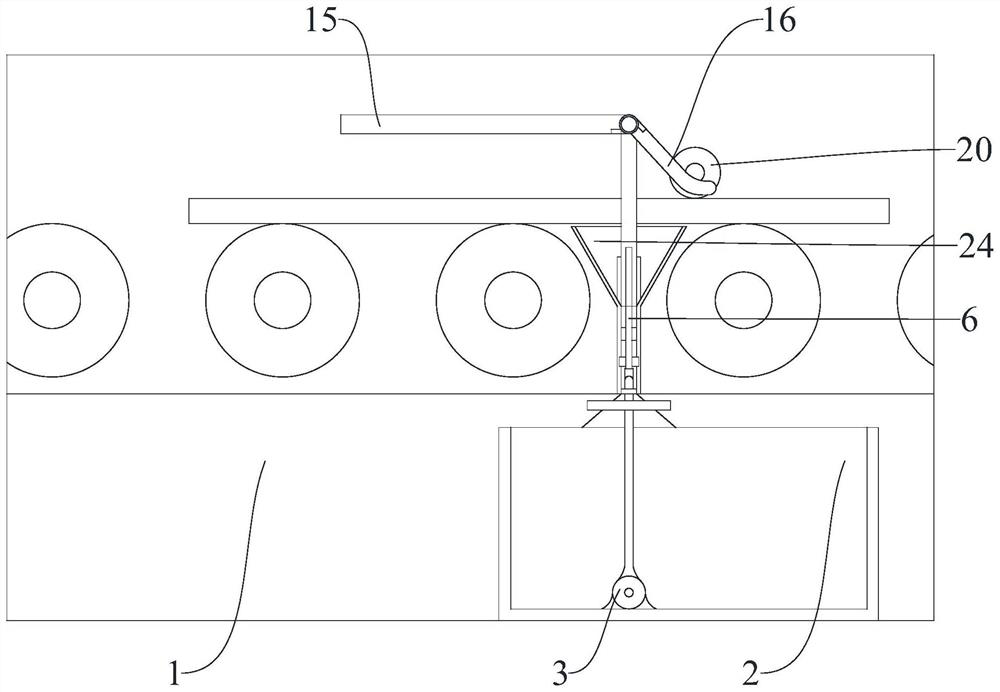

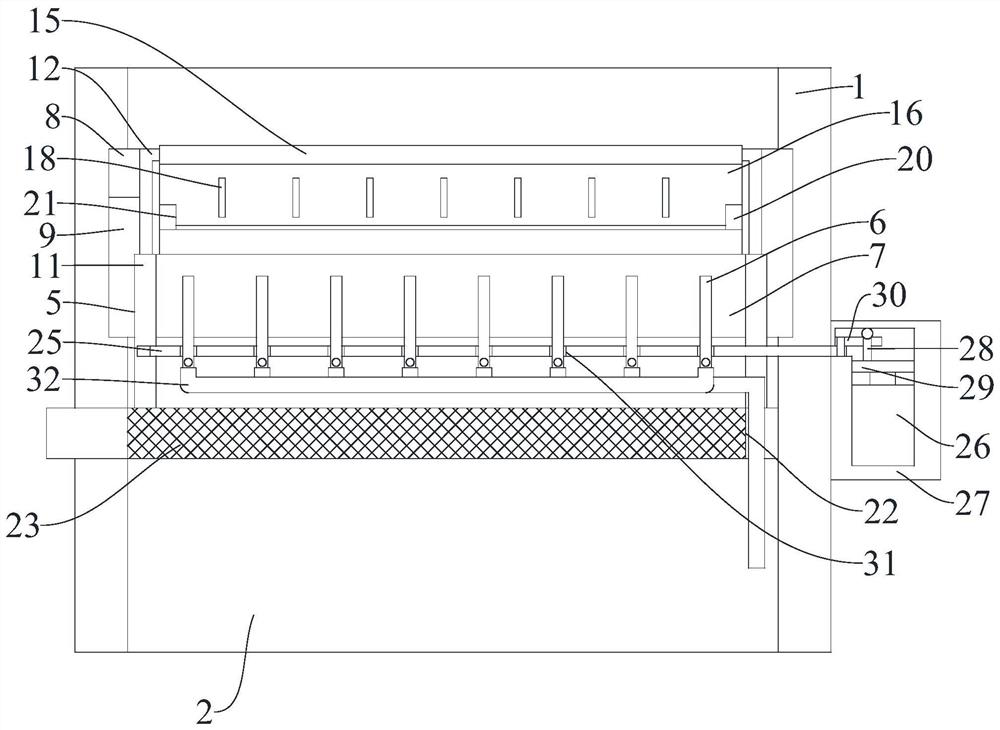

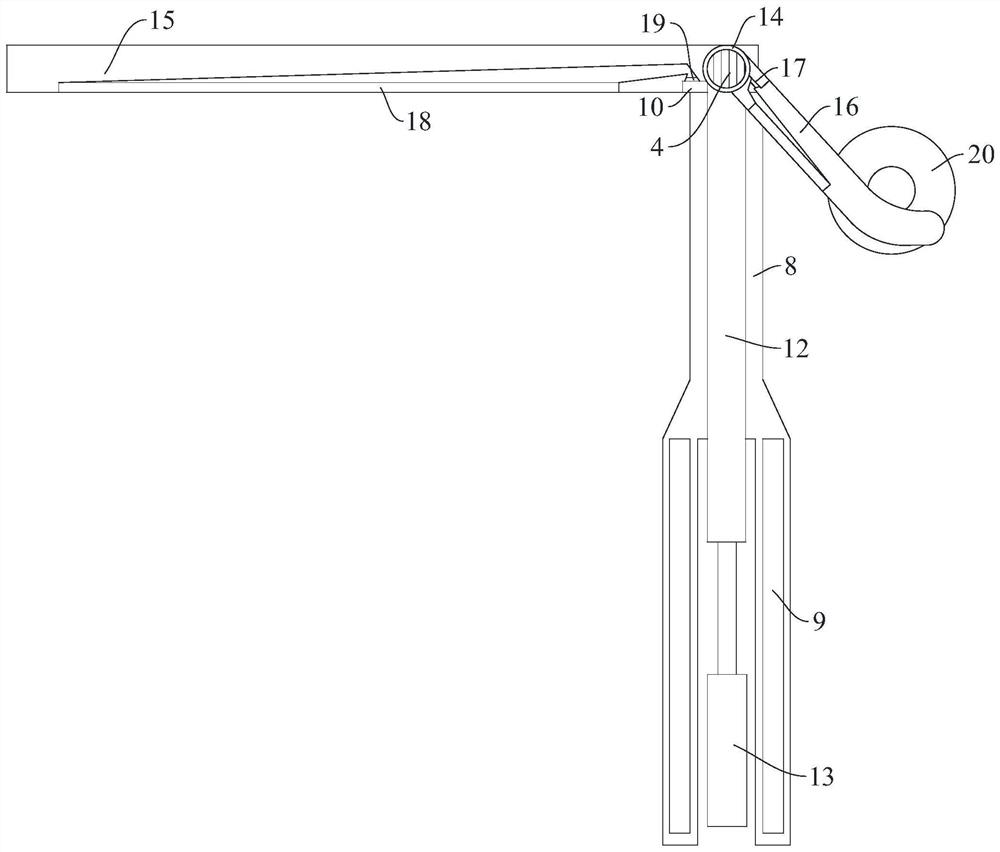

[0026] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0027] figure 1 , figure 2 and image 3 A pre-quenching recovery mechanism for a steel plate conveying mechanism shown, including a bottom conveying platform 1 with top support rollers installed on the surface, a bottom liquid storage tank 2 installed inside the bottom conveying platform 1, and a bottom liquid storage tank 2 installed inside the bottom conveying platform 1 The internal electric centrifugal liquid suction pump 3 and electric centrifugal air pump 4, the upper surface of the bottom conveying platform 1 is provided with a bottom storage tank 5 with a built-in longitudinal quenching frame, and a bottom spray nozzle with a built-in movable spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com